Au-Co-Cu catalyst used in synthesis of vinyl chloride by hydrochlorination of acetylene and preparation method for Au-Co-Cu catalyst

A technology for the production of vinyl chloride and catalysts by chlorination, which is applied in the direction of hydrogen halide addition preparation, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc. Short life and other problems, to achieve long life, high strength, and reduce by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

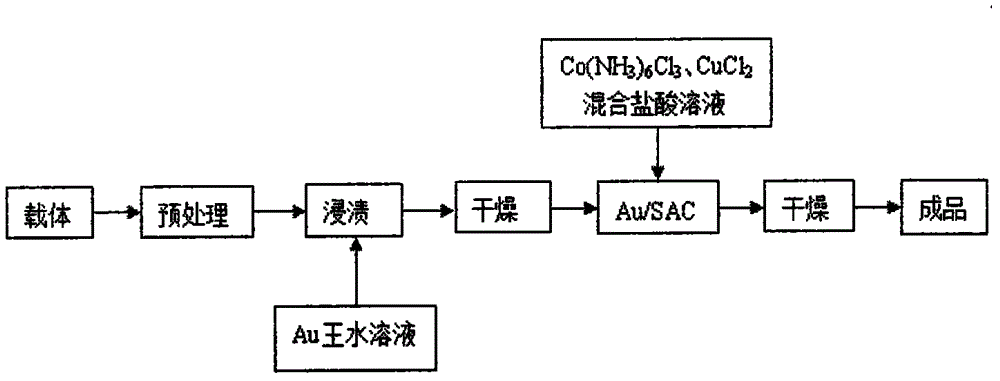

[0017] Example 1: The catalyst for producing vinyl chloride by acetylene hydrochlorination includes an inert carrier and several metal salts, the content of Au accounts for 0.5% to 3% of the catalyst weight, and the molar ratio of Cu and Co(iii) to Au Au / Cu=1:0~5, Au / Co(iii)=1:0~5; the inert carrier is a porous carrier, and it is planned to use pitch-based spherical carbon or powdery activated carbon. The preparation method of the catalyst of producing vinyl chloride with acetylene hydrochlorination is: a, the HAuCl of metering 4 4H 2 O is made into aqua regia solution with newly prepared aqua regia, and the concentration of aqua regia solution makes the content of Au in the final catalyst be 0.5%~3% of catalyst weight; b, inert support is impregnated in Au aqua regia solution, and soaking time is more than 5 hours c, heated on a water bath until the liquid evaporates substantially, and then put it into an oven for drying to obtain an Au catalyst; d, mix copper chloride and h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com