Process for synthesizing p-methoxystyrene from p-methoxyphenethyl alcohol

A technology of methoxystyrene and p-methoxybenzene, which is applied in the gas-solid-phase catalytic dehydration of p-methoxyphenylethanol to generate p-methoxystyrene and the synthesis process field of p-methoxystyrene, which can solve the problem of Complex process route, many raw and auxiliary materials, easy to polymerize and other problems, to achieve the effect of simple equipment structure, simple process, and reduce environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

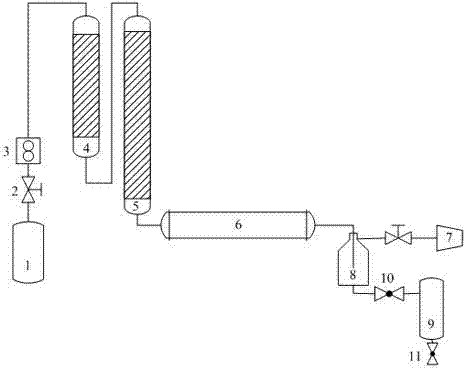

[0013] First put 30ml porcelain beads into the bottom of the reactor, then put 100ml catalyst into the middle and lower part of the reactor, and then fill the upper part of the reactor with porcelain beads. Connect the vaporizer to the reactor and the condenser to the reactor. Check whether there is enough p-methoxyphenethyl alcohol in the raw material tank, turn on the water circulation vacuum pump, and check whether the vacuum degree can meet the requirements to prevent air leakage. After the inspection, turn on the water circulation vacuum pump and turn on the electric heating to heat up the vaporizer and reactor. When the vaporization temperature reaches 270°C and the reaction temperature reaches 275°C, slowly open the regulating valve so that the flow rate of the flowmeter is 0.3-0.5ml / min, and slowly increase the feeding amount during the reaction, and the feeding amount does not exceed 1ml / min, and adjust the feeding through the regulating valve amount to stabilize the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com