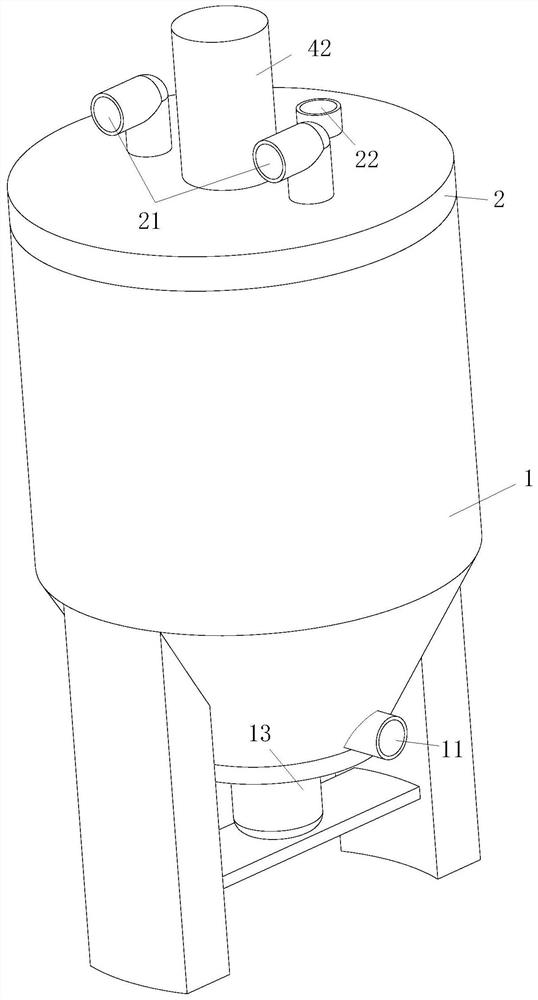

Polyurethane insulation board foaming system

A technology of polyurethane insulation board and foaming system, which is applied in the field of insulation board foaming, can solve the problems of increased labor intensity of workers, reduced effect of split material foaming, and reduced quality of split material mixing, so as to improve the actual application effect, Improve the foaming effect and ensure the foaming quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

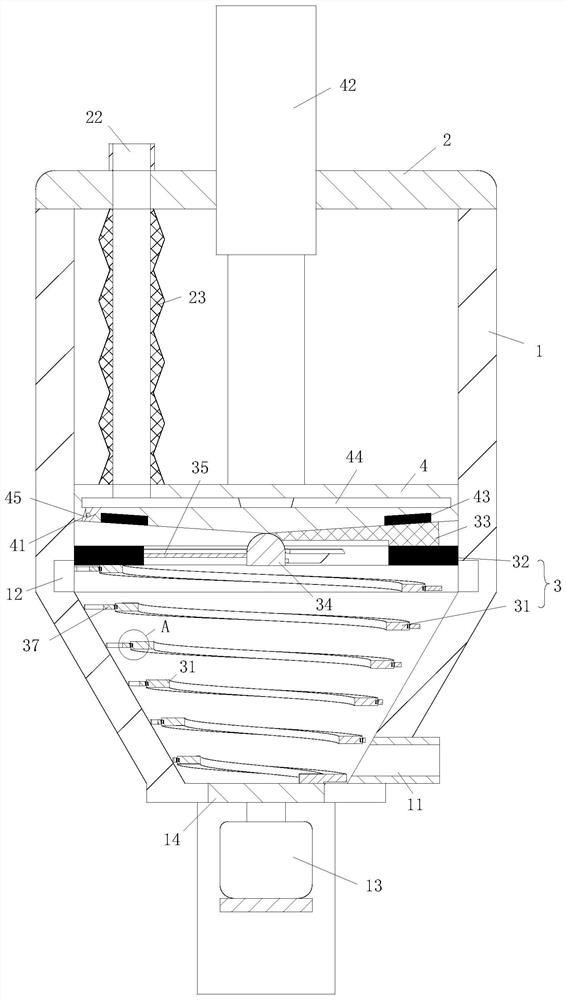

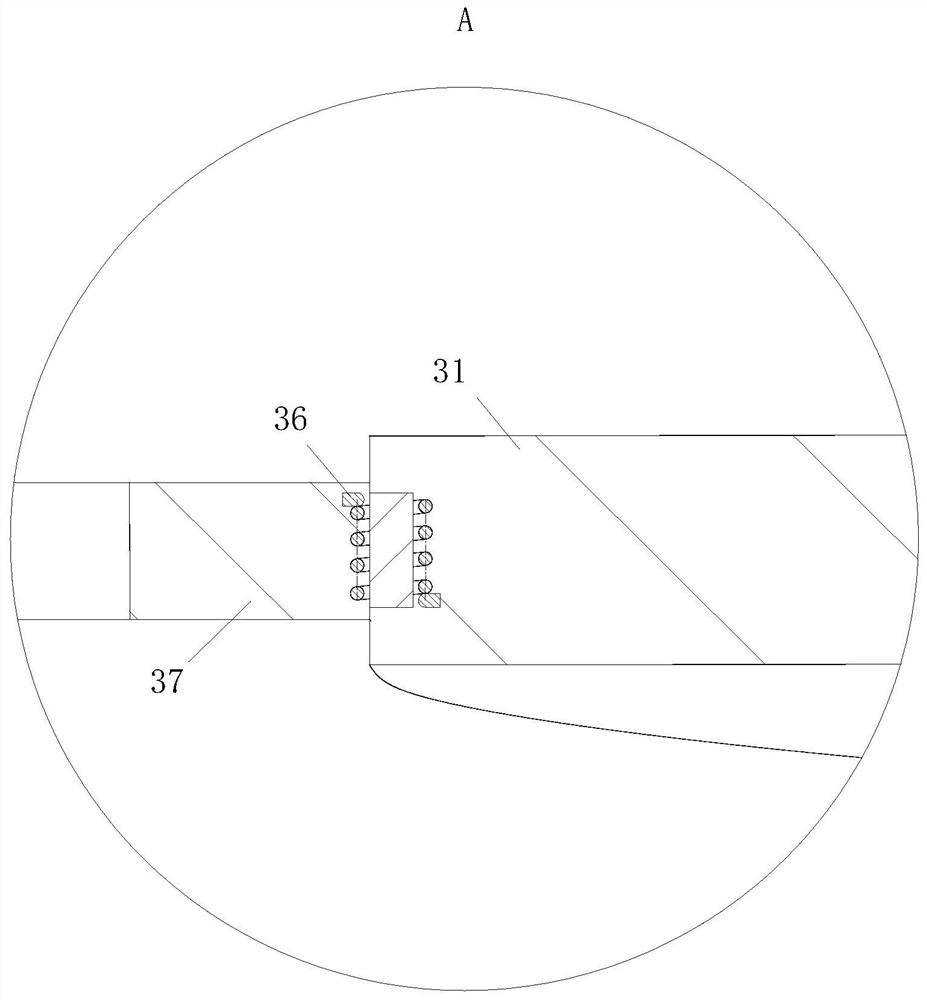

[0032]As an embodiment of the present invention, the ring magnet 32 is provided with a rotating shaft 34; the rotating shaft 34 and the ring magnet 32 are fixedly connected by blades 35; the blades 35 are arranged obliquely; When the material is sprayed from the discharge port 11 to the blade 35, the blade 35 rotates synchronously under the drive of the ring magnet 32, so that the material is mixed rapidly under the rotation of the blade 35. When the ring magnet 32 is driven by the magnetic force of the electromagnet 43 When moving downward under the action of the feed port 21, the material entering from the feed port 21 completely overflows the ring magnet 32, and the ring magnet 32 drives the inner blade 35 to move downward, because the blade 35 rotates under the drive of the ring magnet 32, so that During the downward rotation of the blade 35, the material flows upward along the slope of the blade 35, until the material flows above the slope of the blade 35, the mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com