Drive circuit of laser source of laser projector

A technology for laser projectors and driving circuits, which is applied to circuits, lasers, laser components, etc., can solve problems such as difficult to meet the driving requirements of laser light sources and large volume of laser driving circuits, so as to avoid the use of electronic devices and reduce the volume The effect of small, constant current output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

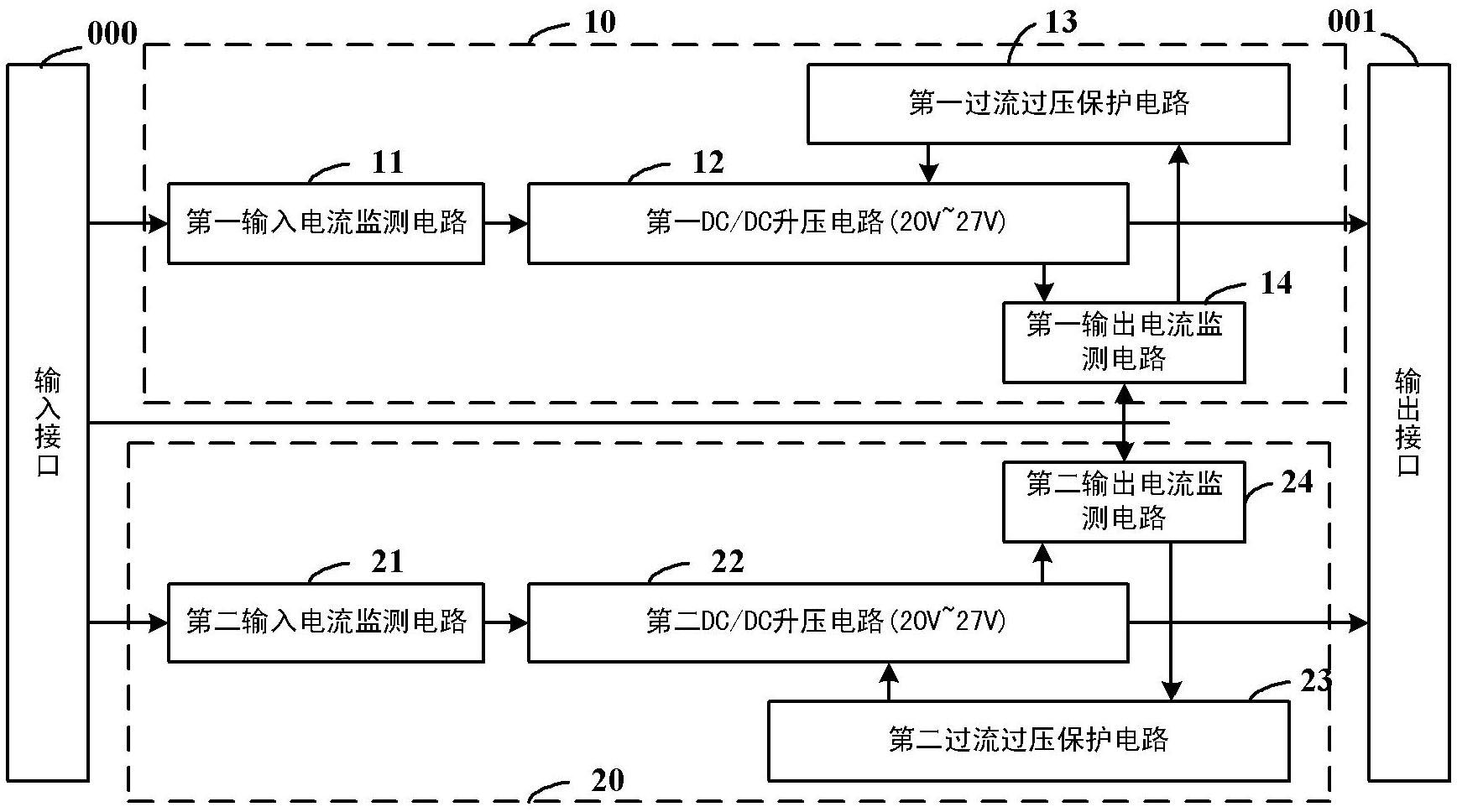

[0033] Such as figure 1 as shown, figure 1 It is a schematic diagram of a driving circuit of a laser light source of a laser projector according to an embodiment of the present invention, and the driving circuit is composed of two parallel driving generating circuits, that is, a first driving generating circuit 10 and a second driving generating circuit 20 . The implementation of the first drive generation circuit 10 and the second drive generation circuit 20 is exactly the same, the two drive generation circuits are symmetrically distributed between the input interface 000 and the output interface 001, the two drive circuits are integrated together, and at the same time through the output interface 001 Powering the lase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com