Ethanol synthesis reactor with heat exchange unit

A synthesis reactor and heat exchange unit technology, applied in the field of coal chemical industry, can solve problems such as poor heat recovery efficiency, easy damage to equipment and pipelines, and easy breakage of expansion joints, so as to eliminate the problem of system flange sealing and heat loss. High recycling rate and effect of eliminating thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

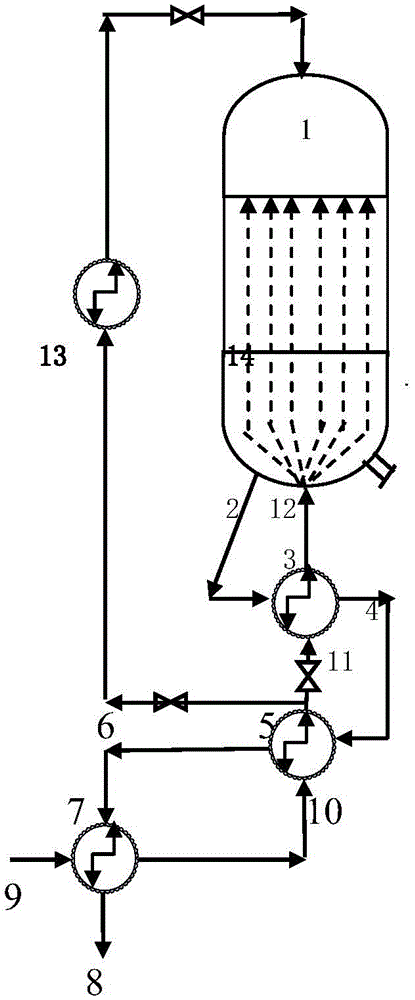

[0021] The invention proposes a direct connection of the heat exchanger of the ethanol synthesis reactor and a graded utilization process of by-product heat, and transforms the reaction equipment accordingly.

[0022] The specific technical scheme is as follows:

[0023] Such as figure 1 As shown, a kind of ethanol synthesis reactor with heat exchange unit includes reactor 1, first heat exchanger 3, second heat exchanger 5, third heat exchanger 7, crude ethanol reactor hot gas outlet pipe 2, Crude ethanol first heat exchanger hot gas outlet pipe 4, crude ethanol second heat exchanger hot gas outlet pipe 6, crude ethanol third heat exchanger outlet pipe 8, raw material hydrogen third heat exchanger inlet pipe 9, acetic acid and hydrogen The inlet pipe 10 of the second heat exchanger of the mixed gas, the inlet pipe 11 of the first heat exchanger of the mixed gas, and the inlet pipe 12 of the mixed gas reactor, characterized in that one end of the hot gas outlet pipe 2 of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com