Separation device and separation method for multi-specific-gravity-concentration sodium sulfate and magnesium sulfate mixed salt solution

A separation method and mixed salt technology, which is applied to the purification of alkali metal sulfite/sulfate, magnesium sulfate, magnesium carbonate, etc., can solve the problems of low recovery rate of elemental salt and waste of energy, and achieve comprehensive utilization and waste reduction. The effect of liquid discharge and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

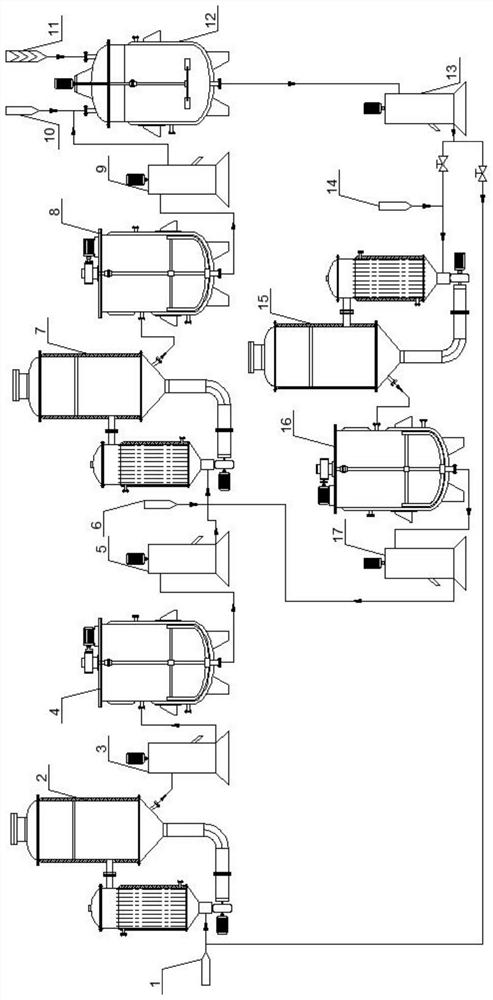

Image

Examples

Embodiment 1

[0041] The present embodiment separates the mixed salt solution L1 of W1 / W2=5 and the mixed salt solution L2 of W1 / W2=0.1, wherein the mixed salt solution L1 is 1000g, W1=8%, W2=1.6%; the mixed salt solution L2 is 1000g, W1=1%, W2=10%.

[0042] Mixed salt solution L1 W1 / W2=5>2.75, L1 is sent to the first forced circulation evaporator to be concentrated by vacuum evaporation at 75°C, and isothermally evaporated to the elemental crystallization area of sodium sulfate, and sodium sulfate crystals are precipitated until sulfuric acid in the liquid phase Sodium concentration is 380g / L, stop evaporating, now sodium sulfate crystallization amount reaches maximum, through the centrifugal separation of first centrifuge, obtain sodium sulfate crystal 36g after oven dry, mother liquor A1175.8g, mother liquor A1 W1=25%, W2= 9.1%, mother liquor A1 enters the first tank type cooling crystallizer and cools to 0°C for cooling and crystallization. After equilibrium, it is centrifuged and sep...

Embodiment 2

[0045] This embodiment separates W1 / W2=5 mixed salt solution L1, W1 / W2=1.5 mixed salt solution L2 and W1 / W2=0.3 mixed salt solution L3, wherein mixed salt solution L1 is 1000g, W1=10%, W2 =2%; mixed salt solution L2 is 1000g, W1=6%, W2=4%; mixed salt solution L3 is 1000g, W1=2.4%, W2=8%.

[0046] Mixed salt solution L1 W1 / W2=5>2.75, L1 is sent to the first forced circulation evaporator to be concentrated by vacuum evaporation at 75°C, and isothermally evaporated to the elemental crystallization area of sodium sulfate, and sodium sulfate crystals are precipitated until sulfuric acid in the liquid phase Sodium concentration is 380g / L, stops evaporation, and this moment sodium sulfate crystallization amount reaches maximum, through the centrifugal separation of first centrifuge, obtains sodium sulfate crystal 45g after oven dry, mother liquor A1219.8g, mother liquor A1 W1=25%, W2= 9.1%, mother liquor A1 enters the first tank type cooling crystallizer and is cooled to 0 ℃ for co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com