High-efficiency organic luminescent device and its production method

An organic light-emitting device, high-efficiency technology, used in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problem of difficult evaporation rate, difficult to optimize device performance, and difficult to control different batches of devices. To simplify the preparation process and ensure repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

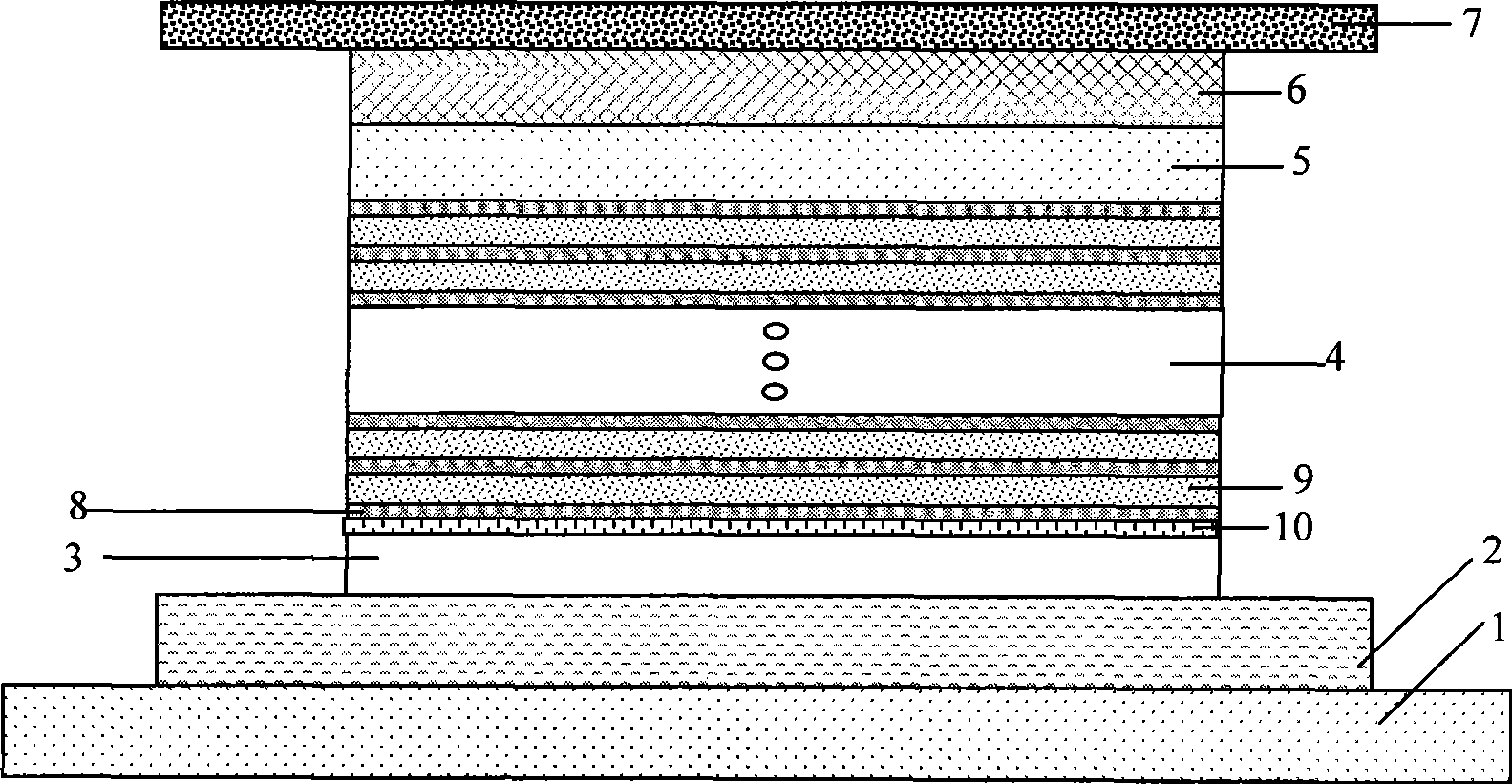

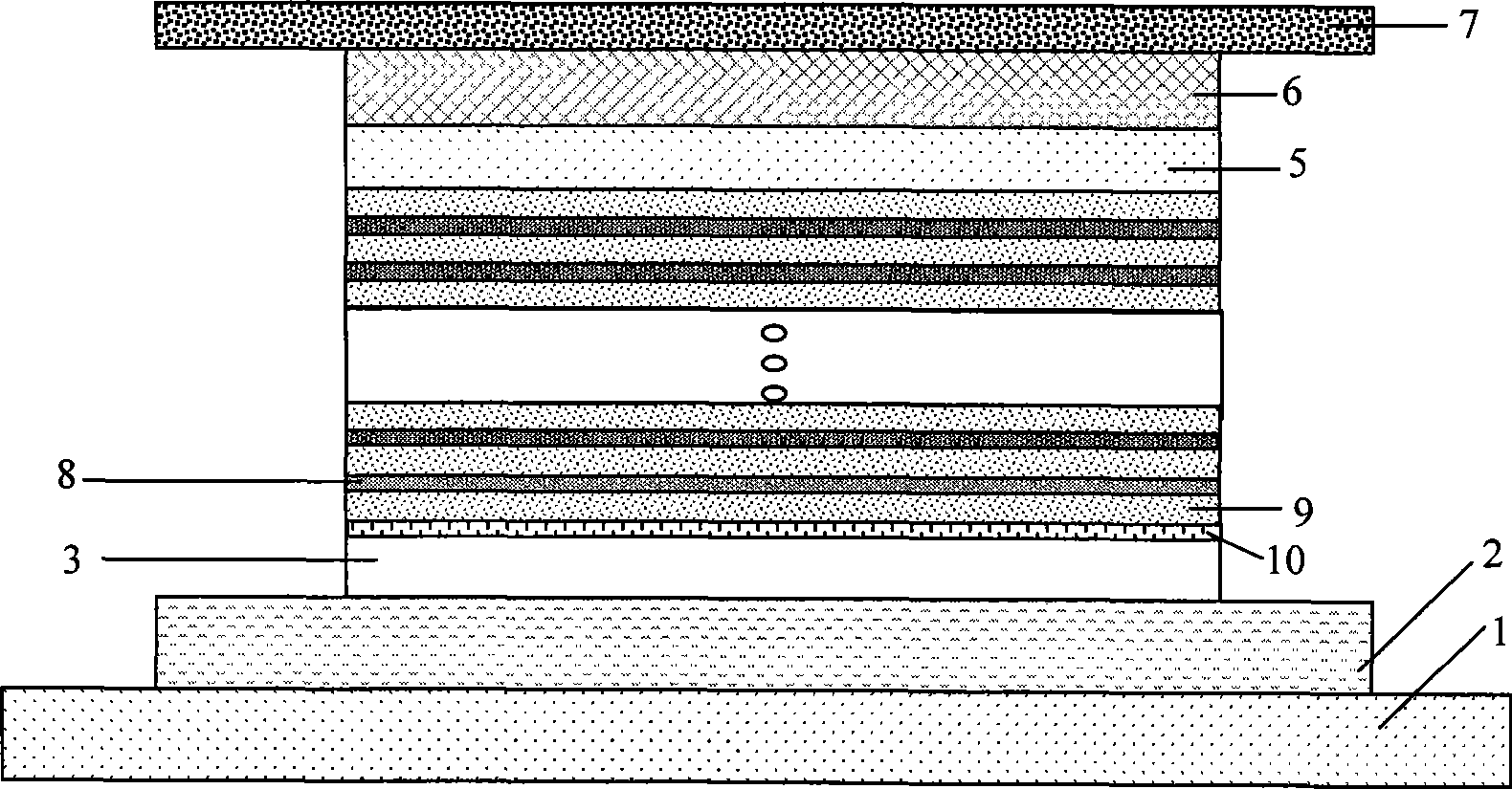

[0030] In the high-efficiency organic light-emitting device of the present invention, an anode electrode 2 is provided on a substrate 1, a hole transport layer 3 is provided on the anode electrode 2, and a periodic arrangement prepared by sequential evaporation is provided on the hole transport layer 3. A light-emitting layer (4) composed of a donor layer 8 and a doped layer 9; a hole-blocking layer 5 is provided on the light-emitting layer, an electron-transporting layer 6 is provided on the hole-blocking layer 5, and a cathode is provided on the electron-transporting layer 6 Electrode 7. Trans(phenylpyrazolyl)iridium was inserted between the hole transport layer 3 and the light emitting layer as an electron blocking layer.

[0031] The donor material and the doping material of the donor layer 8 and the doped layer 9 are small molecule organic materials.

[0032] The thickness of the doped layer is from 0.1nm to 5nm. The thickness of the donor layer is from 1 nm to 30 nm. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com