Manufacturing method for ceramic-lined composite steel pipe

A technology of composite steel pipe and ceramic lining, applied in coating, metal material coating technology and other directions, can solve the problems of erosion, wear and corrosion damage, high price of special alloy steel pipe, affecting service life, etc., to achieve low cost and improve application. The effect of high value and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

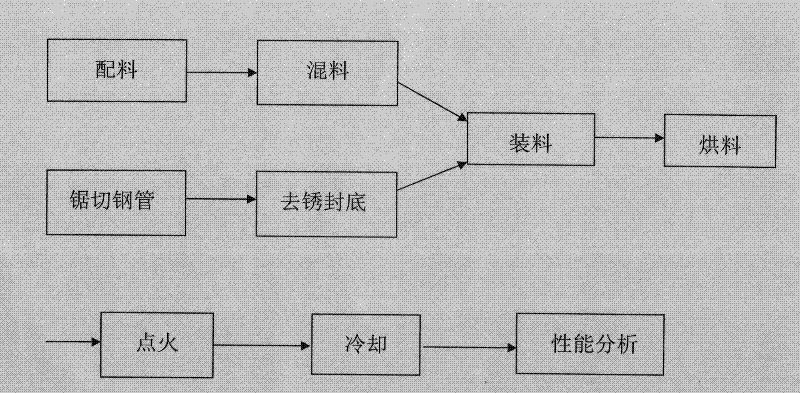

Method used

Image

Examples

Embodiment approach 1

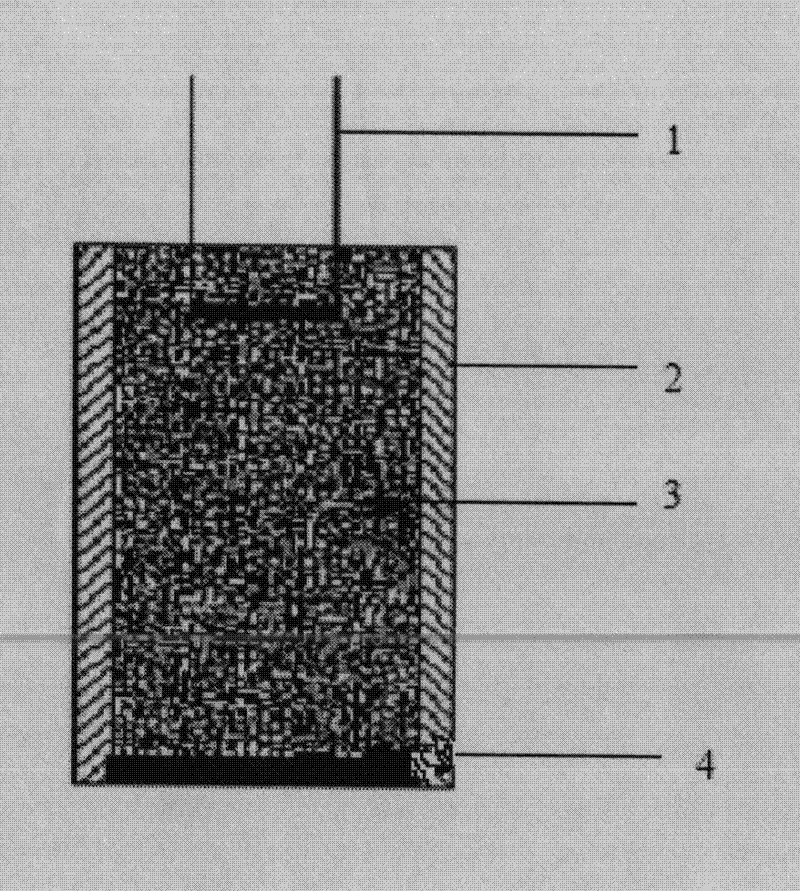

[0031] Use a Q235 welded pipe 2 with a size of Φ15mm×3.5mm×130mm, remove the rust on the inner surface of the welded pipe 2, and seal the bottom end of the steel pipe with a zinc sheet 4; 2 o 3 →Al 2 o 3 +2Fe+836kJ / mol, Fe 2 o 3 The stoichiometric ratio of Al and Al is 1:2.96 by weight, and the particle size is 200 mesh analytically pure powder. The additive rare earth oxide Y 2 o 3 / La 2 o 3 with SiO 2 0.5% by weight: 2% added to thermite 3, the filler density is 1.6g cm -3 , the weight ratio of each reagent is Al:Fe 2 o 3 : SiO 2 : Y 2 o 3 / La 2 o 3 =73.5%:24%:2%:0.5%.

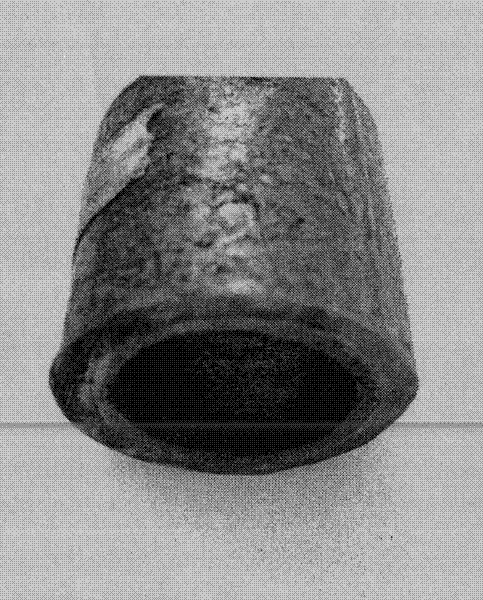

[0032] Ignite the tungsten wire 1, the reaction is rapid and complete, the steel pipe 2 turns red instantly, a small amount of material is splashed, the coating is uniform, the resulting ceramic layer has no pores, the surface is fine and smooth, the texture is good, the quality is grade A, and the thickness of the dense ceramic layer is formed 1.6-2mm.

Embodiment approach 2

[0034] Use a Q235 welded pipe 2 with a size of Φ15mm×3.5mm×130mm, remove the rust on the inner surface of the welded pipe 2, and seal the bottom end of the steel pipe with a zinc sheet 4; 2 o 3 →Al 2 o 3 +2Fe+836kJ / mol, Fe 2 o 3 The stoichiometric ratio of Al and Al is 2.96:1 by weight, and the particle size is 200 mesh analytically pure powder. The additive rare earth oxide Y 2 o 3 / La 2 o 3 with SiO 2 According to the ratio of 1%: 2%, it is added to thermite 3, and the filler density is 1.6g cm -3 , the weight ratio of each reagent is Al:Fe 2 o 3 : SiO 2 : Y 2 o 3 / La 2 o 3 =73%:24%:2%:1%.

[0035] Ignite the tungsten wire 1, the reaction is more violent, the steel pipe 2 turns red instantly, there is a certain amount of material splashing, the coating has no obvious pores, the surface is smooth, the texture is good, but the crystal grains are coarse, the quality is B grade, and the thickness of the dense ceramic layer is formed 1.5-1.8mm.

Embodiment approach 3

[0037] Use a Q235 welded pipe 2 with a size of Φ15mm×3.5mm×130mm, remove the rust on the inner surface of the welded pipe 2, and seal the bottom end of the steel pipe with a zinc sheet 4; 2 o 3 →Al 2 o 3 +2Fe+836kJ / mol, Fe 2 o3 The chemical weight ratio of Al and Al is 2.96:1, and the particle size is 200 mesh analysis pure powder. The additive rare earth oxide Y 2 o 3 / La 2 o 3 with SiO 2 According to the ratio of 1%: 0%, it is added to thermite 3, and the packing density is 1.6g cm -3 , the weight ratio of each reagent is Al:Fe 2 o 3 : SiO 2 : Y 2 o 3 / La 2 o 3 =74%:25%:0%:1%.

[0038] When the tungsten wire 1 is ignited, the reaction proceeds rapidly, sparks are scattered, a large amount of material is ejected, and the welded pipe 2 turns red rapidly. After the reaction, only a thin ceramic layer of about 1mm is attached to the surface of the lower part of the welded pipe 2, while the upper part is not covered with a ceramic layer, and the welded pipe 2 can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com