New process for preparing p-xylylene dichloride by adopting novel reaction equipment

A technology of para-dichlorobenzyl and reaction equipment, applied in the field of preparing para-dichlorobenzyl, can solve the problems of low single-pass yield of dichlorobenzyl, low content of dichlorobenzyl, low reaction selectivity, etc., so as to reduce the generation of by-products , reduce the reaction temperature, the effect of high initiation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

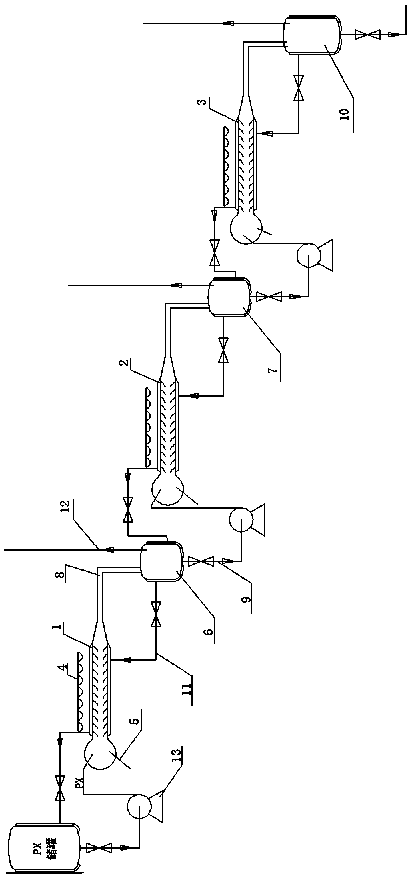

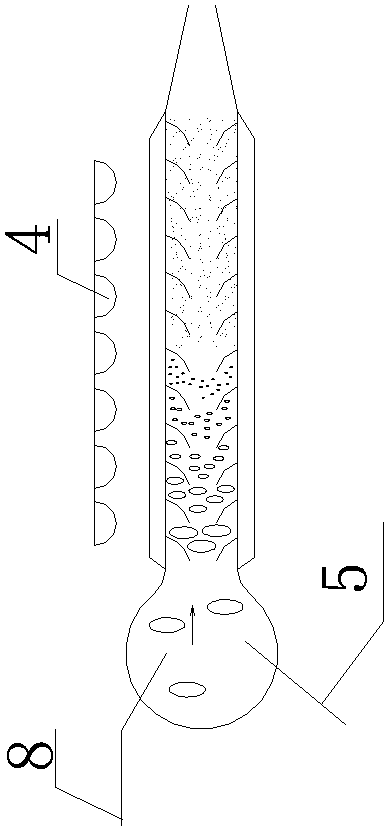

[0043] A novel reaction equipment for preparing p-dichlorobenzyl includes a reactor, a gas-liquid separator, a crystallizer, and an LED lamp;

[0044] The outside of the reactor is fixed with an LED lamp 4, and the reactor is sealed with a chlorine gas inlet pipe 5;

[0045] The reactors are divided into three groups, which are respectively a first-stage reactor 1, a second-stage reactor 2, and a third-stage reactor 3;

[0046] The gas-liquid separator is divided into two groups, which are gas-liquid separator one 6 and gas-liquid separator two 7;

[0047] The gas-liquid separator one 6 is arranged between the first-stage reactor 1 and the second-stage reactor 2, and the first-stage reactor 1 is sealed and connected through the material pipeline 8, and the second-stage reactor 2 is sealed through the reaction liquid pipeline 9; The gas-liquid separator 2 7 is arranged between the second-stage reactor 2 and the third-stage reactor 3, and is sealed and connected to the second-s...

Embodiment 2

[0059] A total of 1000G p-xylene and 1210G chlorine gas are continuously pumped into the chlorinator with a high-pressure pump, and the reaction is initiated by an LED lamp. After a period of chlorine reaction, the material enters the gas-liquid separator to complete the reaction liquid and the hydrogen chloride gas generated by the reaction. After the gas-liquid separation, a reaction solution and chlorine gas are passed into the second-stage reactor, so that chlorine is divided into three sections, and the final reaction solution is sampled and tested (Table 1). The conversion rate of p-xylene is 97.75%, and p-dichlorobenzyl And the total selectivity to benzyl chloride is 99.01%, wherein the content of benzyl chloride is 74.65%. The third section of chlorinated material enters the crystallizer, and after gas-liquid separation and crystallization, the final product is obtained by filtration and separation, and the product content reaches 99.62%.

Embodiment 3

[0061] A total of 1000G p-xylene and 1170G chlorine gas are continuously pumped into the chlorinator with a high-pressure pump, and the reaction is initiated by an LED lamp. After a period of chlorine reaction, the material enters the gas-liquid separator to complete the reaction liquid and the hydrogen chloride gas produced by the reaction. After the gas-liquid separation, a reaction solution and chlorine gas are passed into the second-stage reactor, so that chlorine is divided into three sections, and the final reaction solution is sampled and tested (Table 1). The conversion rate of p-xylene is 96.49%, and p-dichlorobenzyl And the total selectivity to benzyl chloride is 99.09%, wherein the content of benzyl chloride is 70.04%. The third stage of chlorinated material enters the crystallizer, and after gas-liquid separation and crystallization, the final product is obtained by filtration and separation, and the product content reaches 99.59%.

[0062] Substance name ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com