Method for producing biodiesel by adopting microchannel reactor

A technology of microchannel reactor and biodiesel, which is applied in the fields of biofuel, petroleum industry, liquid carbon-containing fuel, etc., can solve the problem of producing biodiesel by transesterification that has not yet been seen, and achieves avoiding severe corrosion of equipment, excellent corrosion resistance, The effect of improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

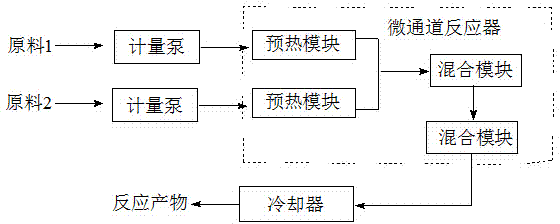

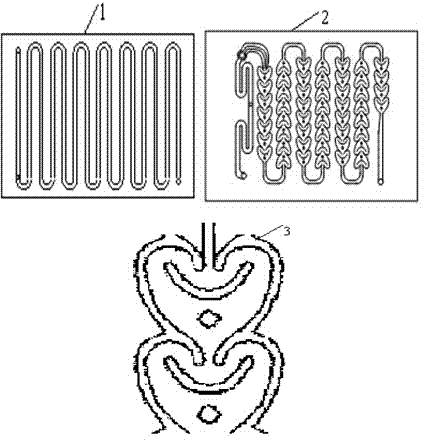

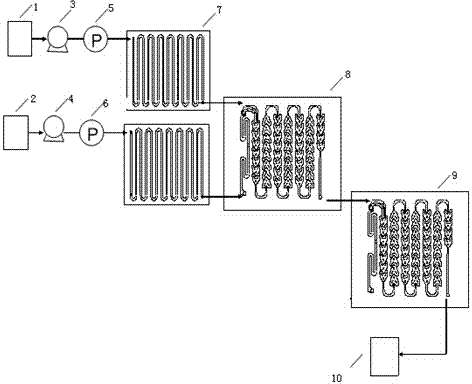

[0038] (1) Device used: high-throughput microchannel reactor (straight channel module + heart-shaped channel module), refer to image 3 Determine the connection mode of the microchannel reactor, the number of mixed reaction modules is determined according to the flow rate and reaction residence time, and the heat transfer medium is heat transfer oil.

[0039] (2) Raw material tanks 1 and 2 are equipped with waste oil and methanol solution (the amount of sodium hydroxide for catalysis is 1% of the weight of waste oil). Set the flow control of each metering pump 3 and pump 4 to change the molar ratio of waste oil:methanol solution=1:4, control the flow rate of waste oil: 1mL / min, control the flow rate of methanol solution: 10mL / min, and inject the materials into each straight-through In the channel preheating module, the reaction temperature is controlled to be 50°C and the pressure is 0.1MPa; the waste oil and methanol solution are pumped into the heart-shaped mixing module 8 o...

Embodiment 2

[0042] (1) Device used: high-throughput microchannel reactor (straight channel module + heart-shaped channel module), refer to image 3 Determine the connection mode of the microchannel reactor, the number of mixed reaction modules is determined according to the flow rate and reaction residence time, and the heat transfer medium is heat transfer oil.

[0043] (2) Raw material tanks 1 and 2 are equipped with waste oil and methanol solution (the amount of calcium hydroxide for catalysis is 1.5% of the weight of waste oil). Set the flow control of each metering pump 3 and pump 4 to change the molar ratio of waste oil:methanol solution=1:5, control the flow rate of waste oil: 2mL / min, control the flow rate of methanol solution: 10mL / min, and inject the materials into each straight-through In the channel preheating module, the reaction temperature is controlled to be 55°C and the pressure is 0.2MPa; the waste oil and methanol solution are pumped into the heart-shaped mixing module ...

Embodiment 3

[0046] (1) Device used: high-throughput microchannel reactor (straight channel module + heart-shaped channel module), refer to image 3 Determine the connection mode of the microchannel reactor, the number of mixed reaction modules is determined according to the flow rate and reaction residence time, and the heat transfer medium is heat transfer oil.

[0047] (2) Raw material tanks 1 and 2 are equipped with waste oil and methanol solution (the amount of potassium hydroxide for catalysis is 1.5% of the weight of waste oil). Set the flow control of each metering pump 3 and pump 4 to change the molar ratio of waste oil:methanol solution=1:6, control the flow rate of waste oil: 3mL / min, control the flow rate of methanol solution: 12mL / min, and inject the materials into each straight-through In the channel preheating module, the reaction temperature is controlled to be 60°C and the pressure is 0.4MPa; the waste oil and methanol solution are pumped into the heart-shaped mixing modul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com