Glass reprocessing method, remade glass substrate, and photo mask blank and photo mask employing same

A technology for glass substrates and photomasks, which is applied to the removal of originals, optics, and solid waste for photomechanical processing, and can solve problems such as traces, existing patterns, and easy pattern defects, so as to reduce regeneration costs and regenerate Ease of handling and reduction of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

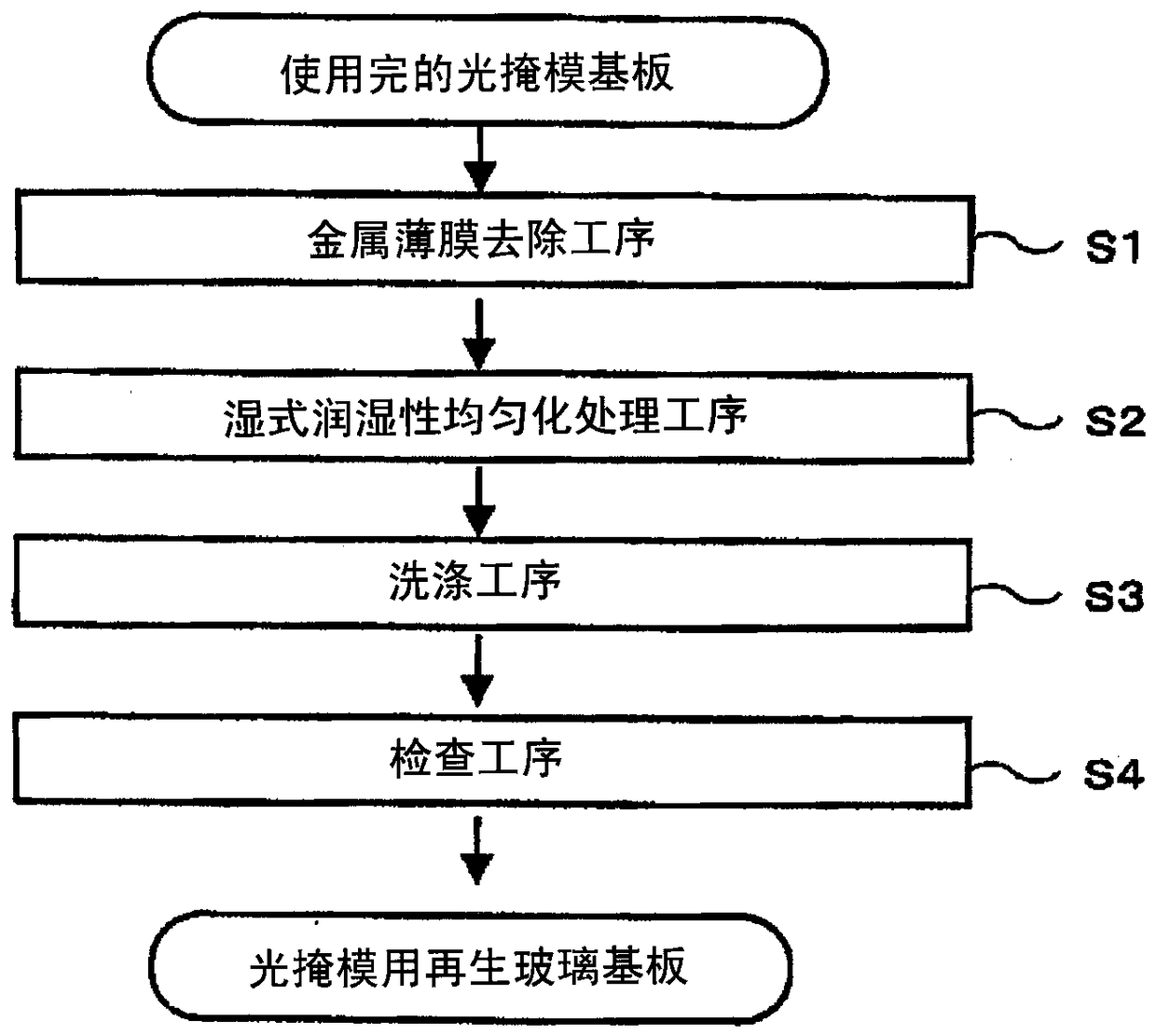

[0226] Hereinafter, in the examples of the present invention, a photomask of synthetic quartz glass with a size of 450 mm×550 mm and a thickness of 5 mm for a liquid crystal panel was used for regeneration treatment.

[0227] The chrome film was completely removed with a chrome etchant about the said used photomask, and it wash|cleaned with pure water was made into the glass blank state. Exhalation image examination was performed in this state, and as a result, traces of the original pattern that were removed were confirmed.

[0228] Next, the regenerated substrate from which the chromium film was removed was immersed in a 5% KOH aqueous solution at a liquid temperature of 25° C. for 4 hours, and washed with pure water. The amount of glass etching was 0.6 μm, and a breath image inspection was performed on the washed substrate. As a result, a glass substrate for a photomask in which the original pattern disappeared and the pattern could not be confirmed by visual inspection was...

Embodiment 2

[0233] The reproduction process of the photomask produced by the same method as Example 1 was performed.

[0234] After the photomask is used, it is regenerated in order to reuse it as a photomask blank.

[0235] The chrome film was completely removed with a chrome etchant for the above used photomask, and washed with pure water to be in a glass blank state. Exhalation image examination was performed in this state, and as a result, traces of the original pattern that were removed were confirmed.

[0236] Next, the regenerated substrate from which the chromium film was removed was immersed in a 10% KOH aqueous solution at a liquid temperature of 25° C. for 4 hours, and washed with pure water. The glass etching amount was 1.5 μm, and a breath image inspection was performed on the washed substrate. As a result, a glass substrate for a photomask in which the original pattern disappeared and the pattern could not be confirmed by visual inspection was obtained.

[0237] Next, a ch...

Embodiment 3

[0240] The reproduction process of the photomask produced by the same method as Example 1 was performed.

[0241] After the photomask is used, it is regenerated in order to reuse it as a photomask blank.

[0242] The chrome film was completely removed with a chrome etchant for the above used photomask, and washed with pure water to be in a glass blank state. Exhalation image examination was performed in this state, and as a result, traces of the original pattern that were removed were confirmed.

[0243] Next, the regenerated substrate from which the chromium film was removed was immersed in solution 3 at a liquid temperature of 25° C. for 4 hours, and washed with pure water. The amount of glass etching was 1 μm or less, and a breath image inspection was performed on the washed substrate, and as a result, a glass substrate for a photomask in which the original pattern disappeared and the pattern could not be confirmed by visual inspection was obtained.

[0244] Next, a chrom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com