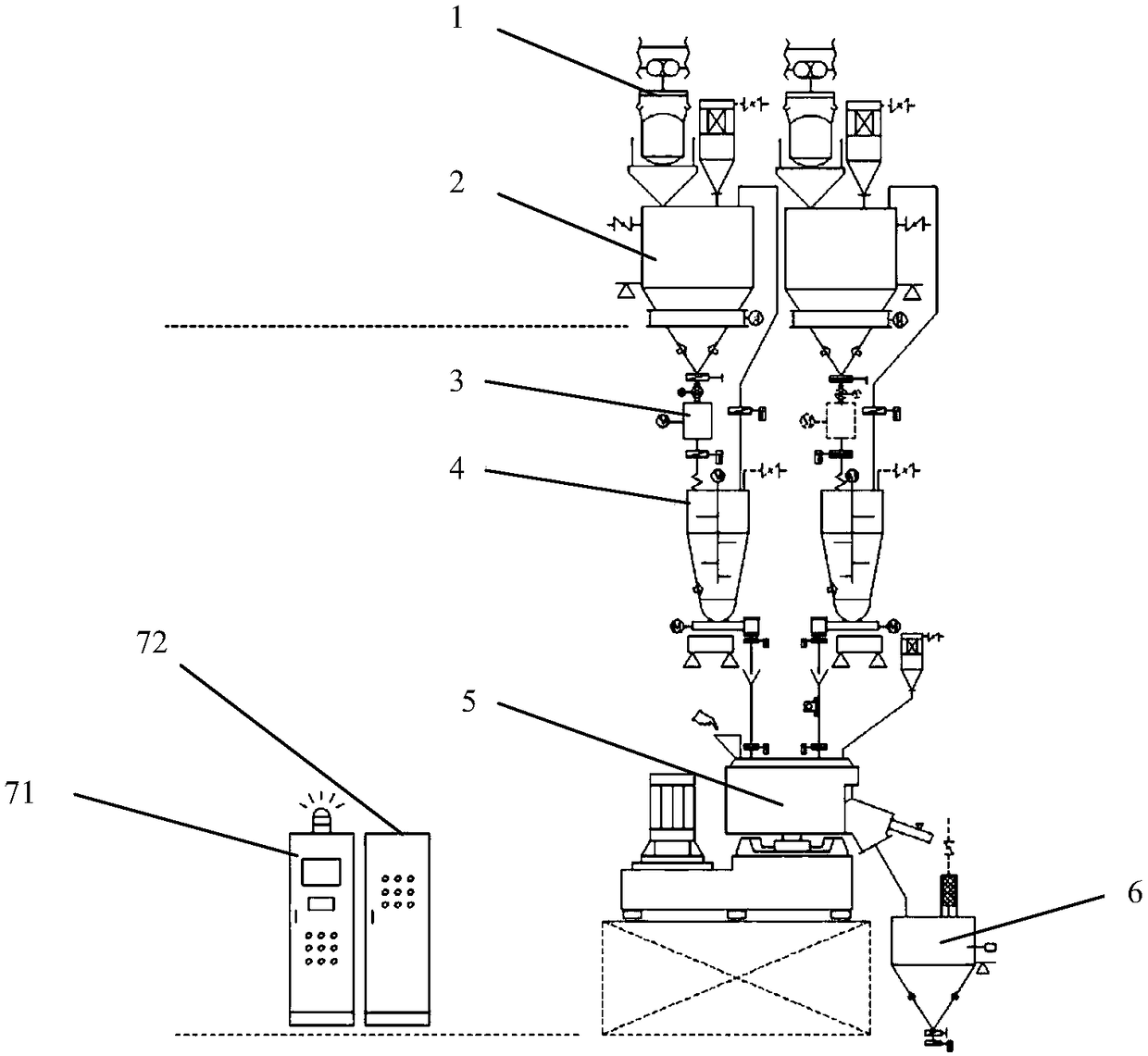

Measuring and mixing device

The technology of a mixing device and a mixing machine, which is applied in the field of mixing devices, can solve the problems of affecting production efficiency, labor and labor, and time-consuming, etc., and achieve the effects of increasing the yield, enhancing the fluidity, and improving the production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

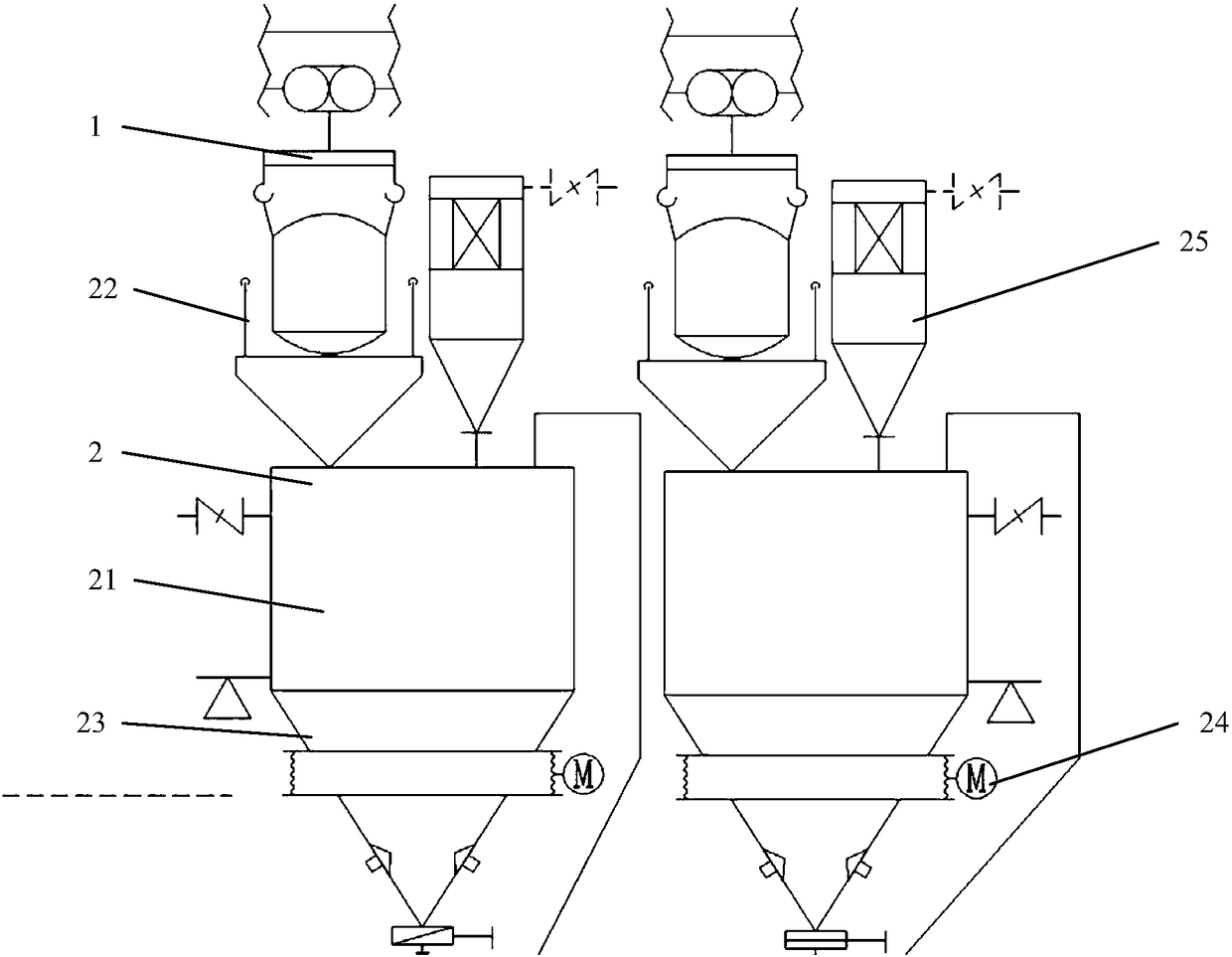

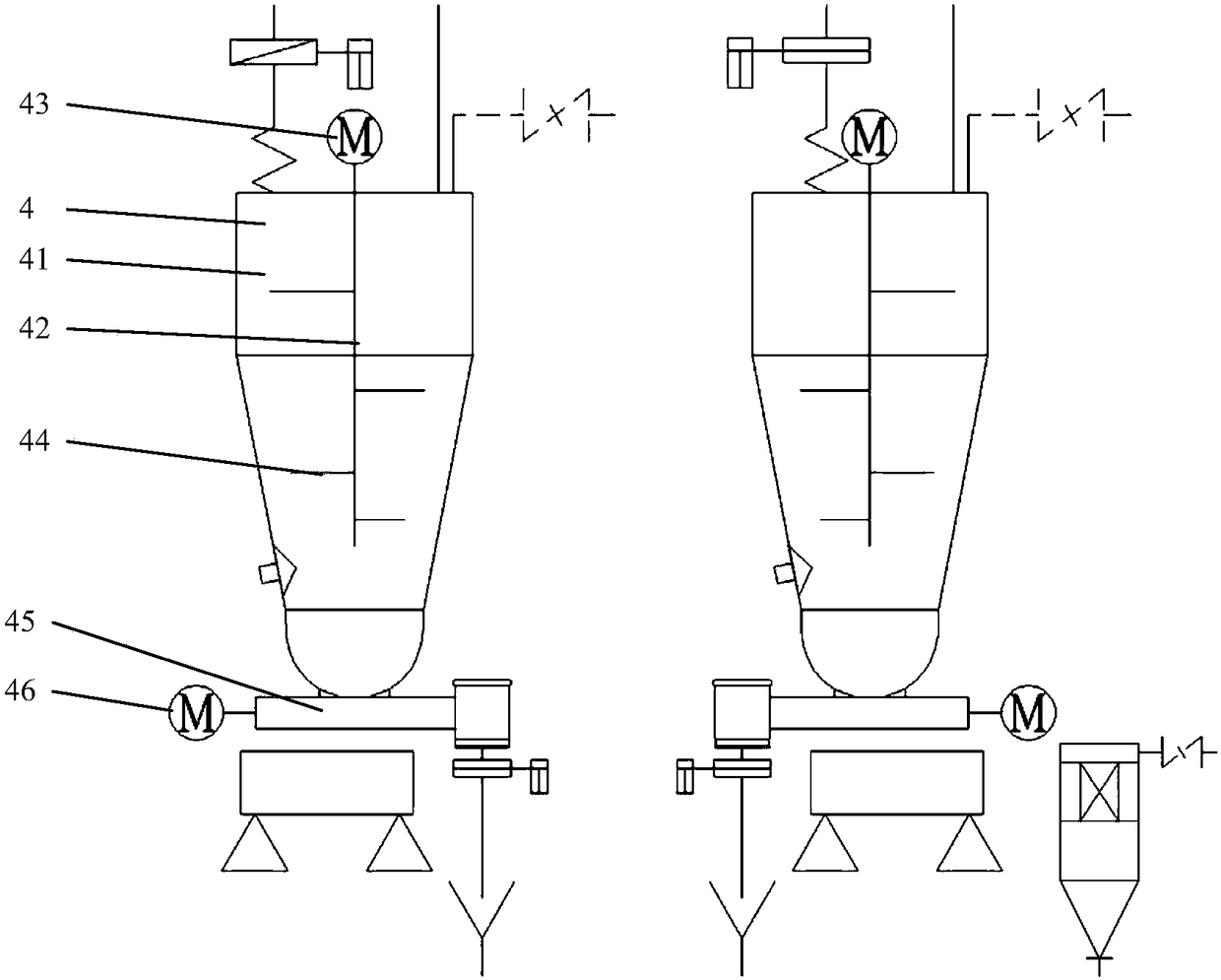

[0037] In further embodiments of the present invention, please continue to refer to Figure 2 to Figure 5 As shown, the storage bin 2 includes: a storage bin cylinder 21, a number of lifting lugs (not shown in the figure) are arranged along the upper part of the storage bin cylinder 21, and a storage The material box loam cake, the storage material box loam cake is provided with material bag feeding opening, and the material bag feeding opening place is provided with foreign matter preventing metal mesh (not shown in the figure).

[0038] In a further embodiment of the present invention, the storage material box 2 includes: a material bag support 22, the material bag support 22 is fixed on the upper surface of the upper cover of the storage material box, and the material bag support 22 surrounds the material bag feeding opening. The bag holder 22 is used to support the bag.

[0039] In a further embodiment of the present invention, the storage bin 2 includes: a storage activa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com