Copper-based catalyst for preparing ethanol by acetate hydrogenation and preparation method

A copper-based catalyst, acetate hydrogenation technology, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problems of low selectivity, poor stability, low activity, etc., and achieve high reaction activity, The effect of low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

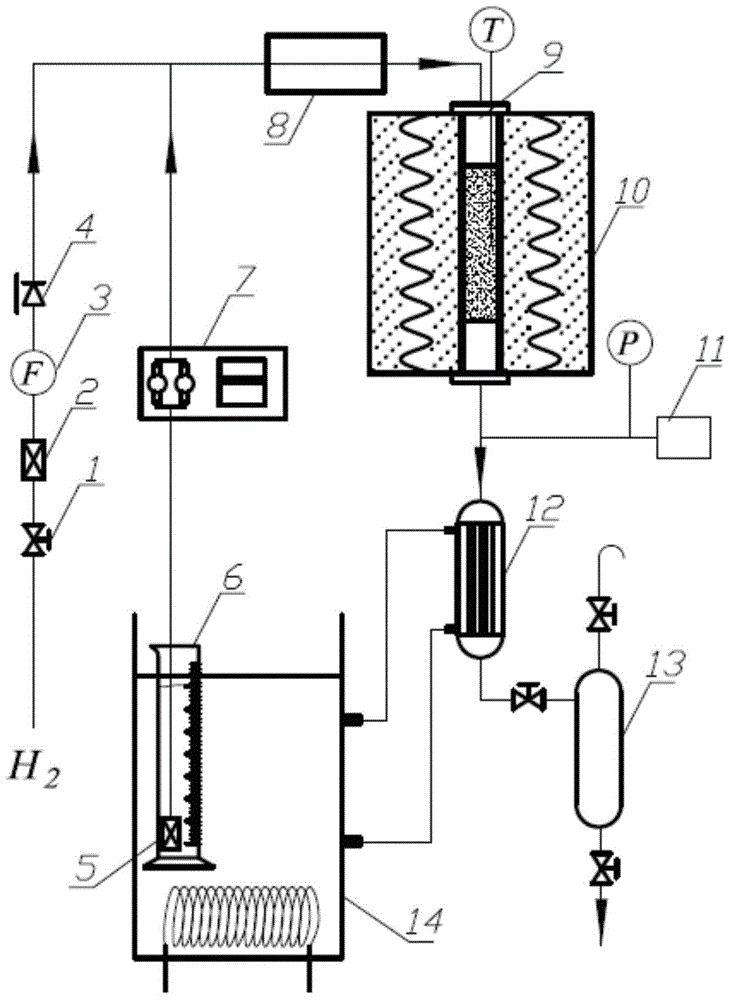

Method used

Image

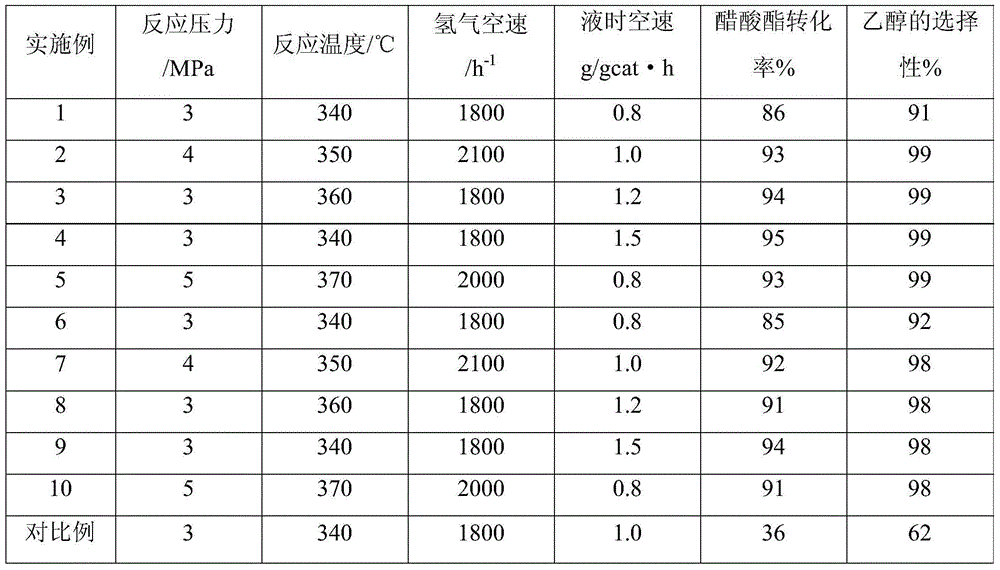

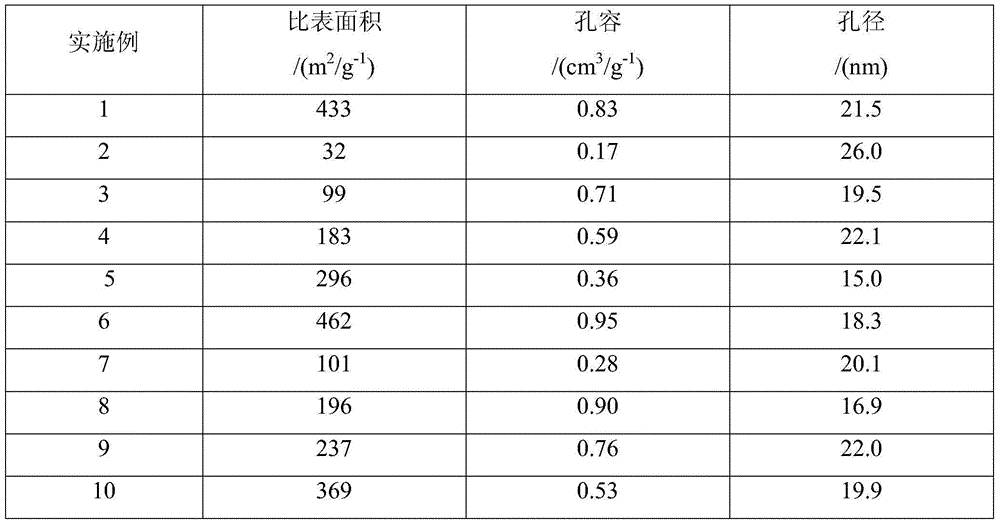

Examples

Embodiment 1

[0022] A kind of preparation method of the copper-based catalyst that hydrogenates acetate to prepare ethanol comprises the steps:

[0023] (1) Copper nitrate is dissolved in 1L of triple distilled water, so that the concentration of copper nitrate is 0.2mol / L;

[0024] (2) Add 5mol magnesium nitrate;

[0025] (3) adding 133.7g mass concentration is 30% silica sol;

[0026] (4) Add 2.56g B 2 o 3 as an auxiliary agent;

[0027] (5) Add ammonia water to adjust pH = 10, mix at room temperature for 5 hours, age in a water bath at 95°C for 3 hours, dry, grind, and roast at 450°C for 3 hours to obtain a copper-based catalyst for hydrogenation of acetate to produce ethanol . Among them, MgO-SiO 2 Medium MgO and SiO 2 The mass ratio is 5:1, the mass of Cu in CuO accounts for 5% of the mass of the copper-based catalyst, and the mass of the additive accounts for 1% of the mass of the copper-based catalyst.

Embodiment 2

[0029] A kind of preparation method of the copper-based catalyst that hydrogenates acetate to prepare ethanol comprises the steps:

[0030] (1) Copper acetate is dissolved in 1L of triple distilled water so that the concentration of copper acetate is 0.2mol / L;

[0031] (2) Add 0.75mol magnesium acetate;

[0032] (3) adding 5g mass concentration is 30% silica sol;

[0033] (4) Add 1.37g of auxiliary agent, the auxiliary agent is La with a mass ratio of 1:1 2 o 3 and ZnO;

[0034] (5) Add ammonia water to adjust pH = 11, mix at room temperature for 2 hours, age in a water bath at 80°C for 4 hours, dry, grind, and roast at 550°C for 4 hours to obtain a copper-based catalyst for hydrogenation of acetate to produce ethanol . Among them, MgO-SiO 2 Medium MgO and SiO 2 The mass ratio is 20:1, the mass of Cu in CuO accounts for 28% of the mass of the copper-based catalyst, and the mass of the auxiliary agent accounts for 3% of the mass of the copper-based catalyst.

Embodiment 3

[0036] A kind of preparation method of the copper-based catalyst that hydrogenates acetate to prepare ethanol comprises the steps:

[0037] (1) Dissolve copper chloride in 1L of triple distilled water so that the concentration of copper chloride is 0.2mol / L;

[0038] (2) Add 1.2mol magnesium chloride;

[0039] (3) adding 10.4g mass concentration is 30% silica sol;

[0040] (4) Add 1.28g of auxiliary agent, the auxiliary agent is Nb with a mass ratio of 1:1:1 2 o 5 , CaO and BaO;

[0041] (5) Add ammonia water to adjust pH = 11, mix at room temperature for 3 hours, age in a water bath at 95°C for 5 hours, dry, grind, and roast at 480°C for 5 hours to obtain a copper-based catalyst for hydrogenation of acetate to produce ethanol . Among them, MgO-SiO 2 Medium MgO and SiO 2 The mass ratio is 15:1, the mass of Cu in CuO accounts for 20% of the mass of the copper-based catalyst, and the mass of the auxiliary agent accounts for 2% of the mass of the copper-based catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com