Device for preparing low carbon olefins from oxygen-containing compound by conversion

A technology for low-carbon olefins and production equipment, which is applied to the production of hydrocarbons from oxygen-containing organic compounds, ethylene production, and hydrocarbon cracking to produce hydrocarbons, etc. , the effect of increasing the selectivity and reducing the cost of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

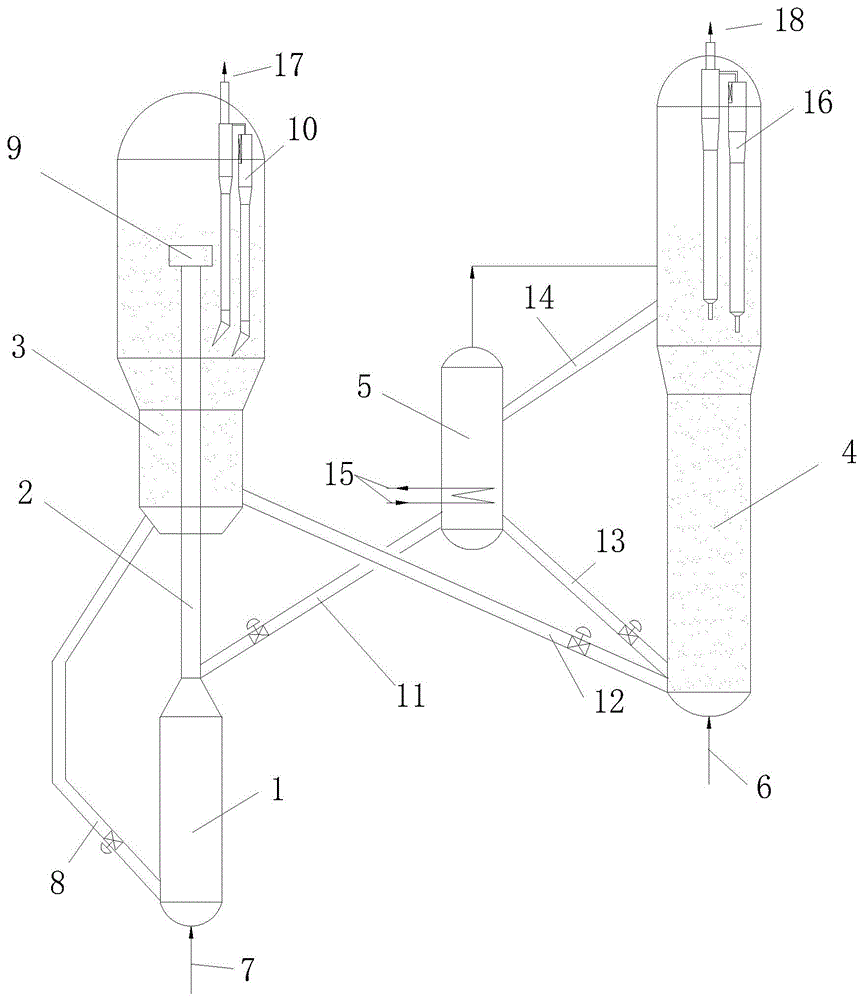

[0019] in such as figure 1 In the production device shown, the diameter ratio of the fluidized bed reactor zone I and the fluidized bed reactor II zone is 2.0:1, and the height ratio is 1:1; the inlet of the catalyst circulation inclined pipe and the fluidized bed reactor The vertical distance at the bottom of Zone I is 0.1 of the height of Zone I of the entire fluidized bed reactor; the vertical distance between Zone II of the fluidized bed reactor and the inclined pipe connection port of the regenerated catalyst at the bottom of Zone II of the fluidized bed reactor is The height of zone II of the entire fluidized bed reactor is 0.1; the cyclone separators in the settler and regenerator are both two-stage.

[0020] Reaction conditions: the average temperature of fluidized bed reactor zone I is 500°C, the average temperature of fluidized bed reactor zone II is 550°C, the pressure at the top of fluidized bed reactor zone II is 0.10MPa in gauge pressure, fluidized Pure methanol...

Embodiment 2

[0022] According to the conditions described in Example 1, the ratio of the diameter of the fluidized bed reactor zone I to the fluidized bed reactor II zone is 4.0:1, and the ratio of the height is 2:1; The distance in the vertical direction from the bottom of Zone I of the reactor is 0.2 of the height of Zone I of the entire fluidized bed reactor; The distance is 0.4 of the height of zone II of the entire fluidized bed reactor; the cyclone separators in the settler and regenerator are both two stages. The stability of catalyst flow control is maintained, the outlet product of the reactor is analyzed by online gas chromatography, and the carbon-based yield of low-carbon olefins reaches 80.5% by weight.

Embodiment 3

[0024] According to the conditions described in Example 1, the ratio of the diameter of the fluidized bed reactor zone I to the fluidized bed reactor zone II is 3.0:1, and the ratio of the height is 0.5:1; The distance in the vertical direction from the bottom of Zone I of the reactor is 0.1 of the height of Zone I of the entire fluidized bed reactor; The distance is 0.2 of the height of zone II of the entire fluidized bed reactor; the cyclone separators in the settler and the regenerator are all three stages. The stability of catalyst flow control is maintained, and the outlet product of the reactor is analyzed by online gas chromatography, and the carbon-based yield of low-carbon olefins reaches 82.0% by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com