Box foaming and conveying system with heat preservation function

A technology of conveying system and incubator, which is applied to household appliances, other household appliances, household components, etc., can solve problems such as large heat loss, and achieve the effect of reducing scrap rate, improving product consistency, and reducing heat loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

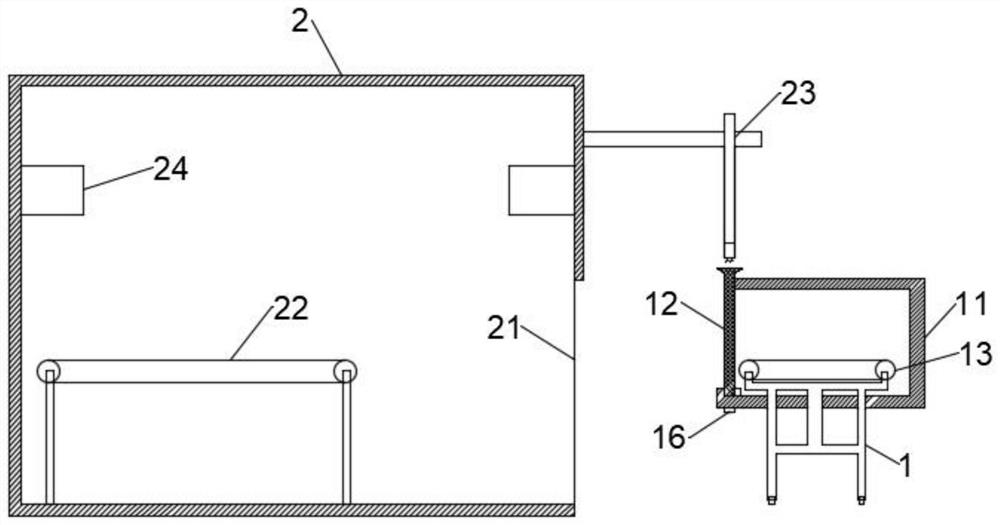

[0017] Such as figure 1 , a box body foaming conveying system with heat preservation function, including an insulation box 11 mounted on a transport vehicle 1, and an oven 2, one side of the insulation box 11 is provided with an insulation box door 12 that can be pulled up and down ; The incubator 11 and the incubator door body 12 are made of thermal insulation materials; the incubator 11 is provided with a conveyor belt mechanism A13 for placing the box body 3 to be foamed; the transport vehicle 1 is provided with a distance sensor 16 .

[0018] The thermal insulation material is selected from wooden materials; and the two ends of the thermal insulation box 11 are open, so that it is convenient to take and place the box body 3 to be foamed through the two ends of the thermal insulation box 11 .

[0019] The top of the oven 2 is provided with a heating fan device 24, one side of the oven 2 is provided with an inlet 21, and the outer wall of the oven 2 just above the inlet 21 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com