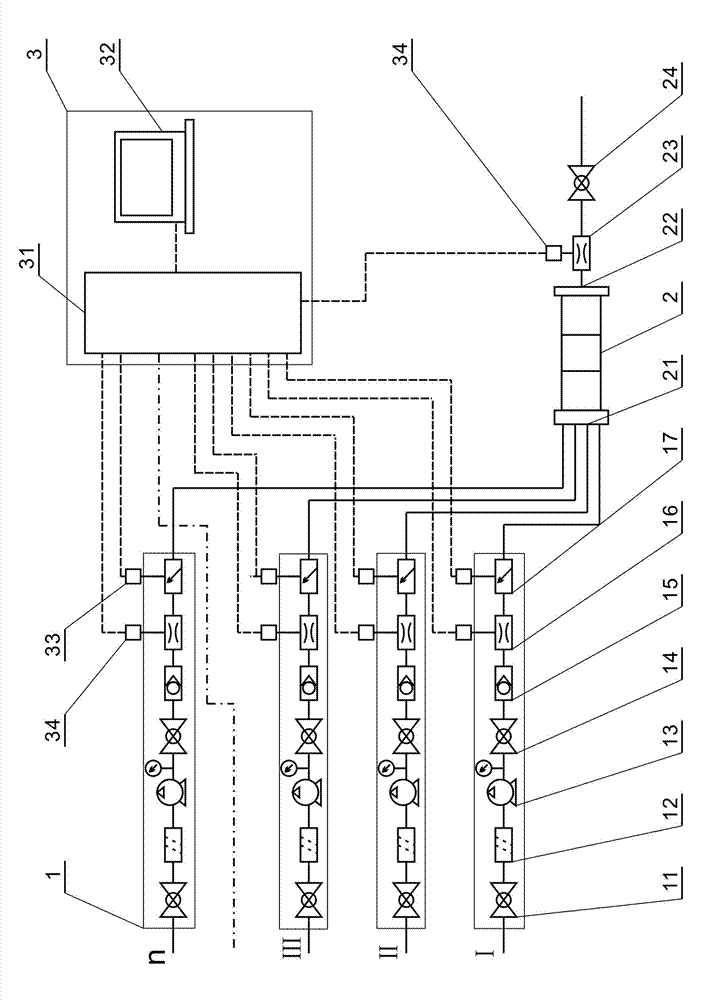

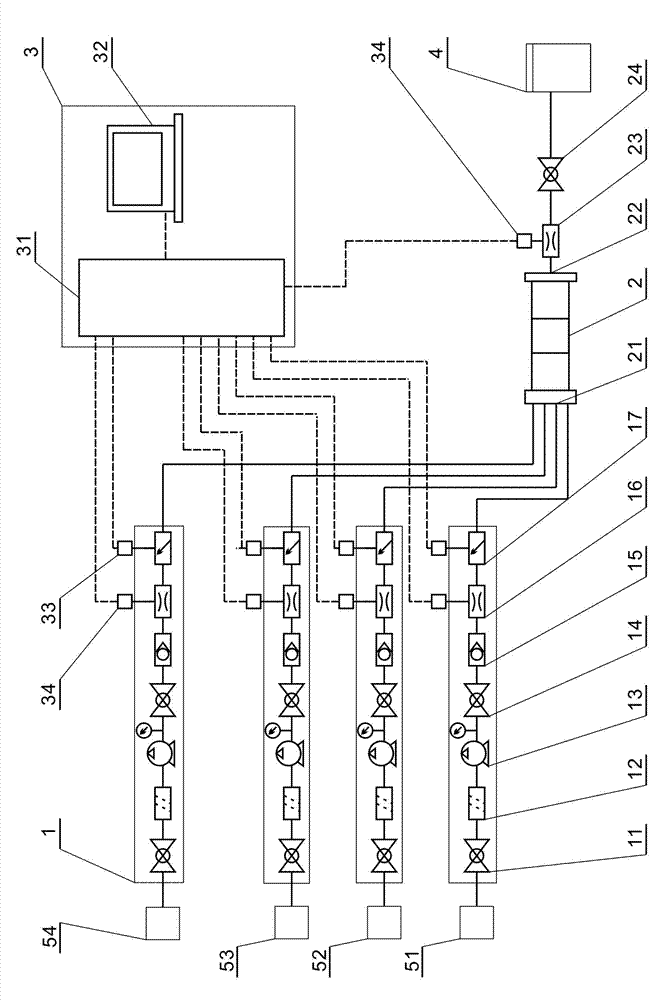

Multi-liquid continuous mixing device

A technology for mixing devices and liquids, which is applied to mixing operation control devices, clay preparation devices, mixing operation control, etc. The effect of stable production and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0012] Produce 5000kg water-reducer compound mixture according to certain formula; Load raw material liquid A (50% sodium gluconate aqueous solution of solid content) in storage tank 51, dress raw material liquid B (vivid800 polycarboxylate water-reducer mother liquor, in storage tank 52, 40% solid content), storage tank 53 is equipped with raw material solution C (vivid600L polycarboxylate superplasticizer mother liquor, 40% solid content), and storage tank 54 is equipped with raw material solution D (tap water).

[0013] First, input the ratio of the four raw material liquids required for the compound formula of concrete and the total finished product to be produced into the PLC system

[0014] Traffic ratio Finished target weight Raw material solution A 1000kg / hr / Raw material solution B 2000kg / hr / Raw material solution C 3000kg / hr / Raw material solution D 4000kg / hr / finished product / 5000kg

[0015] Secondly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com