Method for preparing modified collagen polypeptide leather making filler from chrome-free polymetal tanning leather meal

A collagen peptide, multi-metal technology, applied in leather impregnation, small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather hide/fur chemical treatment, etc. Molecular weight, saving tanning cost, high hydrolysis rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

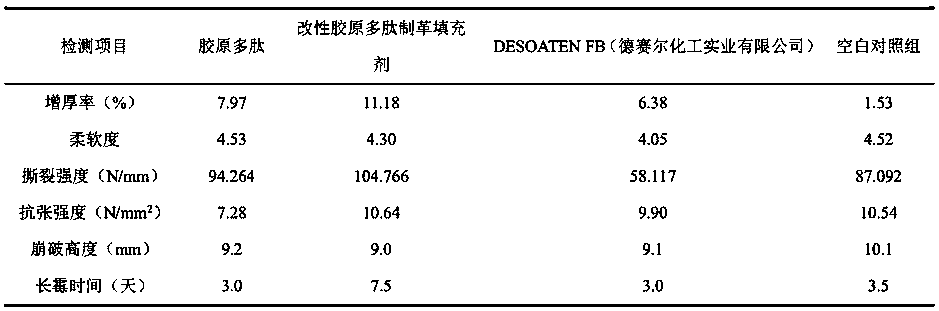

Examples

Embodiment 1

[0020] A method for preparing a modified collagen polypeptide tanning filler from chromium-free multi-metal tanned leather shavings, comprising the steps in turn:

[0021] Step (1) Hydrolysis of leather shavings: take a certain amount of leather shavings and place them in a reactor, based on the quality of leather shavings, add 1% surfactant, 0.5% degreasing agent, 10 times of water, soak and stir the leather shavings for 2 hours, Drain the water, then wash with water twice; add 15% oxalic acid, 7.5 times water, stir and react at 90°C for 8 hours, filter and dry to obtain collagen polypeptide;

[0022] Step (2) Collagen polypeptide modification: Take a certain amount of collagen polypeptide and add it to the reactor. Based on the quality of the collagen polypeptide, add 3 times of water to dissolve it, add 100% absolute ethanol while stirring, add 20% triethylamine, add 40% tetrakis hydroxymethyl quaternary phosphonium salt, adjust the pH to 7, stir and react at 30°C for 6 hou...

Embodiment 2

[0024] A method for preparing a modified collagen polypeptide tanning filler from chromium-free multi-metal tanned leather shavings, comprising the steps in turn:

[0025] Step (1) leather shavings hydrolysis: take a certain amount of leather shavings and place them in a reactor, based on the quality of leather shavings, add 2% surfactant, 0.2% degreasing agent, 15 times of water, soak and stir the leather shavings for 5 hours, Drain the water, then wash with water twice; add 20% oxalic acid, 10 times of water, stir and react at 80°C for 5 hours, adjust the temperature, stir and react at 60°C for 5 hours, filter and dry to obtain collagen polypeptide;

[0026] Step (2) Collagen polypeptide modification: Take a certain amount of collagen polypeptide and add it to the reactor. Based on the quality of the collagen polypeptide, add 5 times of water to dissolve it; take 100% vinyl-containing quaternary ammonium salt in the container, add vinyl-containing quaternary ammonium salt 10...

Embodiment 3

[0028] A method for preparing a modified collagen polypeptide tanning filler from chromium-free multi-metal tanned leather shavings, comprising the steps in turn:

[0029] Step (1) Hydrolysis of leather shavings: take a certain amount of leather shavings and place them in a reactor, based on the quality of leather shavings, add 0.5% surfactant, 1% degreasing agent, 8 times the water, soak and stir the leather shavings for 1 hour, Drain the water, then wash with water twice; add 10% oxalic acid, 15 times water, stir at 70°C for 4 hours, 50°C for 6 hours, and 30°C for 8 hours, filter and dry to obtain collagen polypeptide;

[0030] Step (2) Collagen polypeptide modification: Take a certain amount of collagen polypeptide and add it to the reactor. Based on the quality of the collagen polypeptide, add 5 times the water to dissolve it; take 50% of the vinyl-containing quaternary ammonium salt in the container, and add the vinyl-containing quaternary ammonium salt. 100% water of qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com