Method for preparing porous foam steel by melt foaming process and apparatus thereof

A technology of porous foam and melt foaming, which is applied to the device for realizing the method and the field of preparing porous foam steel, which can solve the problems of poor foaming effect, short retention time, and fast cooling speed, so as to improve the pore structure and The distribution of pores, the increase of residence time, and the effect of preventing the foaming agent from floating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

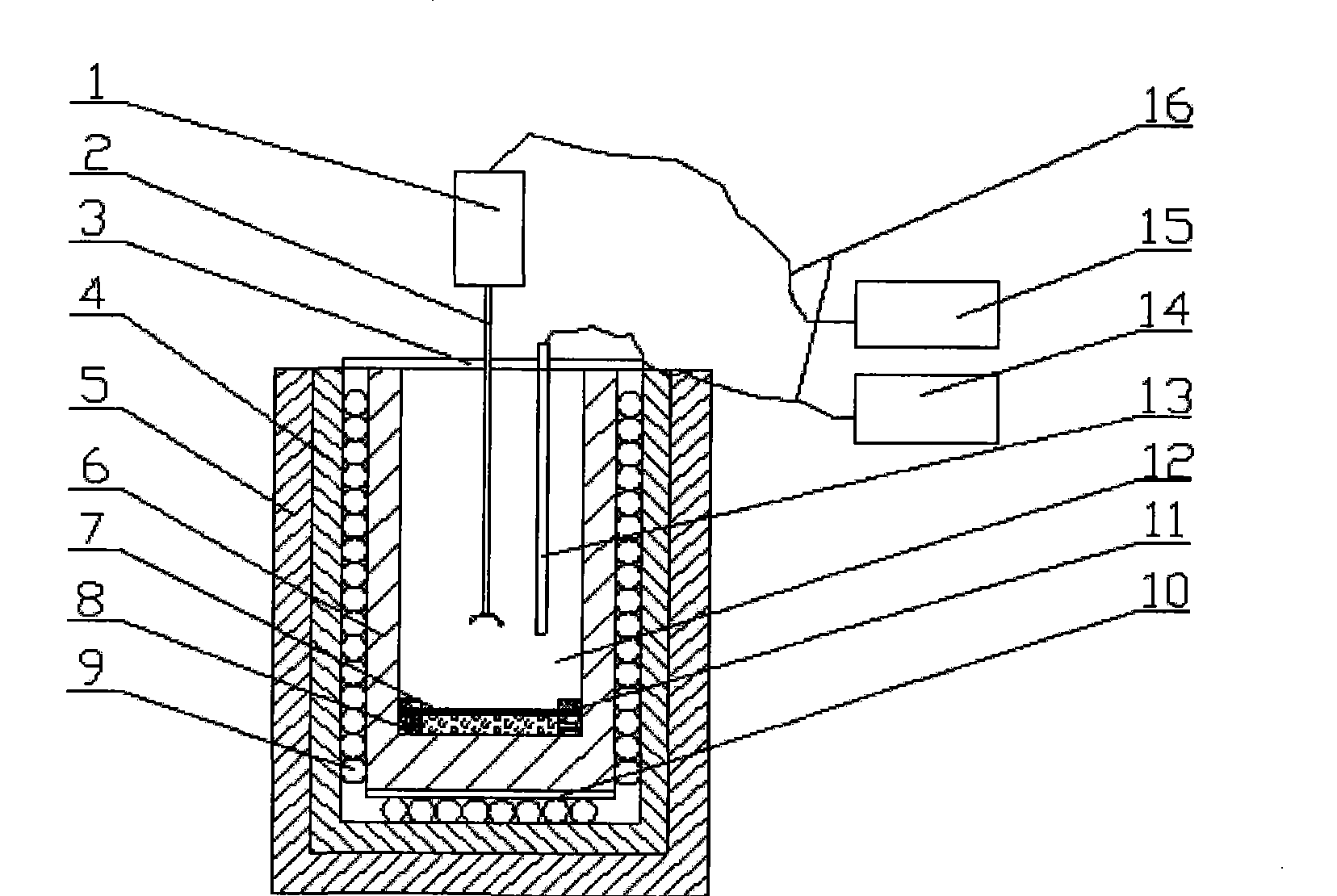

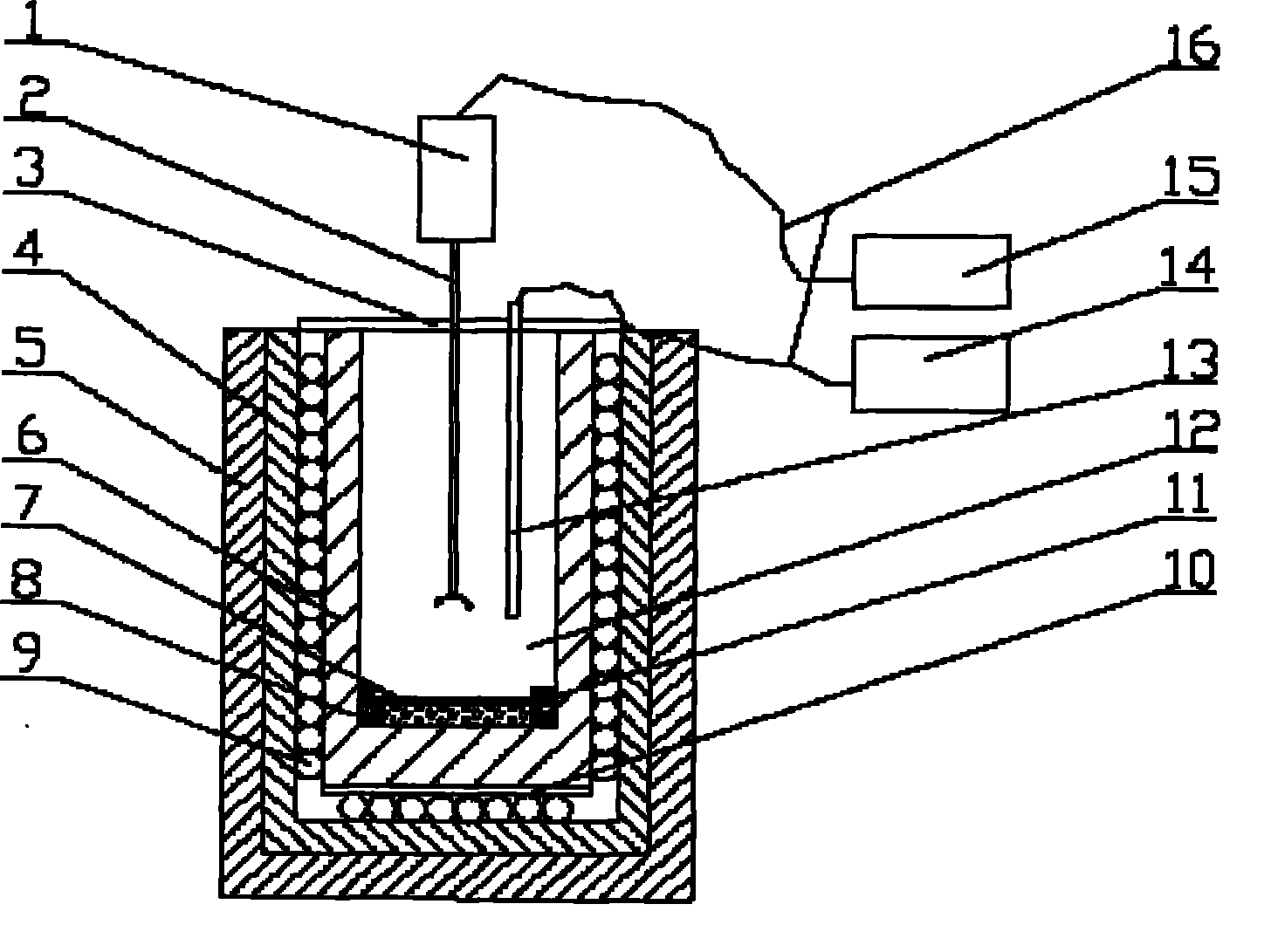

Image

Examples

Embodiment 1

[0026] A, the blowing agent Cr 2 N is spread on the bottom of the crucible of the heating furnace according to the amount of 0.1% of the mass of molten steel, covered with a steel net on the foaming agent, and spread water glass sand on the steel net to harden it. The quality score is 3%;

[0027] B. Place the crucible containing the foaming agent in the heating furnace, raise the temperature to 1005°C for heat preservation, control the temperature rise rate at 5°C / min, keep heat for pouring;

[0028] C. Cast 45 molten steel with a melting temperature of 1450°C into the crucible in the heating furnace, adjust the temperature of the molten steel in the crucible to 1350°C for heat preservation, stir the molten steel at a speed of 200r / min, and heat and stir for 1min;

[0029] D. Take out the crucible and cool it to room temperature in air to make porous foam steel material.

Embodiment 2

[0031] A, the blowing agent Mn 4 N is spread flat on the bottom of the crucible of the heating furnace according to the addition of 0.6% of the molten steel mass, covered with a steel mesh on the foaming agent, and spread water glass sand on the steel mesh to harden it. The quality score is 5%;

[0032] B. Place the crucible containing the foaming agent in the heating furnace, raise the temperature to 1064°C for heat preservation, and control the temperature rise rate at 10°C / min, keep heat for pouring;

[0033] C. Cast molten 40Cr alloy steel molten steel with a pouring temperature of 1550°C into the crucible in the heating furnace, adjust the temperature of the molten steel in the crucible to 1510°C for heat preservation, stir the molten steel at a speed of 800r / min, and heat and stir for 2 minutes;

[0034] D. Take out the crucible and cool it to room temperature in air to make porous foam steel material.

[0035] Implementation results

[0036] The holes in the samples ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com