Janus liquid drop having structural color and based on 3D liquid drop printing, and preparation method of Janus liquid drop

A structural color, droplet technology, applied in 3D object support structures, additive manufacturing, manufacturing tools, etc., can solve the lack of Janus droplet regulation in microfluidics technology, the inability to control the orientation and spatial arrangement of Janus droplets, and the limitation of optical The development and application of features, etc., to achieve the effect of high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: Preparation of Janus droplets with structural color

[0033] Adopt the method of the present invention to prepare Janus droplet, concrete steps are as follows:

[0034] (1) Carbomer 940, nonionic surfactant X-100, FS-30 are dissolved in water, the concentration of carbomer is 0.07wt%, the concentration of X-100 is 0.05wt%, the concentration of FS-30 The concentration was 1.5 wt%, and then 10 wt% NaOH solution was added to adjust the pH of the solution to 7 to obtain a clear hydrogel.

[0035] (2) Mix n-hexane and perfluorohexane at a volume ratio of 4:11 at high temperature to obtain a miscible mixture.

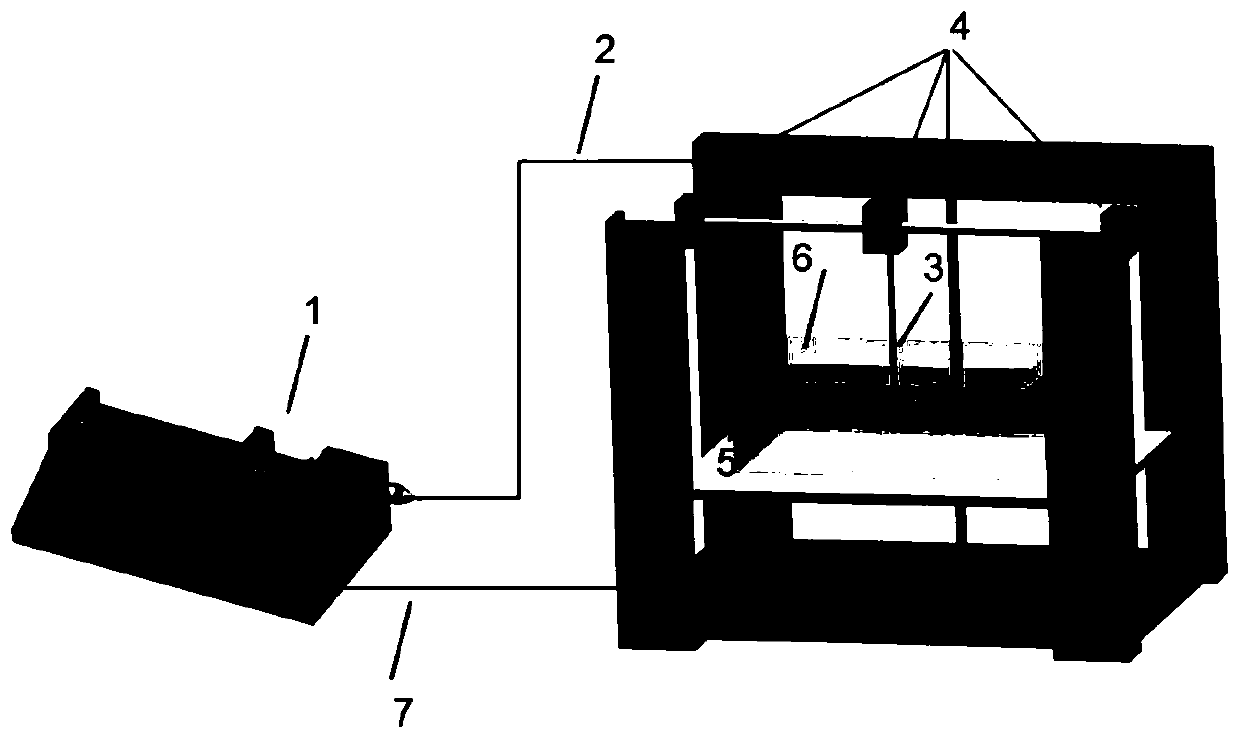

[0036] (3) Pour the hydrogel in step (1) into a rectangular parallelepiped plastic container as a matrix, draw the mixed solution in step (2) with a syringe, then place it on the syringe pump, connect the syringe to the printing nozzle with a PE tube Connect, and immerse the print head into the hydrogel matrix.

[0037] (4) By writing a digital model file...

Embodiment 2

[0039] Example 2: Preparation of a color pattern composed of Janus droplets with structural color

[0040] (1) According to the method in Example 1, n-hexane and perfluorohexane were mixed at a volume ratio of 1:1 at high temperature to obtain a miscible mixed solution.

[0041] (2) Pour the hydrogel in step (1) of Example 1 into a rectangular parallelepiped plastic container as a base, draw the mixed solution in the above step (2) with a syringe, then place it on a syringe pump, and use a PE tube to put the syringe Connect to the print nozzle and immerse the print nozzle into the hydrogel matrix.

[0042] (3) Customize the printing pattern by designing the digital model and generate the G-code code. Then, the path is printed by a 3D printer to obtain a droplet pattern, and the container is placed in a freezer to cool down rapidly, and the two oil phases are separated to form a customized color pattern composed of Janus droplets with structural color, as shown in the attached ...

Embodiment 3

[0043] Embodiment 3: Janus droplet structural color color control

[0044] (1) The change of Janus droplet structure and morphology is mainly affected by interfacial tension, which follows the principle of interface stability, that is, the minimization of interface energy. Nonionic surfactants X-100 and FS-30 can change the surface tension of fluorocarbons and hydrocarbons, and achieve a specific Janus two-phase interface morphology through a certain ratio of the two surfactants.

[0045] (2) Configure FS-30 with concentrations of 1.3wt%, 1.5wt%, and 1.7wt%, and X-100 with concentrations of 0.03wt%, 0.05wt%, and 0.08wt%, respectively, and set up several crossover experimental groups, according to The method in embodiment 1 prepares described Janus droplet, observes the structural form of the Janus droplet obtained, as attached Figure 5 As shown, the results indicate that the structure of Janus droplets can be tuned by adjusting the ratio of nonionic surfactants in the hydrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com