Control system for unmanned milk tea machine

A control system and technology of milk tea machine, applied in the field of control system of unmanned milk tea machine, can solve the problems of uneven quality control of milk tea, affecting the taste and quality control of milk tea, inaccurate addition of pearls or coconut fruit particles, etc. The effect of increasing the feedback mechanism, enriching the categories, and reducing the space occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

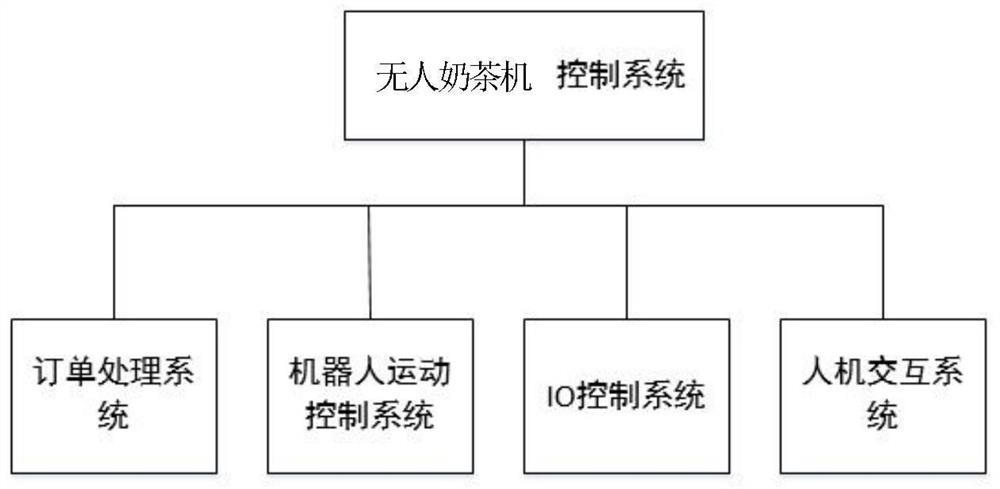

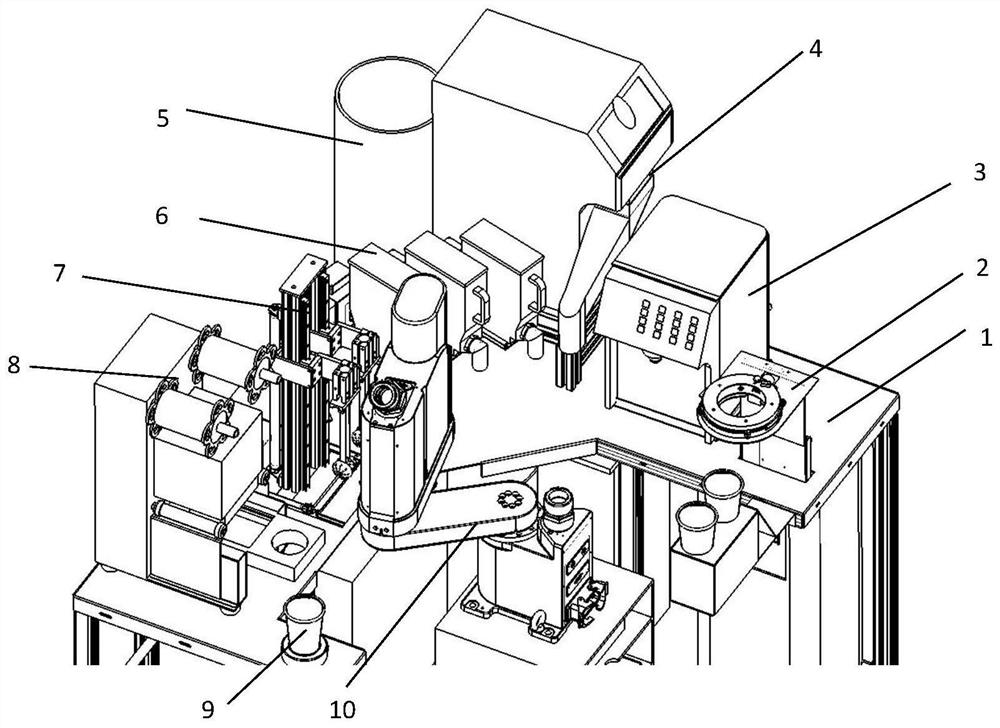

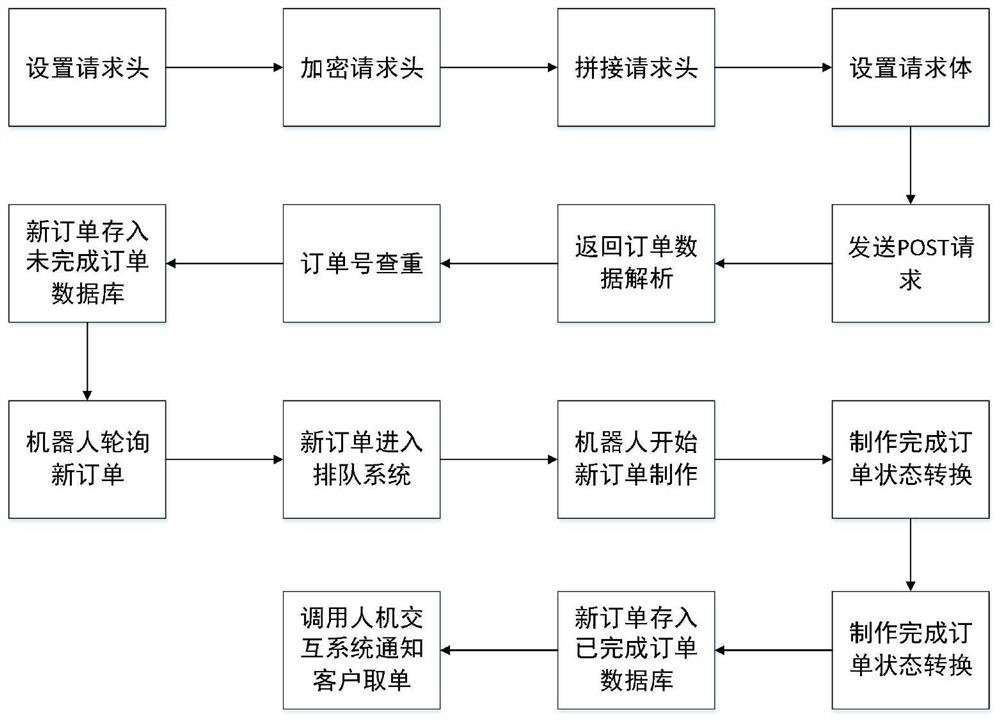

[0022] Such as Figure 1-Figure 2 As shown, a control system for an unmanned milk tea machine includes an order processing system, a robot motion control system, an IO control system and a human-computer interaction system. The order processing system includes an order acquisition system and an order analysis system; the robot motion control system Firstly, the position information of different points of the robot 10 is taught and stored in the controller of the robot 10, and the order processing system analyzes and completes the order. The upper computer controls the robot 10 to perform joint motion or linear motion to reach the designated position for waiting or taking materials, and complete the milk tea making process; The IO control system is used to control the cup drop control mechanism, the fructose quantitative discharge control mechanism, the ice discharge quantitative control mechanism, the solid-liquid separation control mechanism, multiple liquid quantitative disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com