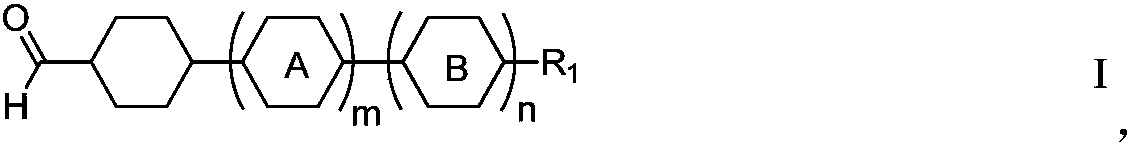

Preparation method of high-purity double-bond liquid crystal monomer

A liquid crystal monomer, high-purity technology, applied in the direction of liquid crystal materials, chemical instruments and methods, etc., can solve the problems of material waste, insufficient reaction, excessive raw materials, etc., achieve high product purity, reduce by-product formation, and reduce waste liquid The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

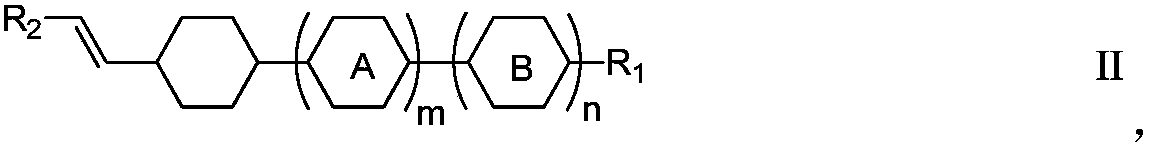

Method used

Image

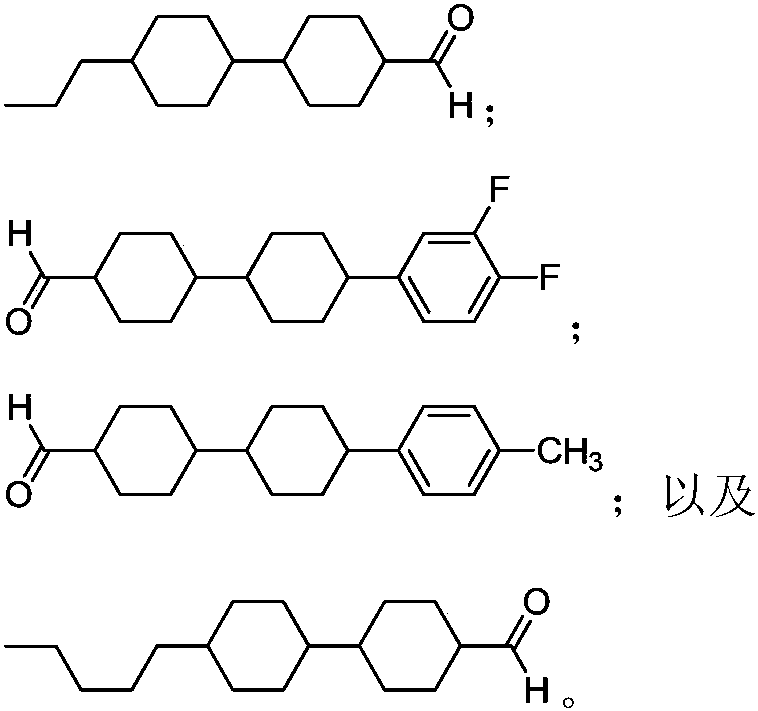

Examples

Embodiment 1

[0032]

[0033] (1) Weigh 236g of a1 in a container, add tetrahydrofuran to dissolve, and determine the final volume as 500mL.

[0034] (2) Add 358g of methyltriphenylphosphine bromide and an appropriate amount of tetrahydrofuran into a 2L glass reactor, under nitrogen protection, add 109.8g of potassium tert-butoxide at 0-5°C under stirring, and stir for 0.5h after the addition, the final volume It is 500mL, and the ylide reagent is prepared under nitrogen protection.

[0035] (3) Two groups of metering pumps are pumped into the microreactor respectively, the flow rate is 0.02mL / min, preheated by the preheating module, and then enter the mixing module for reaction, after mixing and reacting in the mixing module, continue After entering a series of reaction modules, after the reaction is completed, the product flows out from the outlet of the reactor, and then processed after cooling. During the reaction process, the reaction residence time in the microreactor is 90s, and ...

Embodiment 2

[0038]

[0039] (1) Weigh 236kg of a1 in a container, add tetrahydrofuran to dissolve, and determine the final volume as 500L.

[0040] (2) Add 372 kg of ethyltriphenylphosphine bromide and an appropriate amount of tetrahydrofuran into a 1000L tank reactor, under nitrogen protection, add 110 kg of potassium tert-butoxide at 0-5°C under stirring, and stir for 0.5 hours after the addition, the final volume It is 500L, and the ylide reagent is prepared under nitrogen protection.

[0041] (3) Two sets of metering pumps are pumped into the microreactor respectively, and the flow rate is 30L / min. After preheating through the preheating module, it enters the mixing module for reaction. After mixing and reacting in the mixing module, continue to enter the A series of reaction modules, after the reaction is completed, the product flows out from the outlet of the reactor, and then processed after cooling. During the reaction process, the reaction residence time in the microreactor i...

Embodiment 3

[0044]

[0045] (1) Weigh 306g of a3 in a container, add tetrahydrofuran to dissolve, and determine the final volume to be 500mL.

[0046] (2) Add 358g of methyl triphenylphosphine bromide and an appropriate amount of tetrahydrofuran into a 2L glass reactor, under nitrogen protection, add 109.8g of potassium tert-butoxide at 0-5°C under stirring, stir for 0.5h after the addition, and the final volume It is 500mL, and the ylide reagent is prepared under nitrogen protection.

[0047] (3) Two groups of metering pumps are pumped into the microreactor respectively, and the flow rate is 0.04mL / min, which is preheated through the preheating module, and then enters the mixing module for reaction. After mixing and reacting in the mixing module, continue to After a series of reaction modules, after the reaction is completed, the product flows out from the outlet of the reactor, and then processed after cooling. During the reaction process, the reaction residence time in the microrea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mp | aaaaa | aaaaa |

| Mp | aaaaa | aaaaa |

| Mp | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com