Purification method of phloretin powder

A purification method and technology of phloretin are applied in the directions of skin care preparations, separation/purification of carbonyl compounds, cosmetics, etc., and can solve the problems of high cost, difficulty in industrialized large-scale production, etc., and achieve low production cost, easy industrialized production, The effect of reducing the extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

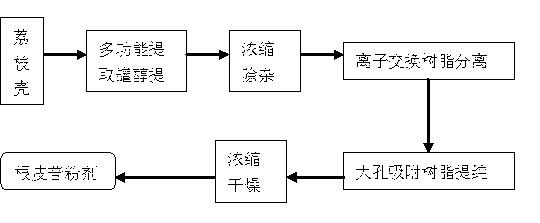

Image

Examples

Embodiment 1

[0023] Take 10 kg of lychee shells, put them in a multi-functional extraction tank, add 100 liters of ethanol solution with a mass concentration of 30%, heat to 100°C, stir and extract for 0.5 hours, and filter to obtain 82 liters of crude extract. The crude extract was concentrated to 8.2 liters by a rotary evaporator, left to cool for 12 hours, and then centrifuged to remove the lower precipitate to obtain 7 liters of a concentrated solution. The concentrated solution was passed through a JK206 homogeneous strong basic anion exchange resin column, and eluted with HCl with a molar mass of 0.1M / L. The collected eluate passed through the HZ-816 macroporous non-polar adsorption resin column and was eluted with 20% ethanol. A total of 21 liters of the eluate was collected, concentrated by a rotary evaporator, and then dried by centrifugal spraying to produce 40 grams of phloretin powder. The content of phloretin was 80.5% as detected by HPLC.

Embodiment 2

[0025] Take 10 kg of lychee shells, put them in a multi-functional extraction tank, add 80 liters of ethanol solution with a mass concentration of 95%, heat to 40°C, stir and extract for 4 hours, and obtain 74 liters of crude extract after filtration. The crude extract was concentrated to 15.8 liters by a rotary evaporator, left to cool for 12 hours, and then centrifuged to remove the lower precipitate to obtain 12 liters of a concentrated solution. The concentrated solution was passed through a JK206 homogeneously porous strongly basic anion exchange resin column, and eluted with HCl with a molar mass of 0.5M / L. The collected eluate passed through the HZ-816 macroporous non-polar adsorption resin column and was eluted with 60% ethanol. A total of 23 liters of the eluate was collected, concentrated by a rotary evaporator, and then dried by centrifugal spraying to prepare 60 grams of phloretin powder.

Embodiment 3

[0027] Accurately weigh about 20 mg of the extract powder in Example 2, put it in a 50 ml brown volumetric flask, add methanol, dissolve it by ultrasonic, let cool to room temperature, dilute to volume, and shake well. Accurately draw 2ml, put it in a 10ml brown volumetric flask, dilute with methanol to constant volume, pass through a 0.45um filter membrane, and inject 5ul. Detection conditions: mobile phase: acetonitrile: 0.1% phosphoric acid water = 30:70 (V:V); detection wavelength: 280nm; flow rate: 1.0ml / min; chromatographic column: C18, 250×4.6mm, 5ul. The content of phloretin was detected by HPLC to be 95.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com