Method for preparing thiodiglycolic acid

A technology for thiodiglycolic acid and dibutyl thiodiglycolic acid, which is applied in the field of preparation of thiodiglycolic acid, can solve the problems of serious environmental pollution, consumption of extraction solvent, poor product purity, etc. The effect of high rate and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

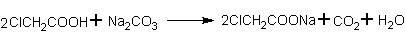

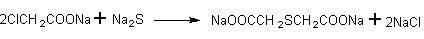

Method used

Image

Examples

Embodiment 1

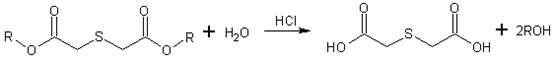

[0027] A kind of preparation method of thiodiglycolic acid, it comprises the following steps: in flask, add dimethyl thiodiglycolate 100g, mass percent concentration is 5% hydrochloric acid 200ml, after refluxing 3h, distill and reclaim 50ml methanol and water, remaining The reaction mixture was crystallized by cooling, and dried by suction filtration to obtain about 78 g of white granular powder thiodiglycolic acid (melting point 128-131 ° C), and 174 g of mother liquor. The yield of this step is 92.5%, and the purity is 99.7%.

Embodiment 2

[0029] A kind of preparation method of thiodiglycolic acid, it comprises the following steps: in flask, add dimethyl thiodiglycolate 100g, mass percentage concentration is the sulfuric acid 400ml of 5%, after reflux 4h, distill out 250ml methanol and water, remaining The reaction mixture was crystallized by cooling, and dried by suction filtration to obtain about 77g of white granular powder thiodiglycolic acid (melting point 128-131°C) and 176g of mother liquor. The yield of this step is 91.3%, and the purity is 99.6%.

Embodiment 3

[0031] A kind of preparation method of thiodiglycolic acid, it comprises the following steps: add thiodiglycolic acid diethyl ester 116g in the flask, mass percent concentration is 10% phosphoric acid 200ml, after refluxing 6h, distill out 60ml ethanol and water, remaining The reaction mixture was crystallized by cooling, and dried by suction filtration to obtain about 76 g of white granular powder thiodiglycolic acid (melting point 128-131 ° C), and 176 g of mother liquor. The yield of this step is 90.2%, and the purity is 99.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com