Intelligent concrete mixer

A technology of concrete mixer and mixing motor, applied in cement mixing device, clay preparation device, batch storage and other directions, can solve the problems of concrete proportion deviation, inconsistent quantity, affecting project quality, etc., and achieve the effect of quality assurance and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

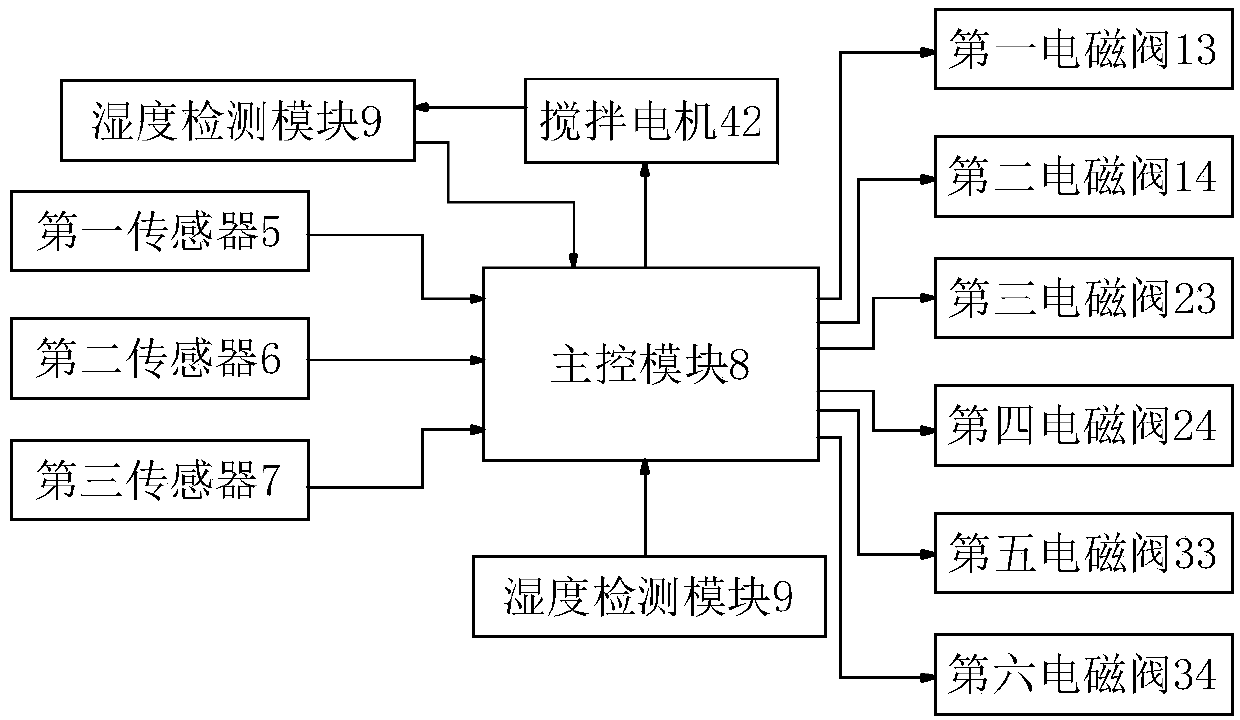

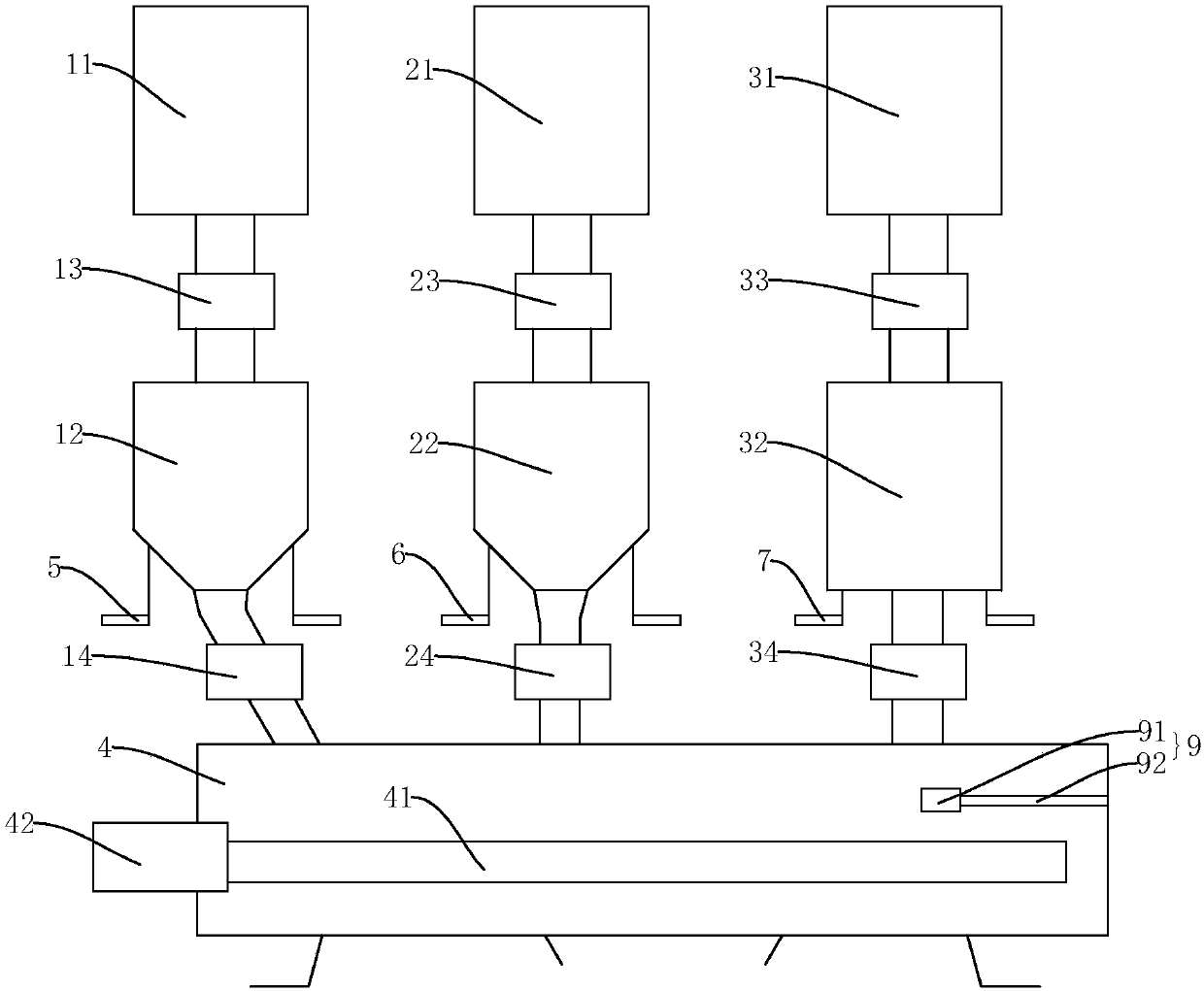

[0021] Such as figure 1 , figure 2 As shown, the intelligent concrete mixer of the present invention includes a cementitious material storage tank 11, an aggregate storage tank 21, and a water storage tank 31 to store the cementitious material, aggregate and water separately. The cementitious material here can be cement. The design also includes a cementitious material preloaded box 12, an aggregate preloaded box 22, a water preloaded box 32, and a mixing box 4, and the gelled material preloaded box 12 is connected to the cementitious material storage box 11 and the mixing box respectively through pipelines. 4 connected, the aggregate preload tank 22 communicates with the aggregate storage tank 21 and the mixing tank 4 through pipelines, and the water preload tank 32 communicates with the water storage tank 31 and the mixing tank 4 through pipelines;

[0022] The first weight sensor 5 used to detect the weight of the gelled material is arranged in the gelled material preload...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com