Method for preparing ethanol by low-temperature digestion and thick mash fermentation of starch as raw material

A technology of thick mash fermentation and starch raw material, applied in fermentation, biofuel, etc., can solve the problems of affecting starch conversion rate, increased production cost, low starch conversion rate, etc., and achieve high yield, low moisture content and high sugar content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] According to the method for preparing ethanol by low-temperature steaming and fermenting thick mash of starch raw material of the present invention, corn and fresh cassava are mixed as raw materials to prepare ethanol, comprising the following steps:

[0031] a. Cleaning and crushing of raw materials

[0032] Wash the starch raw material, use primary crushing, the particle size is 1.2-1.5mm, and set aside;

[0033] b. Precooking to prepare powder slurry

[0034] In step a, wash the pulverized raw materials and put them into the precooking tank. According to the ratio of dry basis of raw materials: water = 1: 2.0, add appropriate amount of water as appropriate, stir and mix well, and continuously and evenly add the product produced by Novozymes (China) Biotechnology Co., Ltd. Li Kefu cooks amylase at low temperature to make it fully contact with the powder slurry, controls the precooking temperature at 50-60°C, controls the amount of amylase added at 8μ / g based on the d...

Embodiment 2~ Embodiment 6

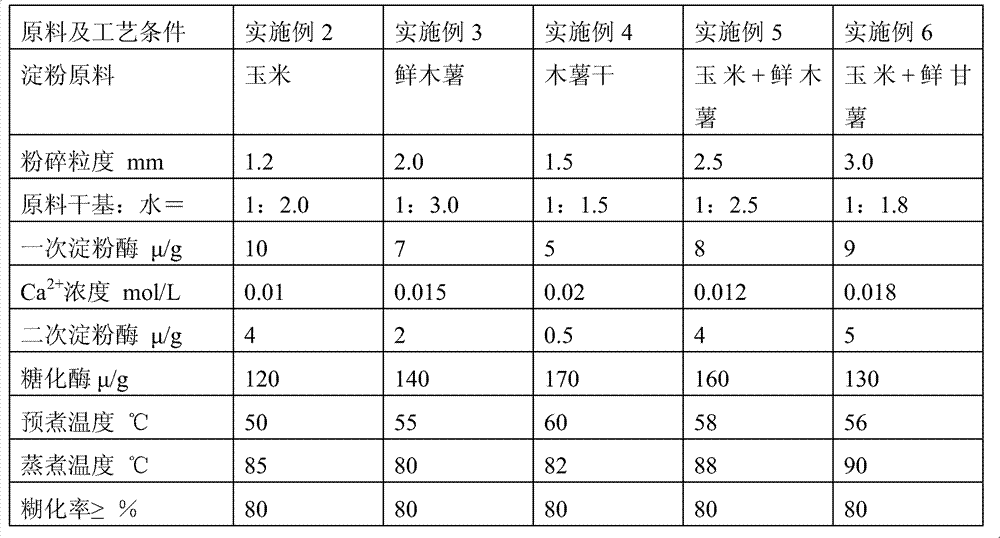

[0040] According to the method and steps of Example 1, according to the processing conditions of Table 1, take cassava as raw material to prepare ethanol

[0041] Table 1

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com