Magnetic solid organic sulfur adsorbent particle material containing organic sulfur adsorption group and preparation method thereof

A particle material and magnetic particle technology, which is applied in the field of environmental materials and resources and environment, can solve the problems of low selectivity of heavy metal atoms and precious metal atoms, and achieve the effects of low cost, easy regeneration, and easy recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

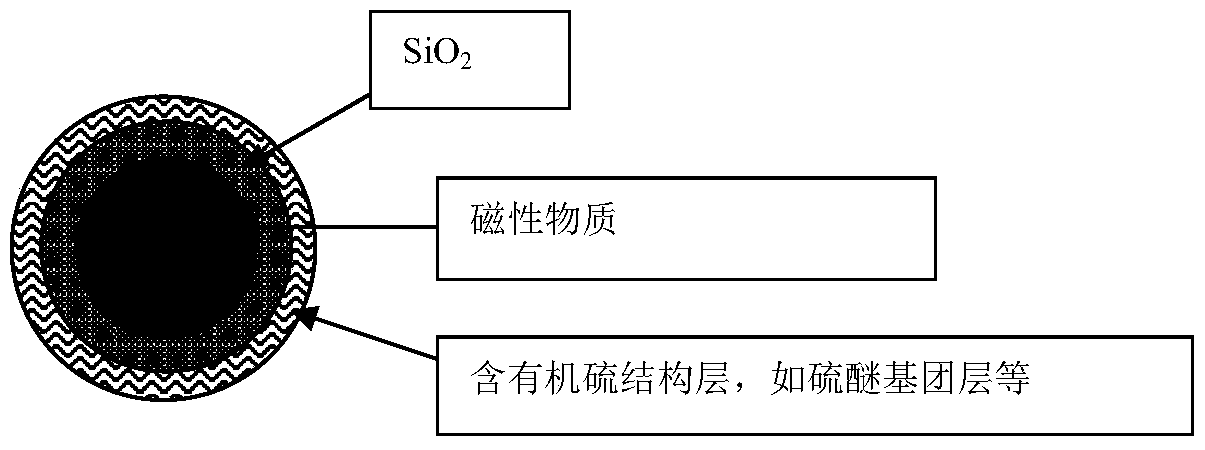

[0032] A magnetic solid organosulfur adsorbent particle material containing organosulfur adsorption groups. When the organosulfur adsorption group is mercapto, it can be divided into core-shell structure magnetic solid organosulfur adsorbent particle materials FS@ R'[-SH], F@R'[-SH] non-core-shell magnetic solid organosulfur adsorbent particle material with thiol on the surface.

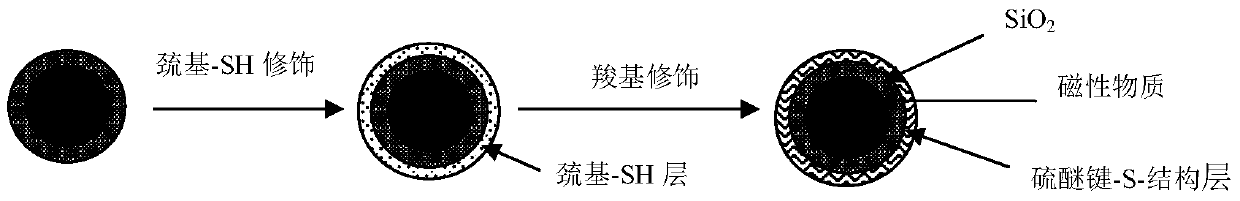

[0033] This example is a core-shell structure magnetic solid organic sulfur adsorbent particle material FS@R’[-SH] with surface mercaptolation, and its preparation method is described as follows:

[0034] Take 100g particle size of 0.10-40.0μm FS powder (magnetic material Fe in FS powder 3 o 4 From natural magnetite, coated with SiO according to the method provided by "Applied Chemical Industry" 2012 41 (12) 2 , to prepare the core-shell structure Fe 3 o 4 @SiO 2 powder) into the reaction bottle, add 500mL of methanol, stir to form a uniform suspension, add 4.0g of silane coupling agent WD-80, s...

Embodiment 2

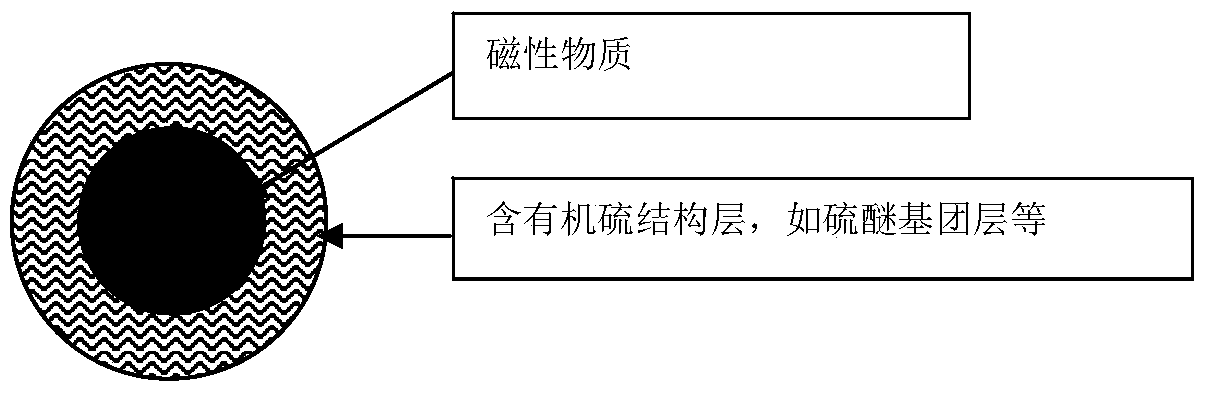

[0037] This example is a non-core-shell structure magnetic solid organosulfur adsorbent particle material F@R’[-SH] with surface mercaptolation, and its preparation method is described as follows:

[0038] Take 100g of magnetic particle material F with a particle size of 0.10-40.0μm in a reaction flask, add 500mL of methanol, stir to form a uniform suspension, add 4.0g of silane coupling agent WD-80, and stir at 70°C for 1.0h; the reaction is complete Finally, the powder was separated with a magnet, washed with methanol, and dried at 70°C for 12 hours to obtain the non-core-shell magnetic particle material F@-(CH 2 ) 3 -SH.

Embodiment 3

[0040] A magnetic solid organic sulfur adsorbent particle material containing organic sulfur adsorption groups, when the organic sulfur adsorption group is a sulfide group, it can be divided into core-shell magnetic solid organic sulfur adsorbent particle materials and non-core-shell Structural Magnetic Solid Organosulfur Adsorbent Granular Materials.

[0041] This example is a core-shell magnetic solid organic sulfur adsorbent particle material FS@R’[-S-R-COONa] grafted with thioether groups on the surface, and its preparation method is described as follows:

[0042] Take by weighing sodium chloroacetate 100.0g, dissolve with 1000ml distilled water, obtain 10% sodium chloroacetate solution; Get the FS@-(CH in 100g embodiment 1 2 ) 3 -SH particles, add 500mL of distilled water, stir the suspension, then add 10ml of the prepared 10% sodium chloroacetate solution above, install a reflux condenser, stir and react in a water bath at 50°C for 6h; after the reaction is complete, se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com