A method for isolating high-purity hyperin from lotus leaves

A hyperin, high-purity technology, applied in chemical instruments and methods, medical preparations containing active ingredients, pharmaceutical formulas, etc., can solve the problem of high heat consumption, solvent consumption and emission, and lack of extraction of flavonoid monomers method, it is difficult to industrialize production and other issues, to achieve the effect of continuous operation, lower development and utilization costs, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

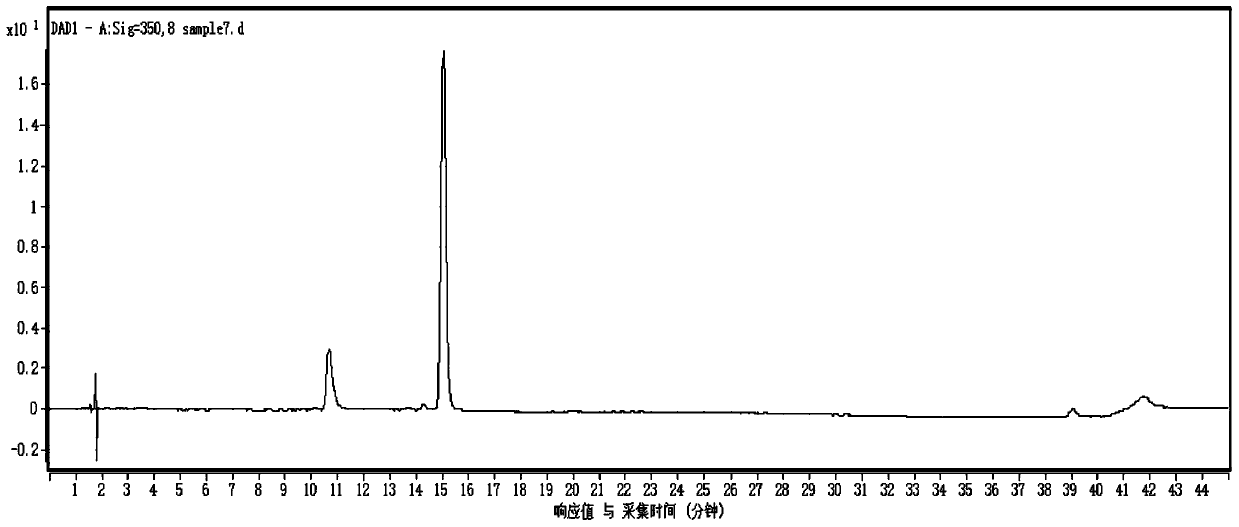

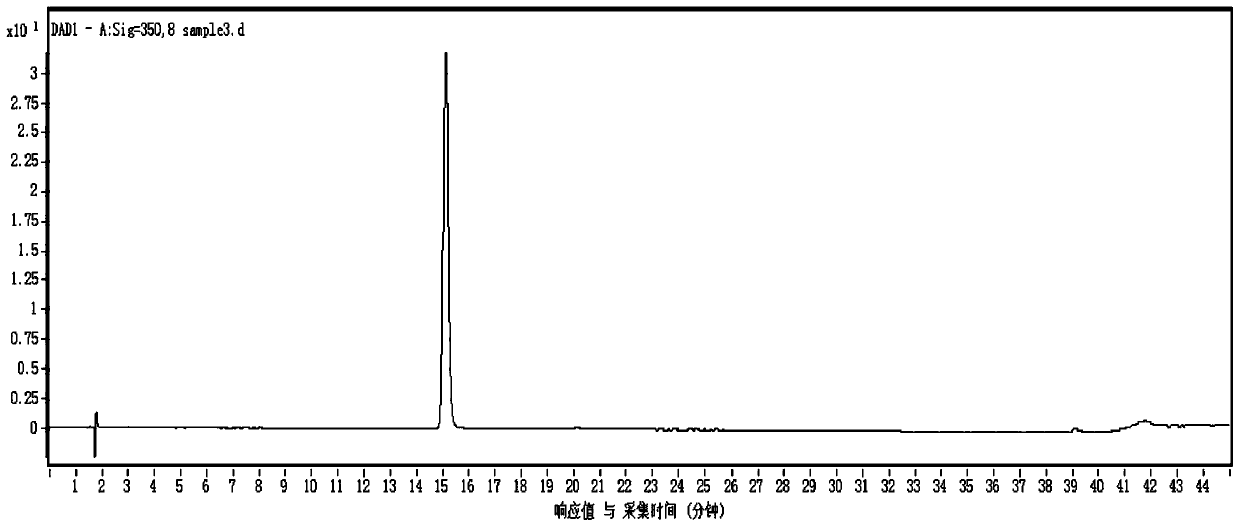

Image

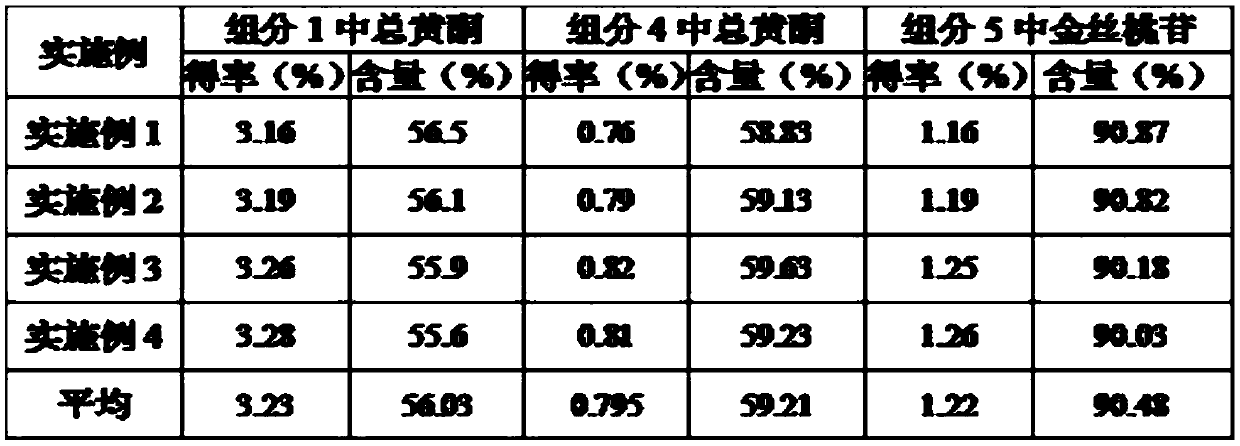

Examples

Embodiment 1

[0075] Take 500g of crushed dry lotus leaf fragments, the size of which is about 3mm, and pre-soak the fragments with 0.09mol / L sodium hydroxide aqueous solution for 18 hours at room temperature; put the soaked lotus leaves from the feeding inlet of a small ultrasonic countercurrent extractor, Weak alkali aqueous solution is added from the outlet of the residue, the ratio of material to liquid is 1:40, the active ingredients of lotus leaves are extracted in the ultrasonic dynamic countercurrent extraction tank, the rotation speed of the auger is 0.3r.p.m, and the ultrasonic power is 3.0kW / m 3 , the lotus leaf fragments stay in the extraction tank for 35min, continuous operation; the residue is squeezed, then washed twice with clear water with a volume of 1:1 with the residue, the washing water is added to the extract, and the total flavonoid content is measured. The extraction rate was 7.89%. However, the extraction rate of total flavonoids was 8.42% in hot alcohol water extra...

Embodiment 2

[0082] Take 1 kg of crushed dry lotus leaf fragments, the size of which is about 2mm, and pre-soak the fragments with 0.07mol / L calcium hydroxide aqueous solution for 24 hours at room temperature; put the soaked lotus leaves from the feeding inlet of a small ultrasonic countercurrent extractor, Weak alkali aqueous solution is added from the outlet of the residue, the ratio of material to liquid is 1:30, the active ingredients of lotus leaves are extracted in the ultrasonic dynamic countercurrent extraction tank, the rotation speed of the auger is 0.5r.p.m, and the ultrasonic power is 2.5kW / m 3 , the lotus leaf fragments stay in the extraction tank for 30 minutes, continuous operation; the residue is squeezed, then washed twice with water with a volume of 1:1 with the residue, and the washing water is added to the extraction solution;

[0083] Adjust the pH of the extract to neutral, after standing still, use a 0.2μm microfiltration membrane to remove residual particles, the ope...

Embodiment 3

[0089] Take 5 kg of crushed dry lotus leaf fragments, the size of which is about 4 mm, and pre-soak the fragments with 0.15 mol / L potassium hydroxide aqueous solution for 12 hours at room temperature; put the soaked lotus leaves from the feeding inlet of a small ultrasonic countercurrent extractor, Weak alkali aqueous solution is added from the outlet of the residue, the ratio of material to liquid is 1:50, the active ingredients of lotus leaves are extracted in the ultrasonic dynamic countercurrent extraction tank, the rotation speed of the auger is 0.2r.p.m, and the ultrasonic power is 2.2kW / m 3 , the lotus leaf fragments stay in the extraction tank for 40 minutes, continuous operation; the residue is squeezed, then washed once with water with a volume of 1:1 with the residue, and the washing water is added to the extraction solution;

[0090] Adjust the pH of the extract to neutral, after standing still, use a 0.2μm microfiltration membrane to remove residual particles, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com