Vibration screening mechanism and early warning device for vibrating screen mesh rupture

An early warning device and vibrating screening technology, which is applied in the direction of filter screen, alarm, solid separation, etc., can solve the problems of loss, heavy workload, large friction between screen and sand, etc., so as to improve product quality and facilitate maintenance and replacement , easy to install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

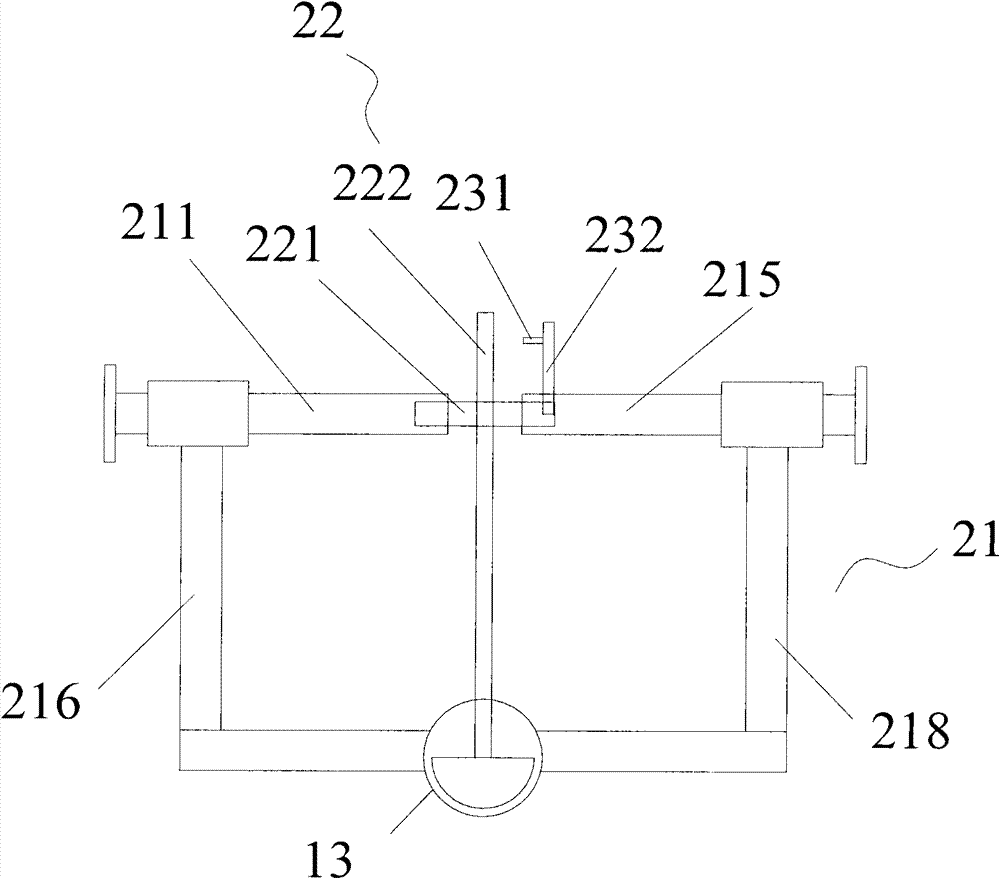

[0025] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

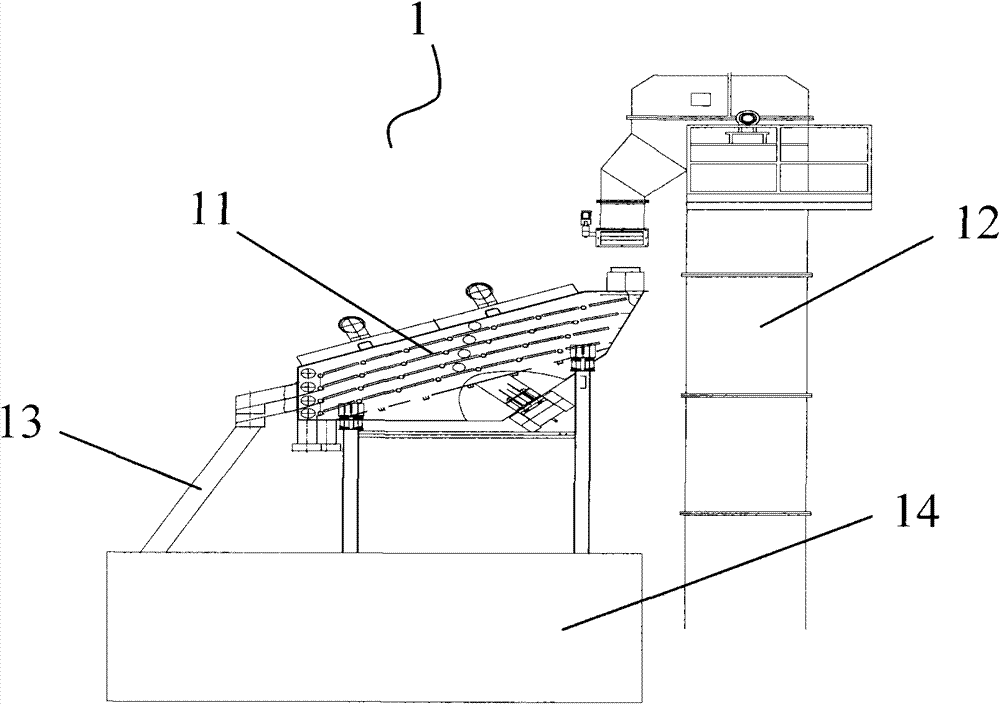

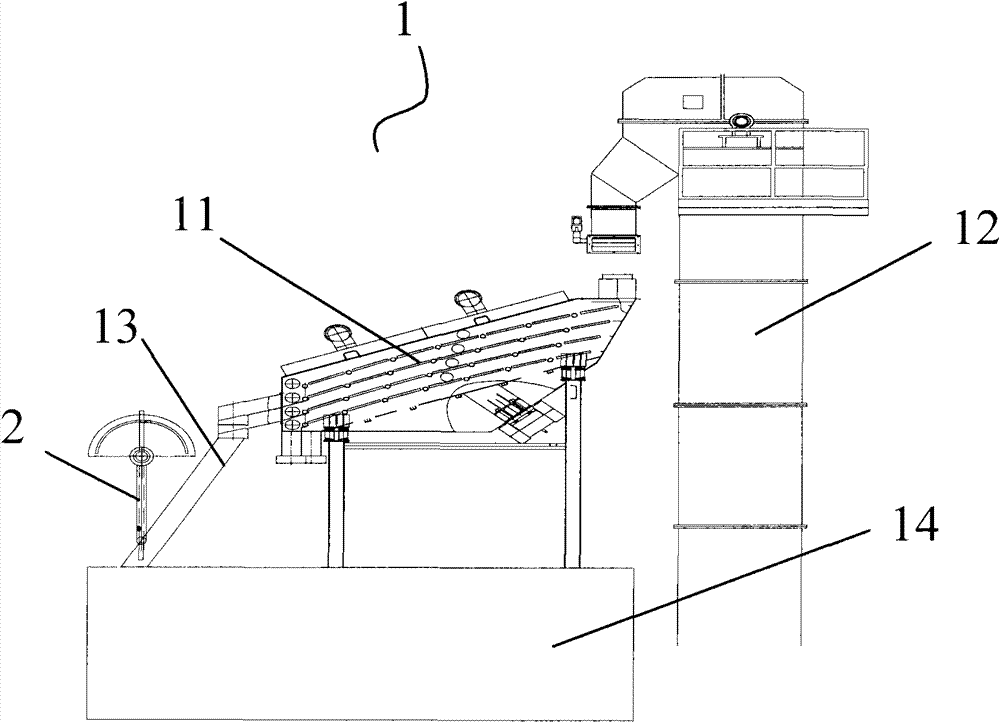

[0026] Such as figure 2 Shown is an embodiment of a vibrating screening mechanism 1 with an early warning device for vibrating screen breakage according to the present invention. In this embodiment, the vibrating screening mechanism 1 is used for screening sand and gravel, and may be any screening mechanism for solid materials in practice. As described in the background art, the vibrating screening mechanism 1 includes one or more vibrating screens 11 , a hoist 12 , one or more discharge conduits 13 and one or more bins 14 . Wherein, the vibrating screen 11 is positioned between the hoist 12 and the top of the feed bin 14, and is inclined; the discharge conduit 13 is connected to the outlet of the vibrating screen 11, and is inclined; the feed bin 14 is arranged under the discharge conduit 13, and its The inlet is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com