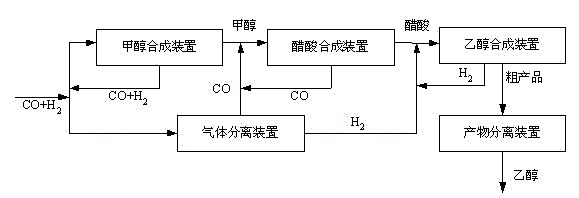

Process for preparing ethanol from synthesis gas via methyl alcohol

A technology for syngas and ethanol production, which is applied in the preparation of hydroxyl compounds, organic compounds, and bulk chemical production. It can solve the problems of high transportation costs, high cost of cellulase, and high cost, and achieve high process energy utilization. , high ethanol yield and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 480,000 tons / year ethanol synthesis (based on 300 days of operation per year)

[0025] H 2 : CO=2:1, the output is 2.46 million m 3 / day syngas is divided into two parts, the first part is 1.23 million m 3 / day for methanol synthesis, the second part 1.23 million m 3 / day for CO and H 2 Separation, as a raw material for acetic acid synthesis and ethanol synthesis. Using the method disclosed in the patent CN102133498A to cryogenically separate CO and H in synthesis gas 2 , the production of CO after separation is 1.07 million m 3 / day, H 2 The output is 160,000 m 3 / sky.

[0026] Methanol synthesis adopts Lurgi tubular isothermal synthesis tower low-pressure synthesis process. The amount of raw material synthesis gas is 1.23 million m 3 / day, the temperature of the gas entering the tower after heat exchange is 225°C, and it directly enters the reaction tube of the synthesis tower from the upper part, and reacts under the action of a catalyst to form methan...

Embodiment 2

[0030] 280,000 tons / year ethanol synthesis (based on 300 days of operation per year)

[0031] H 2 : CO=2:1, the output is 1.48 million m 3 / day syngas is divided into two parts, the first part is 740,000 m 3 / day for methanol synthesis, the second part of 740,000 m 3 / day for CO and H 2 Separation, as a raw material for acetic acid synthesis and ethanol synthesis. Using the method disclosed in patent CN102191086A to separate CO and H in syngas 2 , the production of CO after separation is 640,000 m 3 / day, H 2 The output is 100,000 m 3 / sky.

[0032] Methanol synthesis adopts ICI multi-stage cold shock tower low-pressure synthesis process, the reaction tower is divided into 4 beds, and the catalyst uses ICI51-7 catalyst. The amount of raw material synthesis gas is 980,000 m 3 / day, the temperature of the gas entering the tower after heat exchange is mixed with part of the cold shock gas, and the temperature is 220°C, and enters the first bed layer from the top of the...

Embodiment 3

[0036] 360,000 tons / year ethanol synthesis (based on 300 days of operation per year)

[0037] H 2 : CO=2:1, the output is 1.85 million m 3 / day syngas is divided into two parts, the first part is 925,000 m 3 / day for methanol synthesis, the second part of 925,000 m 3 / day for CO and H 2 Separation, as a raw material for acetic acid synthesis and ethanol synthesis. Using the method disclosed in the patent CN102133498A to cryogenically separate CO and H in synthesis gas 2 , the production of CO after separation is 805,000 m 3 / day, H 2 The output is 120,000 m 3 / sky.

[0038] The methanol synthesis adopts the Linde spiral coil isothermal synthesis tower methanol synthesis process. The amount of raw material synthesis gas is 925,000 m 3 / day, the temperature of the gas entering the tower after heat exchange is 225°C, and it directly enters the reaction tube of the synthesis tower from the upper part, and reacts under the action of a catalyst to form methanol. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com