Pilot plant and process for preparing acrylic acid through propylene oxidation with tail gas circulation

A technology of propylene oxidation and acrylic acid, which is applied in the preparation of organic compounds, organic chemistry, carbon-based compounds, etc., can solve the problems of difficult to control the amount of exhaust gas circulation, complex exhaust gas composition, difficult to control flow, etc., to avoid changes in exhaust gas composition, The effect of real catalyst performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

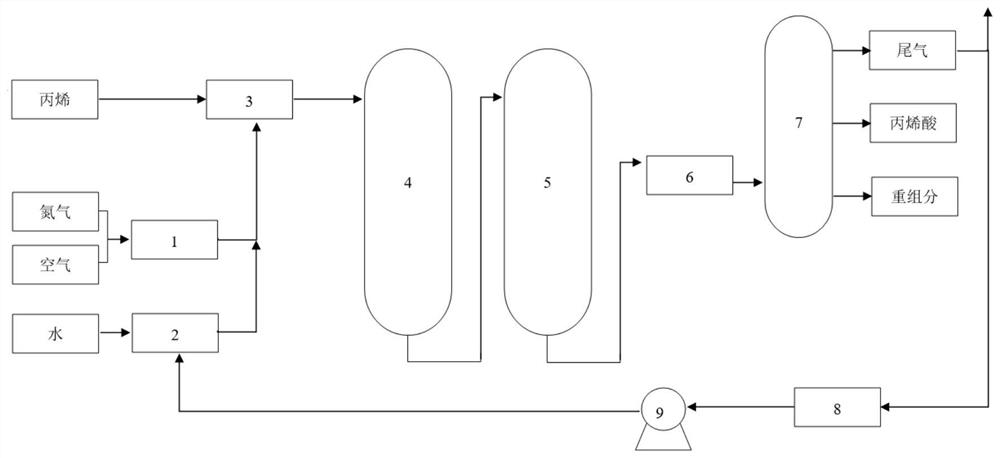

[0044] Such as figure 1 The shown pilot plant for producing acrylic acid by propylene oxidation includes: feed unit, reaction unit, separation unit and tail gas treatment unit. The units are connected by pipelines.

[0045] Among them, the feed unit is composed of propylene feed and flow control system, air feed and flow control system, preheater 1, water feed and flow control system, vaporizer 2, and mixer 3;

[0046] The propylene feed and flow control system, the air feed and flow control system, and the water feed and flow control system are in parallel relationship. The propylene feed and flow control system is connected to the mixer 3, the air feed and flow control system is connected to the preheater 1, the water feed and flow control system is connected to the vaporizer 2, and the materials from the preheater and the vaporizer The water vapor that comes out enters the mixer 3 and mixes with propylene.

[0047] The reaction unit includes a trans-acrylaldehyde reactor...

Embodiment 2

[0060] The difference between the propylene oxidation and acrylic acid pilot plant and Example 1 is that the feed unit consists of propylene feed and flow control system, nitrogen and air feed and flow control and preheater, water and flow control and vaporizer, and mixing device composition. The catalyst loading is 2.5L. All the other are identical with embodiment 1.

[0061] After setting the reaction temperature and pressure according to the reaction requirements, the feed of propylene, nitrogen, air and water vapor is started, and all the tail gas enters the exhaust system at this time. When the propylene feed is gradually increased from the set load of 10% to 50%, 90% of the tail gas is vented, and 10% of the tail gas is dried and mixed with steam feed to enter the reactor. Then gradually increase the propylene feed to 100% load, and the propylene oxidation reaction starts to proceed stably.

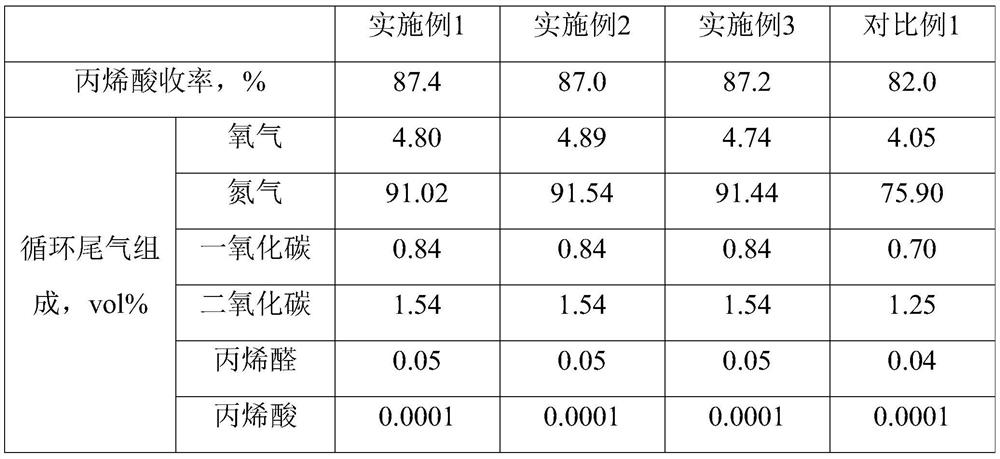

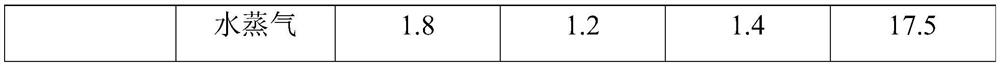

[0062] After the reaction was stable, the yield of acrylic acid and the comp...

Embodiment 3

[0064] The pilot plant of this embodiment is the same as that of Embodiment 1. The catalyst loading is 3.5L.

[0065] After setting the reaction temperature and pressure according to the reaction requirements, the feed of propylene, air and water vapor is started, and all the tail gas enters the exhaust system at this time. When the propylene feed is gradually increased from the set load of 10% to 60%, 50% of the tail gas is vented, and 50% of the tail gas is dried and mixed with steam feed to enter the reactor. Then gradually increase the propylene feed to 100% load, and the propylene oxidation reaction starts to proceed stably.

[0066] After the reaction was stable, the yield of acrylic acid and the composition of the circulating tail gas were analyzed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com