Automatic tea making machine

A tea making machine, automatic technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of difficult cleaning, difficult automation and intelligence, difficult to accurately put tea leaves, etc., to improve taste and quality, and make tea easy to brew. Convenience, taste and good quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

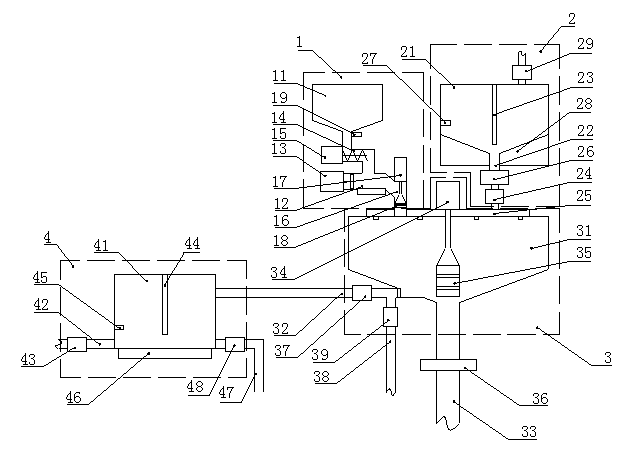

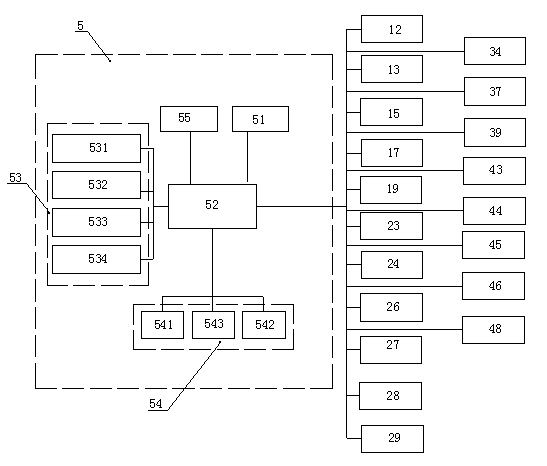

[0035] Embodiment 1: see figure 1 , figure 2, an automatic tea making machine, comprising a control system, a tea supply system, a water supply system and a tea making system, the control system being electrically connected with the tea supply system, the water supply system and the tea making system respectively; the tea supply system comprising a tea The water supply system includes a first water container, the tea making system includes a second water container, the tea pot is located above the second water container, the bottom of the tea pot has a tea outlet, and the tea outlet passes through a The tea delivery pipeline is connected with the second water container, and a can lid capable of opening the tea can is arranged on the top of the tea can, so that tea can be added into the tea can. During implementation, the first water storage container is also located above the second water storage container, and the bottom of the first water storage container has a water outl...

Embodiment 2

[0049] Example 2, see image 3 , Figure 4 , different from Embodiment 1, it also includes a tea storage system, the tea storage system includes a third water container, the third water container is connected with a tea outlet pipe, and a second tea outlet pipe is provided Solenoid valve for tea water; a second liquid level sensor and a second temperature sensor are arranged in the third water container, and a second heating module is arranged at the bottom of the third water container; the third water container is also connected to the residual water drainage A third tea solenoid valve is arranged on the residual water drain pipe; the tea indicator light is used to display the amount of tea in the third water container. Since the tea leaves are soaked in water for a long time, the taste and quality of the differential will also be affected. Therefore, storing the brewed tea through the tea storage system can better ensure the taste and quality of the tea.

[0050] After the...

Embodiment 3

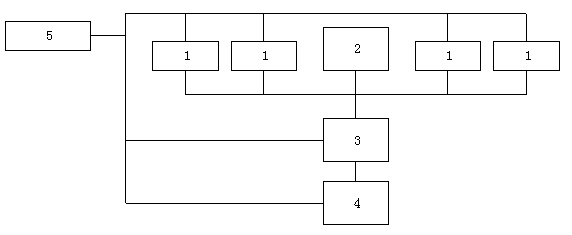

[0054] Example 3, see Figure 5 , Different from Embodiments 1 and 2, the tea supply system is multiple sets. It can store a variety of tea leaves, so that people can choose tea leaves to make tea according to their preferences.

[0055]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com