Method for continuously synthesizing paratoluensulfonyl chloride by using microchannel reactor

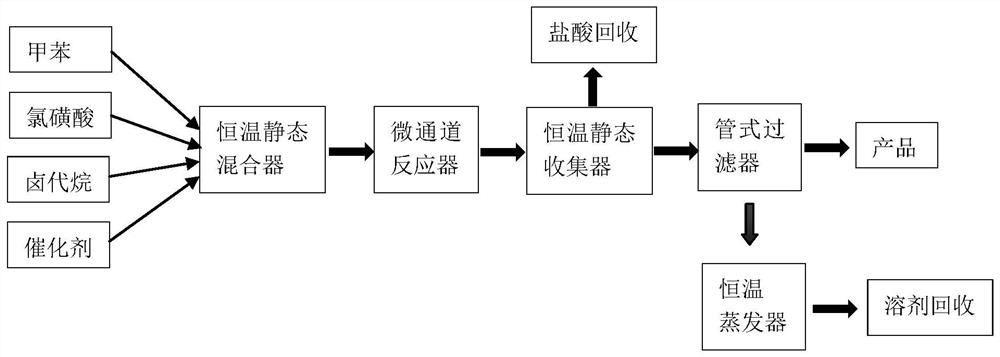

A technology of microchannel reactor and p-toluenesulfonyl chloride, which is applied in chemical instruments and methods, chemical/physical/physicochemical reactors, sulfonic acid preparation, etc., can solve the problem of high raw material cost of thionyl chloride, difficult removal of phosphoric acid, Affect product quality and other issues, to achieve the effect of easy automatic production, increase product yield, and curb side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Embodiment 1, utilize the method for continuously synthesizing p-toluenesulfonyl chloride in microchannel reactor:

[0059] The feed list is shown in Table 1 below; the feed amount refers to the amount of raw materials entering the static mixer.

[0060] Table 1

[0061] name molecular weight moles Feed amount (g) toluene 92.14 1 92.14 Chlorosulfonic acid (calculated by 100%) 116.52 2.01 234.21 1,2-Dichloroethane 98.96 15 1484.40 Tetraethylammonium chloride 165.7 0.05 8.29

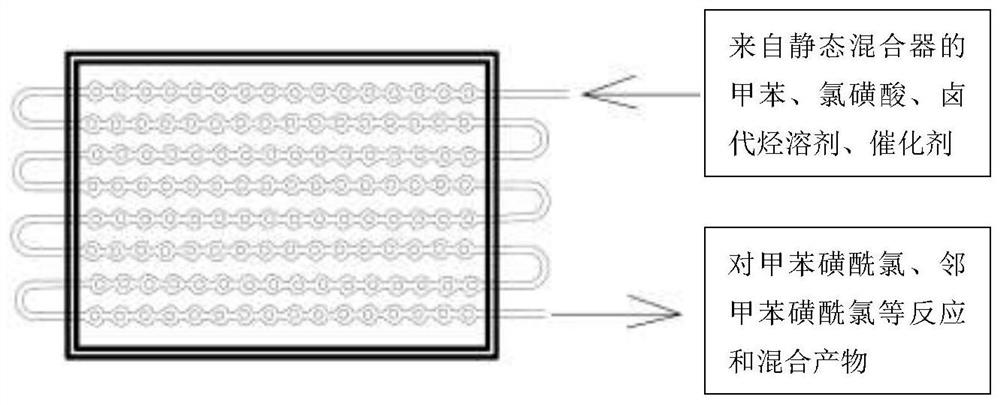

[0062] Send toluene, chlorosulfonic acid, dichloroethane and tetraethylammonium chloride into the constant temperature static mixer with a metering pump at a molar ratio of 1:2.01:15:0.05, and control the temperature of the materials in the constant temperature static mixer Not higher than -5°C (generally -10°C ~ -5°C), the material flowing out from the outlet of the constant temperature static mixer is injected into the microchannel reactor at 1....

Embodiment 2

[0064] The feed list is as shown in Table 2.

[0065] Table 2

[0066] name molecular weight moles Quantity (grams) toluene 92.14 1 92.14 Chlorosulfonic acid (calculated by 100%) 116.52 2.01 234.21 Dichloromethane 84.93 15 1273.95 Piperazine 86.14 0.1 8.61

[0067] The flow rate of the material is 1ml / min, injected into the microchannel reactor, and the temperature of the material in the microchannel reactor is precisely controlled at 60±0.2°C, and the retention time of the material in the reactor is about 26 minutes. The constant temperature static collector controls the temperature 10±0.2°C. The rest are equal to Example 1.

[0068] The result is:

[0069] The filter cake is the crude product of p-toluenesulfonyl chloride. According to capillary gas chromatography analysis, the purity of p-toluenesulfonyl chloride is 98.28%, and the yield is 94.66%. The purity of o-toluenesulfonyl chloride recovered from the filtrate wa...

Embodiment 3

[0071] Feeding table is as follows Table 3.

[0072] table 3

[0073] name molecular weight moles Quantity (grams) toluene 92.14 1 92.14 Chlorosulfonic acid (calculated by 100%) 116.52 2.01 234.21 Dichloromethane 84.93 15 1273.95 Triethylamine 101.19 0.05 5.06

[0074] The flow rate of the material is 1.2ml / min; the channel diameter of the microchannel reactor is about 500 microns, and the length is about 15000mm. The temperature of the material in the microchannel reactor is precisely controlled at 60±0.2°C. The time is about 21 minutes, and the constant temperature static collector controls the temperature at 10±0.2°C. The rest are equal to Example 1.

[0075] The result is:

[0076] The filter cake is crude p-toluenesulfonyl chloride, and analyzed by capillary gas chromatography: the crude p-toluenesulfonyl chloride has a purity of 97.99% and a yield of 90.55%. The purity of o-toluenesulfonyl chloride recovered from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com