Treatment device equipped with catalyst-supporting honeycomb structure and process for producing same

A technology of honeycomb structure and processing device, which is applied in the direction of catalyst carrier, catalyst activation/preparation, and device for coating liquid on the surface, etc., which can solve the problems of increased pressure loss, etc., and achieve the effect of shortening the manufacturing process and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

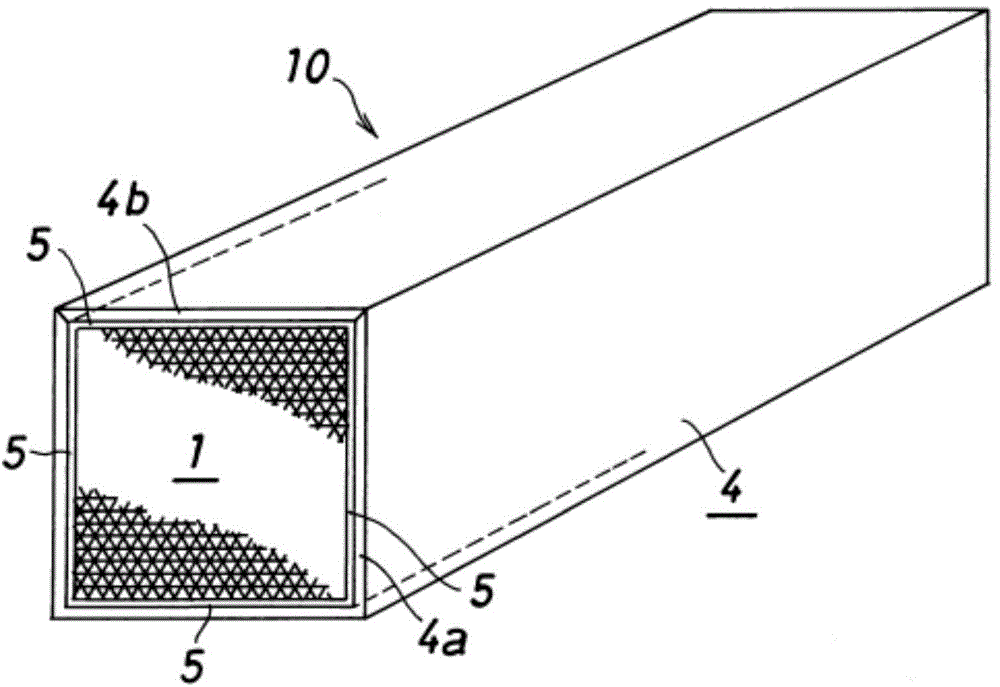

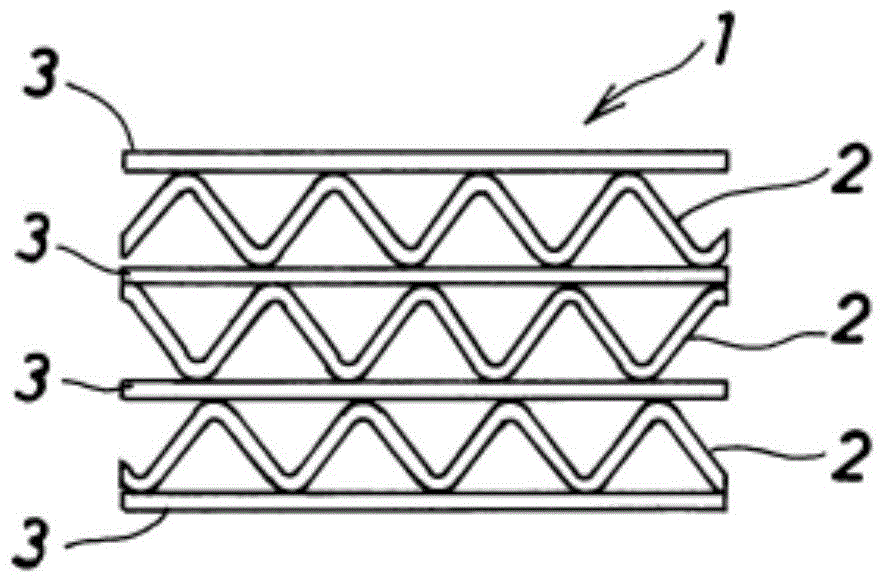

[0117] By the method of the present invention, a denitration catalyst-supporting honeycomb treatment device was produced as follows.

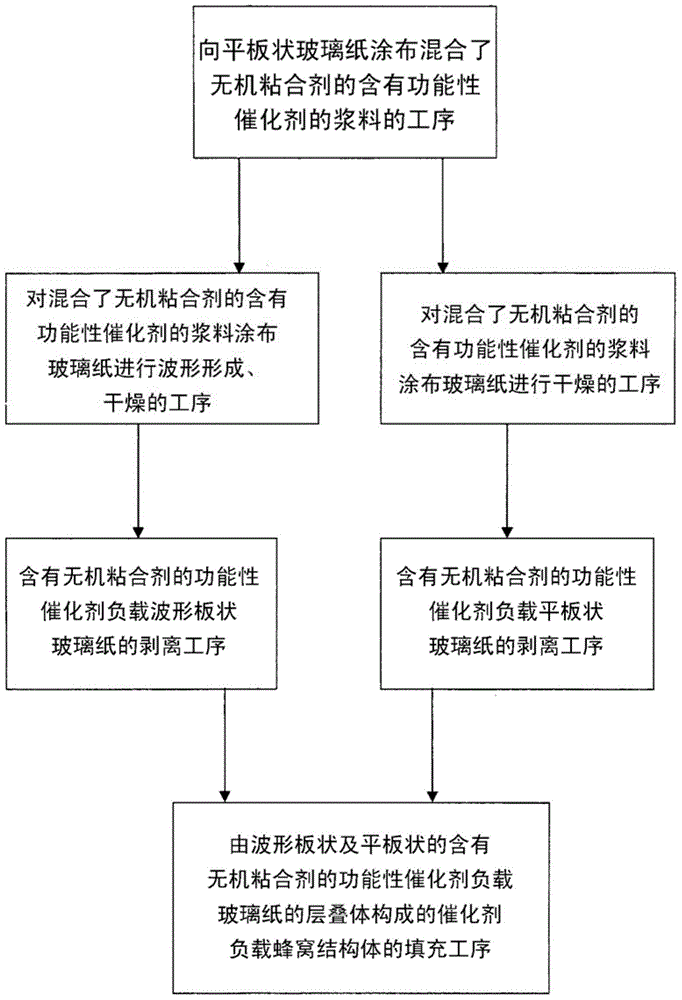

[0118] Implemented in sequence image 3 The manufacturing method of the processing apparatus provided with the catalyst supporting honeycomb structure of this invention is shown.

[0119] First, as a commercially available cellophane, at a fiber content of 100g / m 2 , On a flat cellophane (20×30cm) with a content of 10% by weight of an acrylic resin organic binder, at 1333g / m 2 The coating amount of the functional catalyst-containing slurry mixed with an inorganic binder is coated.

[0120] As the functional catalyst, a denitration catalyst is used. That is, ammonium metavanadate powder is added to the slurry in which titanium dioxide fine particles are suspended in silica sol, and the whole is stirred to adsorb ammonium metavanadate on titanium dioxide. Silica sol was used as an inorganic binder, and the content of silica sol in the denitra...

Embodiment 2

[0130] Similar to the case of the above-mentioned Example 1, the processing device (10) equipped with the denitration catalyst-supported honeycomb structure (1) was manufactured by the method of the present invention, but the difference from the case of the above-mentioned Example 1 is that each mold Heated to a surface temperature of 250°C for use. The processing apparatus (10) provided with the denitration catalyst supporting honeycomb structure (1) of this invention was manufactured similarly to the case of the said Example 1 except the surface temperature of this mold|die.

Embodiment 3

[0132] Similar to the case of the above-mentioned Example 1, the processing device (10) equipped with the denitration catalyst-supported honeycomb structure (1) was manufactured by the method of the present invention, but the difference from the case of the above-mentioned Example 1 is that each mold Heated to a surface temperature of 200°C for use. Except for the surface temperature of the mold, a processing device ( 10 ) including a catalyst-supporting honeycomb structure ( 1 ) of the present invention was produced in the same manner as in Example 1 above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com