Method for improving enzymatic saccharification effect by xylose residue pretreatment

A technology of pretreatment and xylose residue, which is applied in climate change adaptation, fertilizer made from biological waste, agriculture, etc., can solve the problem of low hydrolysis efficiency of cellulase, and improve hydrolysis yield and reducing sugar yield, The effect of reducing discharge and reducing the discharge of waste liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

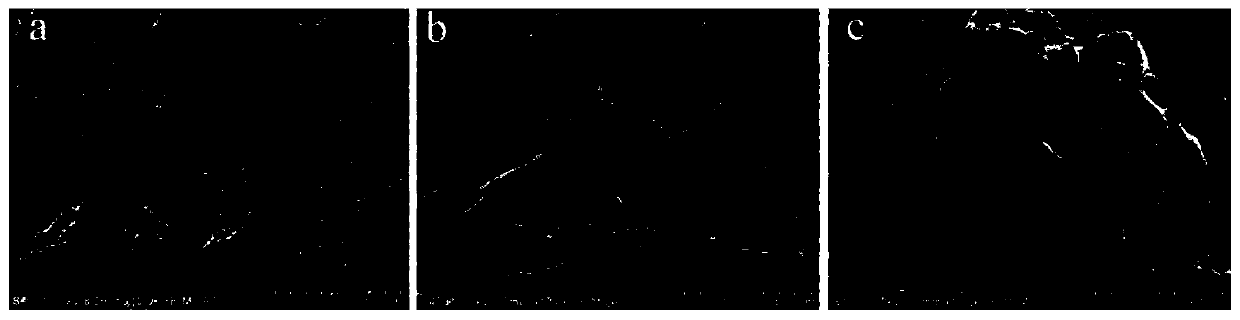

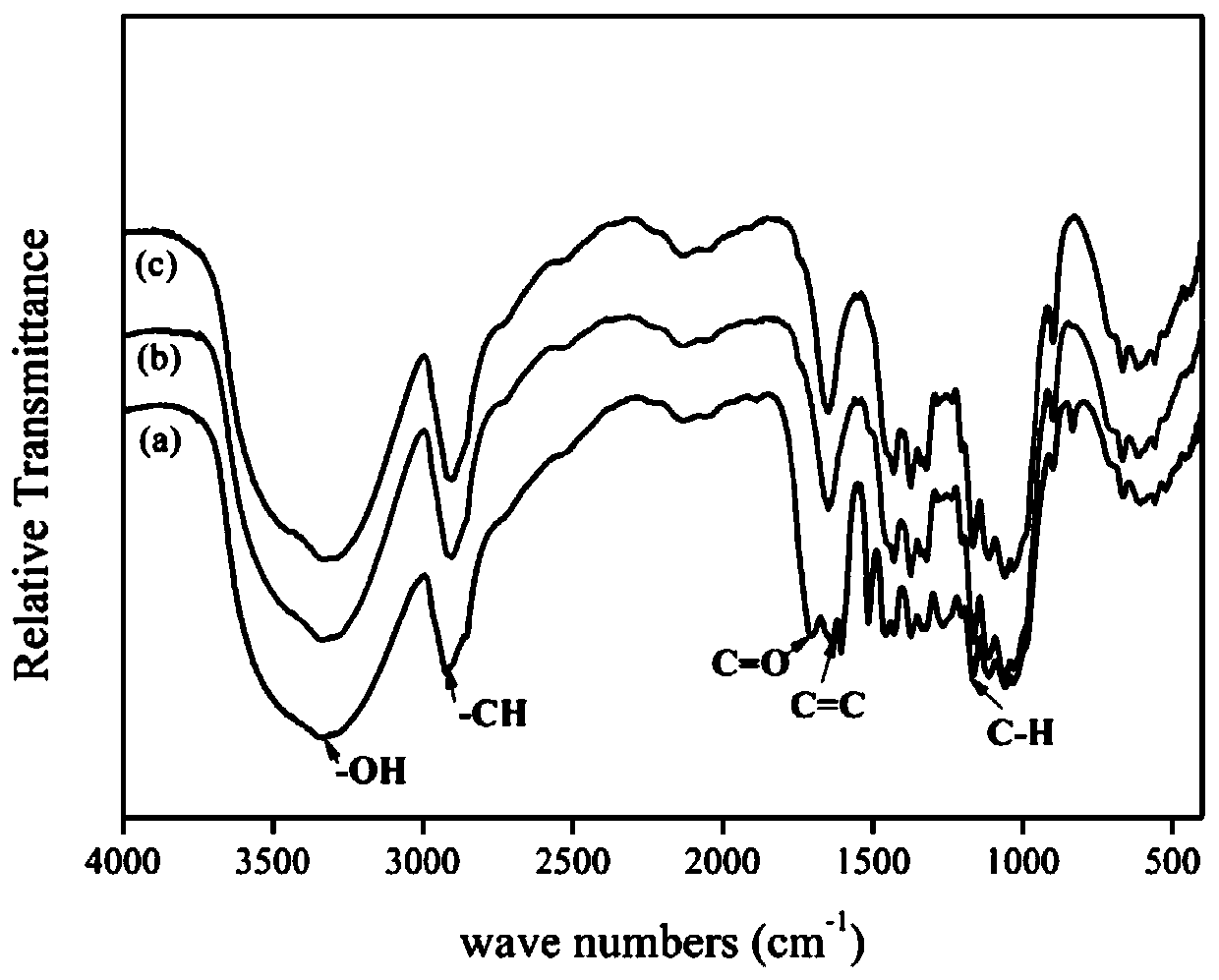

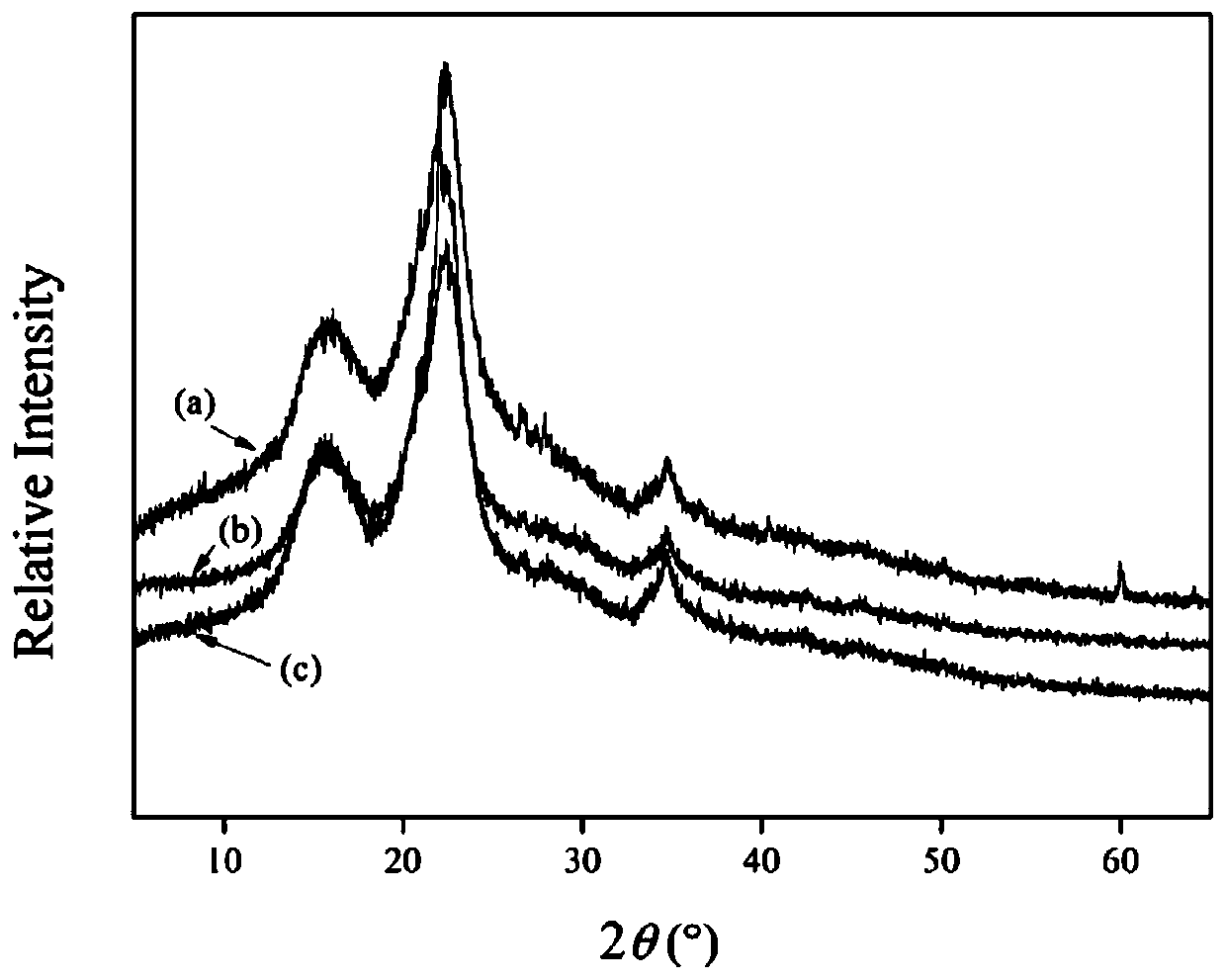

Image

Examples

Embodiment 1

[0037] Weigh 30.0±0.1g of xylose residue, add 300.0±0.1g of DES (choline chloride: lactic acid (molar ratio 1:2)) for pretreatment at 90°C for 1 hour, and perform solid-liquid separation after the reaction. Then take the solid and add 300.0±0.1mL KOH solution with a mass fraction of 7%, pretreat at 70°C for 90min, and separate the solid from the liquid after the reaction; wash the solid part with tap water until it is neutral, and perform enzymatic hydrolysis Saccharification experiment. Enzymatic hydrolysis reaction volume is 20mL, add 3g of pretreated xylose residue (in dry basis) with 15wt.% solid loading, add 0.05mol / L citric acid buffer solution to adjust pH to 4.8, add 0.2mL of Sodium azide solution (0.02 g / mL), and then cellulase was added, the enzyme dosage was 5 FPU / g-substrate, and the reaction was carried out at 50° C. at 120 rpm for 72 h. Then HPLC was used to measure the glucose concentration in the enzymolysis solution. The results showed that the glucose conce...

Embodiment 2

[0039] Weigh 30.0±0.1g of xylose residue, add 300.0±0.1g of DES (choline chloride: lactic acid (1:2)) for pretreatment at 90°C for 1 hour, perform solid-liquid separation after the reaction, and then take Add 300.0±0.1mL of 10% KOH solution to the solid, pretreat at 70°C for 90min, and perform solid-liquid separation after the reaction. The solid part was washed to neutral with tap water, and the enzymatic hydrolysis and saccharification experiment was carried out. Enzymatic hydrolysis reaction volume is 20mL, add 3g of pretreated xylose residue (in dry basis) with 15wt.% solid loading, add 0.05mol / L citric acid buffer solution to adjust pH to 4.8, add 0.2mL of Sodium azide solution (0.02 g / mL), and then cellulase was added, the enzyme dosage was 5 FPU / g-substrate, and the reaction was carried out at 50° C. at 120 rpm for 72 h. Then HPLC was used to measure the glucose concentration in the enzymolysis solution. The results showed that the glucose concentration in the enzymol...

Embodiment 3

[0041] Weigh 30.0±0.1g of xylose residue, add 300.0±0.1g of DES (choline chloride: lactic acid (1:2)) for pretreatment at 90°C for 1 hour, perform solid-liquid separation after the reaction, and then take Add 300.0±0.1mL of KOH solution with a mass fraction of 13% to the solid, pretreat at 70°C for 90min, and perform solid-liquid separation after the reaction. The solid part was washed to neutral with tap water, and the enzymatic hydrolysis and saccharification experiment was carried out. Enzymatic hydrolysis reaction volume is 20mL, add 3g of pretreated xylose residue (in dry basis) with 15wt.% solid loading, add 0.05mol / L citric acid buffer solution to adjust pH to 4.8, add 0.2mL of Sodium azide solution (0.02 g / mL), and then cellulase was added, the enzyme dosage was 5 FPU / g-substrate, and the reaction was carried out at 50° C. at 120 rpm for 72 h. Then HPLC was used to measure the glucose concentration in the enzymolysis solution. The results showed that the glucose conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com