Oil and cutting fluid separation device of cutting fluid purifier

A technology of oil-liquid separation and cutting fluid, which is applied in the fields of chemistry, metal processing machinery parts, maintenance and safety accessories, etc. It can solve the problems of shortening the service life, accelerating the aging and deterioration of cutting fluid, reducing the performance of cutting fluid, etc., and prolonging the use Life expectancy, reduction of pollution and waste discharge, and the effect of reducing enterprise costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

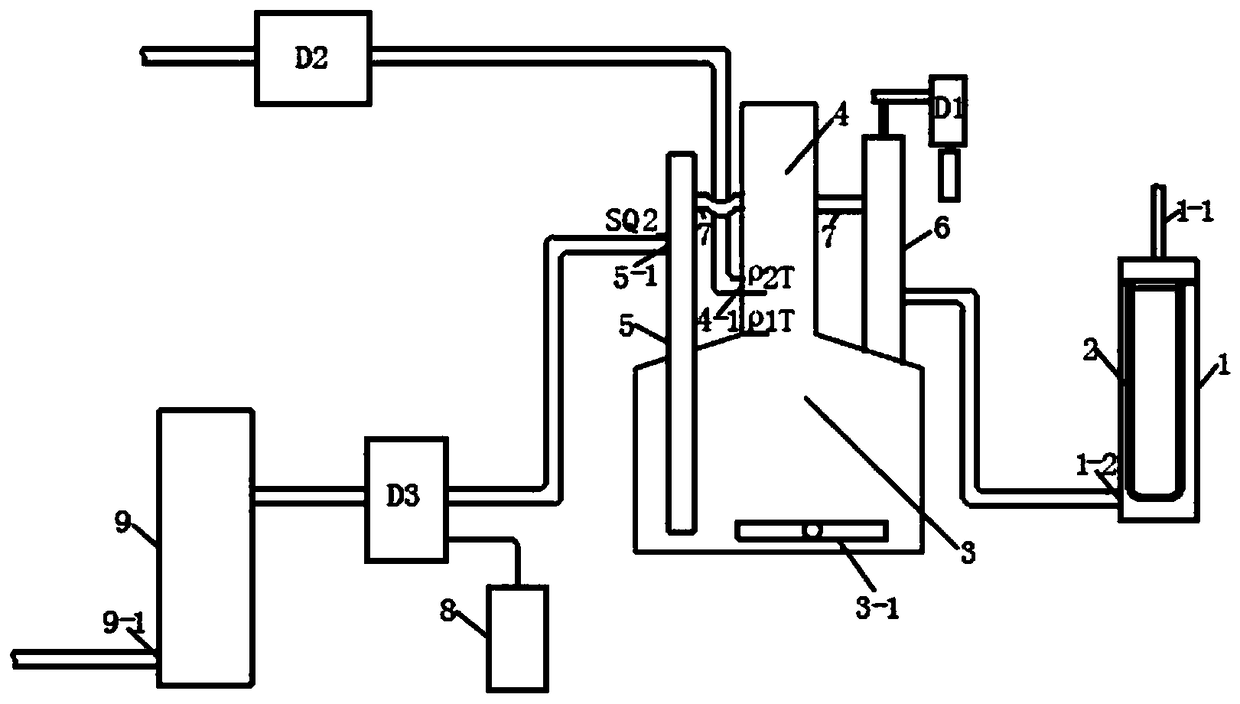

[0022] Depend on figure 1 As can be seen from the shown embodiment, the present embodiment includes a filter device, an oil-liquid separation device and an ozone sterilizing treatment device, the filter device includes a filter container 1, the upper end of the filter container 1 is provided with a liquid inlet 1-1, and the lower end of the filter container 1 There is a liquid discharge port 1-2, and a filter screen 2 is provided between the filter container 1 and the liquid discharge port 1-2. The oil-liquid separation device includes a sedimentation chamber 3, a waste oil collection chamber 4, a negative pressure generating device and a cutting fluid The separation pipe 5, the negative pressure generating device includes a negative pressure pump D1 and a negative pressure pipe 6 connected with the negative pressure pump D1 to genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com