Chitosan quaternary ammonium salt and phytic acid porous composite membrane and method for removing metal impurities

A technology of chitosan quaternary ammonium salt and porous composite membrane, which is applied in the direction of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problems of undiscovered modified chitosan, etc., and achieve The regeneration process is simple and the operation is simple and convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] S101. Dissolve 2g of chitosan quaternary ammonium salt in deionized water, add 0.5g of glycerin, and stir evenly to obtain a solution with a concentration of 2g / 100ml chitosan quaternary ammonium salt; dissolve 0.6g of phytic acid powder in deionized In water, obtain the phytic acid aqueous solution that concentration is 0.05g / ml;

[0046] S102. Slowly add the phytic acid aqueous solution dropwise into the chitosan quaternary ammonium salt solution under stirring to obtain a chitosan quaternary ammonium salt phytic acid mixture;

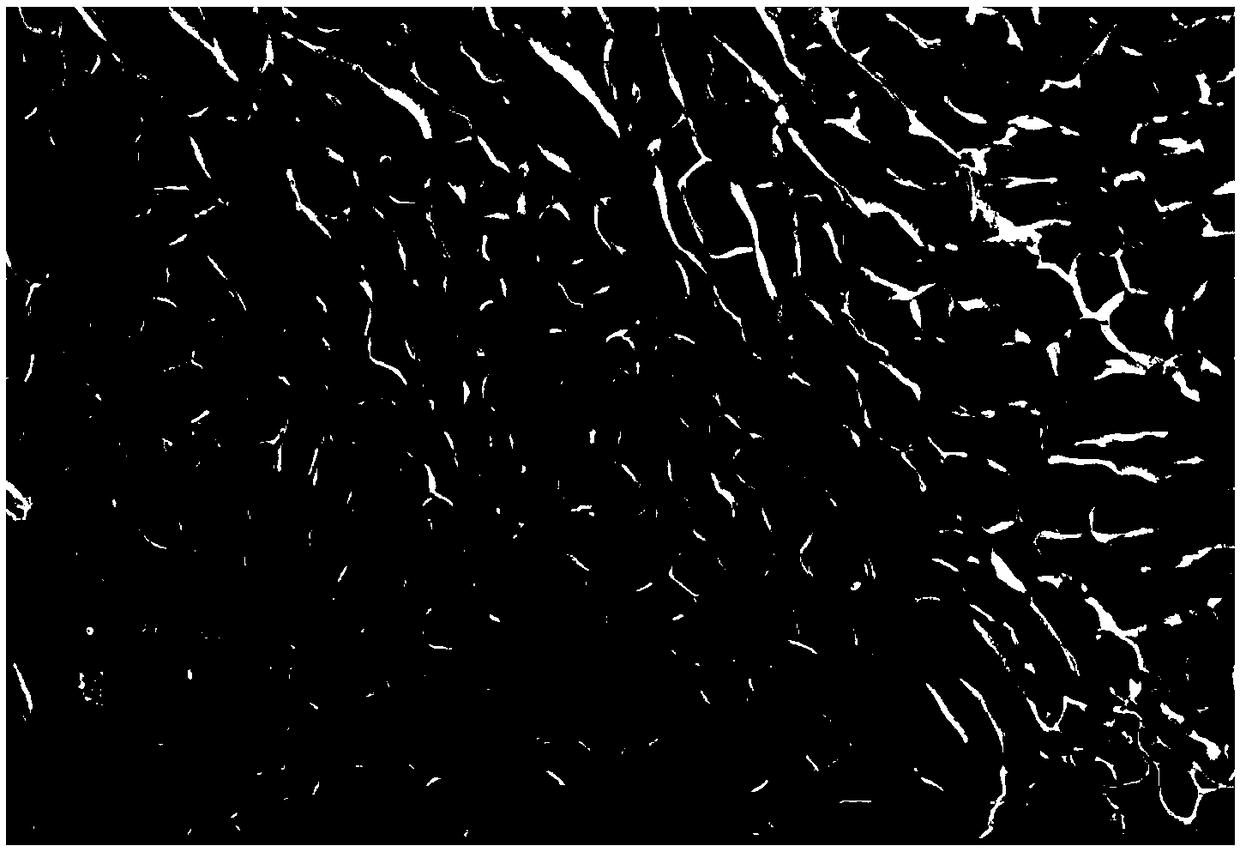

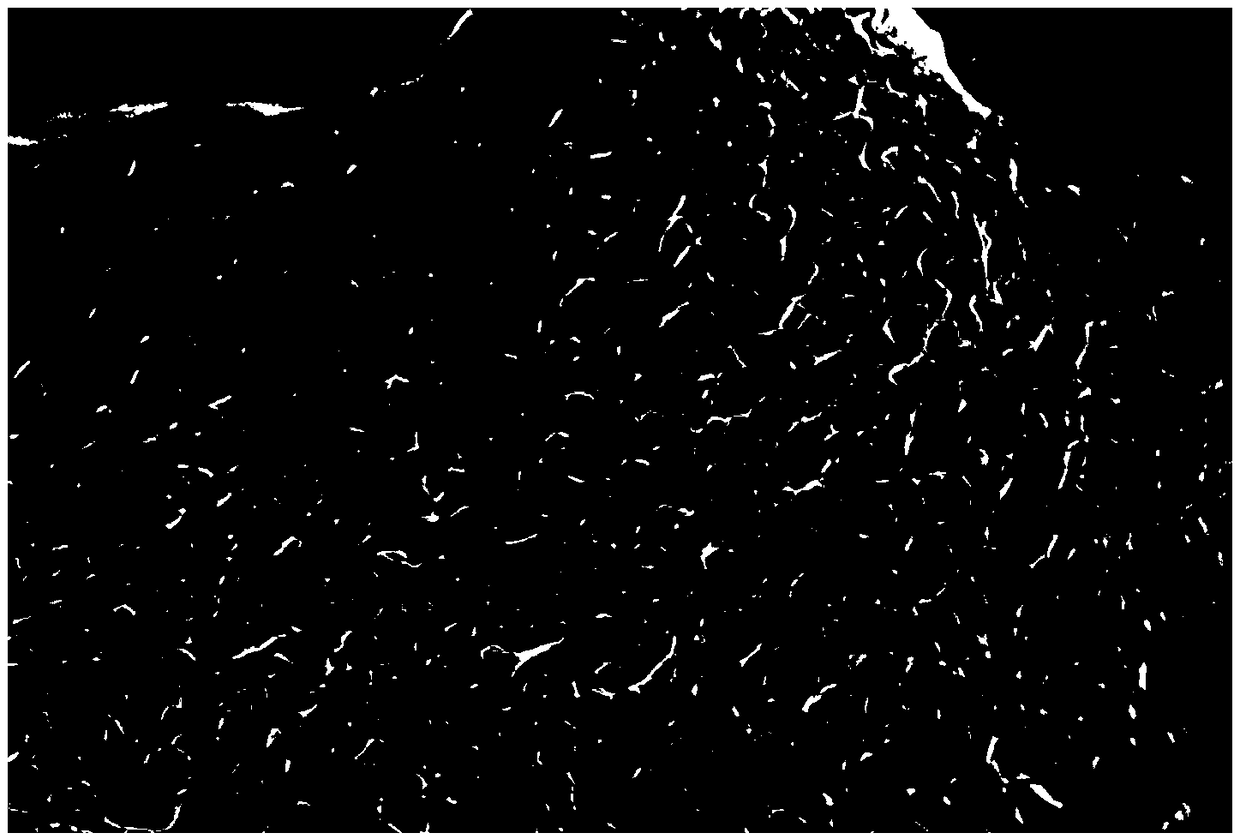

[0047] S103. placing the chitosan quaternary ammonium salt phytic acid mixture in a refrigerator, freezing overnight under 0°C, and then freeze-drying to obtain a porous composite membrane;

[0048] S104. Finally, the freeze-dried porous composite membrane is placed at a temperature of 20° C. and a relative humidity of 95% in a constant temperature and humidity chamber for 24 hours to balance the moisture content of the obtained chitosan quate...

Embodiment 2

[0052] S201. Dissolve 2g of chitosan quaternary ammonium salt in deionized water, add 0.3g of propylene glycol and 0.3g of butanediol, stir well, and obtain a concentration of 1.5g / 100ml chitosan quaternary ammonium salt solution; Phytic acid powder was dissolved in deionized water to obtain a phytic acid aqueous solution with a concentration of 0.3g / ml;

[0053] S202. Slowly add the phytic acid aqueous solution dropwise into the chitosan quaternary ammonium salt solution under stirring state to obtain the chitosan quaternary ammonium salt phytic acid mixture;

[0054] S203. placing the chitosan quaternary ammonium salt phytic acid mixture in a refrigerator, freezing overnight under 0°C, and then freeze-drying to obtain a porous composite membrane;

[0055] S204. Finally, placing the freeze-dried porous composite membrane at a temperature of 25° C. and a relative humidity of 85% in a constant temperature and humidity chamber for 18 hours to balance the moisture content of the ...

Embodiment 3

[0059] S301. Dissolve 2g of chitosan quaternary ammonium salt in deionized water, add 0.1g of glycerin, 0.25g of propylene glycol and 0.2g of butanediol, stir well to obtain a concentration of 3g / 100ml chitosan quaternary ammonium salt solution ; Dissolving 1 g of phytic acid powder in deionized water to obtain a phytic acid aqueous solution with a concentration of 0.1 g / ml;

[0060] S302. Slowly add the phytic acid aqueous solution into the chitosan quaternary ammonium salt solution dropwise under stirring state to obtain the chitosan quaternary ammonium salt phytic acid mixture;

[0061] S303. placing the chitosan quaternary ammonium salt phytic acid mixture in a refrigerator, freezing overnight under 0°C, and then freeze-drying to obtain a porous composite membrane;

[0062] S304. Finally, placing the freeze-dried porous composite membrane at a temperature of 40° C. and a relative humidity of 80% in a constant temperature and humidity chamber for 12 hours to balance the moi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com