Patents

Literature

42results about How to "Simple regeneration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

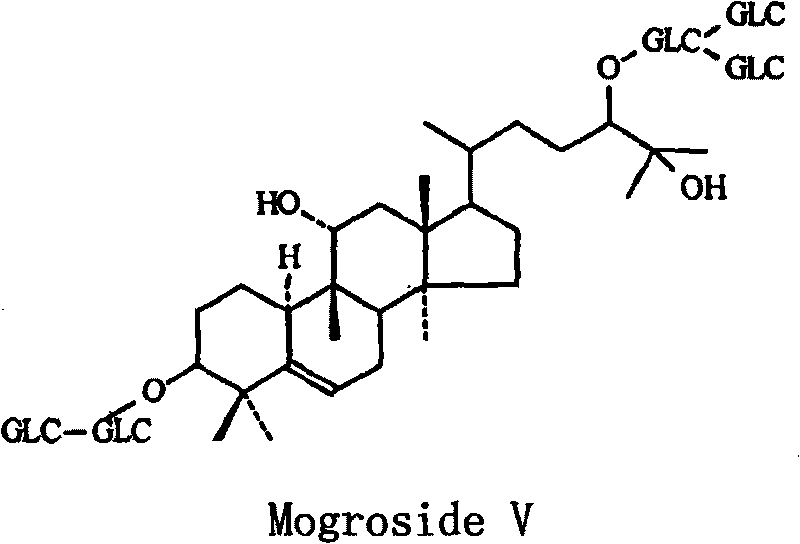

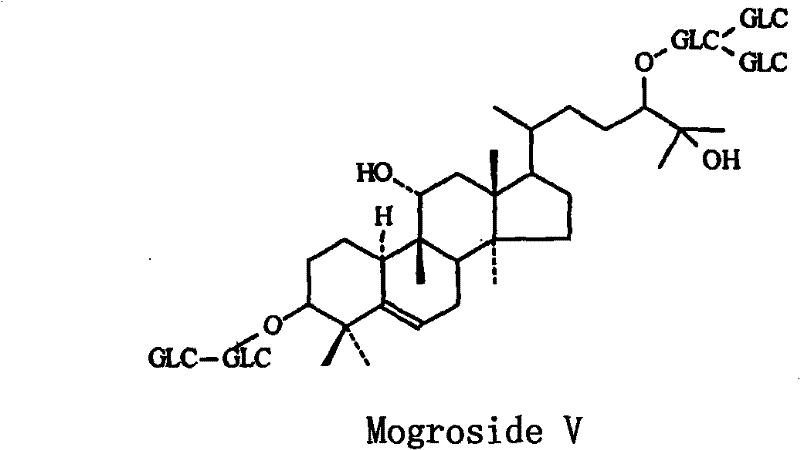

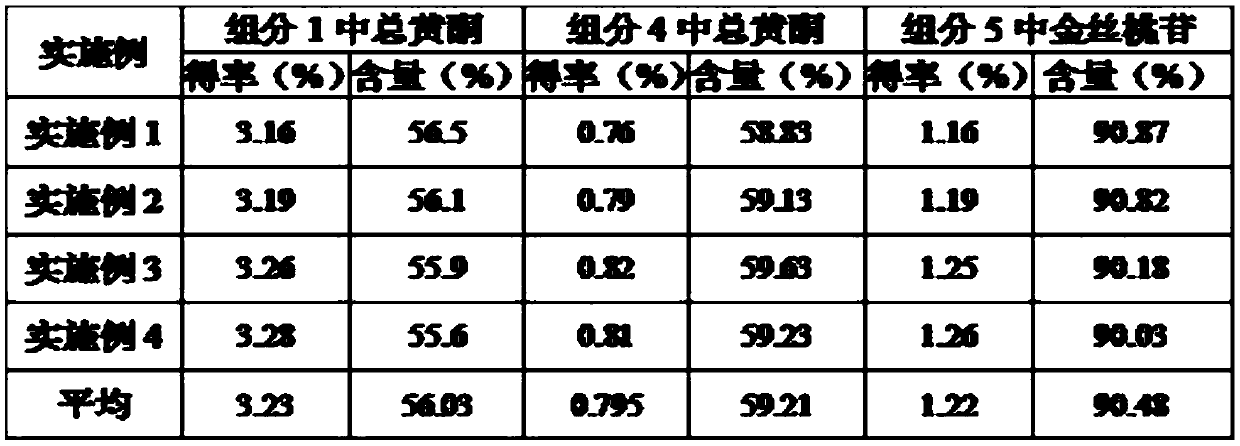

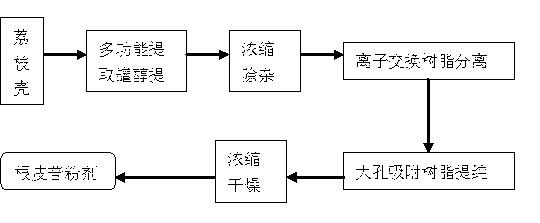

Production method of fructus monordicae extract with over 60% of mogroside V content

ActiveCN101690573APromote leachingEasy to separateCosmetic preparationsToilet preparationsSucroseAdditive ingredient

The invention provides a production method of fructus monordicae extract with over 60% of mogroside V content. In the method, the fresh momordica grosvenori is subjected to the following technique processes: smashing, saccharification, extraction by water, concentration, sedimentation and centrifugation, ion exchange resin refining, macroporous resin refining, concentration, aluminum oxide refining, concentration, spray drying and finishing product. The method can produce high-quality fructus monordicae extract products, reduce material loss, shorten period of production, increase product yield, lower production cost, and is suitable for industrial production. The mogroside V content in the fructus monordicae extract produced by the method is more than or equal to 60%; the fructus monordicae extract has high product purity, single composition, pure white color, good color and taste, fresh and cool sweet taste like that of sugar, simultaneously overcomes the technical problem for industrial production of the high-content and high-quality fructus monordicae extract, and successfully realizes large-scale production.

Owner:YONGZHOU YIDONG BIOTECH

Novel method for preparing high-purity chlorogenic acid

InactiveCN101503356AReduce decompositionHigh purityOrganic compound preparationMetabolism disorderChlorogenic acidOrganic solvent

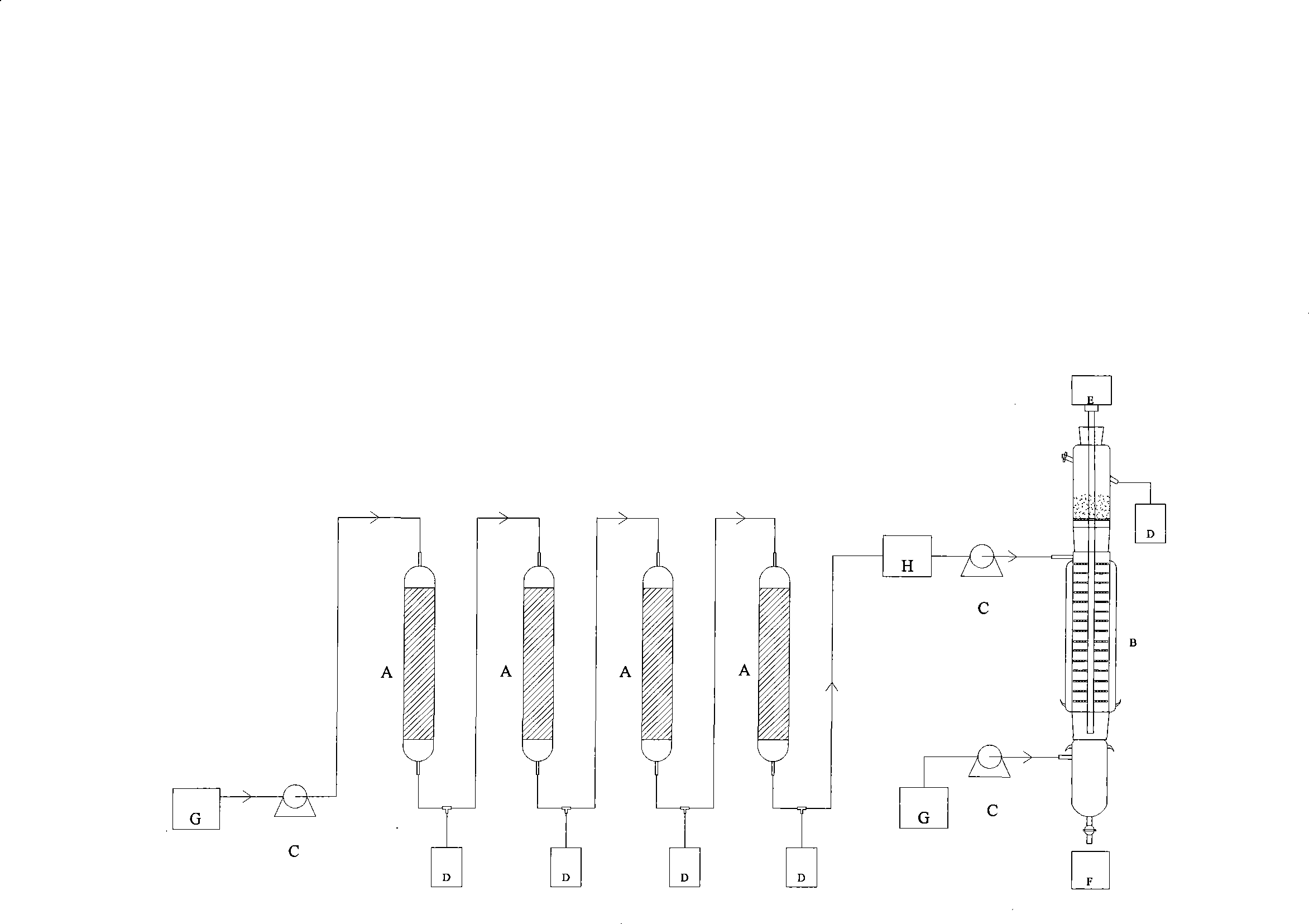

The invention provides a new method for preparing high purity chlorogenic acid, comprising the steps: after the stock solution of the chlorogenic acid is processed by washing impurity and eluting through at least four levels of macroporous resin series connection adsorption column, and then the eluate is regenerated for continuous countercurrent extraction, so that the high purity chlorogenic acid is obtained. The method is applicable to light concentration stock solution of the chlorogenic acid, and can complete the process of absorbing, washing impurity, eluting, regenerating, countercurrent extracting and recycling the solvent in a semicontinuous way; the handling capacity of samples is large, the operation is simple, the production cost can be lowered, the residual organic solvent is reduced, and the environmental pollution is relieved.

Owner:NANJING UNIV OF TECH

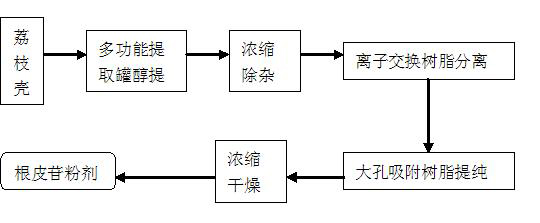

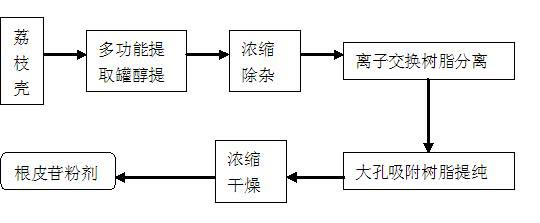

Purification method of phloretin powder

ActiveCN101811949AIncrease profitIncrease added valueCosmetic preparationsToilet preparationsChemical industryPurification methods

The invention relates to a purification method of phloretin powder, belonging to the technical field of the chemical industry. The purification method comprises the following steps of: mixing and purifying leechee shells and an alcohol solution to obtain a crude extract; carrying out ion exchange resin separation after concentration; and finally carrying out macroporous resin separation to obtainthe phloretin powder. The invention has the advantages that the process is simple, the extraction ratio achieves above 60%, the purity of the extracted phloretin can achieve above 95%, and the extracted phloretin is applied to the fields of cosmetics.

Owner:上海利盛生化有限公司

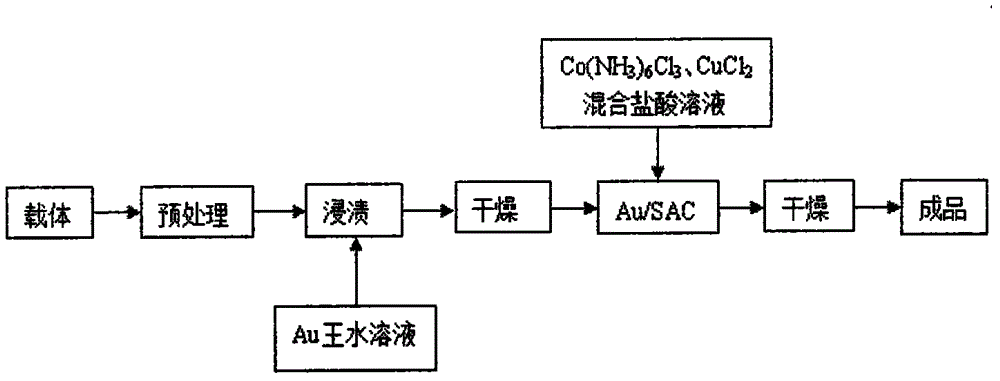

Au-Co-Cu catalyst used in synthesis of vinyl chloride by hydrochlorination of acetylene and preparation method for Au-Co-Cu catalyst

InactiveCN102794187ALow reaction temperatureLess by-productsPreparation by halogen halide additionOrganic-compounds/hydrides/coordination-complexes catalystsIonActivated carbon

The invention discloses a mercury-free catalyst used in the generation of vinyl chloride by the hydrochlorination of acetylene. In the catalyst, gold ions are taken as an active ingredient, and one or two transition metal elements such as copper chloride and hexaamminecobalt trichloride are added additionally; metal salts of the active ingredient can be nitrate, acetate, chloride, a complex and the like; and the active ingredient is loaded by a porous carrier, and the porous carrier is pitch-based spherical activated carbon or powdered activated carbon. The active ingredient is loaded by an impregnation method.

Owner:代斌

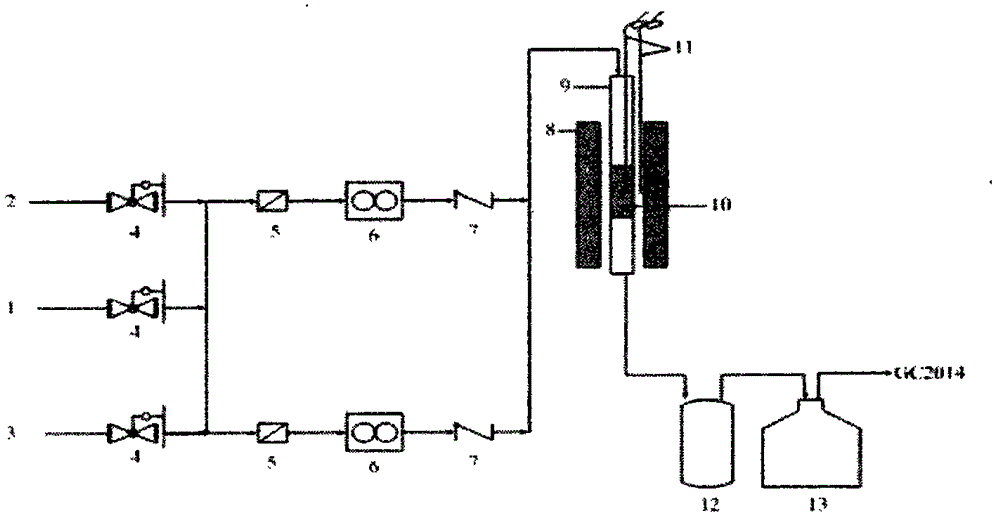

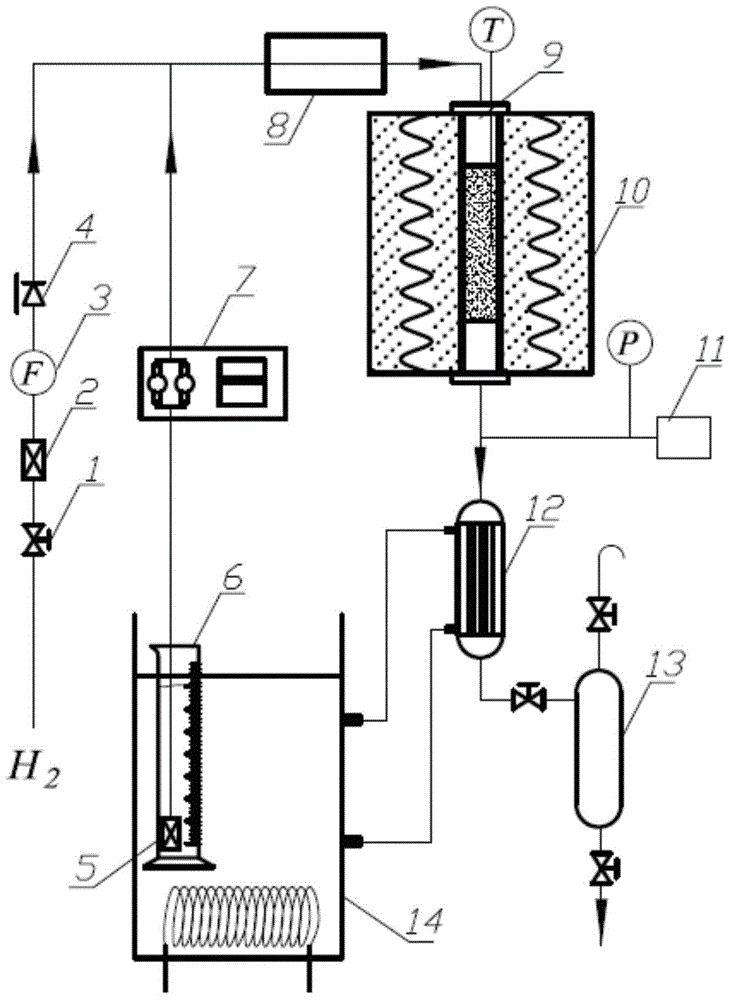

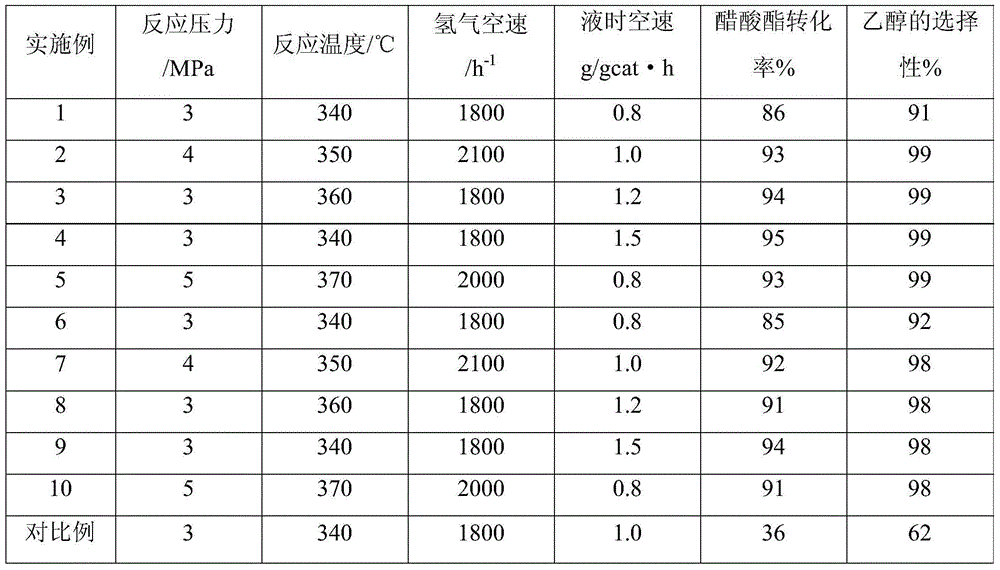

Copper-based catalyst for preparing ethanol by acetate hydrogenation and preparation method

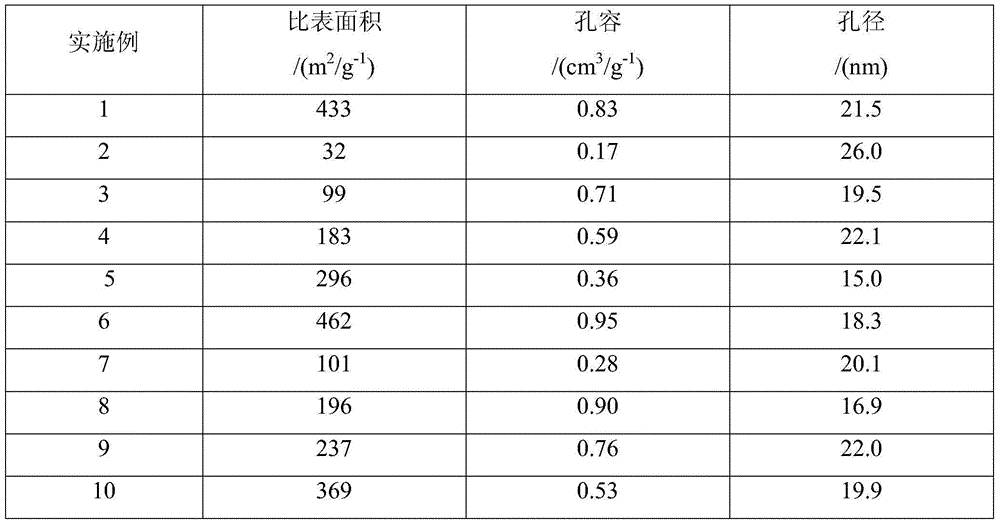

InactiveCN104667925ASimple regenerationSimple preparation processOrganic compound preparationHydroxy compound preparationEthanol synthesisCopper

The invention discloses a copper-based catalyst for preparing ethanol by acetate hydrogenation and a preparation method. The catalyst is obtained by loading CuO and an auxiliary agent on a composite carrier, wherein the composite carrier is at least one of MgO-SiO2 and TiO2-SiO2; the mass ratio of MgO to SiO2 in the MgO-SiO2 ranges from (5:1) to (20:1), and the mass ratio of TiO2 to SiO2 in the TiO2-SiO2 ranges from (5:1) to (20:1); the mass of Cu in the CuO accounts for 5%-28% of the mass of the copper-based catalyst; and the mass of the auxiliary agent accounts for 1%-3% of the mass of the copper-based catalyst. The reaction activity of the catalyst is high when the catalyst is used for catalyzing acetate hydrogenation ethanol synthesis reaction; the conversion rate of acetate is more than 85%; the product selectivity is good and few byproducts are generated; the ethanol selectivity is up to 99%; and the catalyst can be simply regenerated after the reaction. The preparation method is simple and easy to operate, and has low cost.

Owner:TIANJIN UNIV

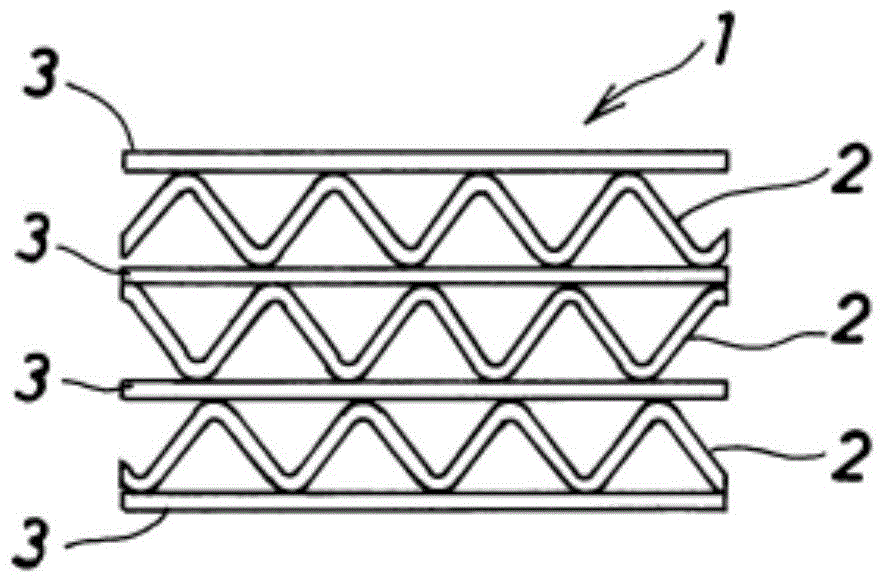

Processing apparatus equipped with catalyst-supporting honeycomb structure, and method for manufacturing same

ActiveCN104245123AReduce contact areaReduce manufacturing costHydrogenGas treatmentGlass fiberPtru catalyst

Owner:HITACHI ZOSEN CORP

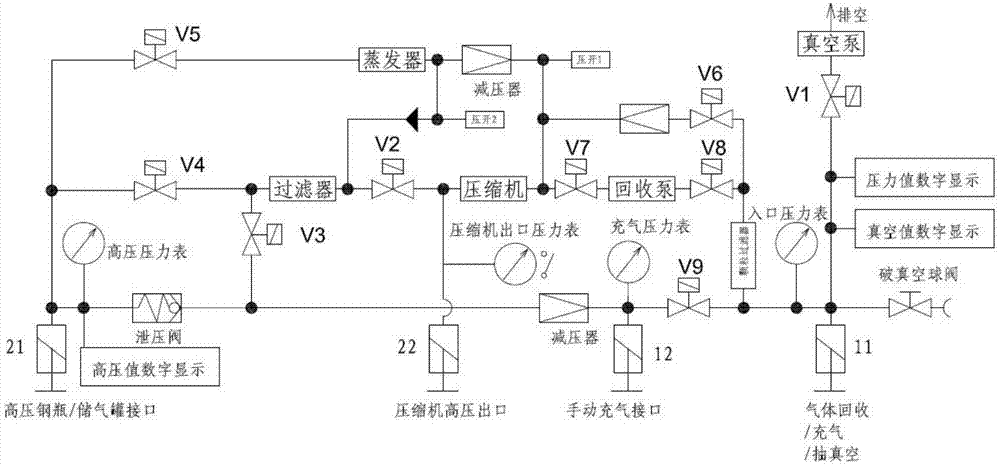

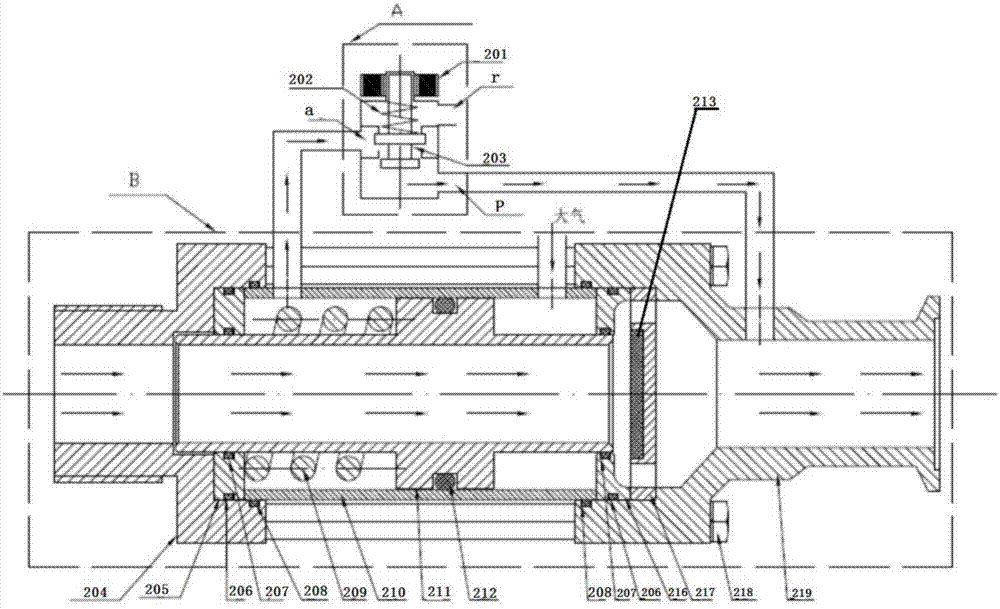

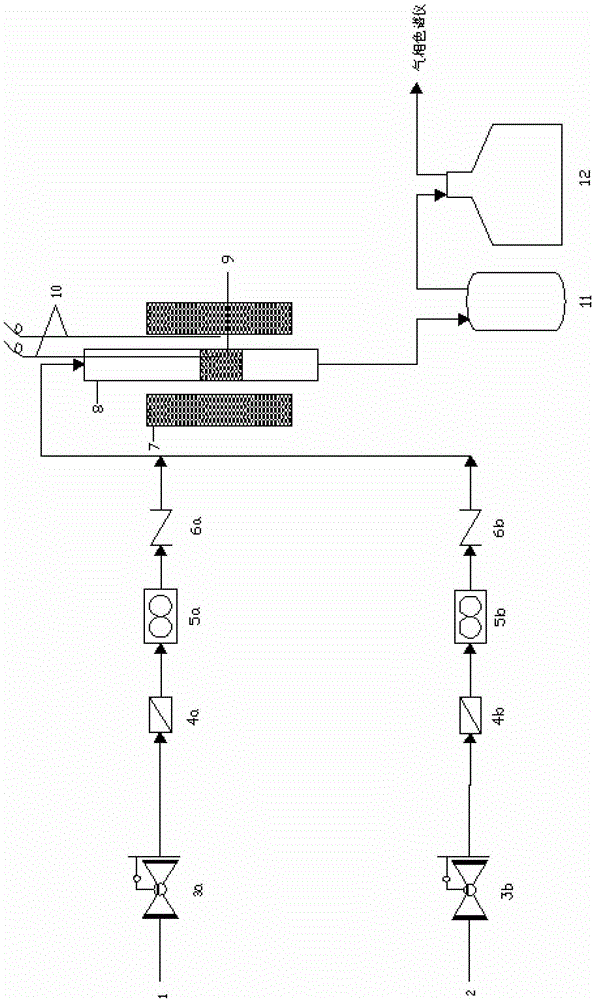

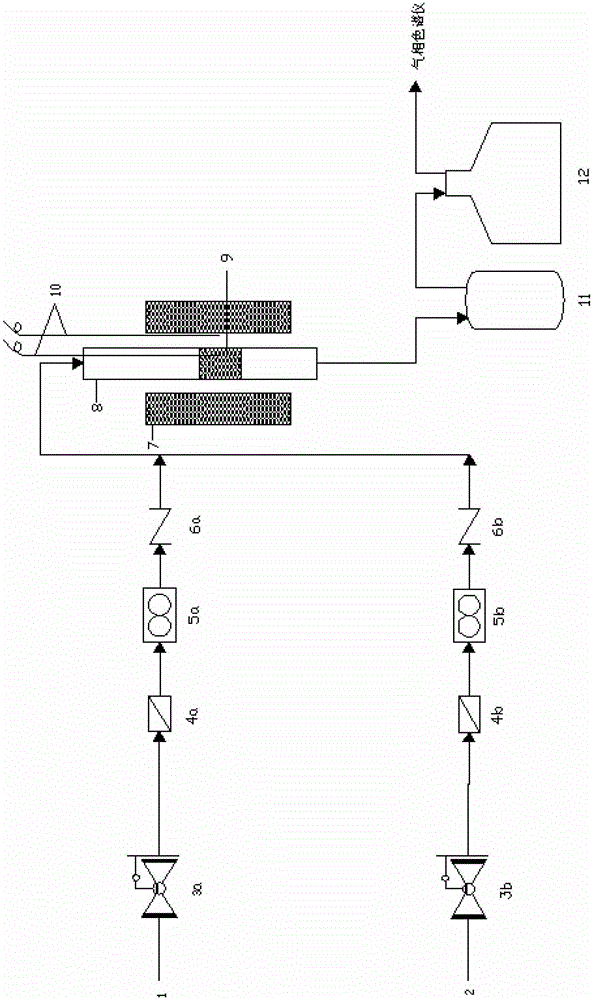

Sulfur hexafluoride automatic recycling device

ActiveCN107289325ASimple regenerationEasy maintenanceVessel mounting detailsVessel geometry/arrangement/sizePower transmissionDisplay device

The invention provides a sulfur hexafluoride automatic recycling device. The sulfur hexafluoride automatic recycling device is characterized by comprising a gas storage device, a filter system, a compression system, a pipeline system and an electric control system which are mounted on a supporting device; the filter system comprises a granule filter and a water filter; the compression system comprises a compressor and a recovery pump; the pipeline system comprises pipelines connecting the devices and control valves on the pipelines; and the electric control system comprises a sensor, an electric control member and an instrument display device. By adopting a lubricating oil-free and leakage-free non-metal spacer sleeve magnetic coupled power transmission compressor, the recovered gas does not contain oil, and regeneration of gas is quite simple and feasible, and the device is leakage-free and the influence on the environment is reduced to the lowest extent. Meanwhile, the sulfur hexafluoride automatic recycling device is simple and feasible to maintain, low in cost and faster to maintain.

Owner:南通虹登机械设备有限公司

Ru-Pt-Ni catalyst used for synthesizing vinyl chloride by hydrochlorinating acetylene

ActiveCN103623836AHigh strengthSolution to short lifePreparation by halogen halide additionChemical recyclingNickel saltPlatinum salts

The invention discloses a Ru-Pt-Ni catalyst used for synthesizing vinyl chloride by hydrochlorinating acetylene. The Ru-Pt-Ni catalyst comprises an inert porous carrier, a ruthenium salt, a nickel salt and a platinum salt, wherein the ruthenium salt, the nickel salt and the platinum salt are carried on the inert porous carrier, the weight of the Ru is 0.01%-5% of the weight of the Ru-Pt-Ni catalyst, and the mole ratio of the Ru, the Pt and the Ni is 1:0.1-10:0.1-10. The Ru-Pt-Ni catalyst is advantageous in that: by using the Ru-Pt-Ni catalyst for synthesizing the vinyl chloride by hydrochlorinating acetylene, the reaction temperature can be decreased to be lower than 180 DEG C, the selectivity of a reaction product is good, byproducts are little, the reaction activity is high, the conversion rate of acetylene exceeds 99% and the selectivity of the vinyl chloride reaches 99.9%; the catalyst is high in strength and long in service lifetime; and regeneration of the catalyst after an reaction is simple. A preparation method is simple in technology and is easy to operate.

Owner:TIANJIN UNIV

Production method of fructus monordicae extract with over 60% of mogroside V content

ActiveCN101690573BPromote leachingEasy to separateCosmetic preparationsToilet preparationsSucroseSaccharum

The invention provides a production method of fructus monordicae extract with over 60% of mogroside V content. In the method, the fresh momordica grosvenori is subjected to the following technique processes: smashing, saccharification, extraction by water, concentration, sedimentation and centrifugation, ion exchange resin refining, macroporous resin refining, concentration, aluminum oxide refining, concentration, spray drying and finishing product. The method can produce high-quality fructus monordicae extract products, reduce material loss, shorten period of production, increase product yield, lower production cost, and is suitable for industrial production. The mogroside V content in the fructus monordicae extract produced by the method is more than or equal to 60%; the fructus monordicae extract has high product purity, single composition, pure white color, good color and taste, fresh and cool sweet taste like that of sugar, simultaneously overcomes the technical problem for industrial production of the high-content and high-quality fructus monordicae extract, and successfully realizes large-scale production.

Owner:YONGZHOU YIDONG BIOTECH

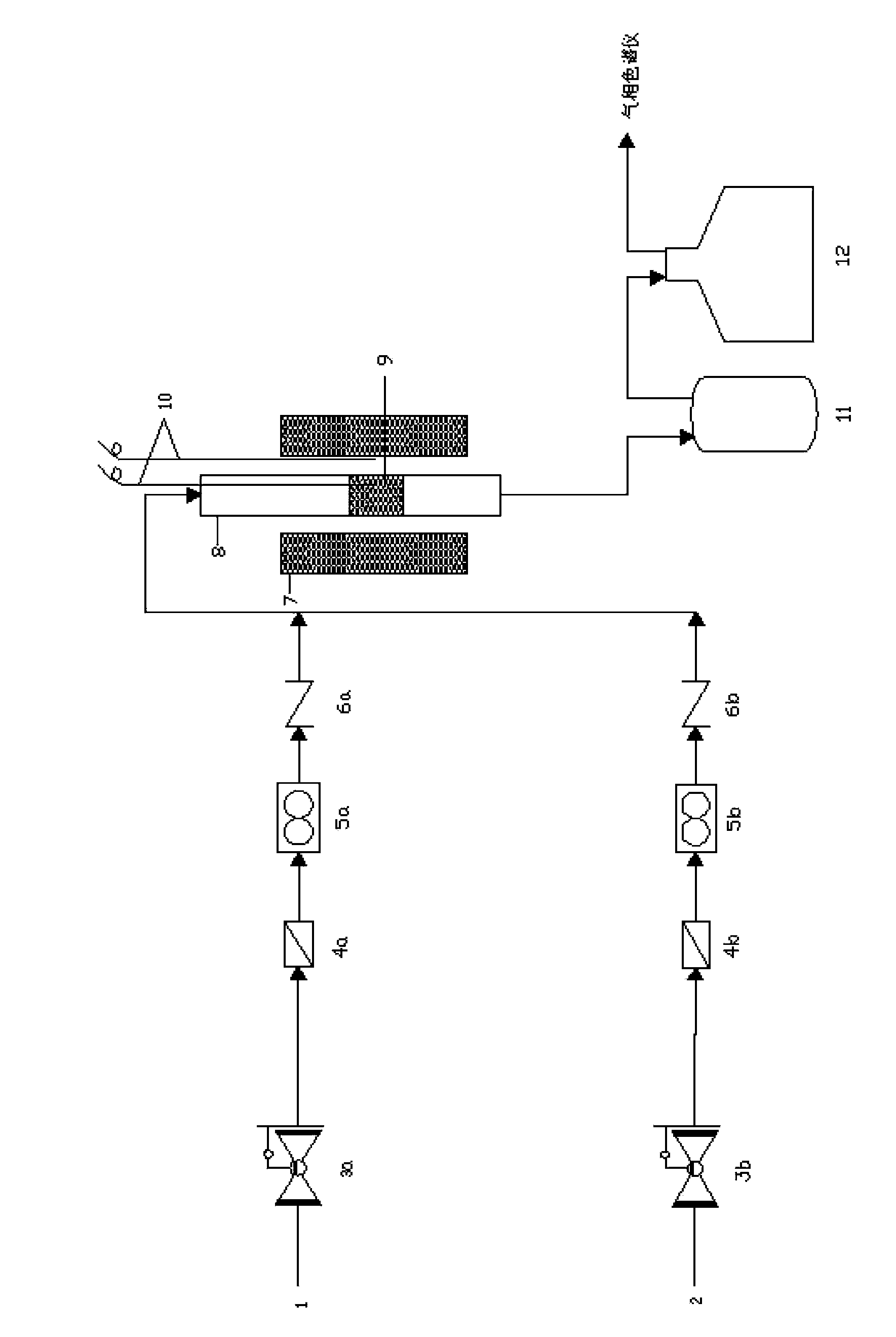

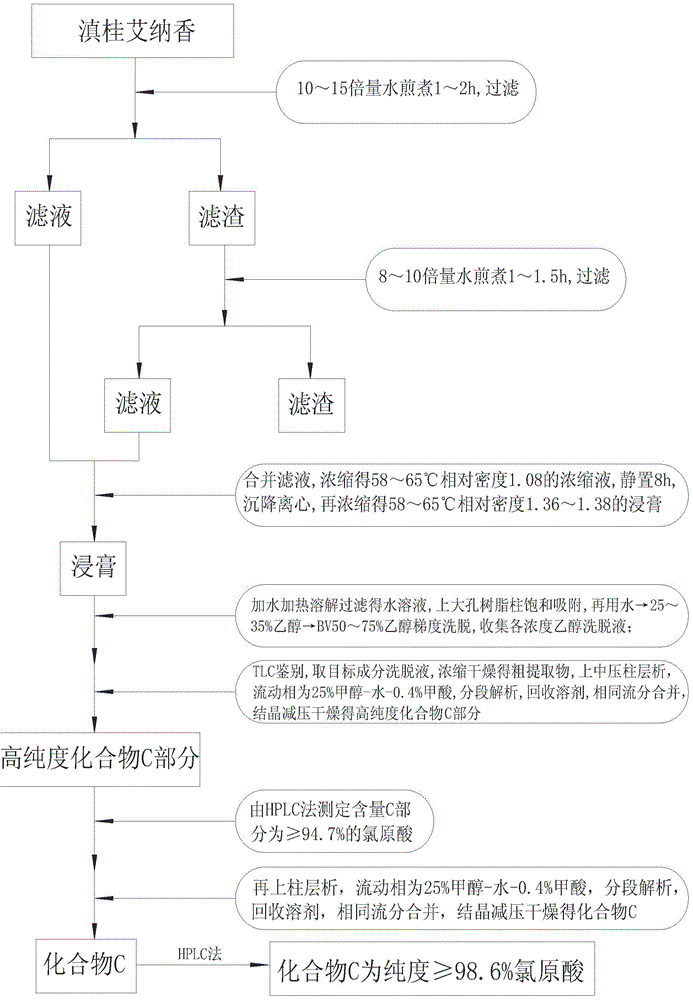

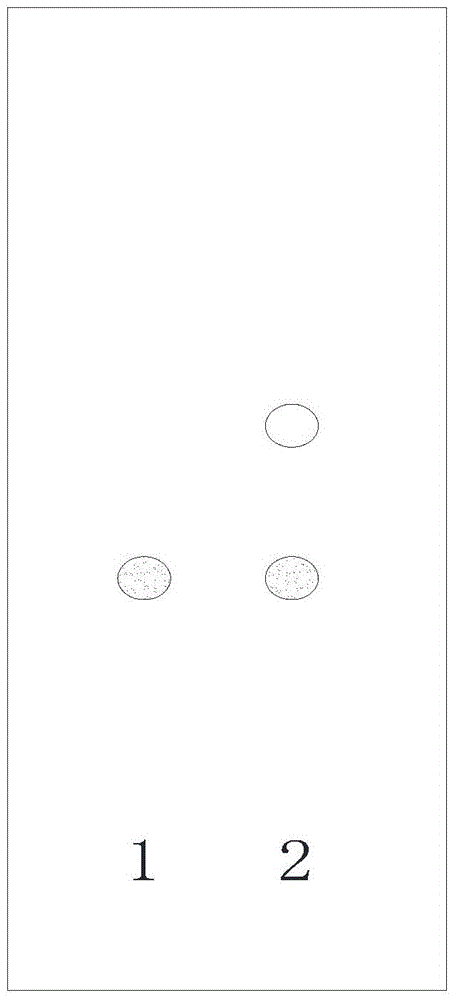

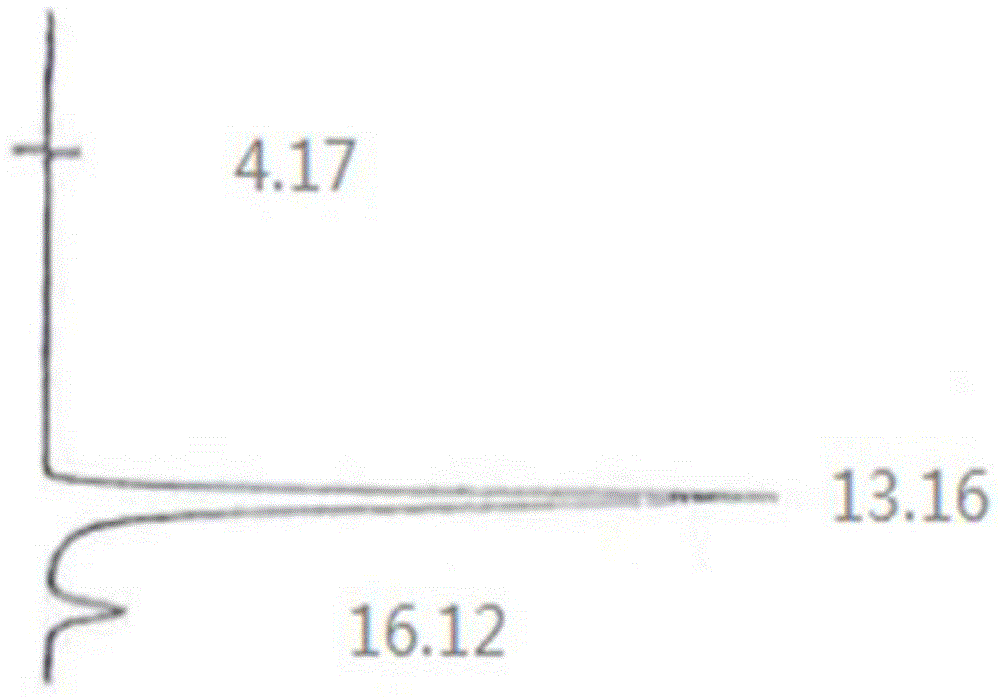

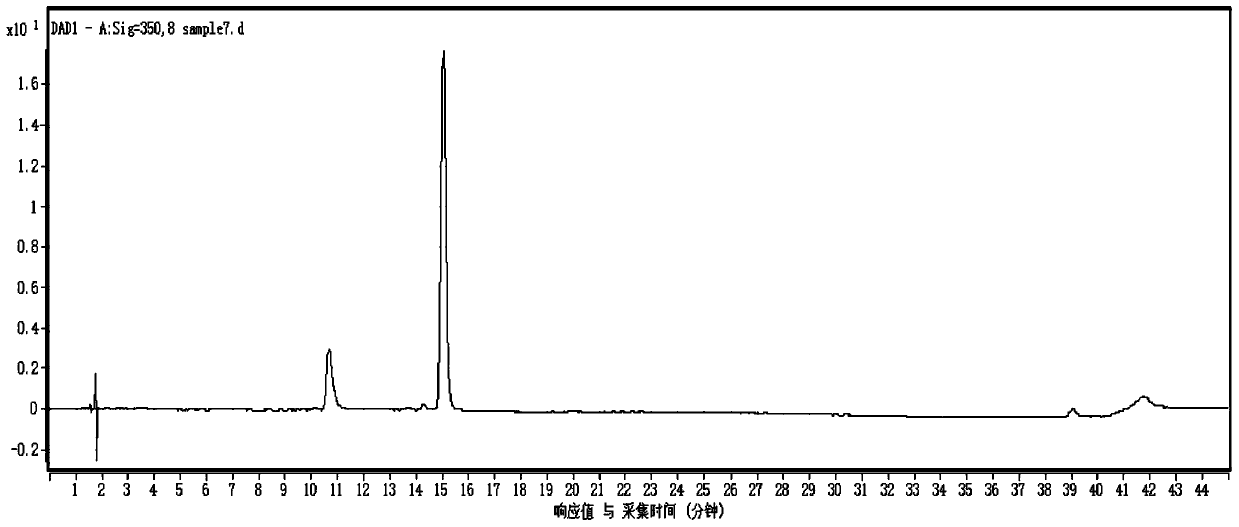

Process method for extracting chlorogenic acid from blumea riparia(BL.)DC

ActiveCN104130127AImprove adsorption capacityRemove completelyOrganic compound preparationCarboxylic acid esters separation/purificationChlorogenic acidSolvent

The invention discloses a process method for extracting chlorogenic acid from blumea riparia(BL.)DC, and belongs to the technology field of traditional Chinese medicine extraction process. According to the method, a chlorogenic acid monomer is prepared from the following process: water extraction, concentration, macroporous resin adsorption and separation, elution, purification, and further purification, wherein a compound C is analyzed and determined to be chlorogenic acid with the content of not less than 98.6% by HPLC and is the chlorogenic acid monomer. The process method for extracting the chlorogenic acid from blumea riparia(BL.)DC solves the problems that the preparation purity is not high, the preparation amount is small, the preparation course is complicated and industrialized production is difficult to realize; with combination of the polar macroporous resin column enrichment and a mixed solvent split-phase method, the chlorogenic acid distribution gradient purification is realized, the extraction purity is high, the process steps are simple, and the process method is suitable for industrialized production.

Owner:广西万寿堂药业有限公司

Method and device for removing trace water in single polycrystalline silicon cutting fluid

InactiveCN105214338ALow costSimple regenerationIon-exchange process apparatusIon-exchanger regenerationMicrosphereSilica gel

The invention relates to a method and a device for removing trace water in a single polycrystalline silicon cutting fluid. The method is characterized in that by utilizing a centrifugal pump, the cutting fluid which contains trace water is fed into a drying device with a drying agent therein from a feeding tube; after the cutting fluid sufficiently exchanges with the drying agent in the drying device, the cutting fluid with qualified water content is discharged from a discharge tube; the drying agent is a mixture obtained by mixing a little allochroic silicagel into a molecular sieve or aluminium oxide microspheres; and when the allochroic silicagel is completely changed into red, hot air with a temperature of 120 DEG C is introduced into the drying device for carrying out drying regeneration treatment on the drying agent. The invention has the advantages that the method is simple and convenient, the device is simple, the dehydrating effect is good, the drying agent can be repeatedly used, the energy consumption of enterprises is reduced, and the like.

Owner:江苏华研精粹新能源有限公司

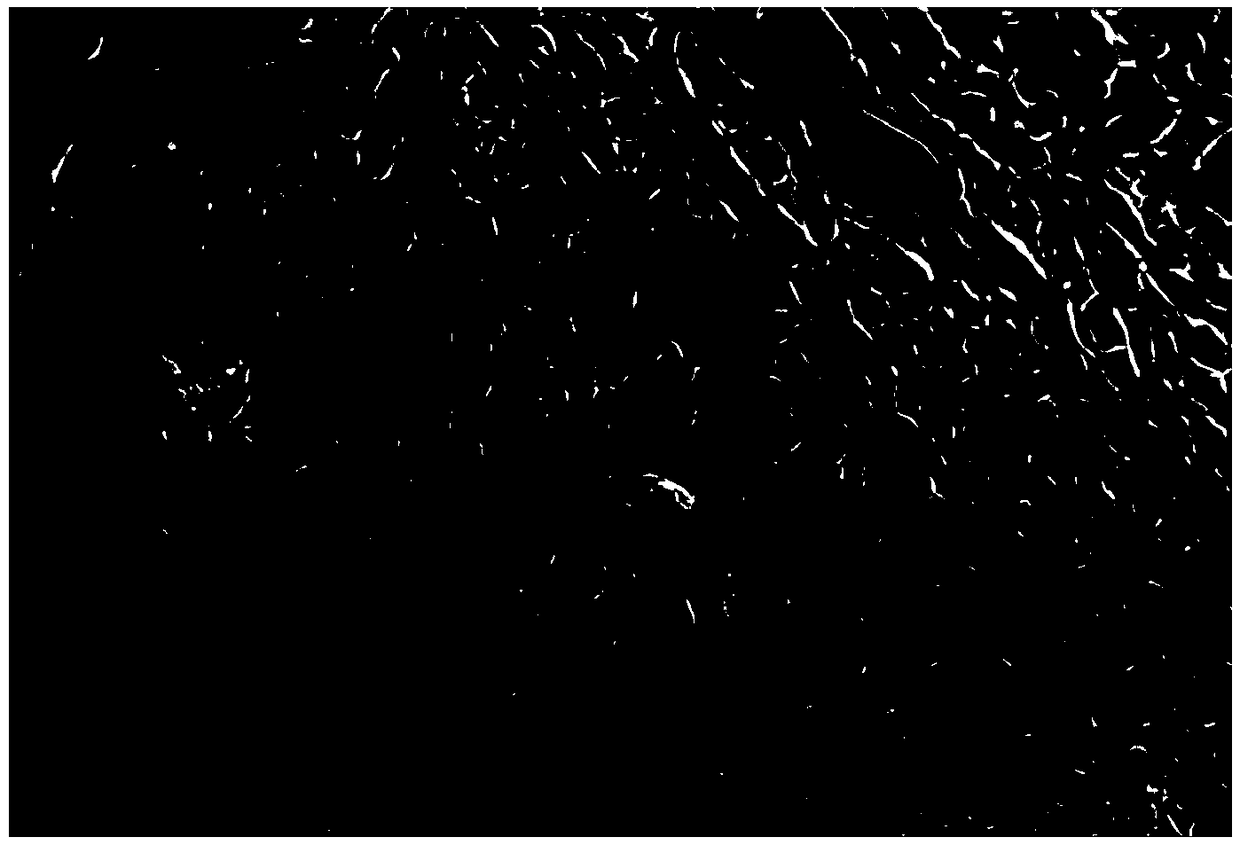

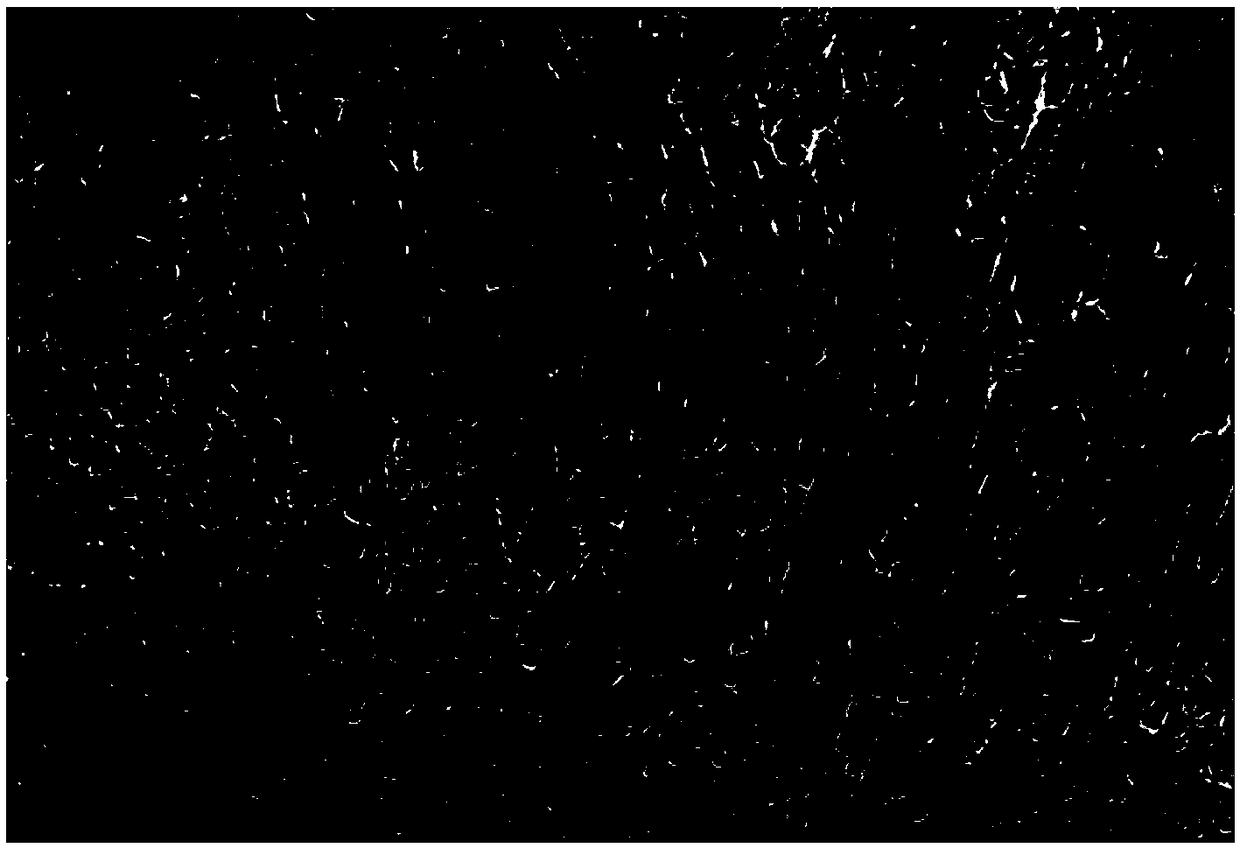

Magnetic high polymer material glass slide and cover glass and manufacturing method thereof

InactiveCN103777340AHigh mechanical strengthGood chemical stabilityMicroscopesPolymer sciencePlastic materials

The invention relates to a specimen making material, in particular to a magnetic high polymer material glass slide and cover glass and a manufacturing method thereof. The glass slide and cover glass are made of a magnetic high polymer transparent plastic material, and a compound type magnetic high polymer material is adopted in the magnetic high polymer transparent plastic material. The manufacturing method of the magnetic high polymer material glass slide and cover glass comprises the steps that (1) in the production process of the magnetic high polymer transparent plastic material, trace amounts of magnetic materials are evenly mixed, so that the compound type magnetic high polymer plastic material is manufactured; (2) the compound type magnetic high polymer plastic raw material is manufactured to be a glass slide base material with the thickness being 0.8-1.2 mm and a cover glass base material with the thickness being 0.1-0.2 mm through a rolling forming technology; (3) a semi-finished glass slide and cover glass are made to form a permanent magnetism high polymer material glass slide and cover glass by the way that magnetic material micro powder is in ordered arrangement in the easy magnetization direction under the action of an external magnetic field.

Owner:XINXIANG MEDICAL UNIV

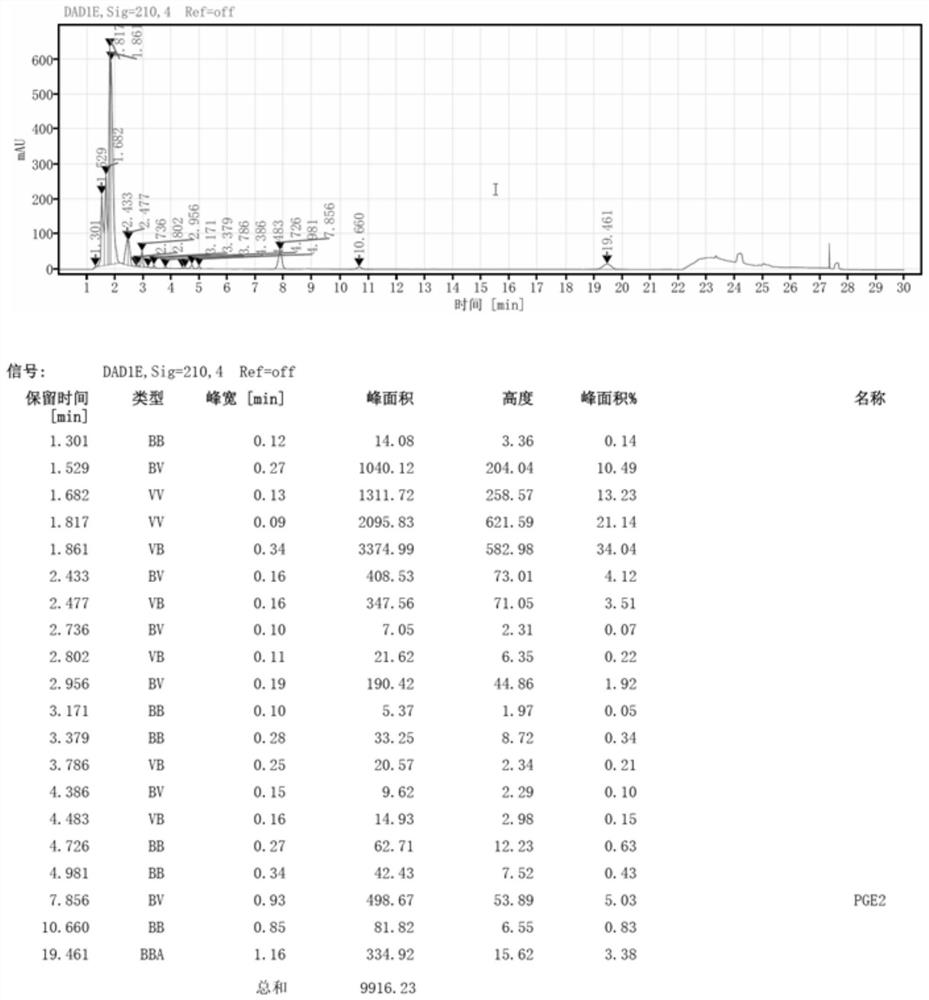

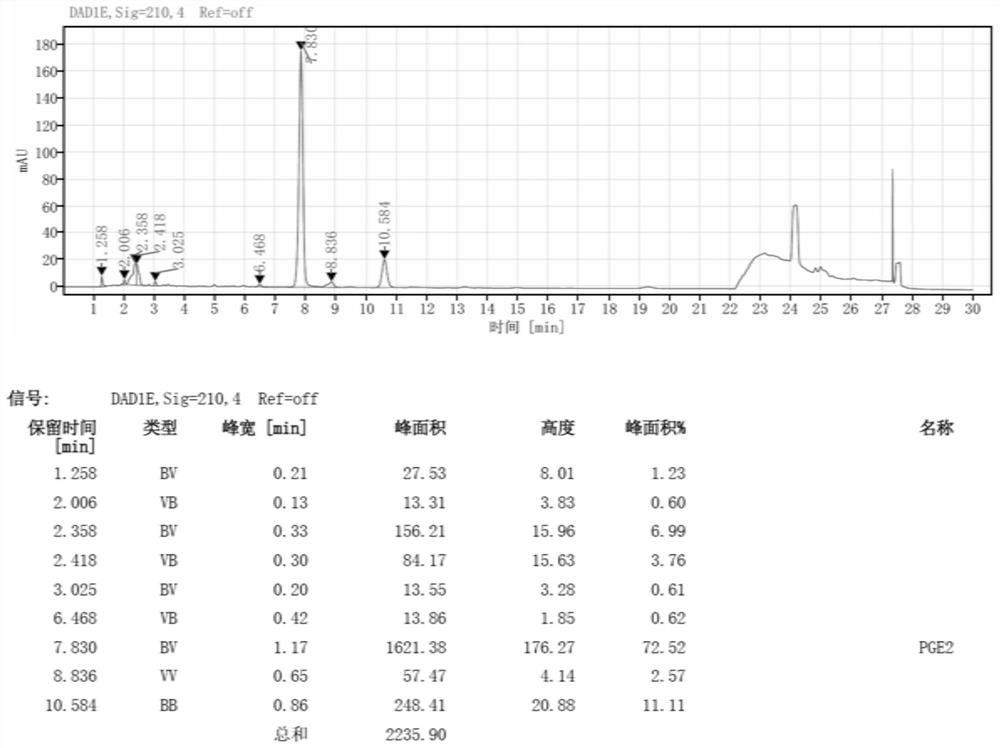

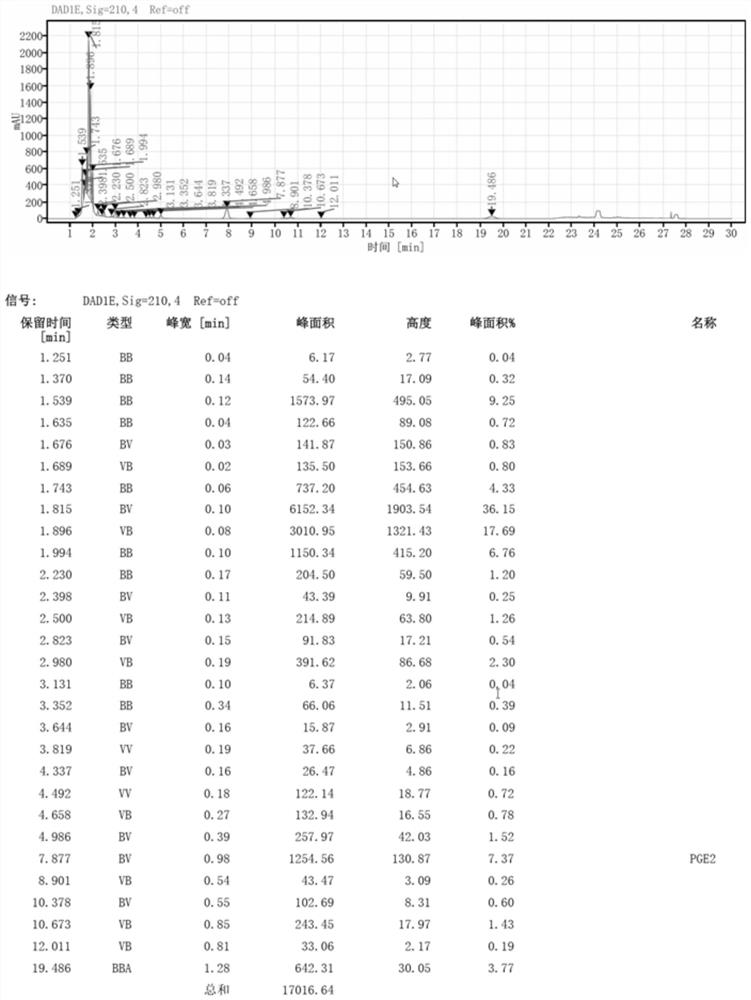

Method for purifying dinoprostone

The invention discloses a method for purifying dinoprostone. The method comprises the following steps: S1, taking enzymatic reaction liquid of dinoprostone, and sequentially carrying out microfiltration, ultrafiltration and nanofiltration treatment to obtain nanofiltration liquid; S2, feeding the nanofiltration liquid into a chromatographic column, pre-washing the liquid with a solution A, eluating the liquid with a solution B and collecting an eluant, removing the solvent to acquire dinoprostone, wherein a filler of the chromatographic column is silica gel Unisil 10 to 120 C18. The inventioncan effectively separate and purify the enzymatic reaction liquid of the dinoprostone, and the obtained dinoprostone is high in purity and yield.

Owner:开封康诺药业有限公司 +1

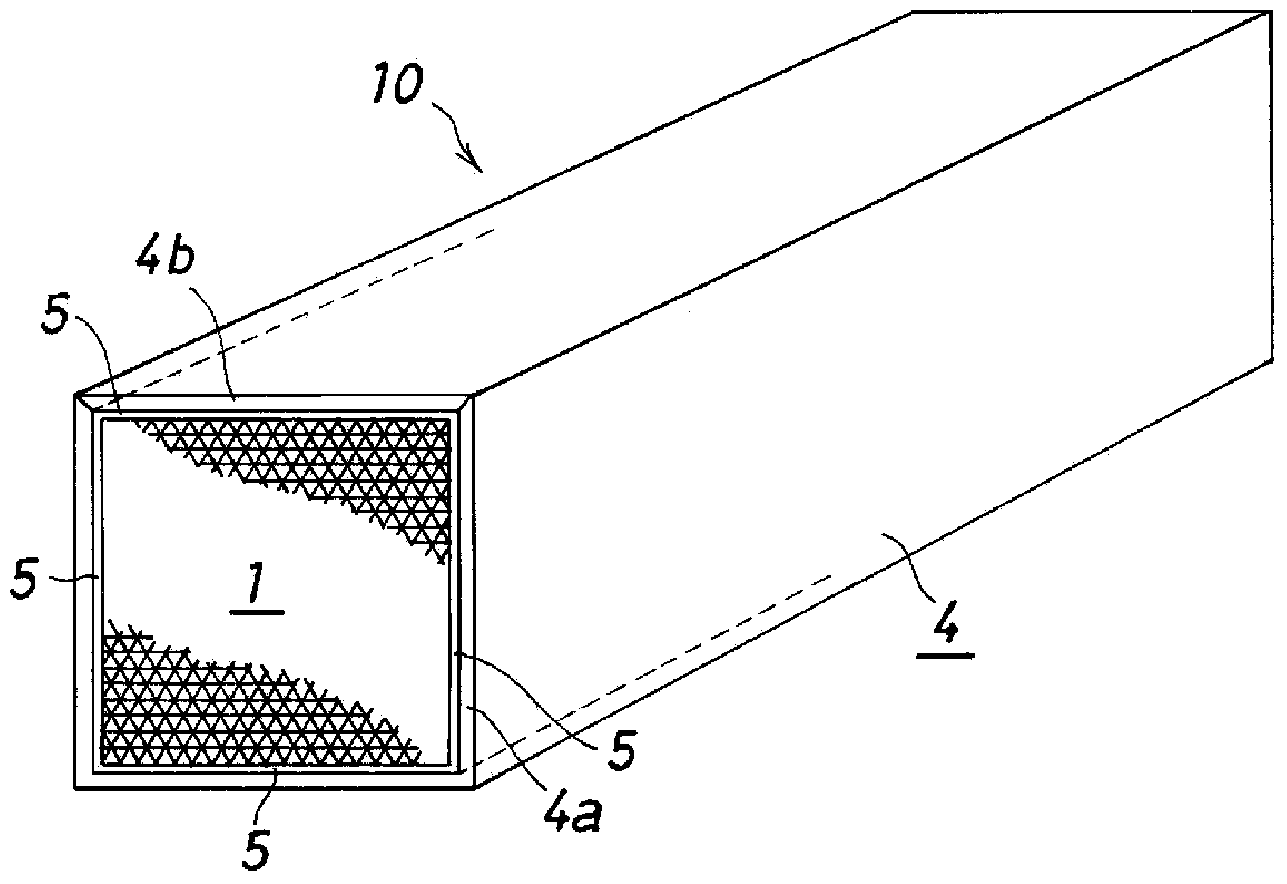

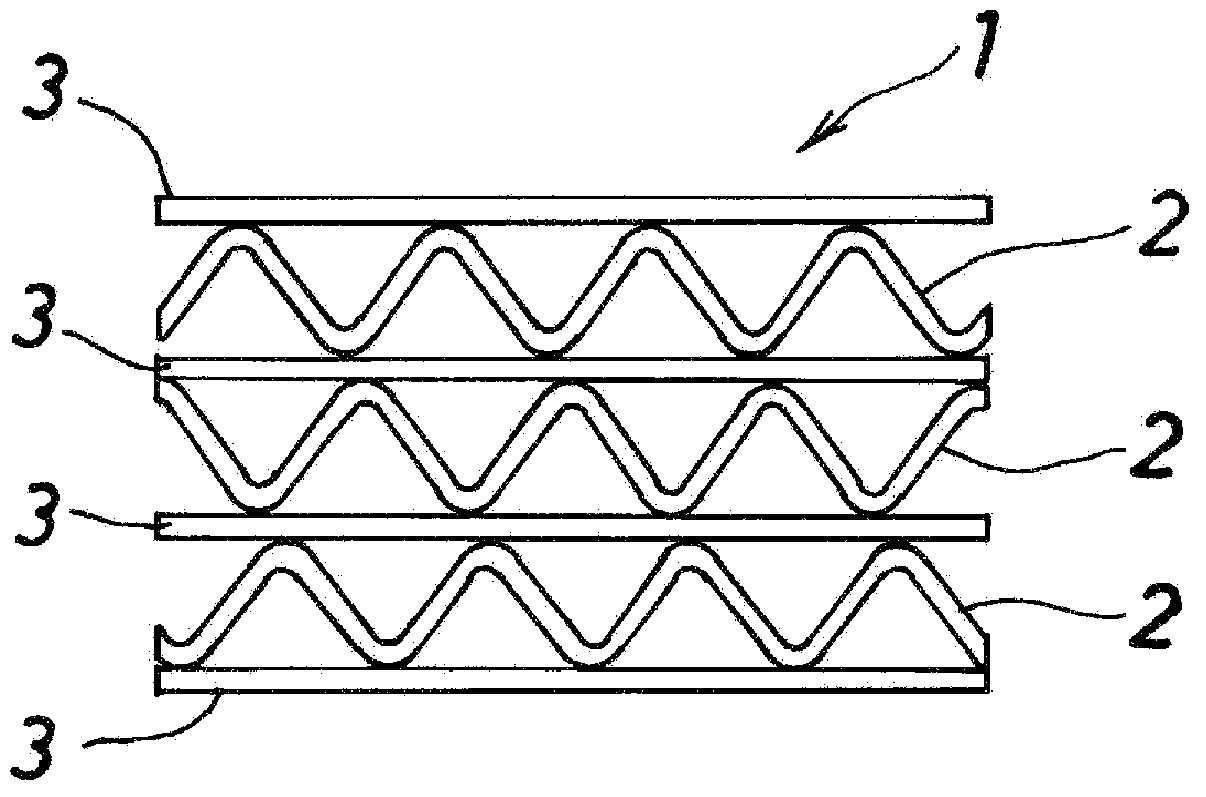

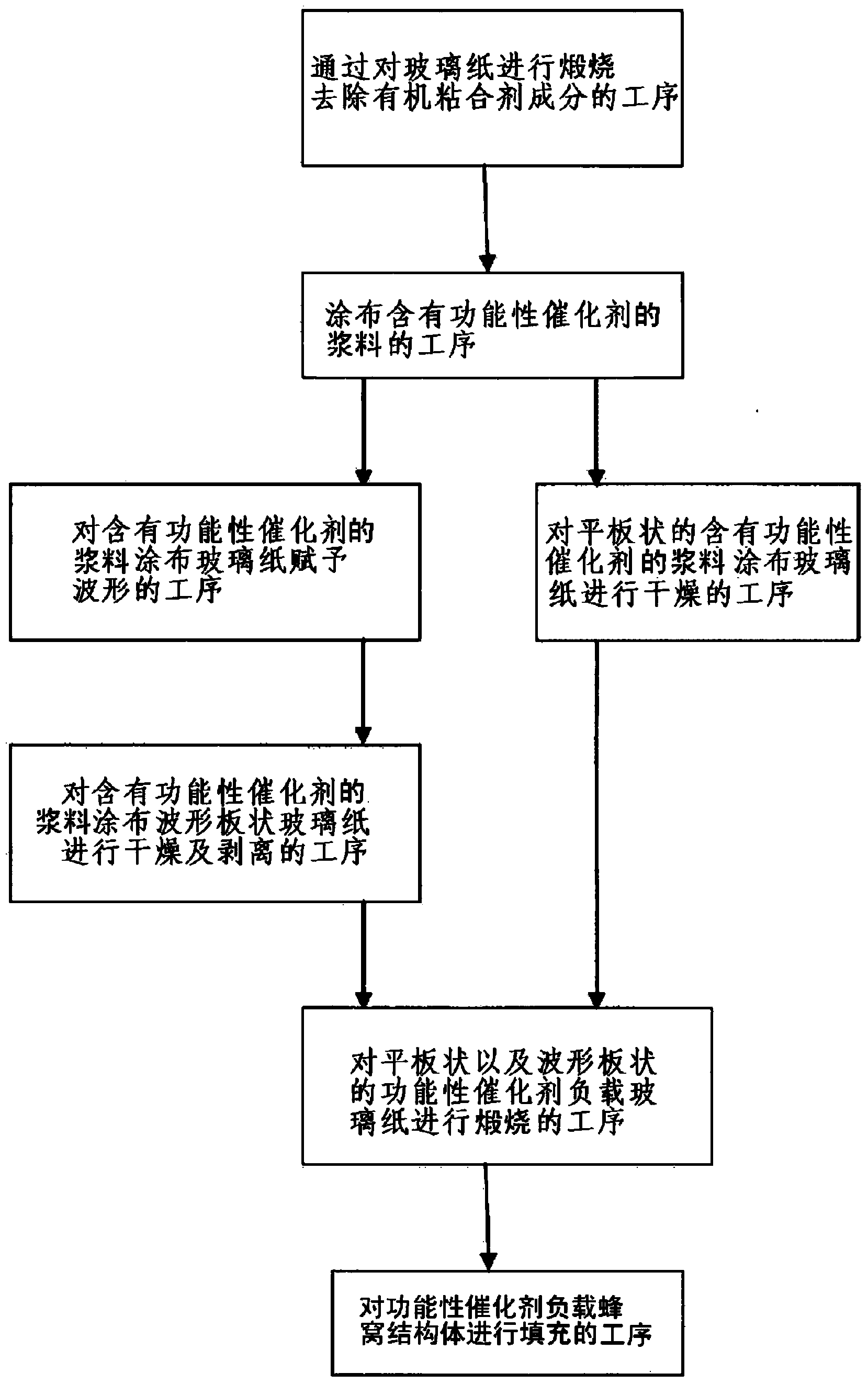

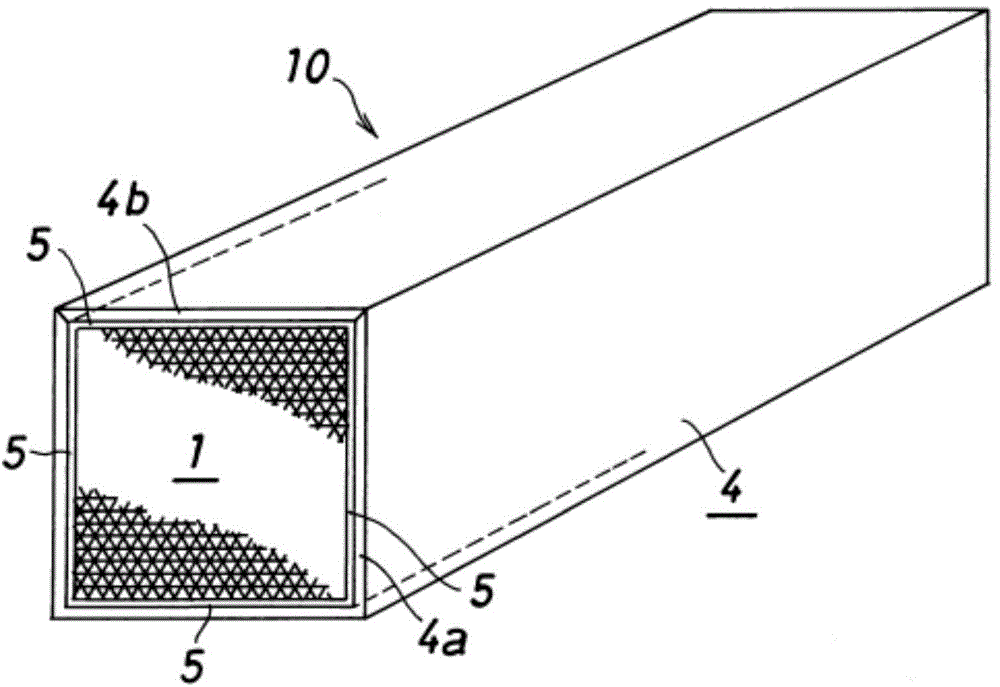

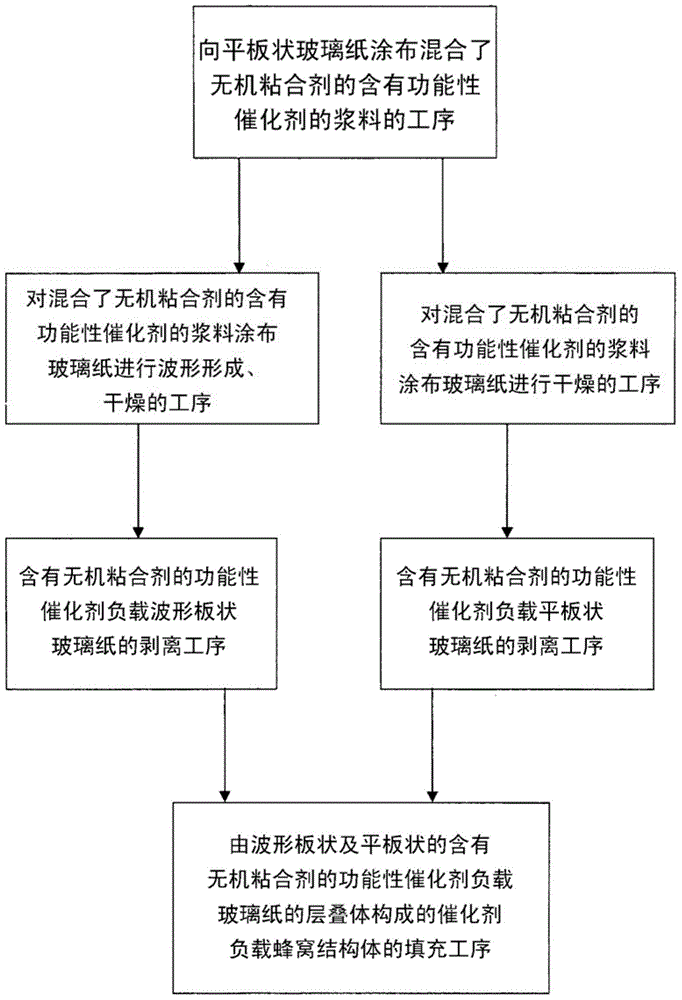

Treatment device equipped with catalyst-supporting honeycomb structure and process for producing same

ActiveCN104918702AReduce production processReduce manufacturing costLiquid surface applicatorsInternal combustion piston enginesFlat glassDecomposition

[Problem] To provide a treatment device equipped with a catalyst-supporting honeycomb structure, the device being for use in, for example, discharge gas purification or hydrogen production by ammonia decomposition, and a process for producing the treatment device. The catalyst-supporting honeycomb structure is produced by forming corrugated glass paper on which an inorganic-binder-containing functional catalyst is supported, without the necessity of removing the organic binder intrinsically contained in the glass paper, and by using the corrugated glass paper in combination with flat glass paper on which an inorganic-binder-containing functional catalyst is supported. Due to this, not only steps for producing a treatment device equipped with a catalyst-supporting honeycomb structure are greatly shortened, but also the production cost is lowered. [Solution] The treatment device equipped with a catalyst-supporting honeycomb structure comprises the catalyst-supporting honeycomb structure (1) and a casing (4) in which the catalyst-supporting honeycomb structure (1) has been packed, the catalyst-supporting honeycomb structure (1) having been formed by alternately superposing corrugated glass paper that has an inorganic-binder-containing functional catalyst supported thereon and flat glass paper that has, supported thereon, the same inorganic-binder-containing functional catalyst.

Owner:HITACHI ZOSEN CORP

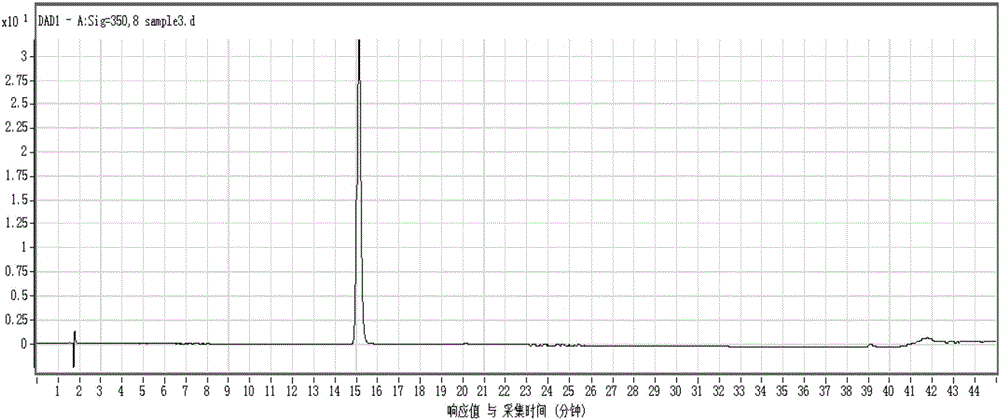

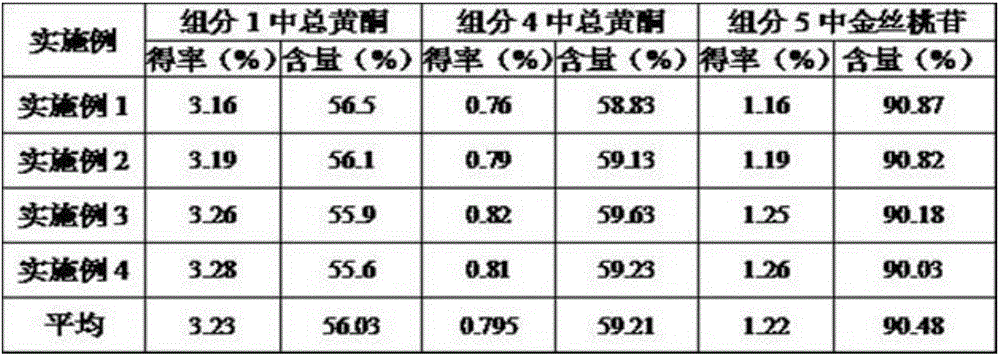

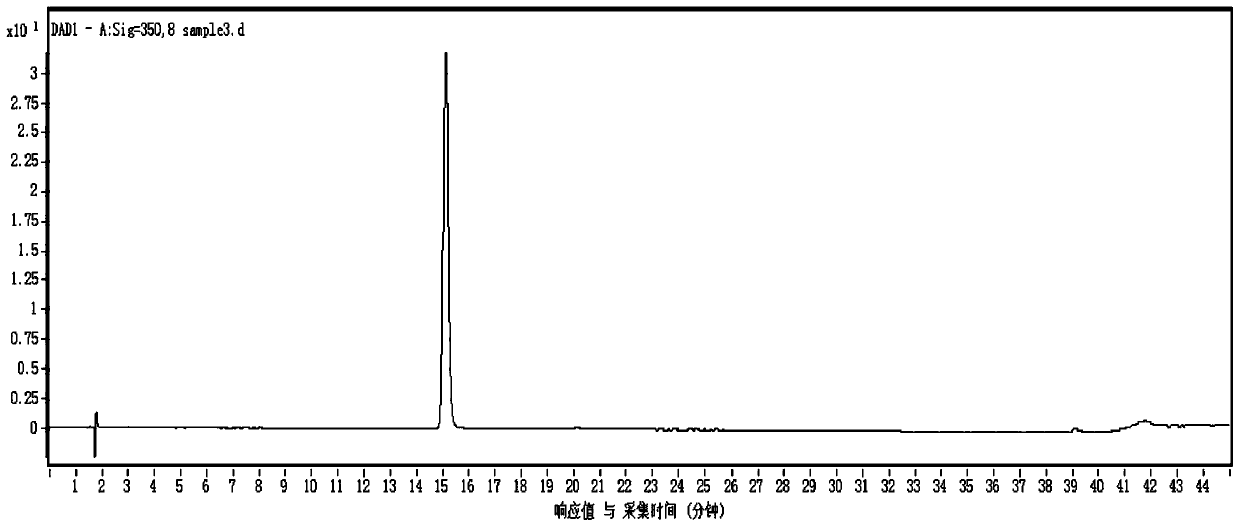

Method of separating high-purity hyperin from lotus leaf

InactiveCN106749456AImprove adsorption capacityExtended service lifeSugar derivativesChemical industrySeparation technologyUltrafiltration

The invention discloses a method of separating high-purity hyperin from a lotus leaf, and relates to a method of separating high-purity hyperin from a natural plant particularly the lotus leaf and synchronously preparing lotus leaf general flavones, in particular to a method that normal-temperature weak-base water solution ultrasonic-assisted continuous dynamic countercurrent extracting is adopted to replace conventional alcohol-water hot solvent extracting and used for extracting in combination with ultrafiltration impurity removal, nanofiltration solvent recovery and the multiple-unit macroreticular resin separation technology, and high-purity hyperin and other lotus leaf general flavones are collected through sequential elution. The method of separating high-purity hyperin from the lotus leaf is definite in functional factor, suitable for industrial production, low in cost, capable of separating high-purity hyperin from the lotus leaf in an environment-friendly and energy-saving mode and suitable for industrial development and utilization of lotus leaf flavones resources, and the extracted hyperin is high in purity.

Owner:YANGZHOU BAOLIAN BIOLOGICAL SCI & TECH CO LTD +1

Chitosan quaternary ammonium salt and phytic acid porous composite membrane and method for removing metal impurities

InactiveCN109092266ALarge specific surface areaImproves Structural IntegrityIon-exchange process apparatusOther chemical processesFreeze-dryingMetal impurities

The invention provides a chitosan quaternary ammonium salt and phytic acid porous composite membrane and a method for removing metal impurities. The chitosan quaternary ammonium salt and phytic acid porous composite membrane is prepared with the following method: dissolving chitosan quaternary ammonium salt in water, adding a plasticizer, and performing stirring uniformly to obtain a chitosan quaternary ammonium salt solution; dissolving phytic acid powder in water to obtain a phytic acid aqueous solution; adding the phytic acid aqueous solution dropwise slowly to the chitosan quaternary ammonium salt solution under stirring to obtain a mixed solution; freezing the mixed solution, and performing freeze-drying to obtain the porous composite membrane; placing the porous composite membrane ina constant temperature and constant humidity box to obtain the chitosan quaternary ammonium salt and phytic acid porous composite membrane. The method for removing the metal impurities comprises thefollowing steps: mixing the chitosan quaternary ammonium salt and phytic acid porous composite membrane with to-be-treated mineral oil, and performing filtering after reaction. The chitosan quaternaryammonium salt and phytic acid porous composite membrane has larger specific surface area, excellent structural integrity and good contact adsorption, can effectively remove the metal impurities, is simple and convenient to operate, and is suitable for large-scale industrial application.

Owner:HUBEI ENG UNIV

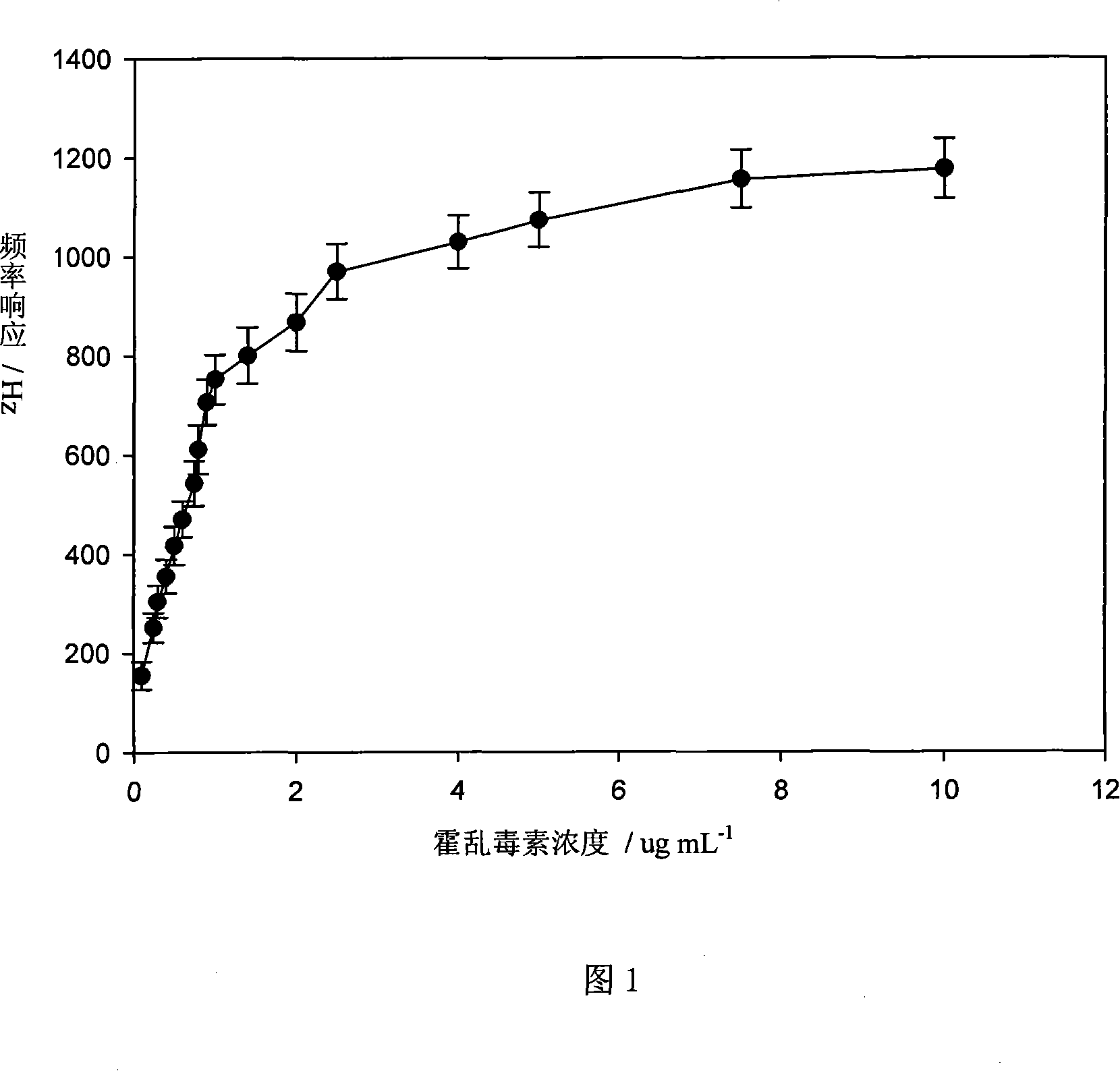

Cholera morbus toxin detection immunosensor and its preparation method and uses

InactiveCN101149378ASimple regenerationReduce non-specific adsorptionBiological testingCholera MorbusToxin detection

This invention provides a kind of cholera toxin detection immunity sensor, includes the quartz crystal shake, the lyophobic layer in the quartz crystal shake and the phosphatides film in the lyophobic layer; this invention also gives the preparation method of the said cholera toxin detection immunity sensor. The preparation of the cholera toxin detection immunity sensor is simple, the reaction is sensitive, the detection is fast, the cost is small and it can be used again and again.

Owner:HUNAN UNIV

Ru-ni-cu Catalyst for the Synthesis of Vinyl Chloride by Hydrochlorination of Acetylene

ActiveCN103623839BHigh strengthSolution to short lifePreparation by halogen halide additionMetal/metal-oxides/metal-hydroxide catalystsNickel saltRuthenium

The invention discloses a Ru-Ni-Cu catalyst for acetylene hydrochlorination synthesis of vinyl chloride. The catalyst comprises a porous inert carrier and the inert porous carrier of ruthenium salts, copper salts and nickel salts supported on the porous inert carrier. Ru accounts for 0.001-5% of the weight of the Ru-Ni-Cu catalyst for acetylene hydrochlorination synthesis of vinyl chloride, and the molar ratio of Ru, Ni and Cu is 1:0.1-10:0.1-10. The invention has the advantages that: for catalysis of acetylene hydrochlorination synthesis of vinyl chloride, the catalyst provided by the invention can reduce the reaction temperature to below 180 DEG C, and the reaction generates product with good selectivity, a small amount of by-products, and has high reaction activity, conversion rate of acetylene over 99% and vinyl chloride selectivity reaching 99.9%. The catalyst provided by the invention has high strength and long service life, and is simple for regeneration treatment after the reaction. The method is simple in preparation process and easy to operate.

Owner:TIANJIN TIANDI CHUANGZHI TECH DEV

Preparation method of Clinodiside A

InactiveCN102443035AReduce dosageExtend the life cycleSugar derivativesSteroidsChromatographic separationMacroporous resin

The invention provides a preparation method of Clinodiside A, comprising the following technological steps of: crushing clinopodium polycephalum, adding 8-15 times of water, heating up and extracting for 2-3 times, sinking the extract by the addition of a sinking agent, adding a macroporous resin into a filtered solution for adsorption, carrying out elution by an ethanol solution with the concentration of 60-80%, carrying out vacuum concentration on the eluent, extracting for 2-3 times by using water-saturated n-butanol, carrying out vacuum concentration on the extract, letting the concentrate pass through a gel column for chromatographic separation, carrying out elution by using ethanol with the concentration of 30-35%, collecting a lower column liquid, reducing pressure and recovering ethanol, and drying to obtain Clinodiside A. The technology provided by the invention is simple to operate, has good reappearance and is suitable for the preparation of the high-content Clinodiside A product.

Owner:苏州宝泽堂医药科技有限公司

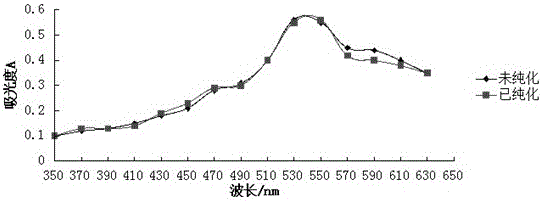

Method for purifying peony seed shell pigment by using macroporous resin

The invention belongs to the technical field of extraction of natural pigment, and particularly relates to a method for purifying peony seed shell pigment by using macroporous resin. According to the technical scheme, the method comprises the following process steps: peony seed shell collecting, drying, pulverizing and sieving, ultra-high-pressure extracting, filtering to obtain filtrate, rotary evaporation to obtain concentration liquor, resin pretreatment, resin static screening, extraction liquid and resin dynamic adsorption, ethanol dynamic elution, and vacuum drying of eluant to obtain the finished product. By spectral characteristics and comparison of color values before and after purification, the original ingredients and characters of the pigment are proved to be retained well in a purification process, and the color value is increased.

Owner:翟益彤

Chitosan-phytic acid porous composite membrane, and method for removing metal impurities

InactiveCN109174028ALarge specific surface areaImproves Structural IntegrityOther chemical processesAlkali metal oxides/hydroxidesFiltrationFreeze-drying

The invention provides a chitosan-phytic acid porous composite membrane, and a method for removing metal impurities. A production method of the chitosan-phytic acid porous composite membrane comprisesthe following steps: dissolving chitosan powder in an acid solution, adding a plasticizer, and performing uniform mixing to obtain a chitosan solution; dissolving phytic acid powder in water to obtain an aqueous phytic acid solution; slowly dropwise adding the aqueous phytic acid solution to the chitosan solution while stirring in order to obtain a chitosan and phytic acid mixed solution; freezeing the chitosan-phytic acid mixed solutionn, and then freeze-drying the frozen mixed solution to obtain a porous composite membrane; and placing the chitosan-phytic acid porous composite membrane in aconstant temperature and humidity chamber to obtain the chitosan-phytic acid porous composite membrane. The method for removing metal impurities comprises the following steps: mixing of the chitosan-phytic acid porous composite membrane with mineral oil to be treated, reacting, and filtration. The chitosan-phytic acid porous composite membrane has the advantages of large specific surface area, excellent structural integrity, good contact adsorption property, effectiveness in removal of the metal impurities, simplicity and convenience in operation, and suitableness for large-scale industrial applications.

Owner:HUBEI ENG UNIV

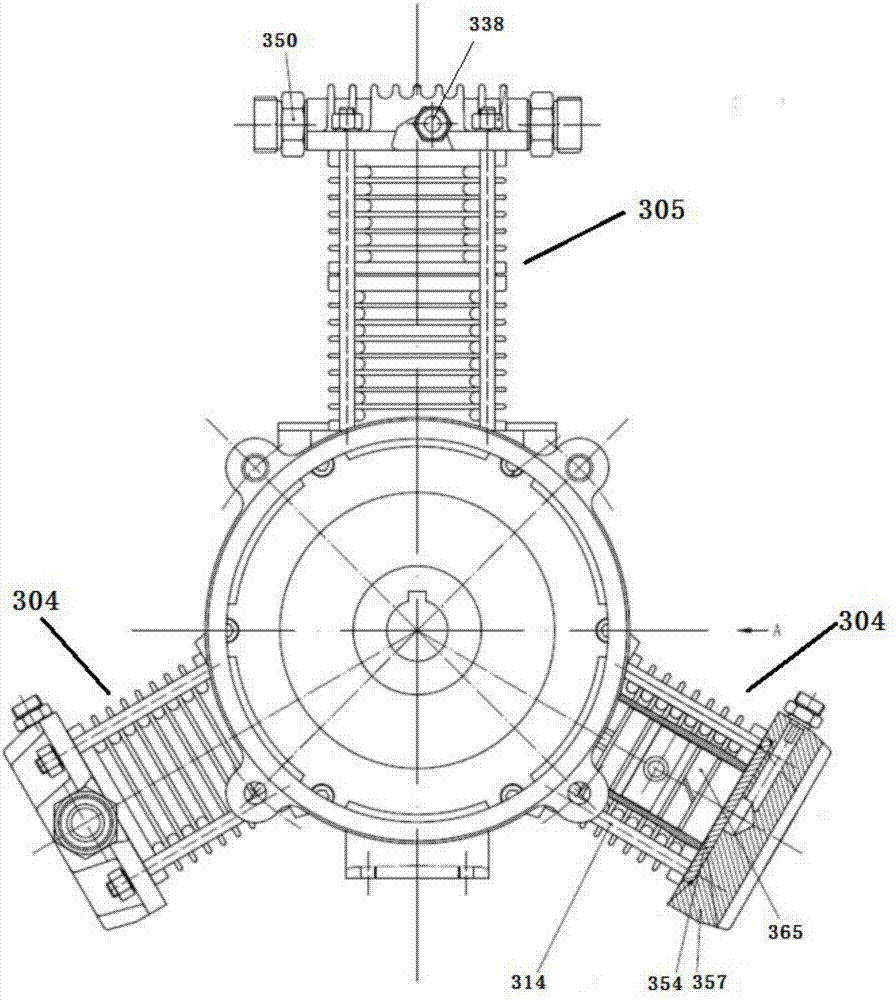

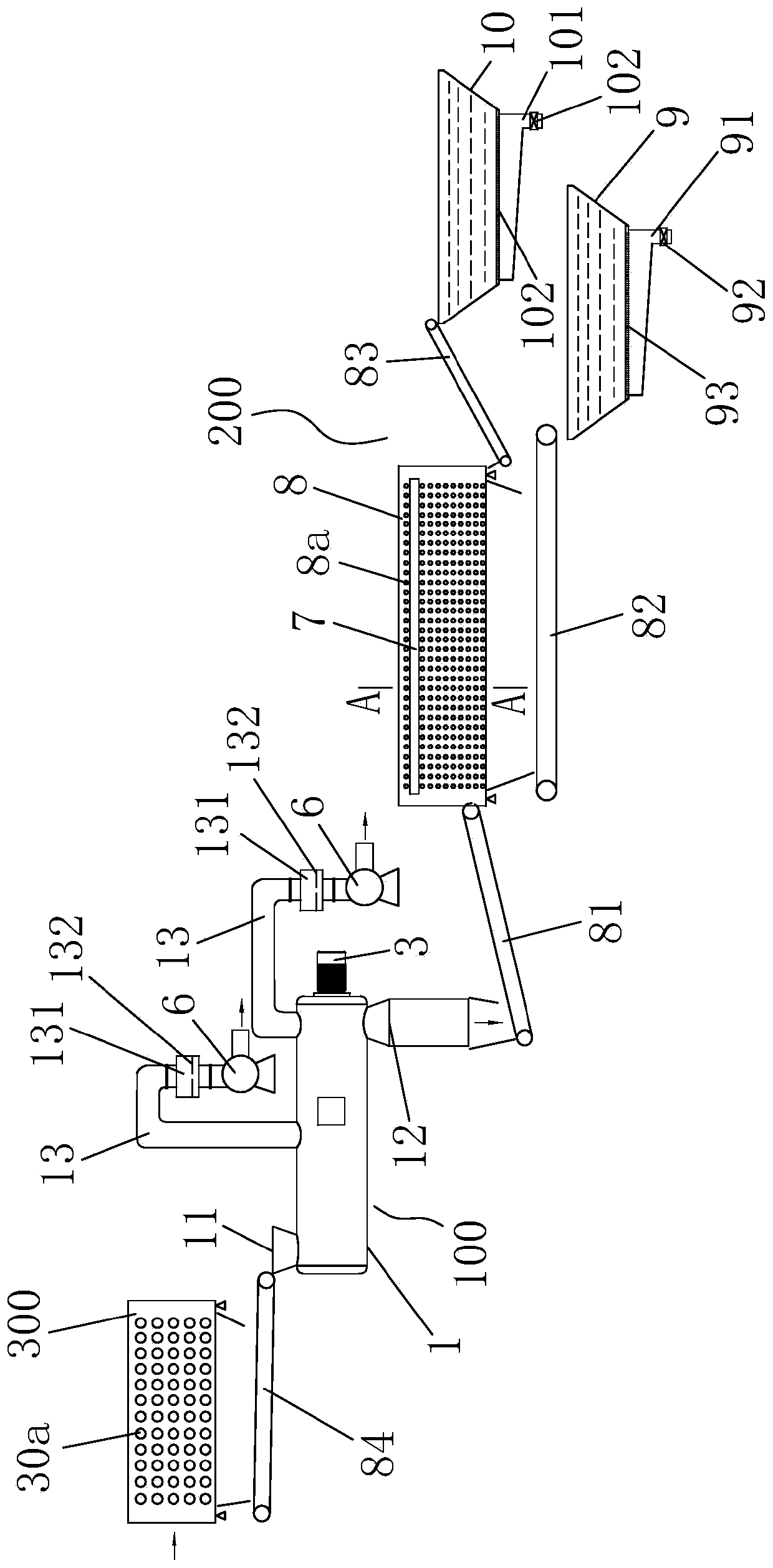

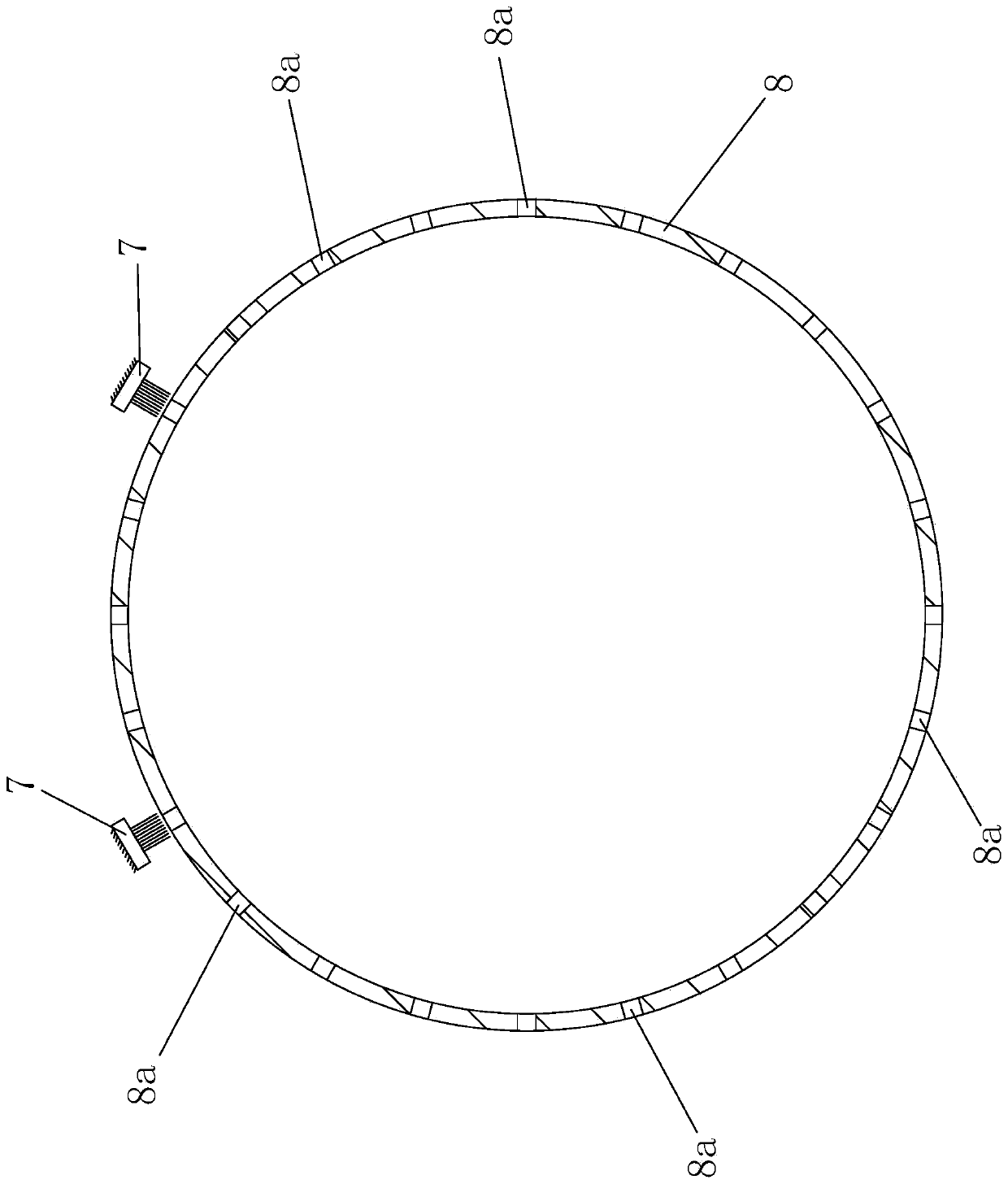

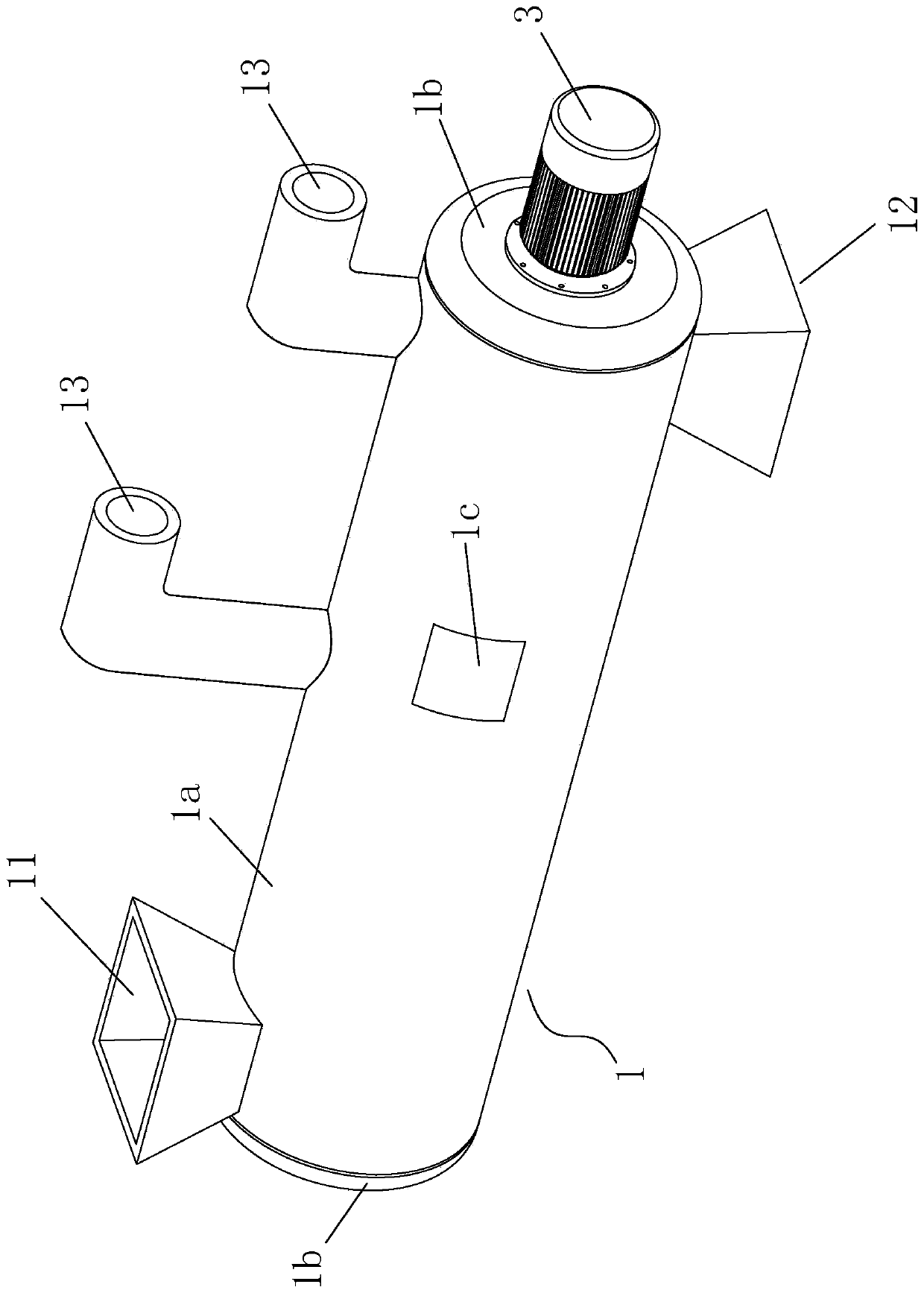

Recycled hollow daily chemical packaging bottle automatic decomposition and material sorting system

PendingCN110549516ASimple regenerationImprove processing efficiencyPlastic recyclingDecompositionEngineering

The invention discloses a recycled hollow daily chemical packaging bottle automatic decomposition and material sorting system. The recycled hollow daily chemical packaging bottle automatic decomposition and material sorting system comprises a decomposition label stripping machine and a material sorting device, wherein the decomposition label stripping machine comprises a cylindrical tank body horizontally arranged, a rotating shaft is installed between the two ends of the cylindrical tank body, the upper side of the front end of the cylindrical tank body is provided with a material inlet, theside face or the lower side of the rear end of the cylindrical tank body is provided with a material outlet, the middle rear portion of the upper side of the cylindrical tank body is provided with atleast one negative pressure air pipe, the rotating shaft is provided with a plurality of moving cutters, each moving cutter is arranged to be inclined to the axis of the rotating shaft, the inner surface of the cylindrical tank body is provided with a plurality of fixed cutters, and the moving cutters flap materials and drive the materials to squeeze through gaps between the moving cutters and thefixed cutters to move towards the material outlet direction when rotating along with the rotating shaft; and the material sorting device comprises a drum screen, a first conveyer, a first flotation pool, a second flotation pool, a second conveyer and a third conveyer. By means of the recycled hollow daily chemical packaging bottle automatic decomposition and material sorting system, hollow dailychemical packaging bottles can be decomposed automatically and material sorting is performed, and realization of industrial recycling treatment is facilitated.

Owner:漳州市陆海环保产业开发有限公司 +1

ru-pt-ni Catalyst for Synthesis of Vinyl Chloride by Hydrochlorination of Acetylene

ActiveCN103623836BHigh strengthSolution to short lifePreparation by halogen halide additionChemical recyclingPlatinum saltsNickel salt

The invention discloses a Ru-Pt-Ni catalyst used for synthesizing vinyl chloride by hydrochlorinating acetylene. The Ru-Pt-Ni catalyst comprises an inert porous carrier, a ruthenium salt, a nickel salt and a platinum salt, wherein the ruthenium salt, the nickel salt and the platinum salt are carried on the inert porous carrier, the weight of the Ru is 0.01%-5% of the weight of the Ru-Pt-Ni catalyst, and the mole ratio of the Ru, the Pt and the Ni is 1:0.1-10:0.1-10. The Ru-Pt-Ni catalyst is advantageous in that: by using the Ru-Pt-Ni catalyst for synthesizing the vinyl chloride by hydrochlorinating acetylene, the reaction temperature can be decreased to be lower than 180 DEG C, the selectivity of a reaction product is good, byproducts are little, the reaction activity is high, the conversion rate of acetylene exceeds 99% and the selectivity of the vinyl chloride reaches 99.9%; the catalyst is high in strength and long in service lifetime; and regeneration of the catalyst after an reaction is simple. A preparation method is simple in technology and is easy to operate.

Owner:TIANJIN UNIV

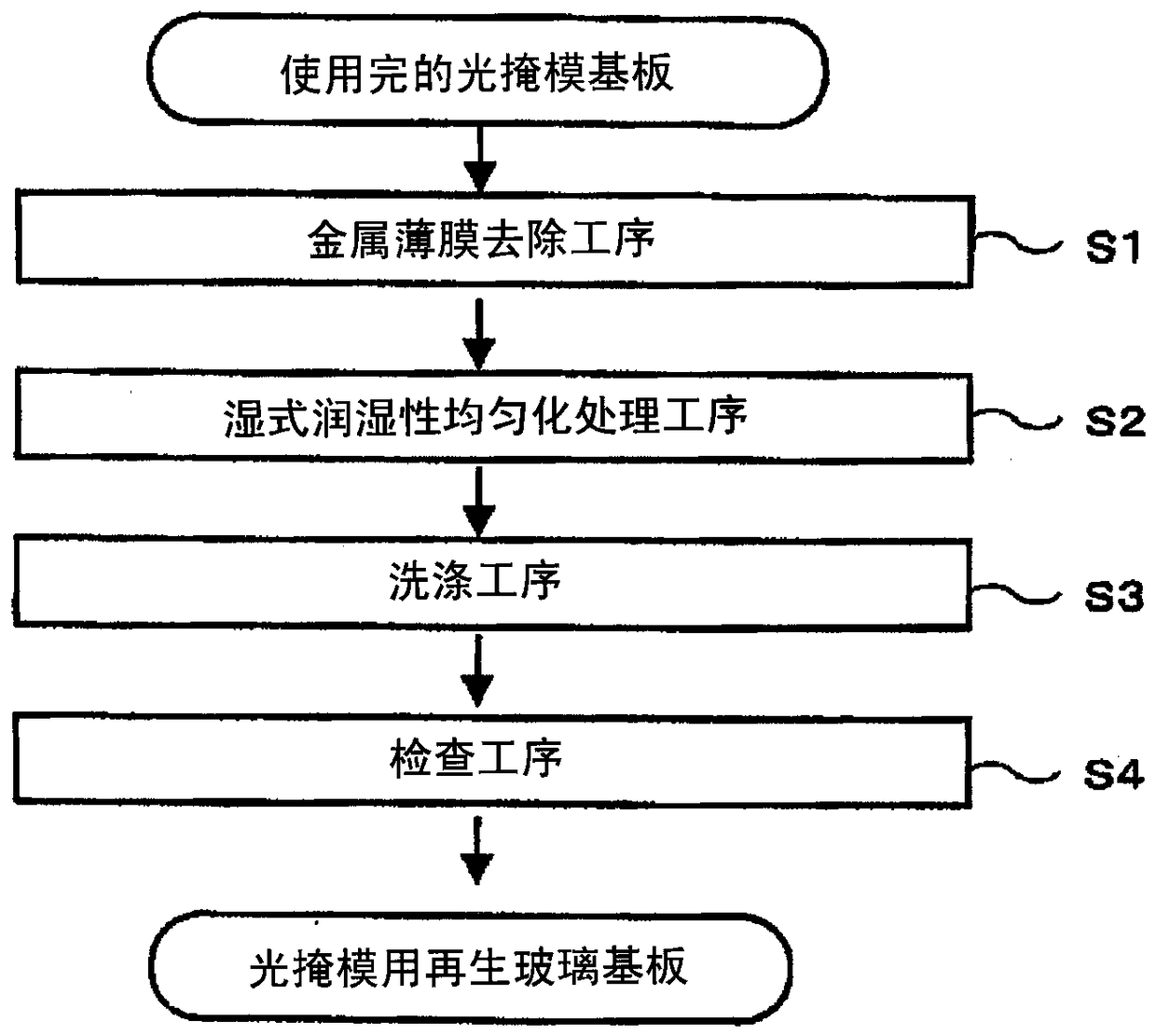

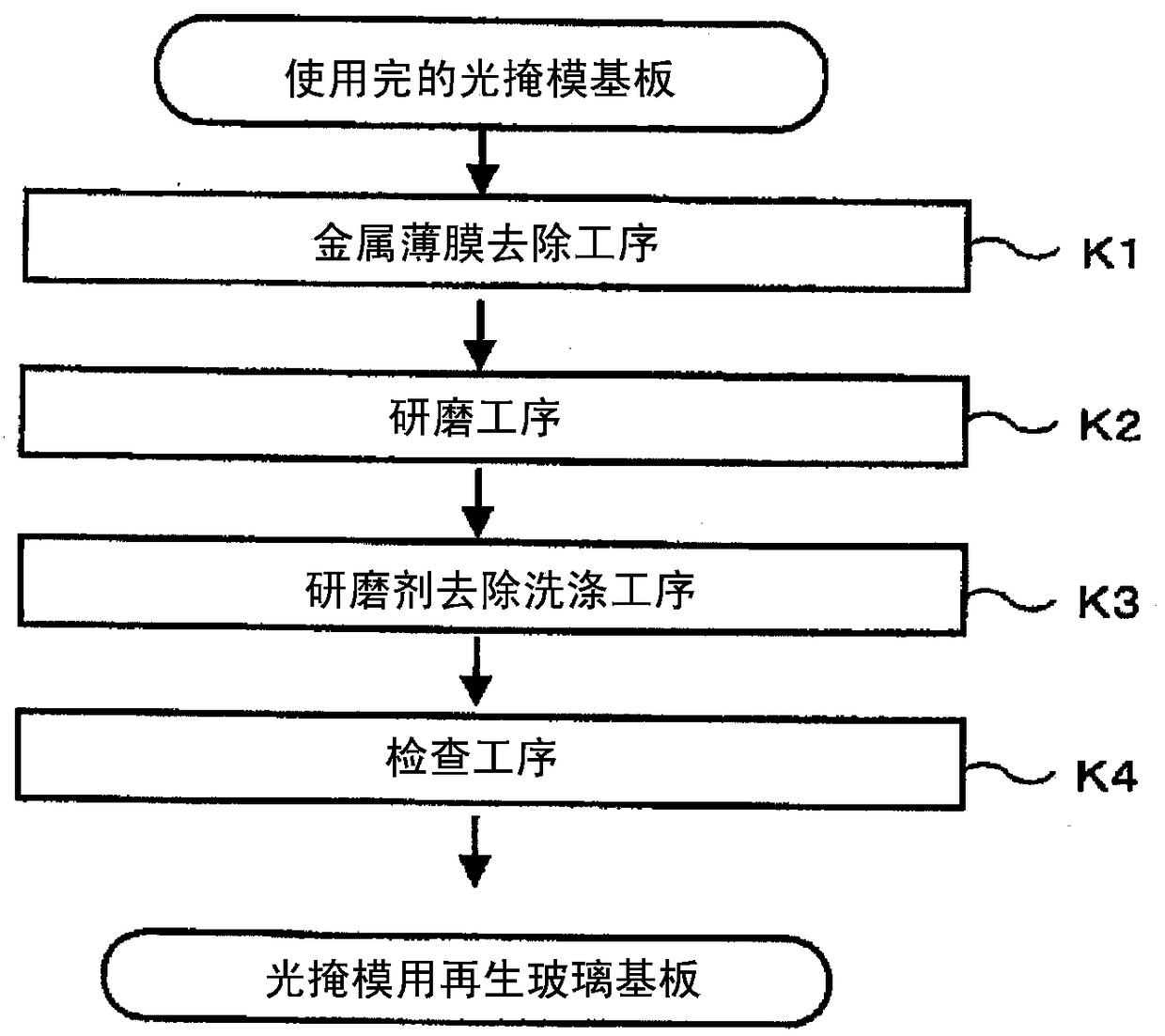

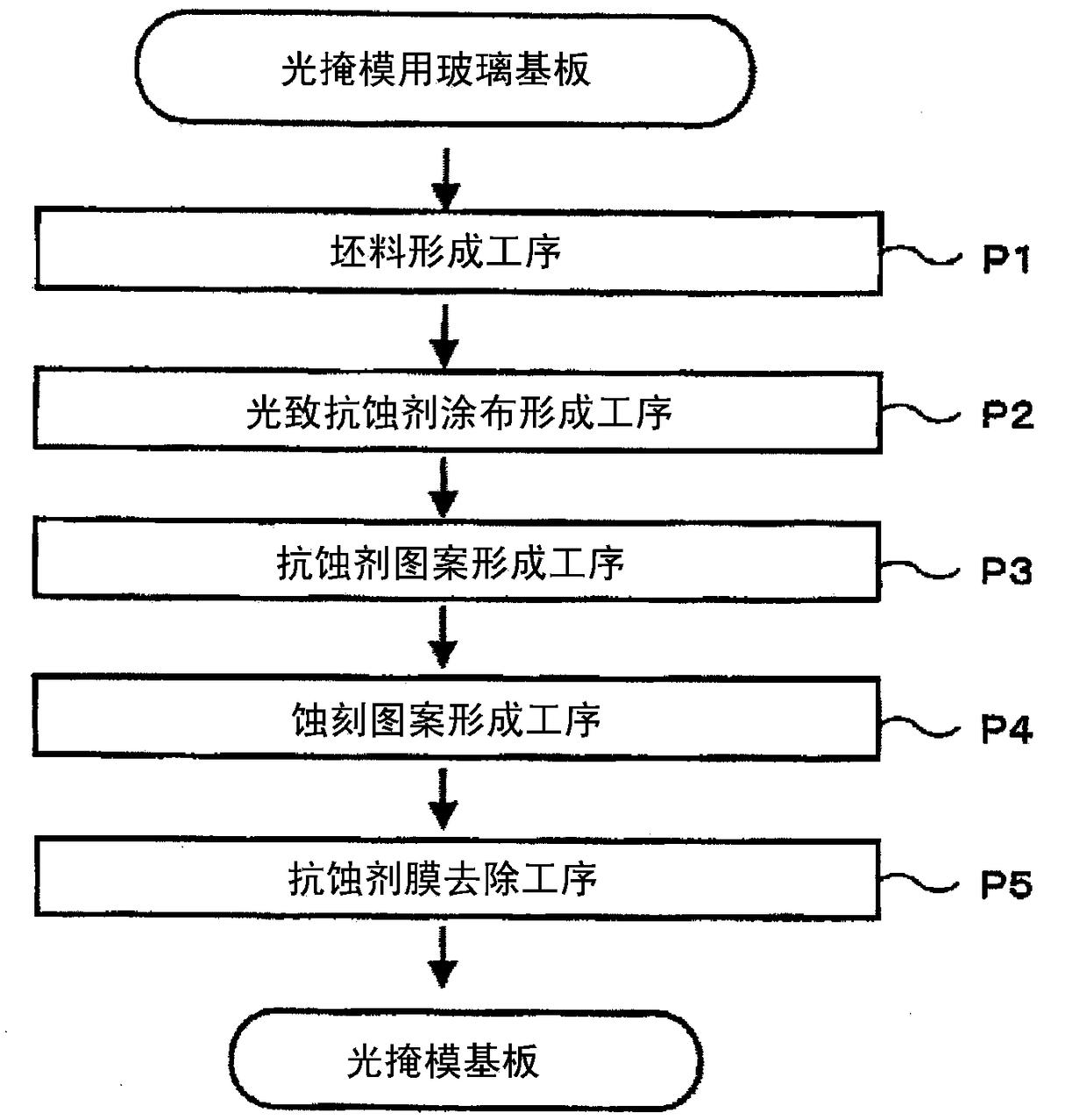

Glass reprocessing method, remade glass substrate, and photo mask blank and photo mask employing same

ActiveCN109298594ASimple regenerationReduce recycling costsSolid waste disposalOriginals for photomechanical treatmentOptoelectronicsPhotomask

The present invention relates to a reprocessing method for remaking as a new photo mask glass substrate either a photo mask which is used up in each type of flat panel manufacturing or a photo mask which is rendered defective in a photo mask fabrication process, as well as a photo mask glass substrate which is remade in this reprocessing method, and a blank mask and photo mask used therein. The method allows obtaining a remade glass substrate with few defects and at low cost, by a process which makes wettability uniform such that traces of an original pattern do not appear in breath figure inspection, without carrying out a conventional physical polishing process upon the surface of the remade glass substrate.

Owner:DAI NIPPON PRINTING CO LTD

A method for isolating high-purity hyperin from lotus leaves

InactiveCN106749456BImprove adsorption capacityExtended service lifeSugar derivativesChemical industryBiotechnologyOrganic chemistry

The invention discloses a method of separating high-purity hyperin from a lotus leaf, and relates to a method of separating high-purity hyperin from a natural plant particularly the lotus leaf and synchronously preparing lotus leaf general flavones, in particular to a method that normal-temperature weak-base water solution ultrasonic-assisted continuous dynamic countercurrent extracting is adopted to replace conventional alcohol-water hot solvent extracting and used for extracting in combination with ultrafiltration impurity removal, nanofiltration solvent recovery and the multiple-unit macroreticular resin separation technology, and high-purity hyperin and other lotus leaf general flavones are collected through sequential elution. The method of separating high-purity hyperin from the lotus leaf is definite in functional factor, suitable for industrial production, low in cost, capable of separating high-purity hyperin from the lotus leaf in an environment-friendly and energy-saving mode and suitable for industrial development and utilization of lotus leaf flavones resources, and the extracted hyperin is high in purity.

Owner:YANGZHOU BAOLIAN BIOLOGICAL SCI & TECH CO LTD +1

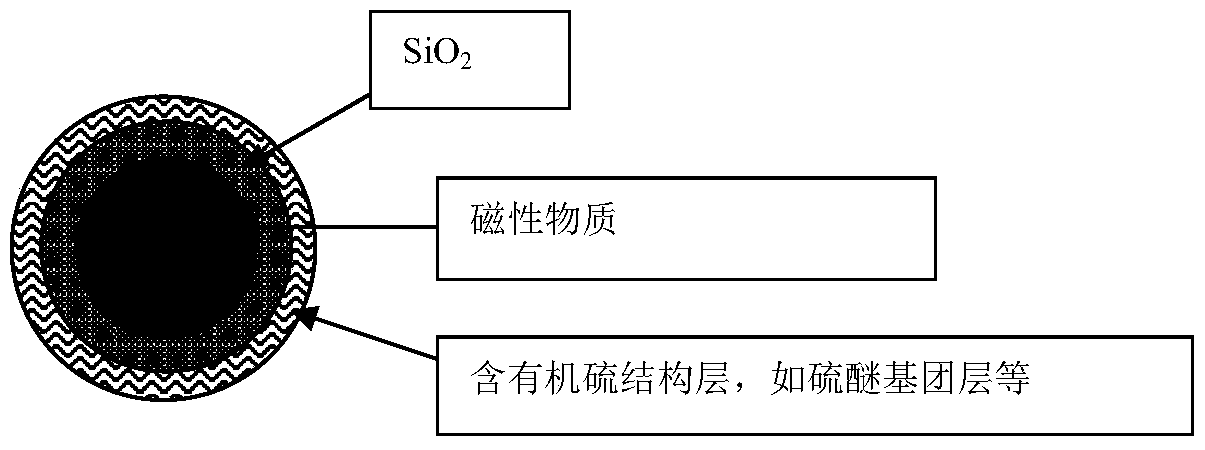

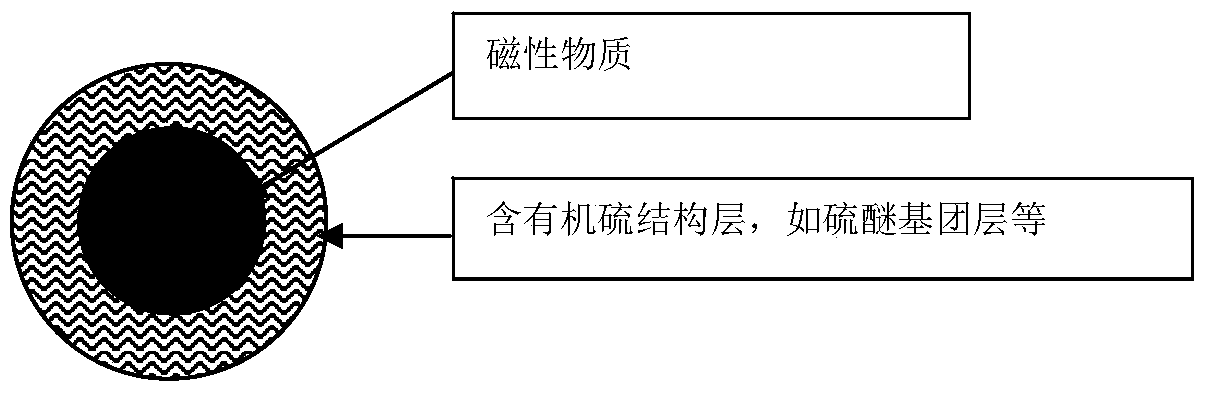

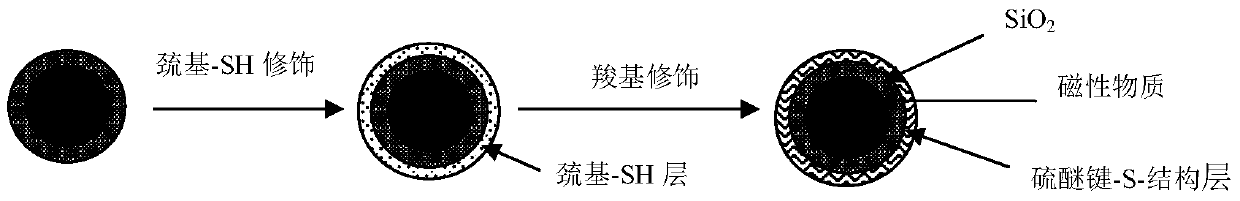

Magnetic solid organic sulfur adsorbent particle material containing organic sulfur adsorption group and preparation method thereof

InactiveCN105983391BEasy to recycleLow costOther chemical processesAlkali metal oxides/hydroxidesSorbentSulfur

Disclosed is a granular material of a magnetic solid-organosulfur adsorbent containing an organosulfur adsorption group, wherein the organosulfur adsorption group is a sulfhydryl group, thioether group or thiocarbonylthio group, and the like.

Owner:CUG WUHAN GOLDEN SHIELD ENVIRONMENTAL TECH CO LTD

A kind of manufacturing method of magnetic polymer material slide glass and cover glass

InactiveCN103777340BHigh mechanical strengthGood chemical stabilityMicroscopesPolymer sciencePlastic materials

The invention relates to a specimen making material, in particular to a magnetic high polymer material glass slide and cover glass and a manufacturing method thereof. The glass slide and cover glass are made of a magnetic high polymer transparent plastic material, and a compound type magnetic high polymer material is adopted in the magnetic high polymer transparent plastic material. The manufacturing method of the magnetic high polymer material glass slide and cover glass comprises the steps that (1) in the production process of the magnetic high polymer transparent plastic material, trace amounts of magnetic materials are evenly mixed, so that the compound type magnetic high polymer plastic material is manufactured; (2) the compound type magnetic high polymer plastic raw material is manufactured to be a glass slide base material with the thickness being 0.8-1.2 mm and a cover glass base material with the thickness being 0.1-0.2 mm through a rolling forming technology; (3) a semi-finished glass slide and cover glass are made to form a permanent magnetism high polymer material glass slide and cover glass by the way that magnetic material micro powder is in ordered arrangement in the easy magnetization direction under the action of an external magnetic field.

Owner:XINXIANG MEDICAL UNIV

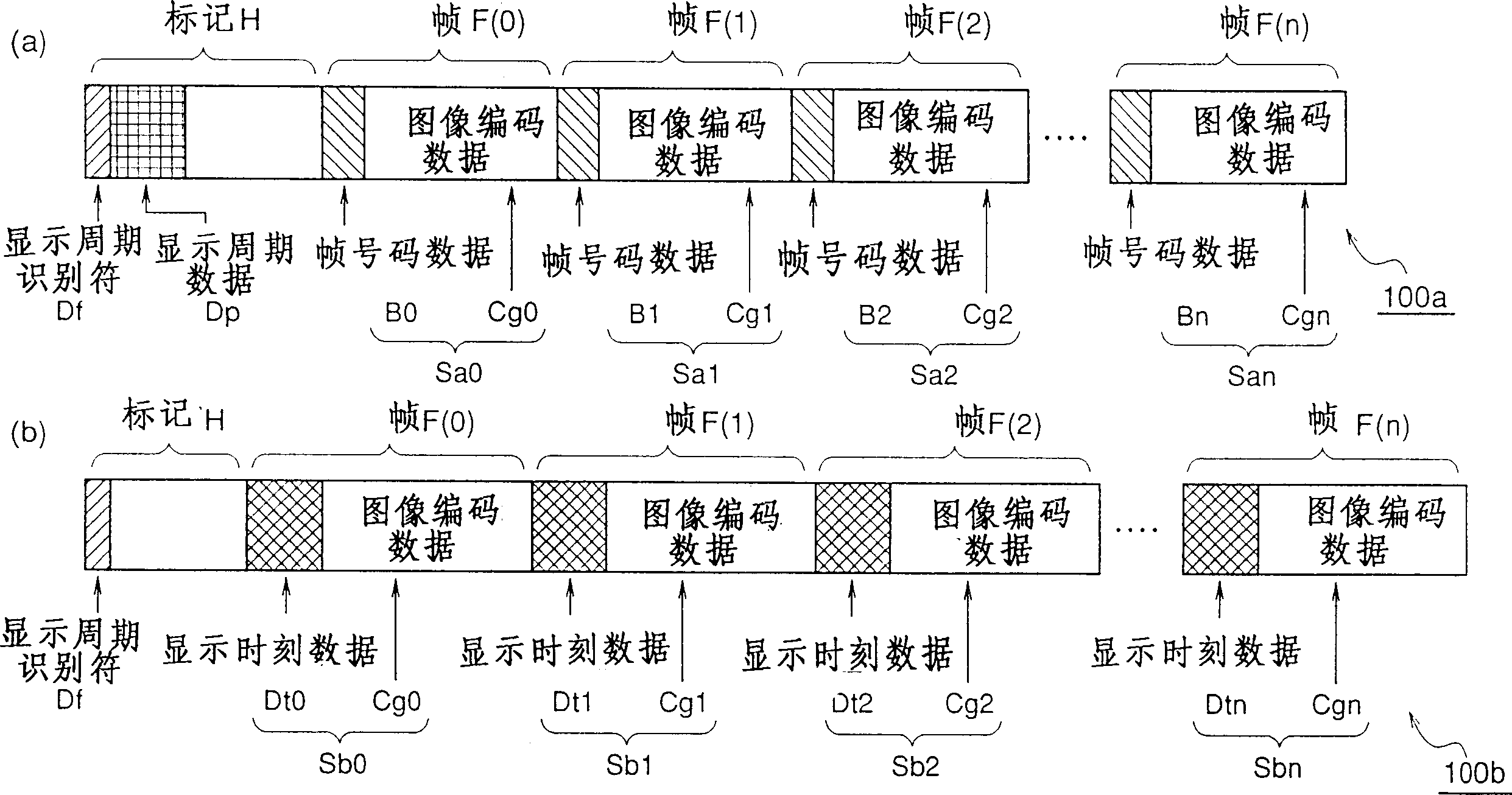

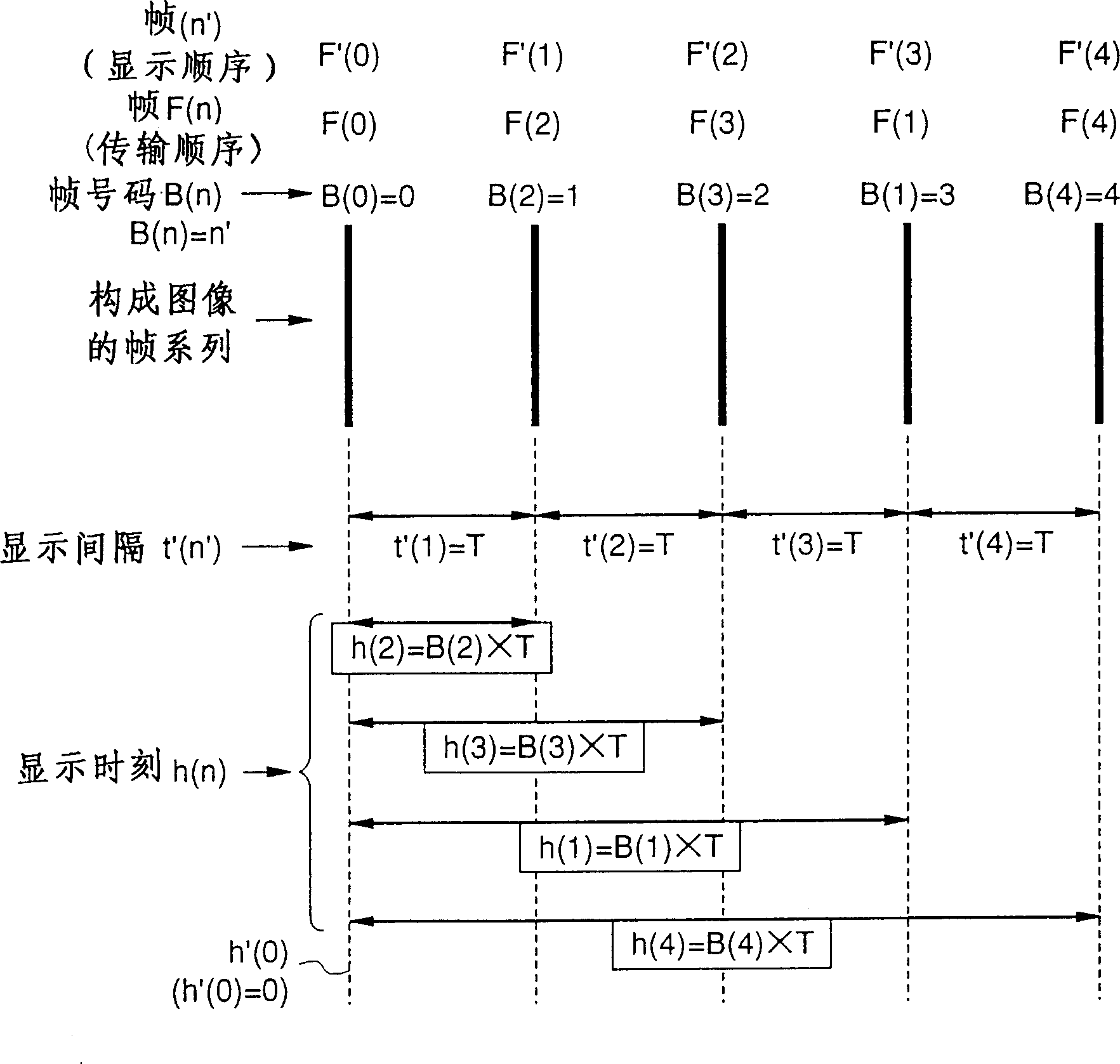

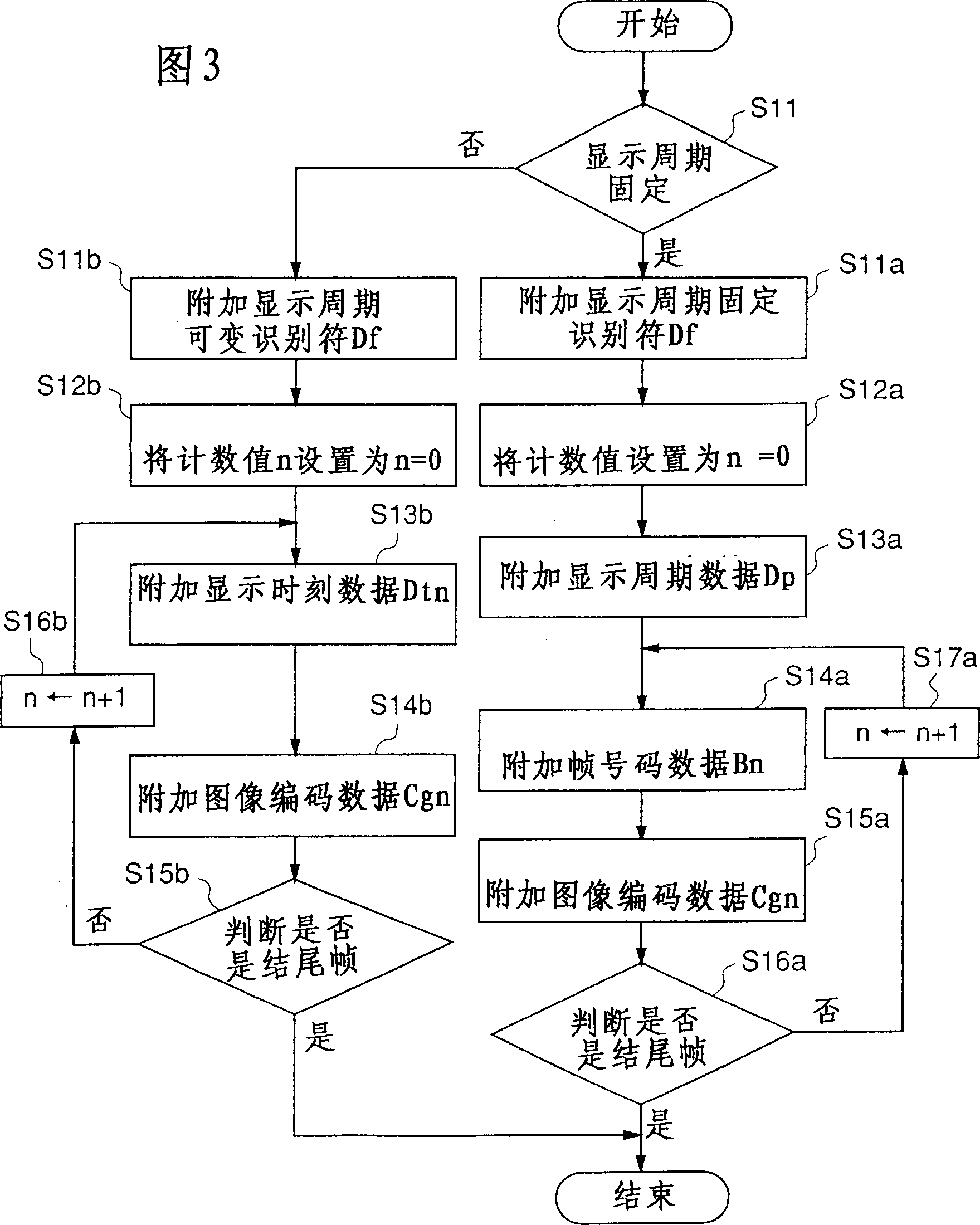

Image coding method and image coding device

InactiveCN1163078CSimple compositionReduce digitsTelevision system detailsPulse modulation television signal transmissionDecoding methodsComputer graphics (images)

The present invention relates to a data structure of an image signal, image encoding and decoding method. The data structure of the invention is capable of reducing the bit number required by the defined display time when the frame has a fixed display cycle, comparing with the foregone image data structure. Furthermore, this data structure can be applied to a coded image signal having a variable display cycle. A data structure of an image signal includes a reproduction cycle identifier indicating whether the cycle of image display for each frame is variable or not. When the display cycle identifier indicates that the display cycle is fixed, display cycle data is inserted in a labeled part of the image data, and data relating to the frame number is inserted in each frame. On the other hand, when the display cycle identifier indicates that the display cycle is variable, display time data is inserted for each frame.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

A kind of impregnated ceramic particles

The invention discloses impregnated ceramic granules. The impregnated ceramic granules contain the raw materials in parts by weight: 40-60 parts of diatomite, 20-30 parts of purple sand, 15-30 parts of wheat starch and 1.7-3.5 parts of AlC13 and FeCl3 mixed solution. According to the impregnated ceramic granules, common cheap raw materials are adopted and are modified by adding iron ions, so that the sintering temperature is lowered, the economic cost is low, and the cost performance is high; aluminum ions are not used any more, so that the safety in use is improved; obtained adsorption ceramics are high in adsorption efficiency, and the regeneration treatment is simple after the adsorption ceramics are applied to pollutant adsorption.

Owner:浙江创魏新材股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com