A sulfur-resistant methanation catalyst and its preparation method

A sulfur-resistant methanation and catalyst technology, applied in the direction of catalyst activation/preparation, carbon compound catalyst, catalyst, etc., can solve the problems of shortening the production cycle, achieve the effect of improving activity and stability, improving interaction, and realizing clean production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

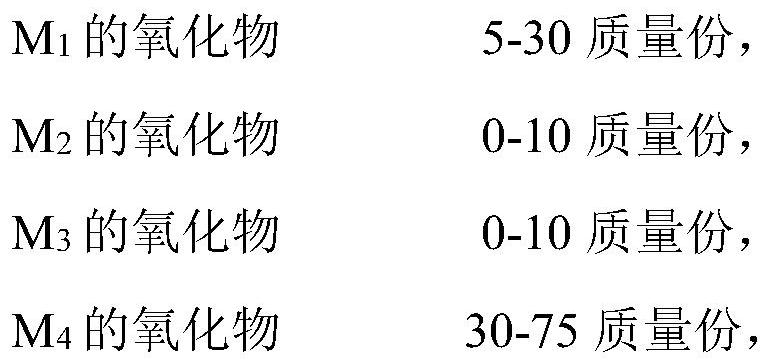

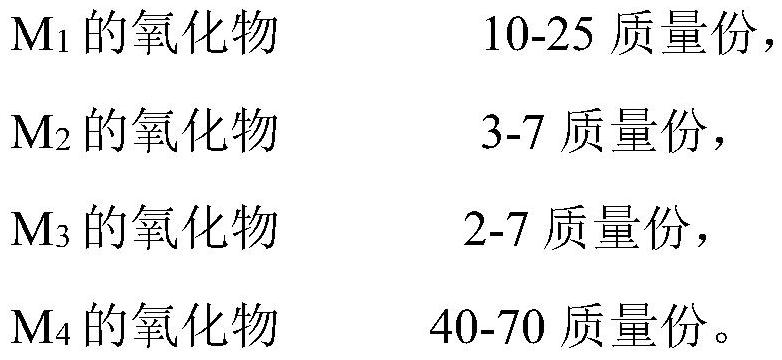

[0048] The mass percentage of oxides shown in the table below is used for feeding.

[0049] MoO 3

NiO Co 3 O 4

CeO 2

ZrO2 Al 2 O 3

15% 5% 5% 5% 21% 49%

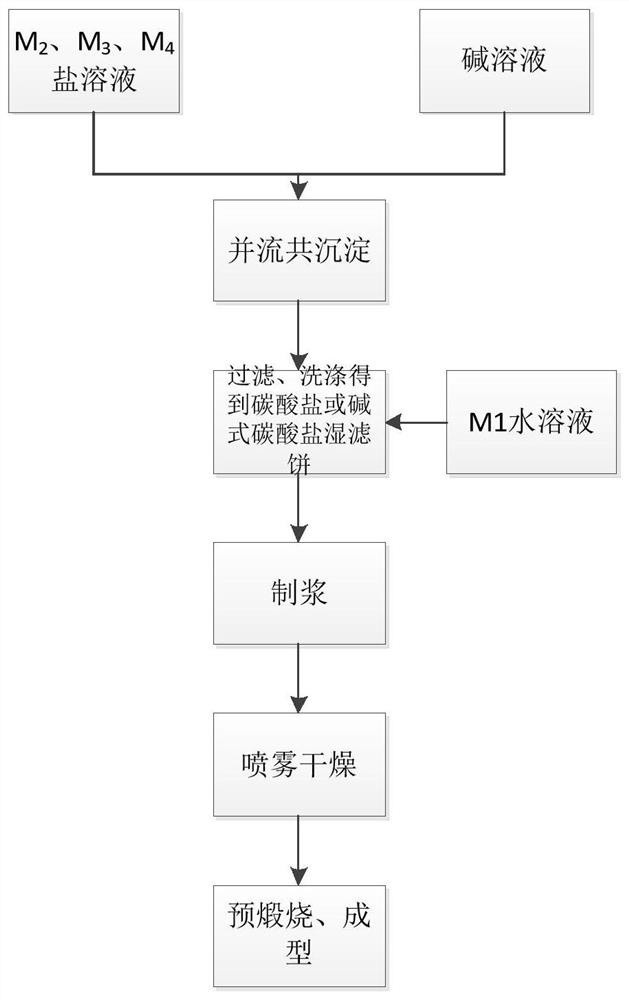

[0050] like figure 1 Process flow shown:

[0051] 1. Preparation of additives and carrier precursors by precipitation method: Weigh 38.9g of nickel nitrate hexahydrate, 25.2g of cerium nitrate hexahydrate, 36.2g of cobalt nitrate hexahydrate, 146.3g of zirconium nitrate pentahydrate, 721.12g of nonahydrate Dissolve aluminum nitrate in deionized water to prepare solution A with a metal ion concentration of 1.5 mol / L, weigh 720 g of anhydrous sodium carbonate, configure sodium carbonate solution B with a solubility of 1.5 mol / L, and mix both solutions A and B. The water bath was heated to 75℃, and then co-precipitated. The flow rates of the two solutions A and B were 51.1ml / min and 100.7ml / min, respectively. The pH value of the precipitation was 7.5-7.8. The precipitation t...

Embodiment 2

[0055] The mass percentage of oxides shown in the table below is used for feeding.

[0056] MoO 3

NiO Co 3 O 4

CeO 2

ZrO 2

Al 2 O 3

25% 3% 2% 3% 30% 37%

[0057] 1. Preparation of additives and carrier precursors by precipitation method: Weigh 23.4g of nickel nitrate hexahydrate, 15.1g of cerium nitrate hexahydrate, 14.5g of cobalt nitrate hexahydrate, 209.1g-, 544.5g of aluminum nitrate nonahydrate to dissolve Prepare solution A with a metal ion concentration of 1.5 mol / L in deionized water, weigh 605 g of anhydrous sodium carbonate, configure sodium carbonate solution B with a solubility of 1.5 mol / L, and heat both solutions A and B in a water bath to 65 ℃, then co-precipitate, the flow rates of A and B solutions are 49.7ml / min and 108.7ml / min respectively, the PH value of the precipitation is 8.0-8.3, the precipitation time is 35min, after the precipitation is completed, age at 65 ℃ for 2h, filter, The resulting prec...

Embodiment 3

[0061] The mass percentage of oxides shown in the table below is used for feeding.

[0062] MoO 3

WO 3

NiO Co 3 O 4

ZrO 2

Al 2 O 3

15% 8% 3% 2% 20% 52%

[0063] 1. Preparation of additives and carrier precursors by precipitation method: Weigh 23.4g of nickel nitrate hexahydrate, 139.4g of zirconium nitrate pentahydrate, 14.5g of cobalt nitrate hexahydrate, and 765g of aluminum nitrate nonahydrate and dissolve them in deionized water. Solution A with a metal ion concentration of 1.5 mol / L, weigh 737 g of anhydrous sodium carbonate, configure sodium carbonate solution B with a solubility of 1.5 mol / L, heat both solutions A and B in a water bath to 65 ° C, and then mix Flow co-precipitation, the flow rates of the two solutions A and B are 51.5ml / min and 92.76ml / min respectively, the pH value of the precipitation is 8.5-8.7, the precipitation time is 50min, after the precipitation is completed, age at 80 °C for 2h, filter and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com