Preparation method of cobalt manganese oxide coating layer precursor

A manganese-cobalt oxide coating and precursor technology, applied in chemical instruments and methods, inorganic chemistry, cobalt compounds, etc., can solve the problems of high cost, long reaction time, complex coating precursor process, etc., and achieve extended service life , small size, strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

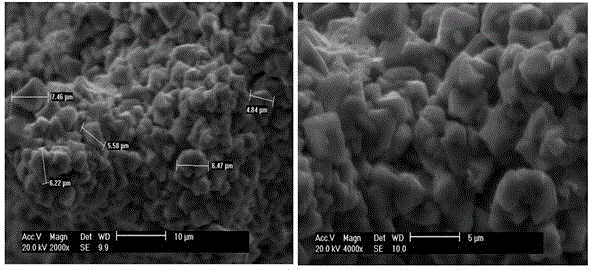

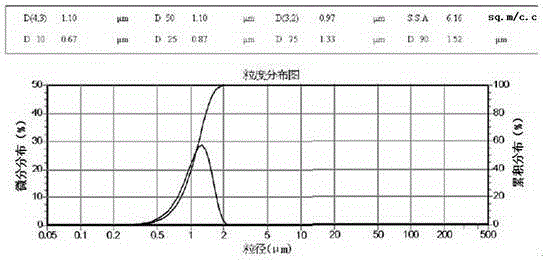

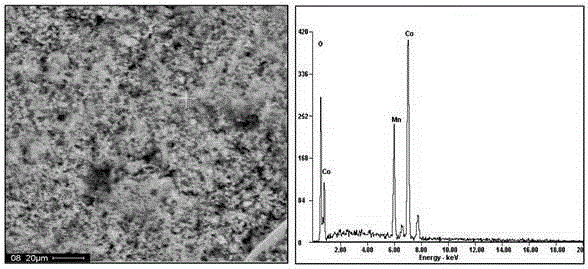

[0018] The method for preparing manganese oxide cobalt coating precursor by sol-gel described in this embodiment specifically includes the following steps:

[0019] (1) Add cobalt nitrate and manganese nitrate to constant temperature distilled water at 70°C, and stir evenly to obtain a mixed solution A; the amount of cobalt nitrate added in solution A is 2.9105g / ml, and the amount of manganese nitrate added is 1.2501g / ml;

[0020] (2) Add chelating agent citric acid (C 6 h 8 o 7 ·H 2 O) obtain solution B;

[0021] (3) Slowly add ammonia water (NH 3 ·H 2 O) until flocculent sol-gel is produced;

[0022] (4) Sintering the flocculent sol-gel to obtain the precursor of manganese oxide cobalt coating.

[0023] The sintering conditions described in the step (4) of the present invention are as follows: at a heating rate of 1°C / min, the temperature is raised to 85°C and kept for 480 minutes; then the temperature is continued to be raised to 300°C and kept for 300 minutes; then ...

Embodiment 2

[0026] The method for preparing manganese oxide cobalt coating precursor by sol-gel described in this embodiment specifically includes the following steps:

[0027] (1) Add cobalt nitrate and manganese nitrate to constant-temperature distilled water at 80°C, and stir evenly to obtain a mixed solution A; the amount of cobalt nitrate added in solution A is 0.1039g / ml, and the amount of manganese nitrate added is 1.2501g / ml;

[0028] (2) According to the addition amount of 0.2980g / ml, 0.1035g / ml and 0.2436g / ml, add chelating agents polyvinyl alcohol, ethylene glycol and adipic acid to solution A to obtain solution B;

[0029] (3) Slowly add ammonia water (NH 3 ·H 2 O) until flocculent sol-gel is produced;

[0030] (4) Sintering the flocculent sol-gel to obtain the precursor of manganese oxide cobalt coating.

[0031] The sintering conditions described in the step (4) of the present invention are: according to the heating rate of 1°C / min, the temperature is raised to 200°C and ...

Embodiment 3

[0033] The method for preparing manganese oxide cobalt coating precursor by sol-gel described in this embodiment specifically includes the following steps:

[0034] (1) Add cobalt nitrate and manganese nitrate to constant-temperature distilled water at 90°C, and stir evenly to obtain mixed solution A; the amount of cobalt nitrate added in solution A is 9.4591g / ml, and the amount of manganese nitrate added is 1.2501g / ml;

[0035] (2) According to the addition amount of 0.4470g / ml and 0.4552g / ml, add the chelating agent polyvinyl alcohol and ethylene glycol into solution A to obtain solution B;

[0036] (3) Slowly add ammonia water (NH 3 ·H 2 O) until flocculent sol-gel is produced;

[0037] (4) Sintering the flocculent sol-gel to obtain the precursor of manganese oxide cobalt coating.

[0038] The sintering conditions described in the step (4) of the present invention are: according to the heating rate of 1°C / min, the temperature is raised to 300°C and kept for 60 minutes; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com