Ru-ni-cu Catalyst for the Synthesis of Vinyl Chloride by Hydrochlorination of Acetylene

A technology of acetylene hydrochlorination and ru-ni-cu, which is applied in the field of mercury-free catalysts and preparations, can solve the problems of inability to realize industrialization, poor activity, and short catalyst life, and achieve good selectivity of reaction products, long life, and side effects The effect of less product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

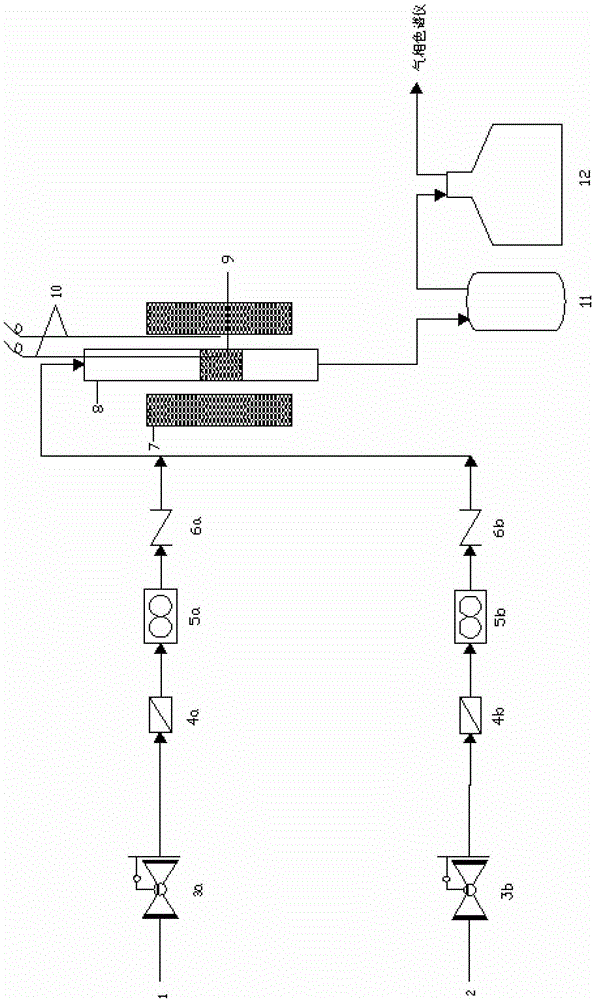

Method used

Image

Examples

Embodiment 1

[0017] A Ru-Ni-Cu catalyst for the synthesis of vinyl chloride by hydrochlorination of acetylene, comprising pitch-based spherical activated carbon and ruthenium nitrate III, copper nitrate II and nickel dichloride carried on the pitch-based spherical activated carbon, the quality of Ru Accounting for 0.3% of the mass of the Ru-Ni-Cu catalyst for the synthesis of vinyl chloride by hydrochlorination of acetylene, the molar ratio of Ru, Ni and Cu is 1:3:3.

Embodiment 2

[0019] A Ru-Ni-Cu catalyst for the synthesis of vinyl chloride by hydrochlorination of acetylene, which includes pitch-based spherical activated carbon and ruthenium acetate III supported on the pitch-based spherical activated carbon, copper acetate II and chlorine with a mass ratio of 1:1 The mass of copper chloride II, nickel nitrate, and Ru accounts for 0.1% of the mass of the Ru-Ni-Cu catalyst for the synthesis of vinyl chloride by hydrochlorination of acetylene, and the molar ratio of Ru, Ni and Cu is 1:1:5.

Embodiment 3

[0021] A Ru-Ni-Cu catalyst for the synthesis of vinyl chloride by hydrochlorination of acetylene, comprising powdery activated carbon and ruthenium trichloride, ruthenium sulfate III, and copper sulfate II with a mass ratio of 1:1 carried on the powdery activated carbon and nickel sulfate, the quality of Ru accounts for 0.5% of the mass of the Ru-Ni-Cu catalyst for the synthesis of vinyl chloride by acetylene hydrochlorination, and the molar ratio of Ru, Ni and Cu is 1:5:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com