Patents

Literature

33results about How to "Structure will not break" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

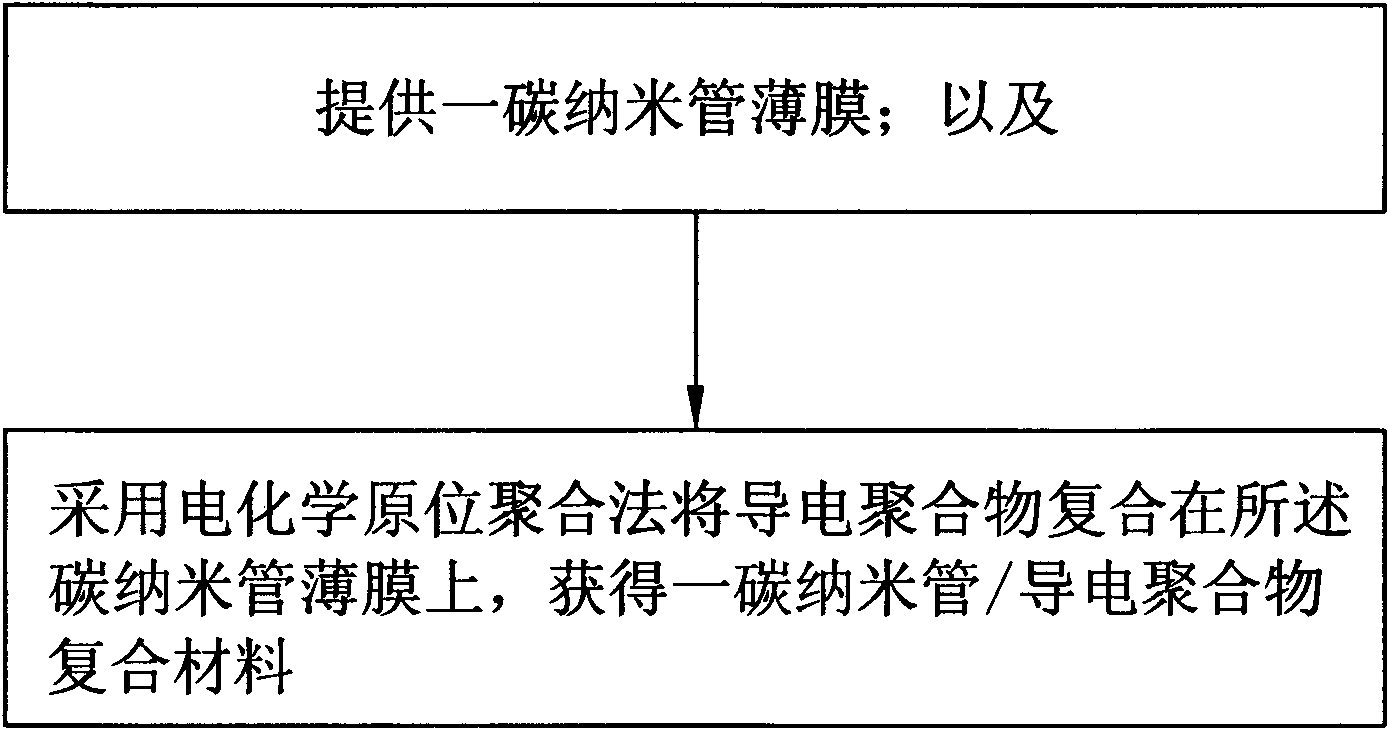

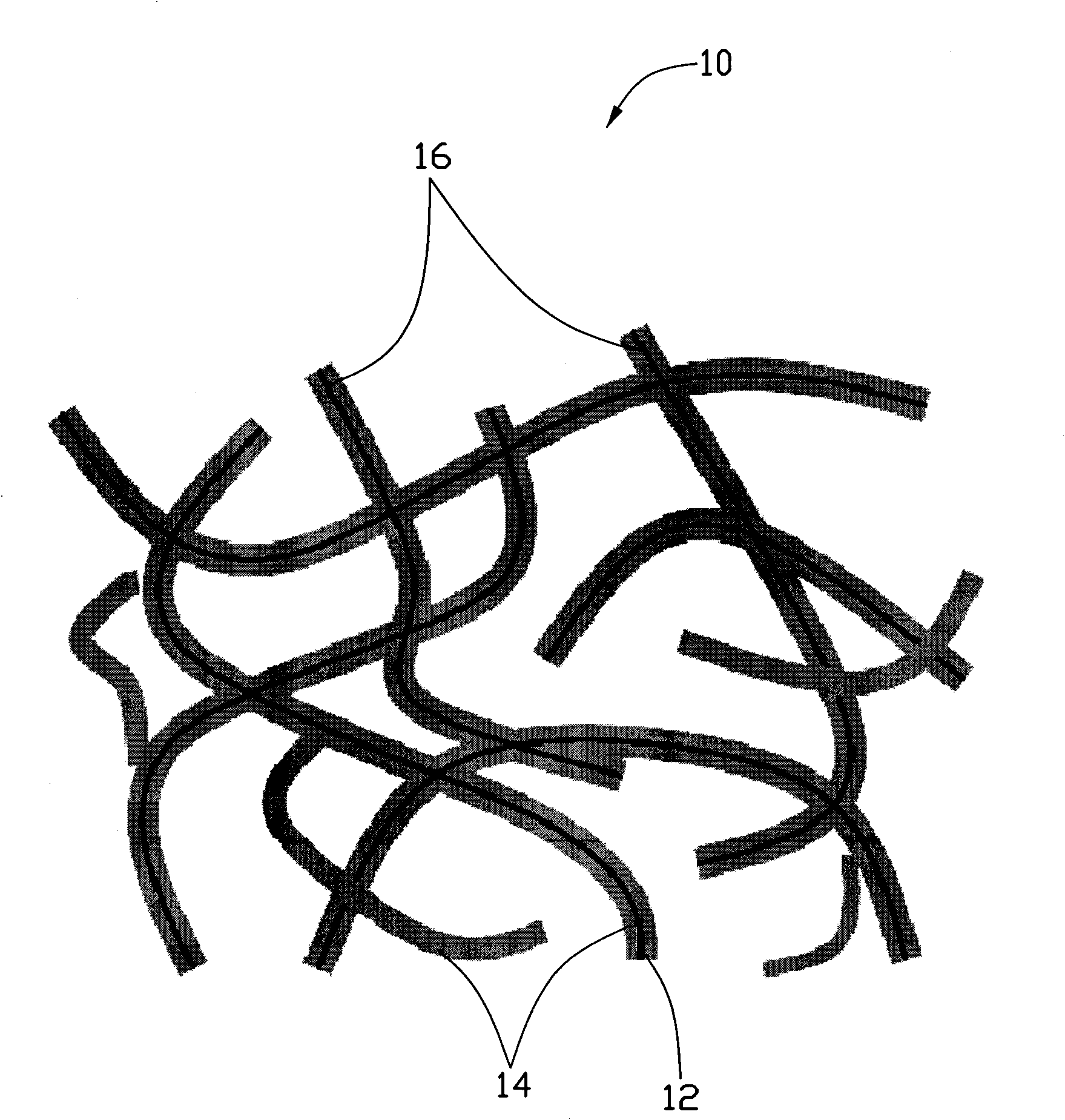

Preparation method for carbon nano tube/conducting polymer composite material

ActiveCN101659789AEvenly dispersedComplete structureMaterial nanotechnologyConductive materialConductive polymerIn situ polymerization

The invention discloses a preparation method for a carbon nano tube / conducting polymer composite material, which comprises the following steps: providing a carbon nano tube film; and adopting electrochemistry in-situ polymerization to composite conducting polymer on the carbon nano tube film to prepare the carbon nano tube / conducting polymer composite material.

Owner:TSINGHUA UNIV +1

Ganoderma lucidum polysaccharide extracting method

InactiveCN108341890AImprove extraction efficiencyConducive to dissolutionChemistryLiquid temperature

The invention discloses a ganoderma lucidum polysaccharide extracting method. The extracting method comprises the steps: firstly, smashing ganoderma lucidum sporocarp and sieving by a 80-mesh sieve; then putting into a steam explosion device to be exploded, adding into water to be soaked for 1.5h according to a solid to liquid ratio as 1 to (10 to 20) and then heating to 30 to 50 DEG C to performultrasonic treatment; adjusting a material liquid temperature, a pH value, protease and cellulase; after enzymolysis finishes, warming to denaturalize enzyme, centrifuging, decoloring resin, deproteinizing, filtering, vacuum concentrating and vacuum drying under a lower temperature to obtain high-activity and high-purity ganoderma lucidum polysaccharide solid powder. Therefore, a polysaccharide extracting rate and a polysaccharide production efficiency are improved, a space structure of polysaccharide is prevented from being damaged, biological activity of the polysaccharide is prevented frombeing reduced, and the ganoderma lucidum polysaccharide extracting method is more suitable for industrial production.

Owner:四川岚晟生物科技股份有限公司

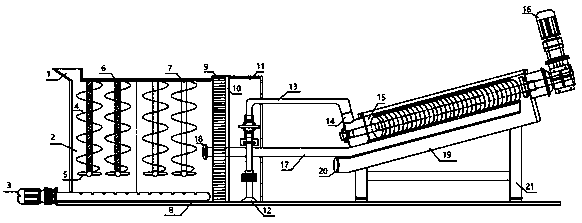

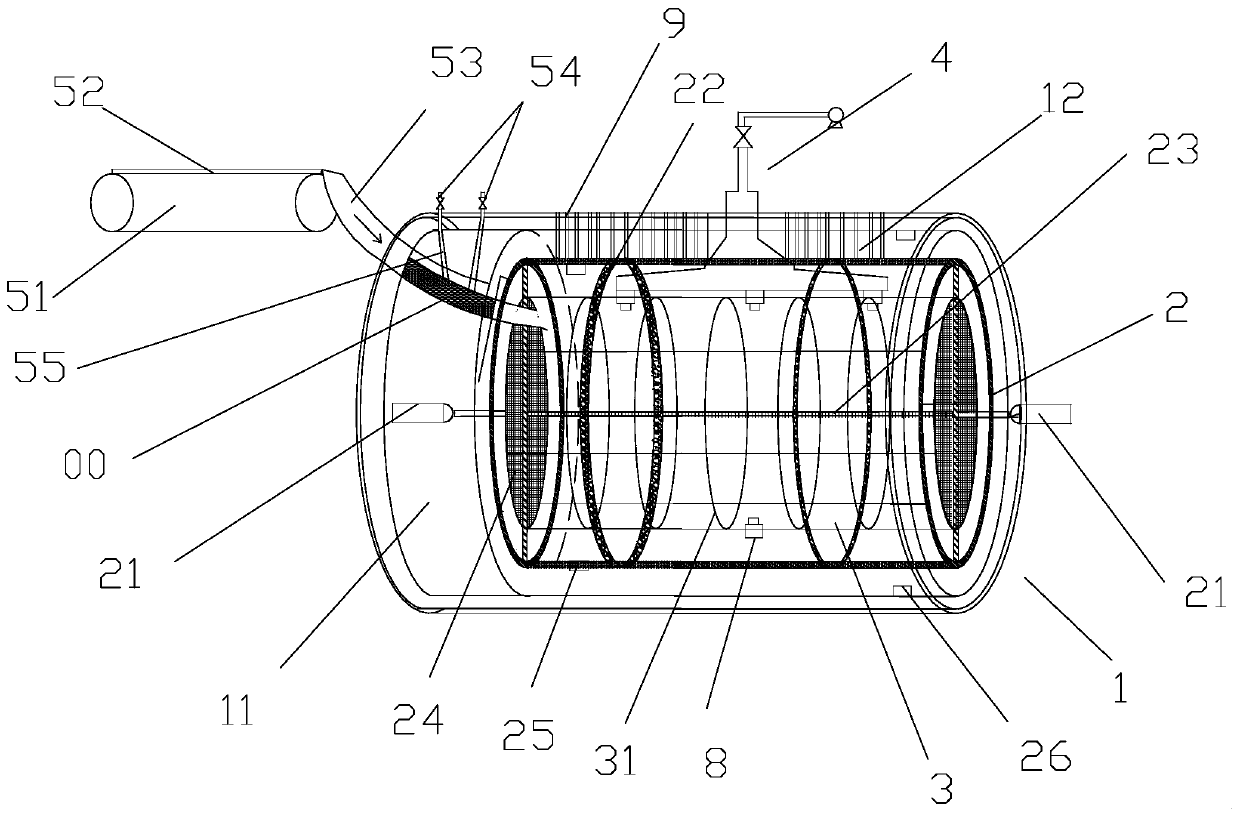

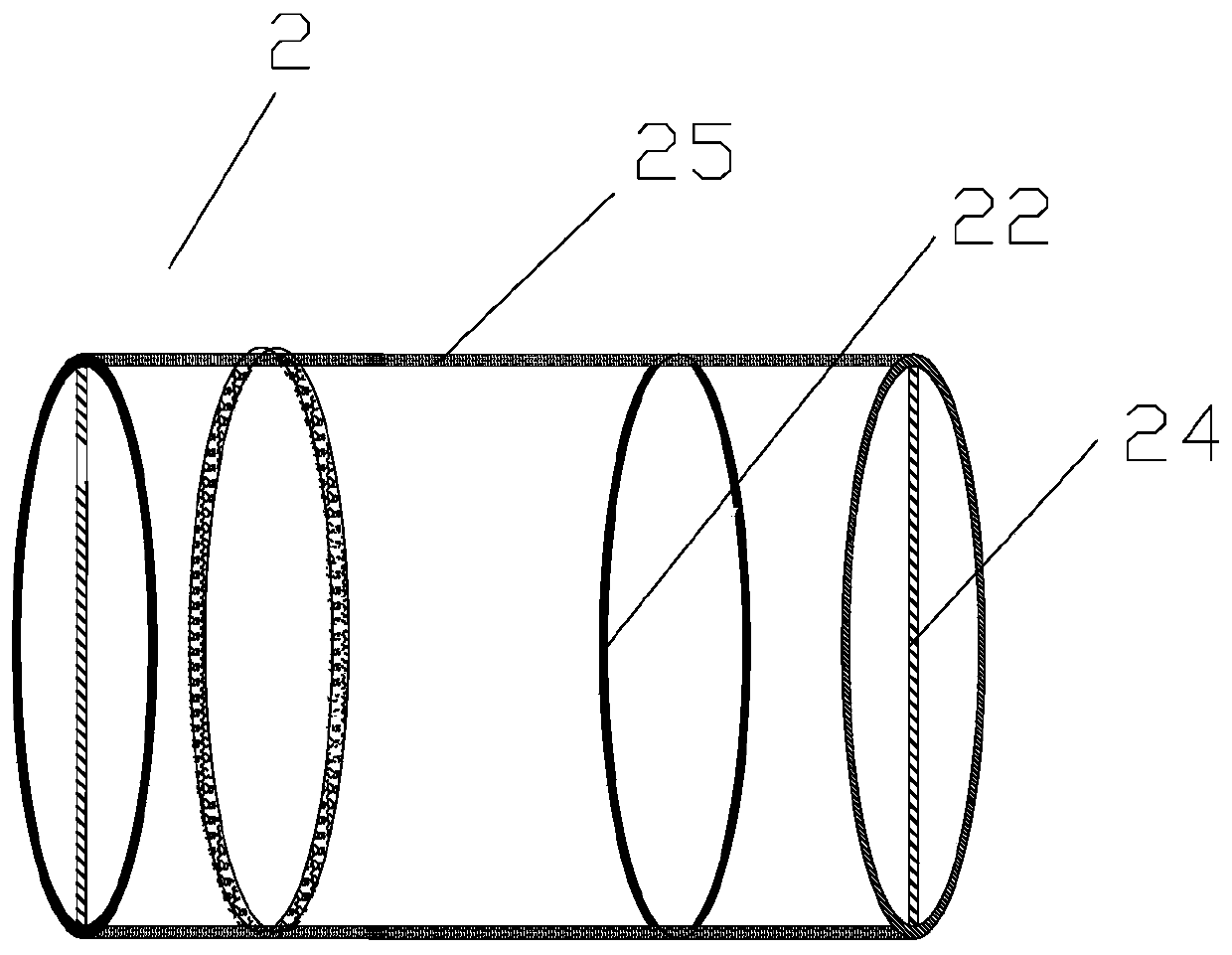

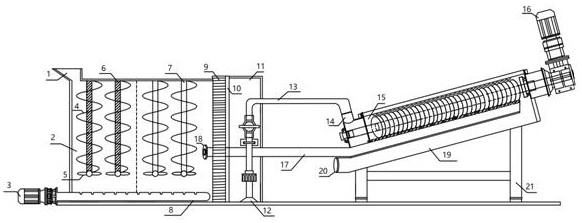

Method and device for removing heavy metals and POPs in organic wastes by electromagnetic reinforcement

The invention discloses a method and a device for removing heavy metals and POPs in organic wastes by electromagnetic reinforcement. The method comprises the following steps of: firstly preparing theorganic wastes into slurry; applying a magnetic field to the slurry to make sure that the heavy metals and the POPs in the slurry are transformed into a water solution state; separating the organic waste slurry into two components; afterwards applying an electric field to the slurry, migrating water molecules and the heavy metals and POPs which are continuously transformed into the water solutionstate to a cathode region of the electric field under the effect of electro-migration, and meanwhile migrating the components of the organic wastes to an anode region of the electric field so as to realize separation of the two components; and filtering and dehydrating the organic waste slurry to finally obtain harmless low-water-content organic wastes. The method and the device disclosed by the invention can be used for efficiently removing large-particle impurities, some heavy metals and the POPs in the organic wastes, can also reduce the water content of the organic wastes to 30% to 50%, thereby overcoming the defects that a traditional organic waste treatment method is low in efficiency, takes effect slowly and has no oneness.

Owner:KUNMING UNIV OF SCI & TECH

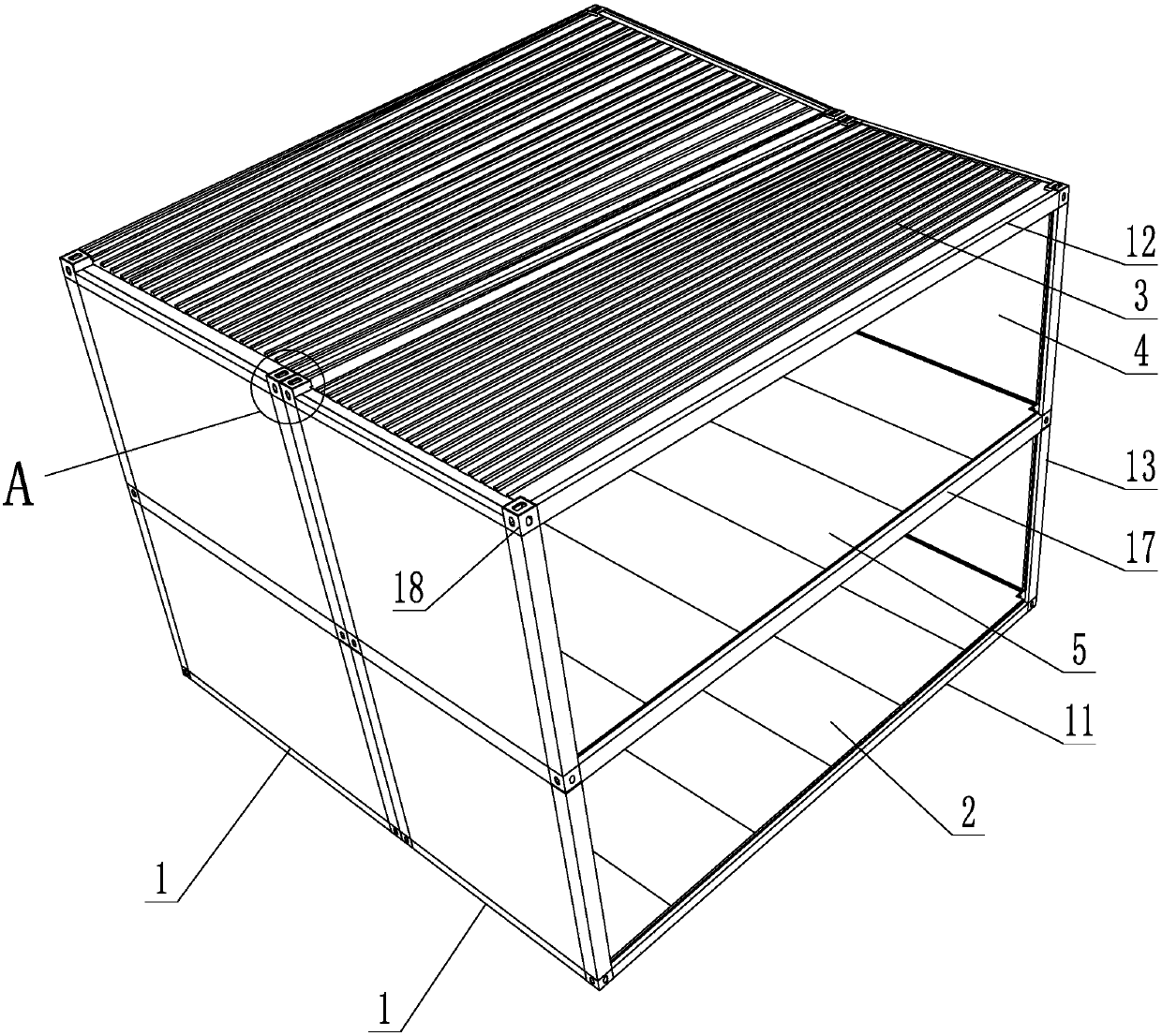

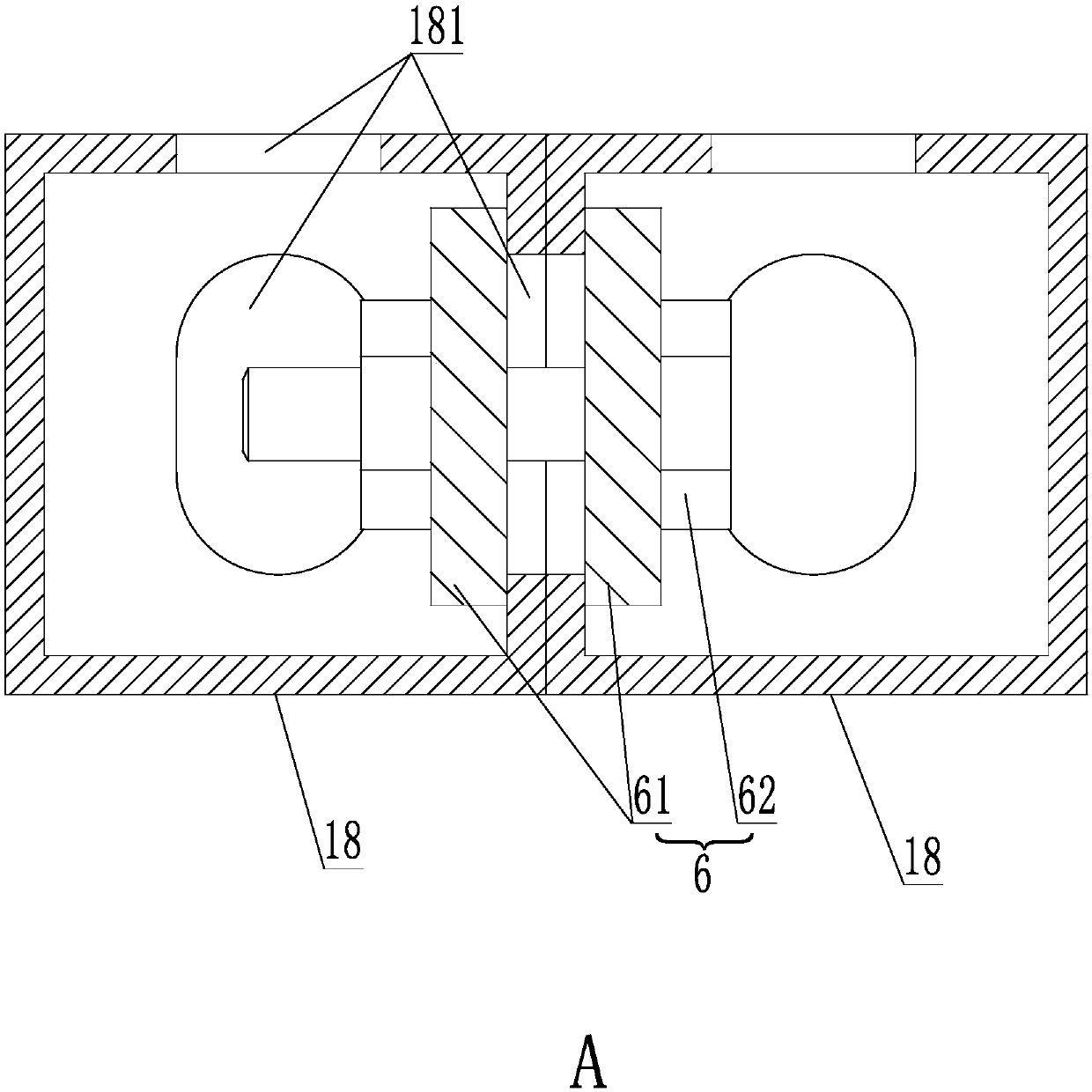

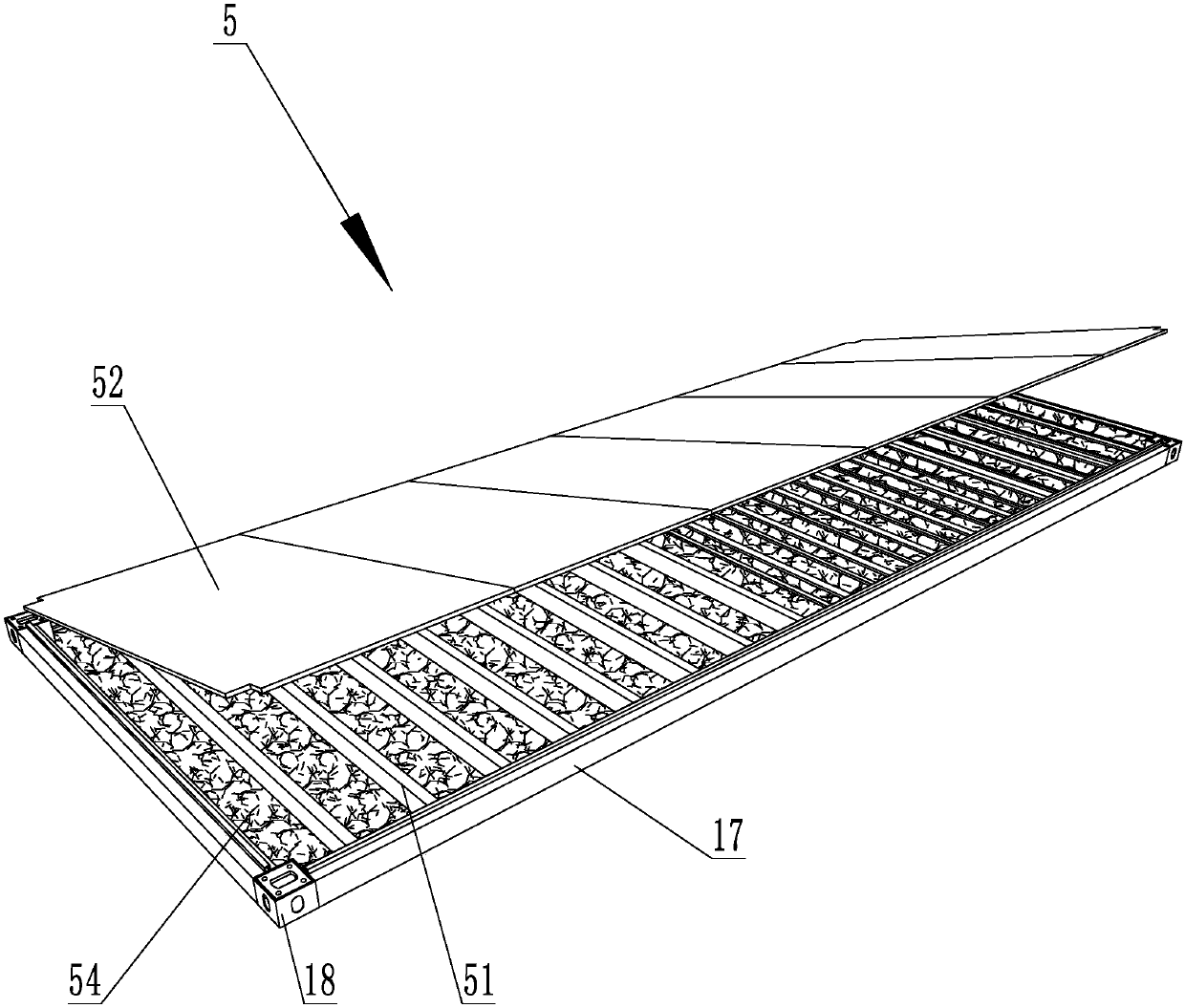

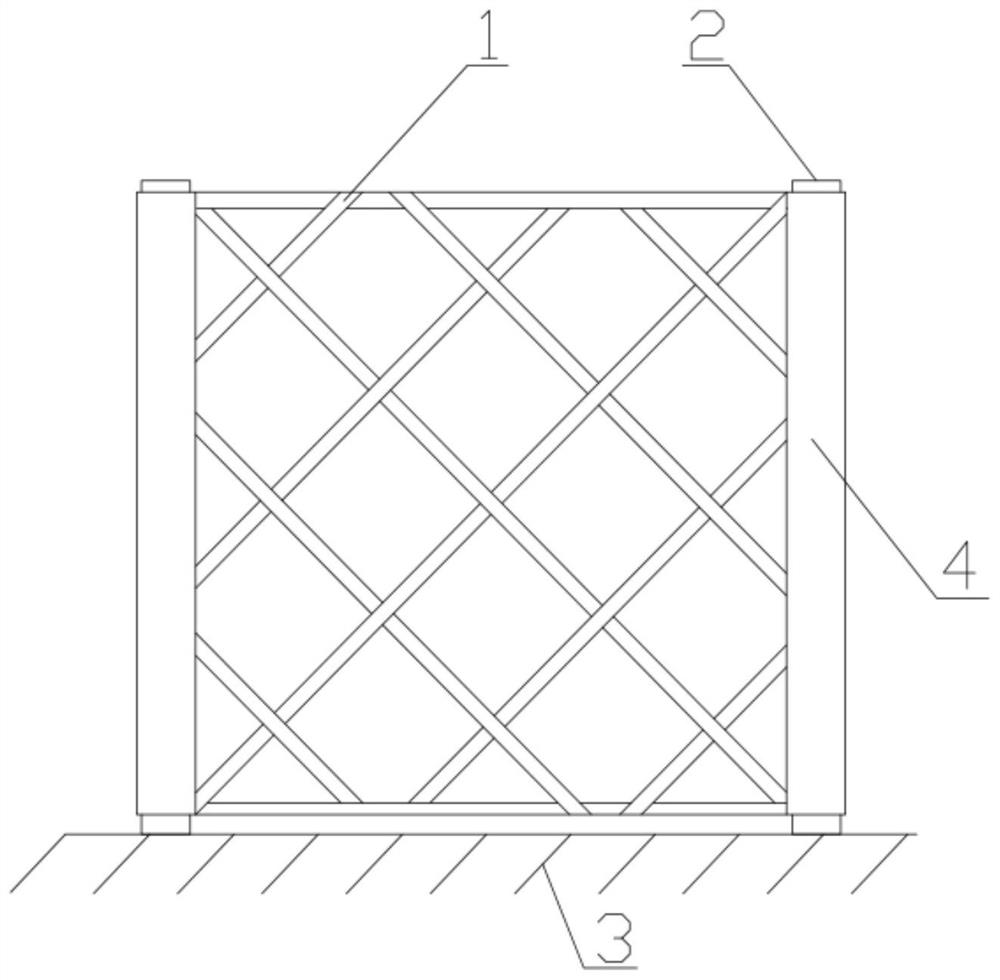

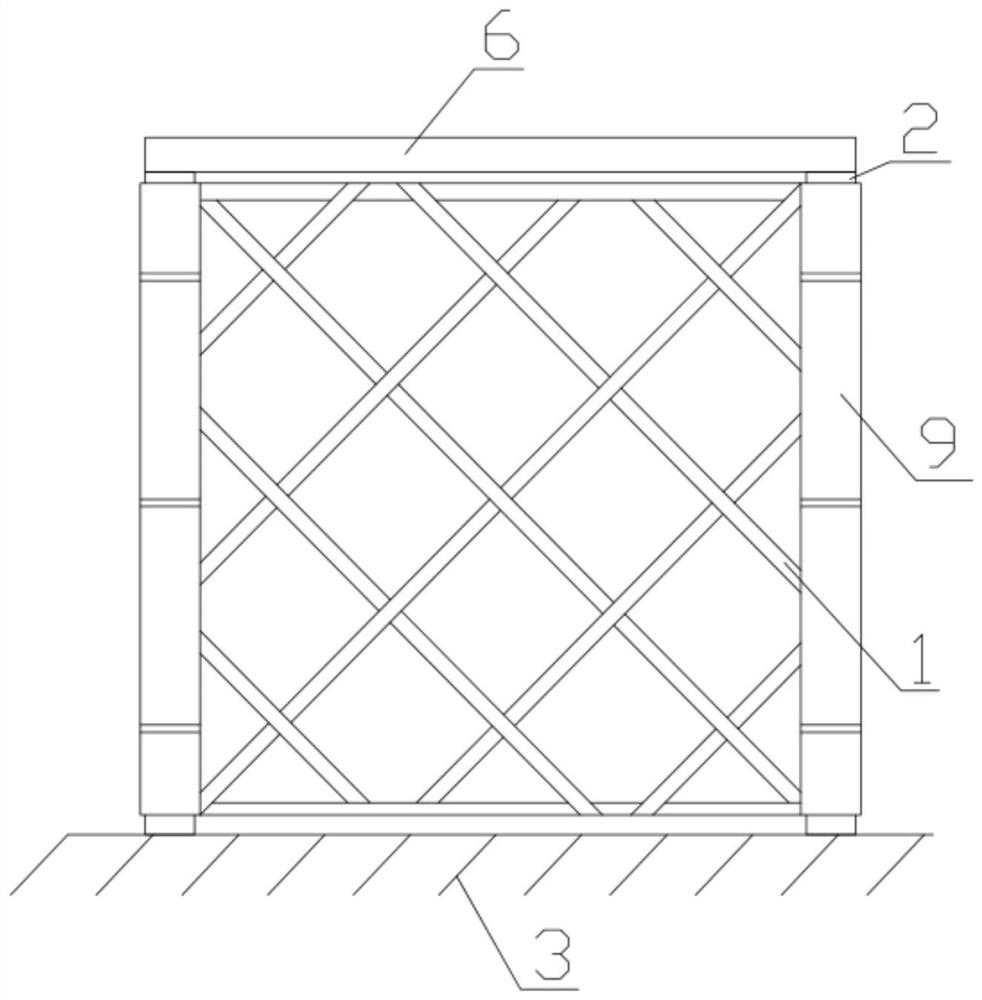

Assembly-type prefabricated-steel frame module house

The invention relates to an assembly-type prefabricated-steel frame module house. The module house includes multiple monomer houses, and each monomer house includes a floor installed on the bottom surface of a house body, a roof installed on the top surface of the house body, and wallboards installed on the side surfaces of the periphery of the house body; the floor includes a bottom frame with asupport function, the roof includes a top frame with a support function, and uprights are arranged between the floor and the roof for connection; the upper side surface of the bottom frame is providedwith a lower flange arranged along the frame, and the lower flange is connected with a lower clamping piece in a clamping mode; the end, away from the room interior, of the lower clamping piece is provided with a lower clamping groove with an upward opening, and the lower side surface of the top frame is provided with an upper flange arranged along the frame; the side, positioned in the room interior, of the top frame is connected with a support piece for supporting the roof, and the support piece is connected with an upper clamping piece; an upper clamping groove, with a downward opening andopposite to the lower clamping groove, is formed between the upper clamping piece and the upper flange, and the upper and lower ends of each wallboard are arranged in an inserting mode in the lower clamping groove and the upper clamping groove through sliding. The wallboards and roofs of the module house can be recycled repeatedly, which not only saves the costs, but also protects the environment.

Owner:BEIJING CHENGDONG INT MODULAR HOUSING

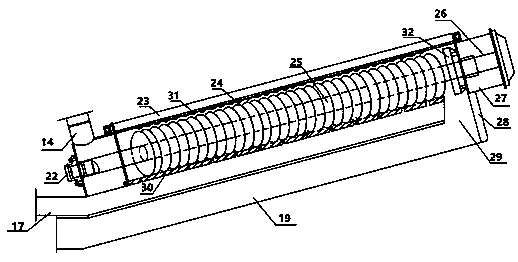

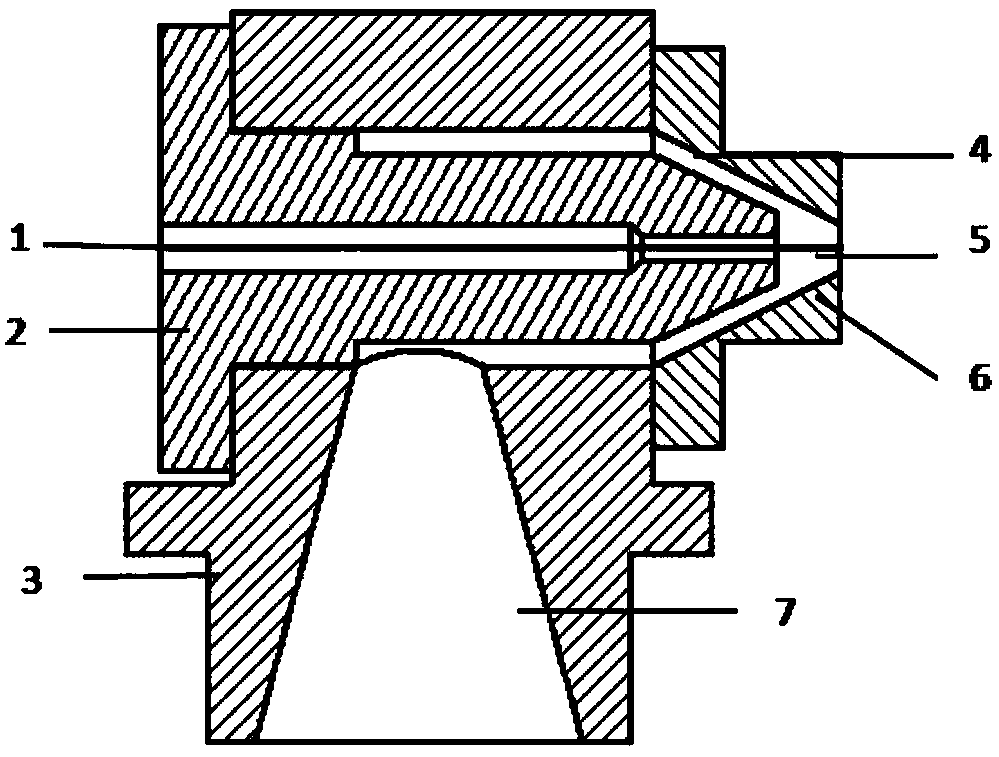

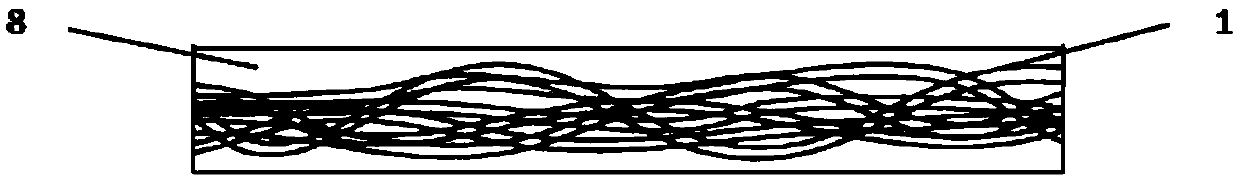

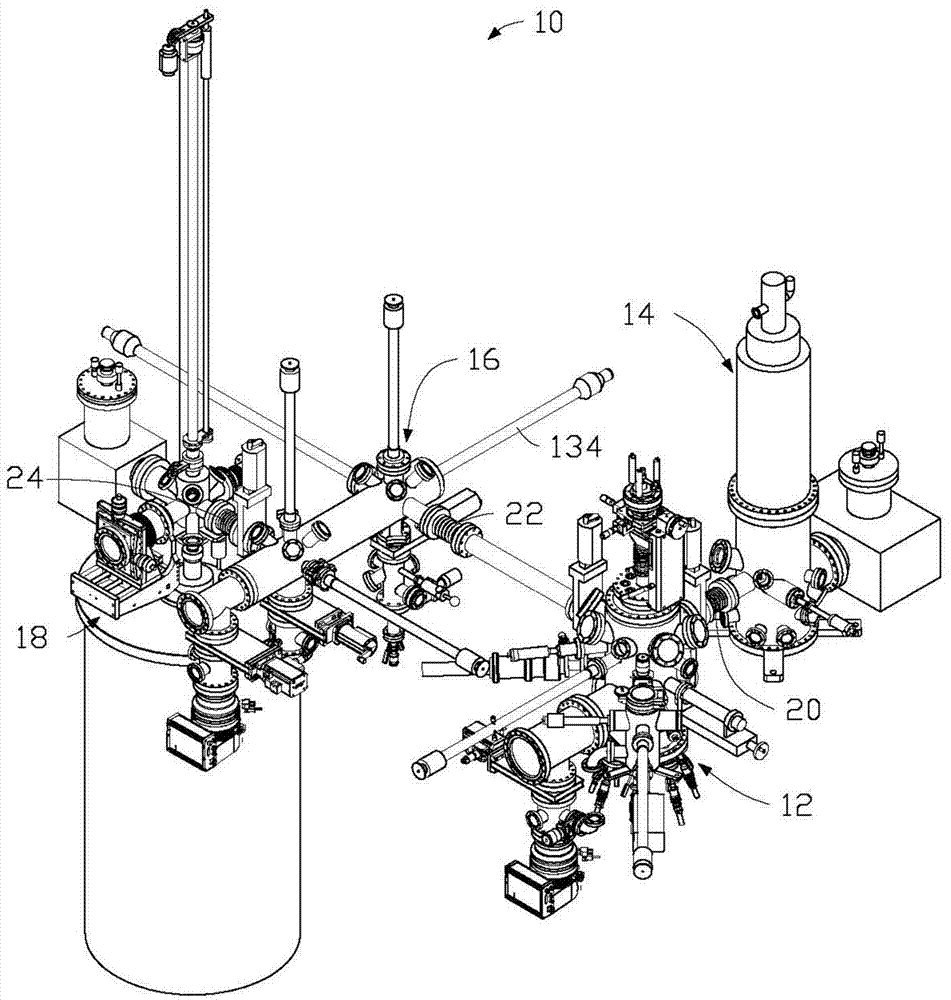

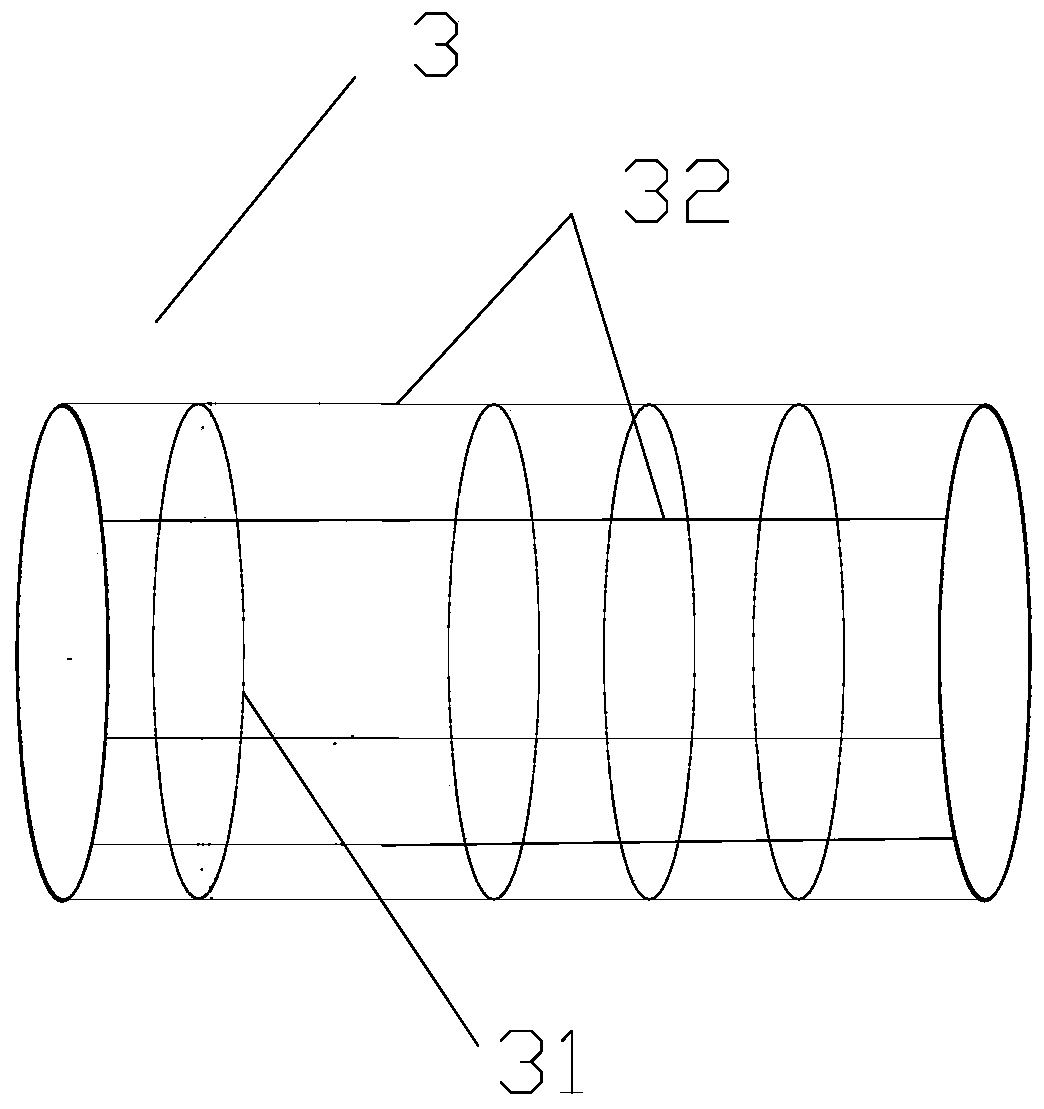

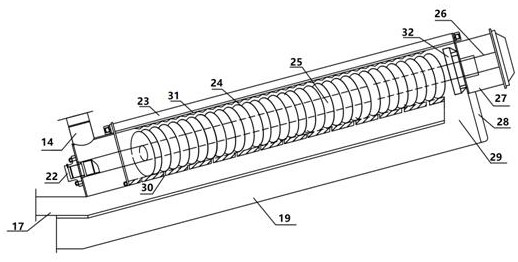

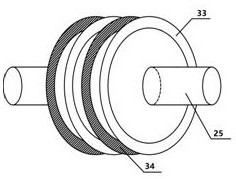

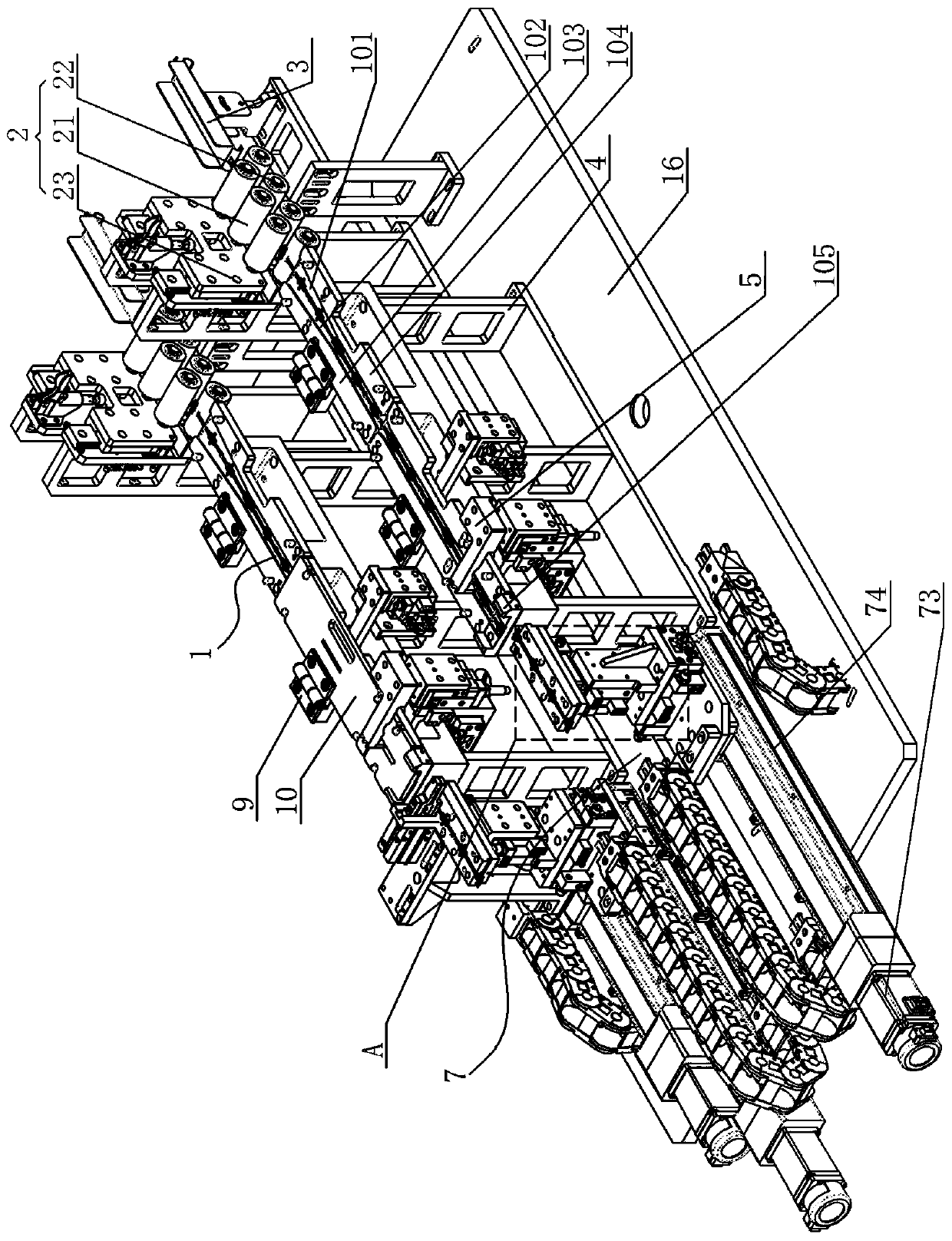

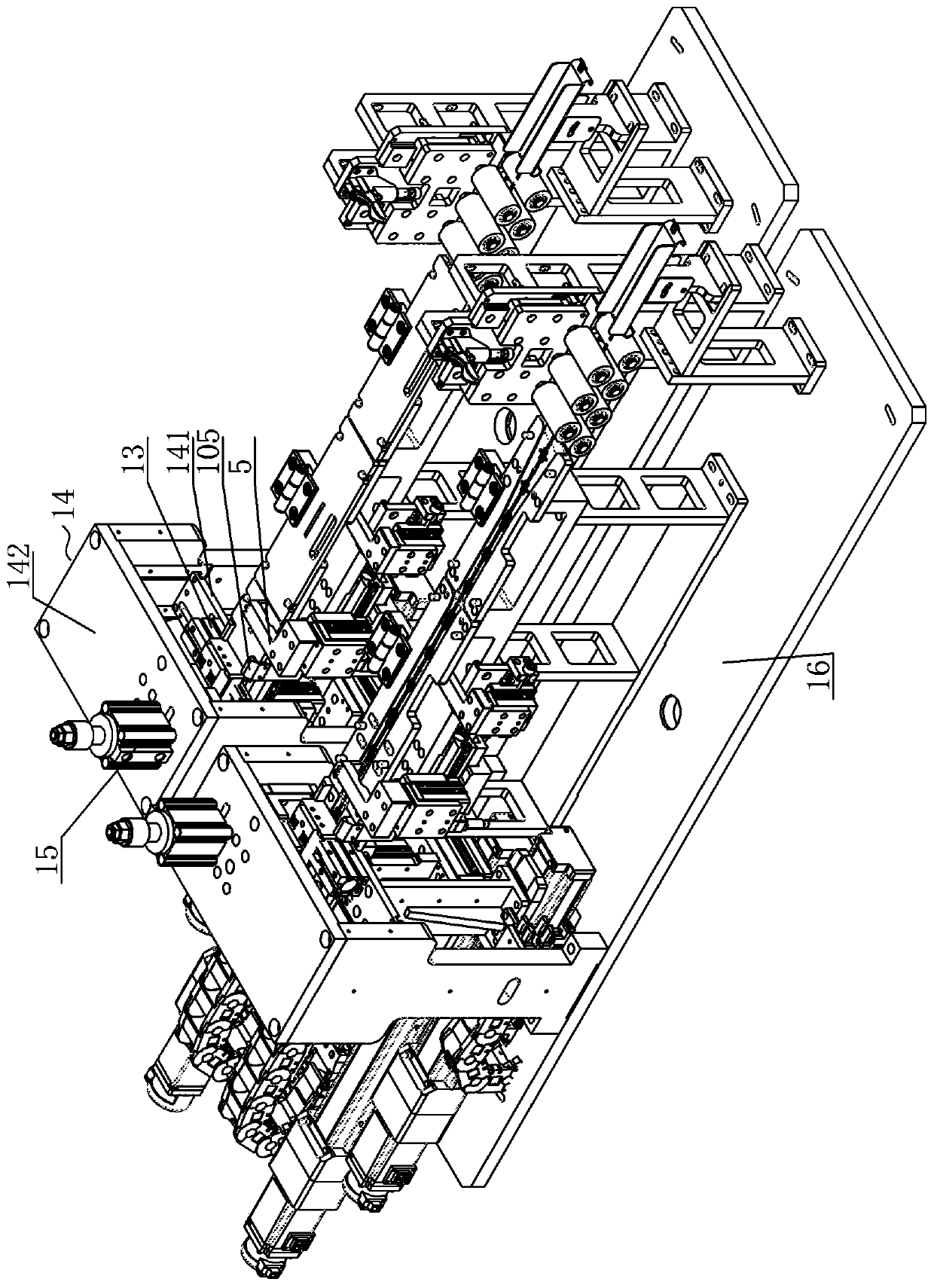

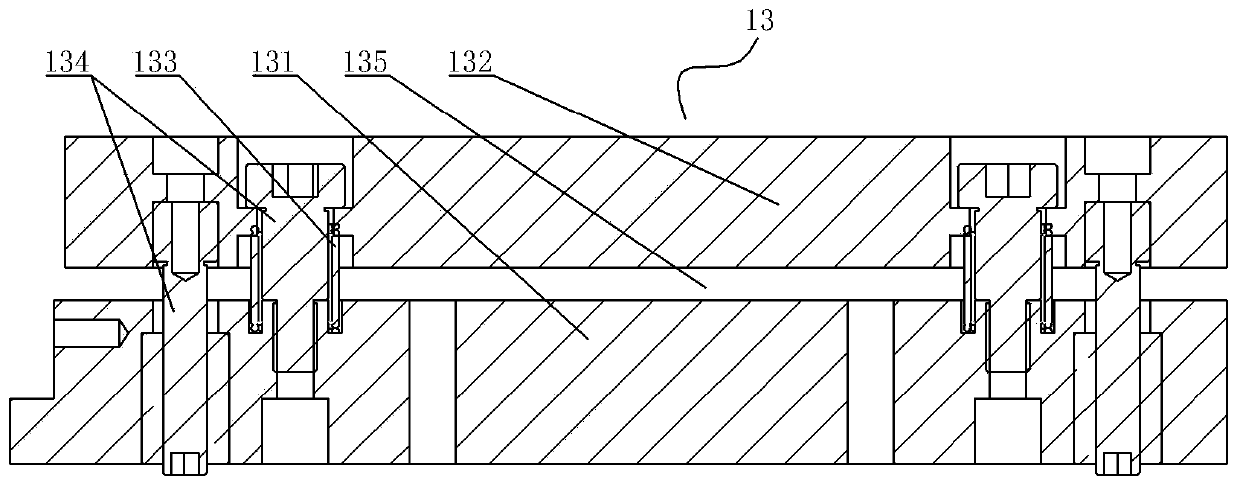

Method and device for preparing consumable material of continuous fiber bundles

The invention discloses a method and device for preparing a 3D printing linear material of a continuous fiber bundle reinforced composite material. The device comprises a motor, a feeding device, an extrusion molding device, a cooling device, a traction machine and a wire winding device, wherein an extrusion head forming mold of the extrusion molding device comprises a mold sleeve, a mold core and a mold head which are sequentially arranged in the feeding direction, continuous fiber bundles are arranged inside a center cavity after the mold core and the mold head are nested, the heated molten polymer raw material are fed from a feeding hole of the mold sleeve through extrusion so as to wrap the continuous fiber bundles, the diameter of an extruding object is adjusted by adjusting the traction force and the traction speed of the traction machine, and then the extruding object is collected through the air cooling device and the winding device to obtain the continuous fiber bundle 3D printing linear consumable material. The preparation device of the continuous fiber bundle 3D printing linear material is reasonable in structure and can realize industrial production of the 3D printing linear material of the continuous fiber bundle reinforced composite material, the processing technology is simple, the structures of the continuous fiber bundles cannot be damaged, the linear material forming effect is good, the operation is convenient, the production efficiency is improved, and the production cost is saved.

Owner:SHEN ZHEN QIANHAI SCICORE 3D TECH CO LTD

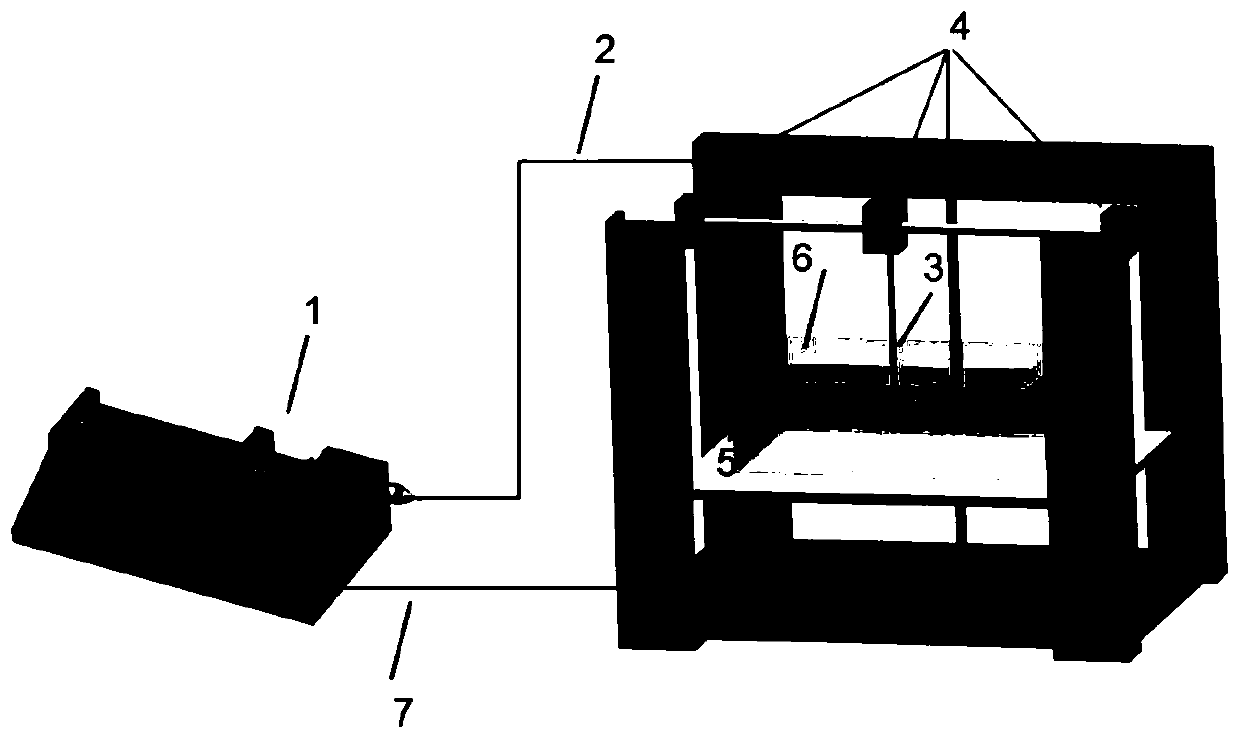

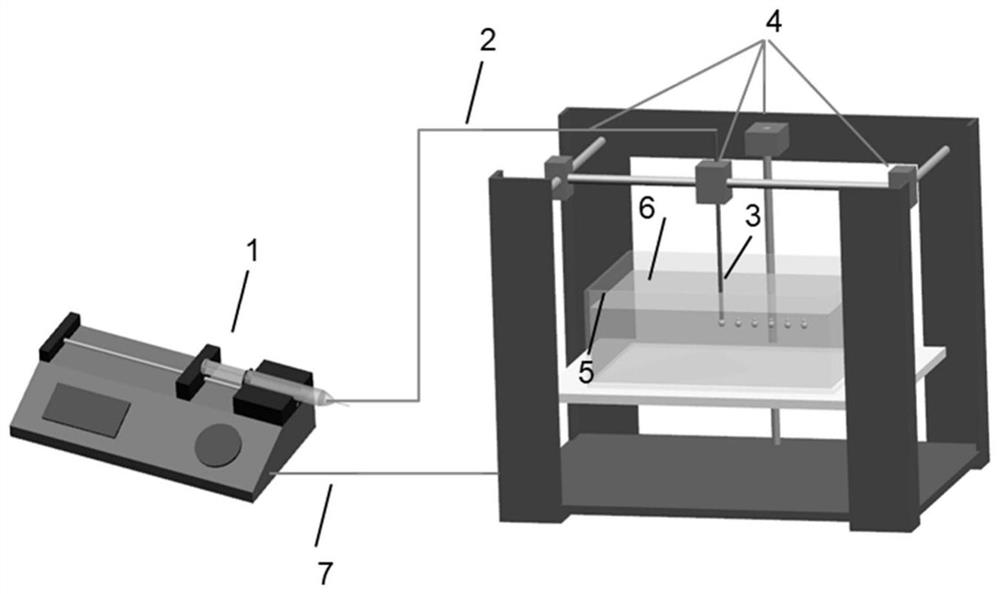

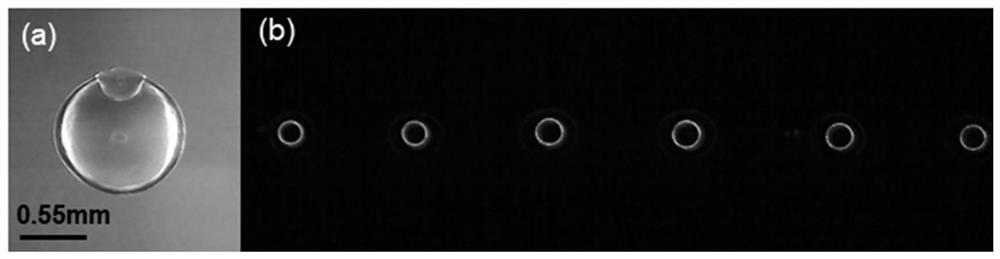

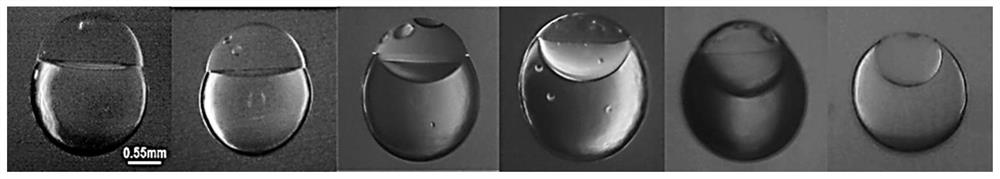

Janus liquid drop having structural color and based on 3D liquid drop printing, and preparation method of Janus liquid drop

ActiveCN111171341AHigh application valuePrecise size controlAdditive manufacturing apparatus3D object support structuresPhysicsRefractive index

The invention discloses a Janus liquid drop having structural color and based on 3D liquid drop printing, and a preparation method of the Janus liquid drop. A hydrogel with a shear thinning property is used as a matrix, two oil phases which are mutually soluble at high temperature and separatable at low temperature are used as dispersion phases, an injection pump is controlled by a 3D printer, thedispersion phases with high temperature are injected into the matrix to form liquid drops, and the two oil phases are induced to be separated by reducing the temperature so as to the form Janus liquid drops. Due to the fact that the two oil phases have different refractive indexes, incident light can form interference between interfaces, and an annular structural color is shown. The structural colors of the Janus liquid drops can be adjusted through the type or proportion of a non-ionic surfactant in the hydrogel, the positions and sizes of the Janus liquid drops can be accurately controlledthrough 3D printing, color patterns composed of the Janus liquid drops are generated, and high application value is achieved in the fields of function display, sensing and the like.

Owner:ZHEJIANG UNIV

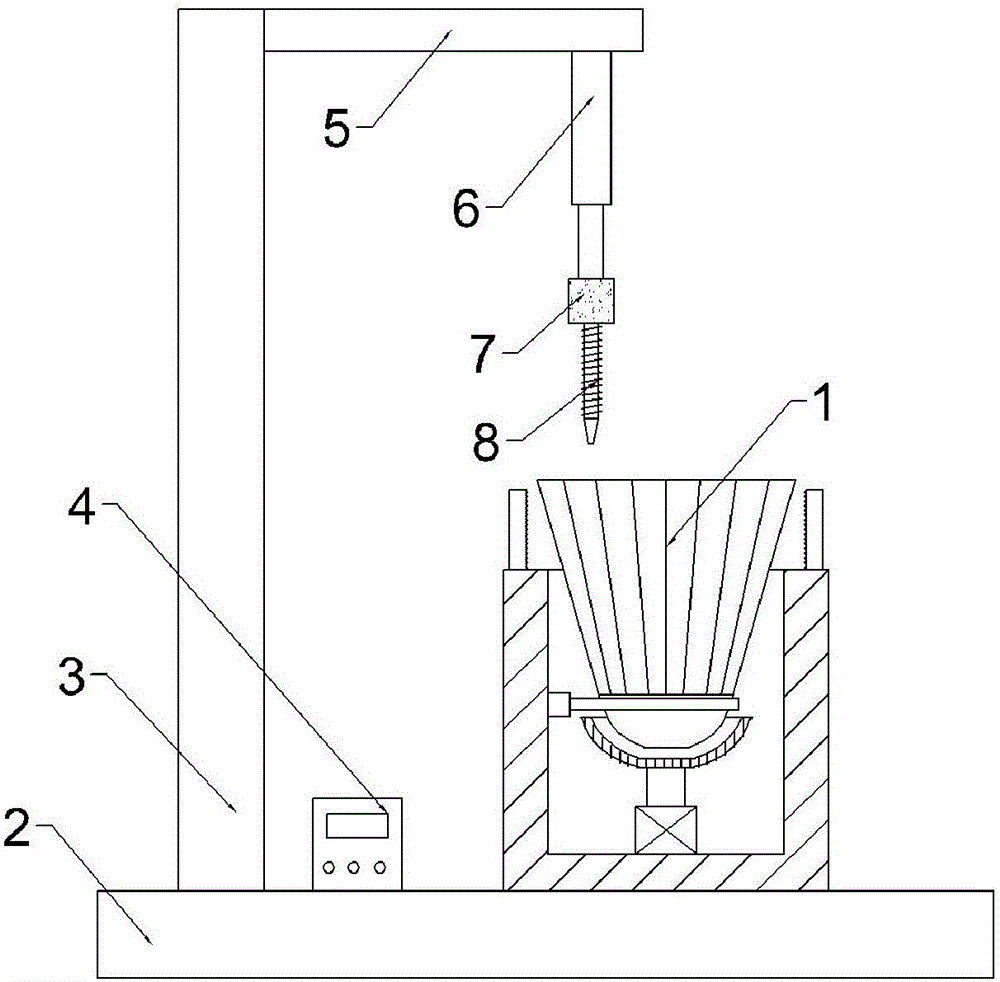

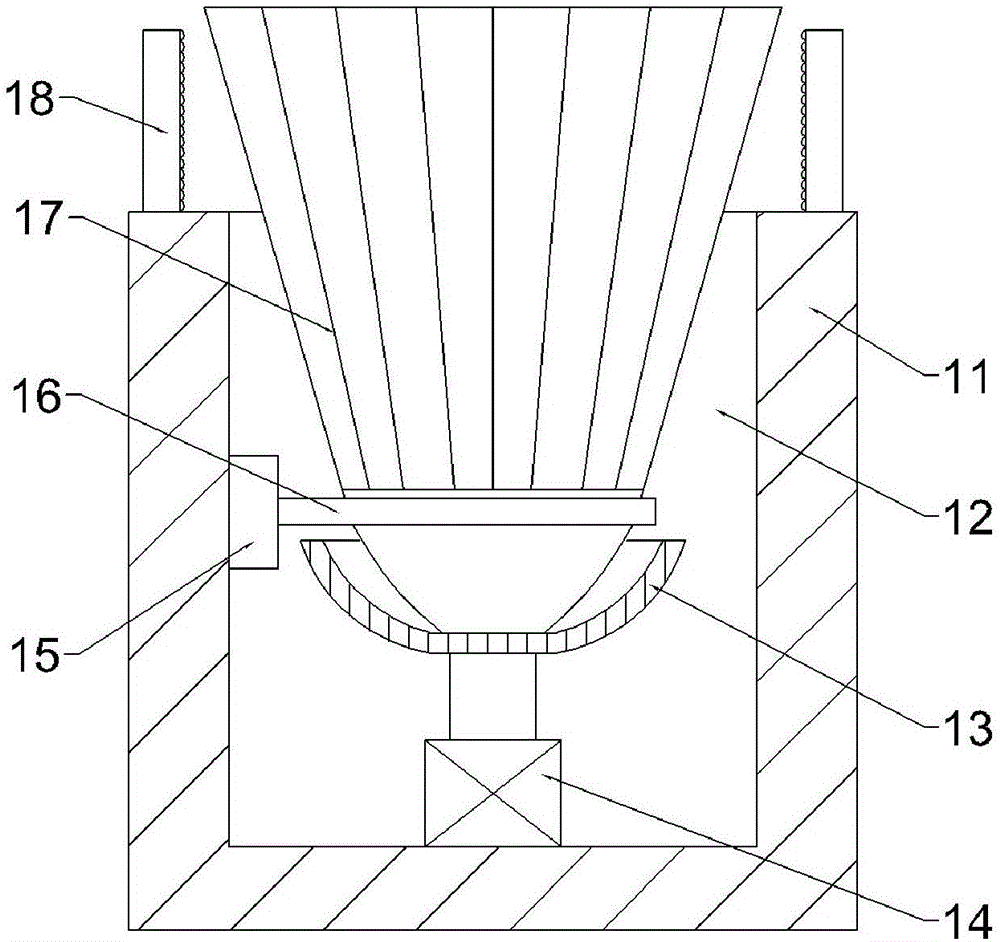

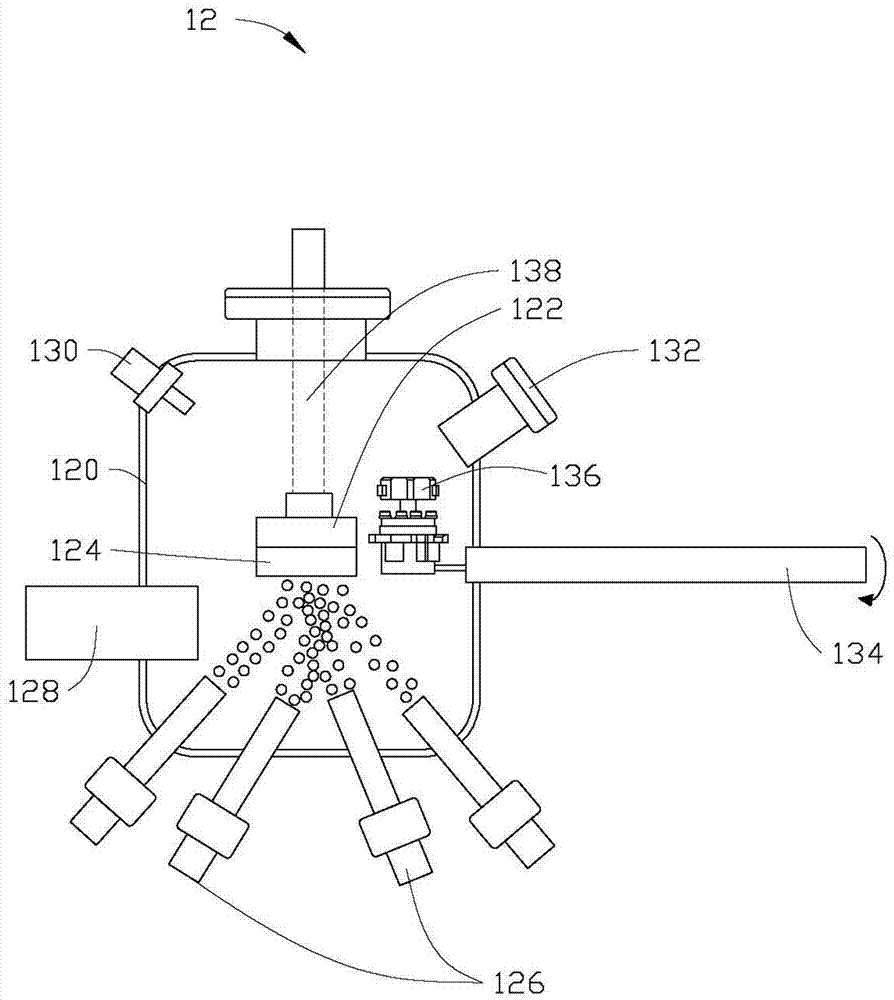

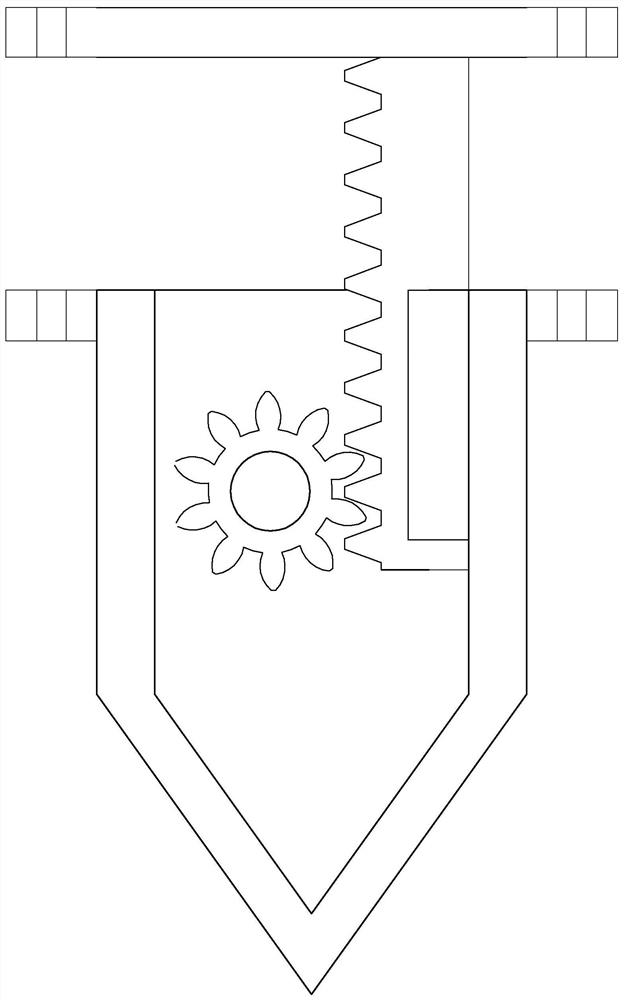

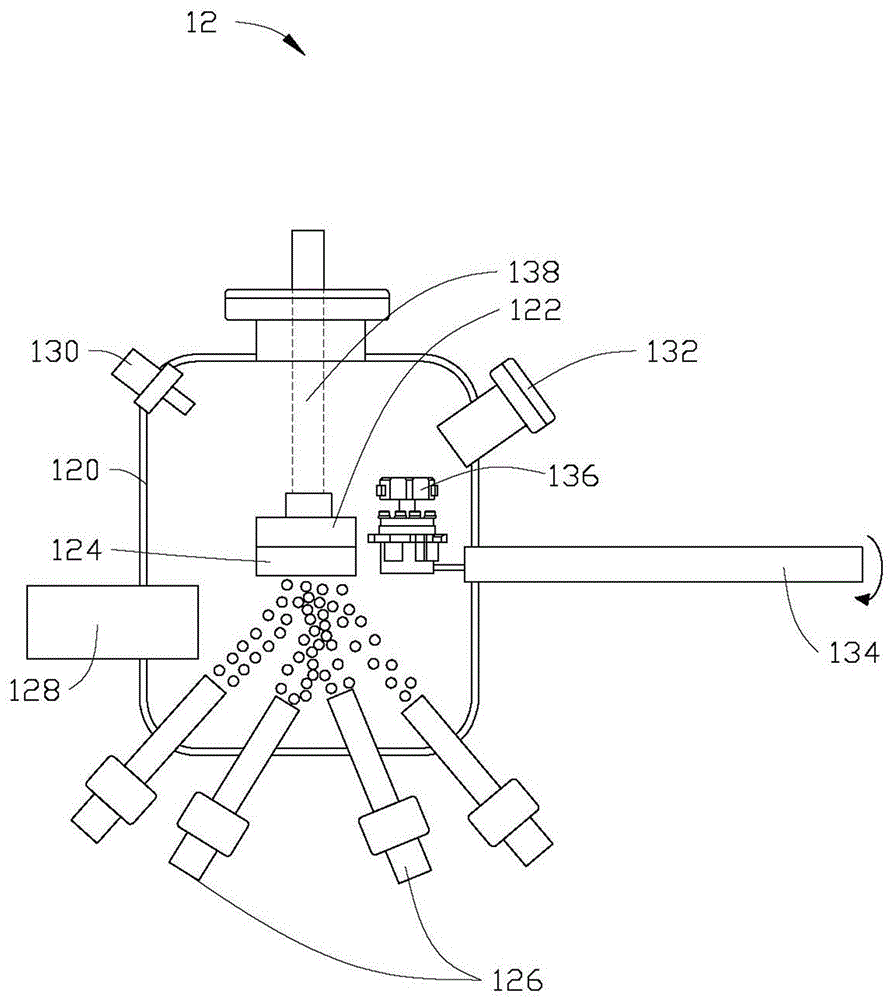

Drilling device

ActiveCN106363692ASimple structural designStructure will not breakMetal working apparatusEngineeringPositioning system

The invention relates to a drilling device. The drilling device comprises a base and a supporting column. A horizontal rod is arranged at the upper end of the supporting column. An electric telescopic rod is fixedly arranged on the lower side of the horizontal rod. The free end of the electric telescopic rod is downwards arranged, the bottom end of the free end is fixedly connected with a first motor, and the lower side of the first motor is connected with a drill bit through a connecting rod. A badminton ball clamping device is arranged below the drill bit and arranged on the base and comprises a positioning base, a groove is formed in the positioning base, and a second motor is arranged at the bottom of the groove. The top end of an output shaft of the second motor is connected with a tray, and a badminton ball is placed in the tray. The drilling device has the beneficial effects that the structural design is simple and reasonable, so that drilling of the badminton ball is more convenient and rapid, and the production efficiency is effectively improved; and an original structure of the badminton ball cannot be damaged, and high popularization and application value is achieved.

Owner:WUHU YINXING AUTO PARTS

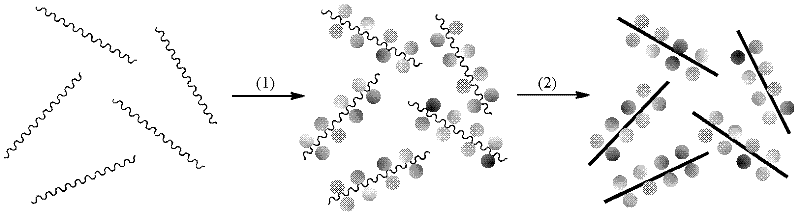

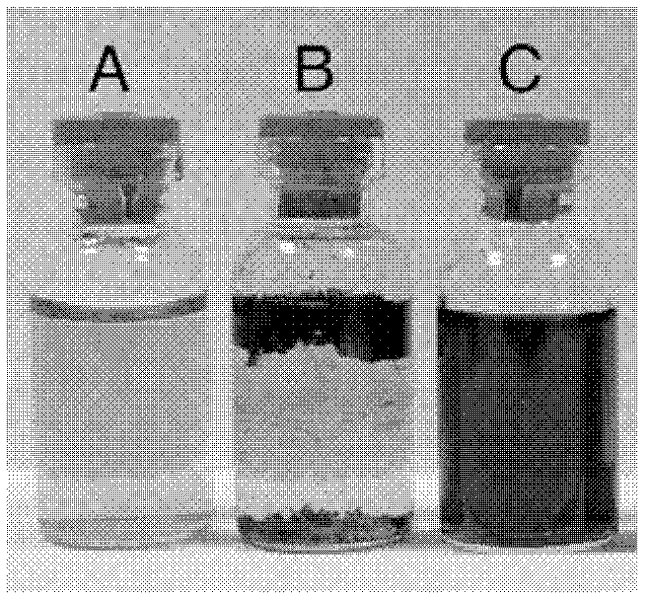

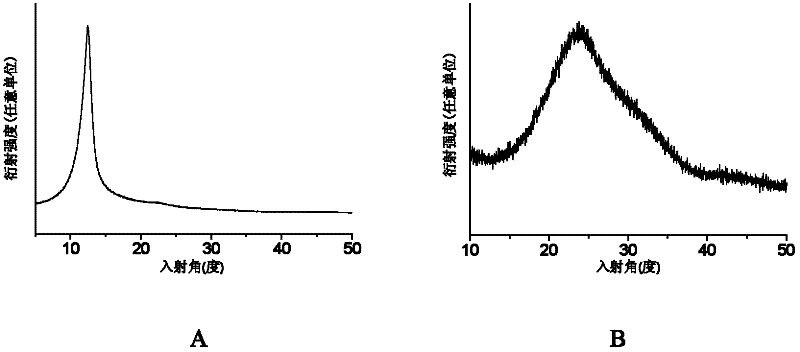

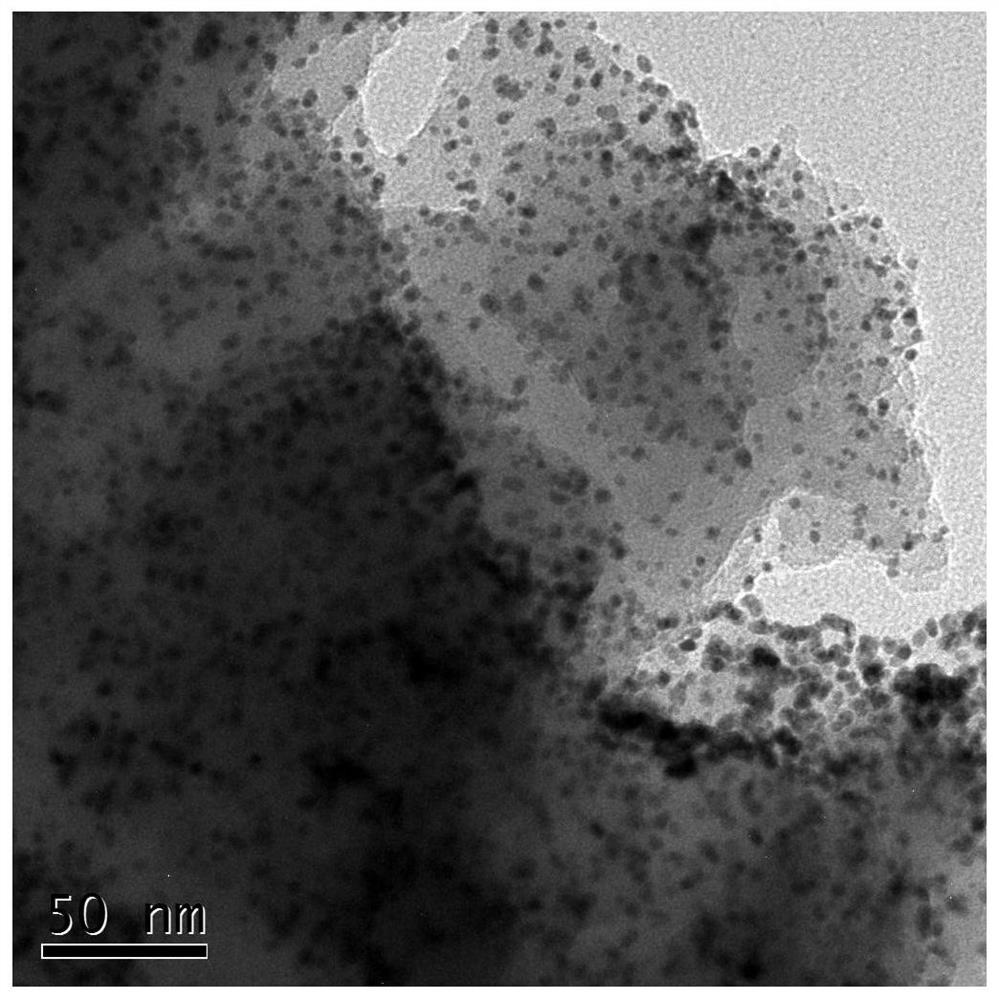

Method for preparing graphene aqueous solution by using water soluble coronene derivative as solubilizer

ActiveCN102303862AStructure will not breakImprove electrical performanceTransportation and packagingMixingCoroneneHydrazine compound

The invention discloses a method for preparing graphene aqueous solution by using a water soluble coronene derivative as a solubilizer, which comprises: dispersing graphene solid in ultrapure water, adding the water soluble coronene derivative, mixing, adding hydrazine hydrate, stirring, centrifuging, removing supernate, dissolving precipitate in ultrapure water, and thus, obtaining graphene aqueous solution. In the invention, the operation is simple, the property of the prepared graphene aqueous solution is stable, the dispersion state of the graphene in water can be regulated by changing the used amount of solubilizer, and the method has a bright application prospect in nano science, biomedicine and material science.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

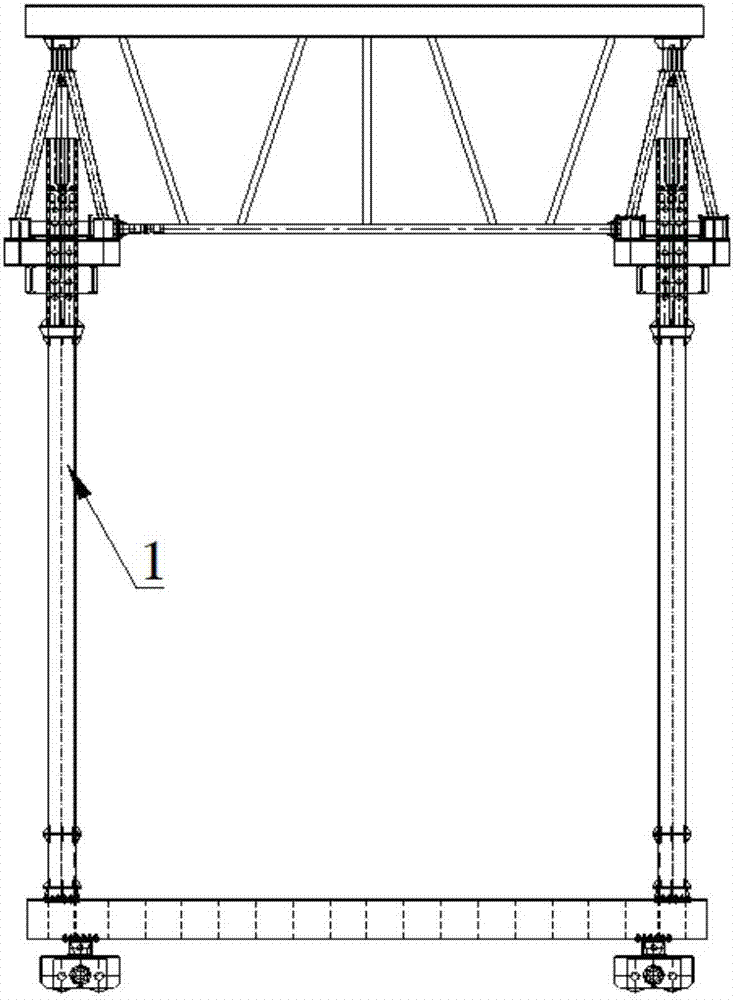

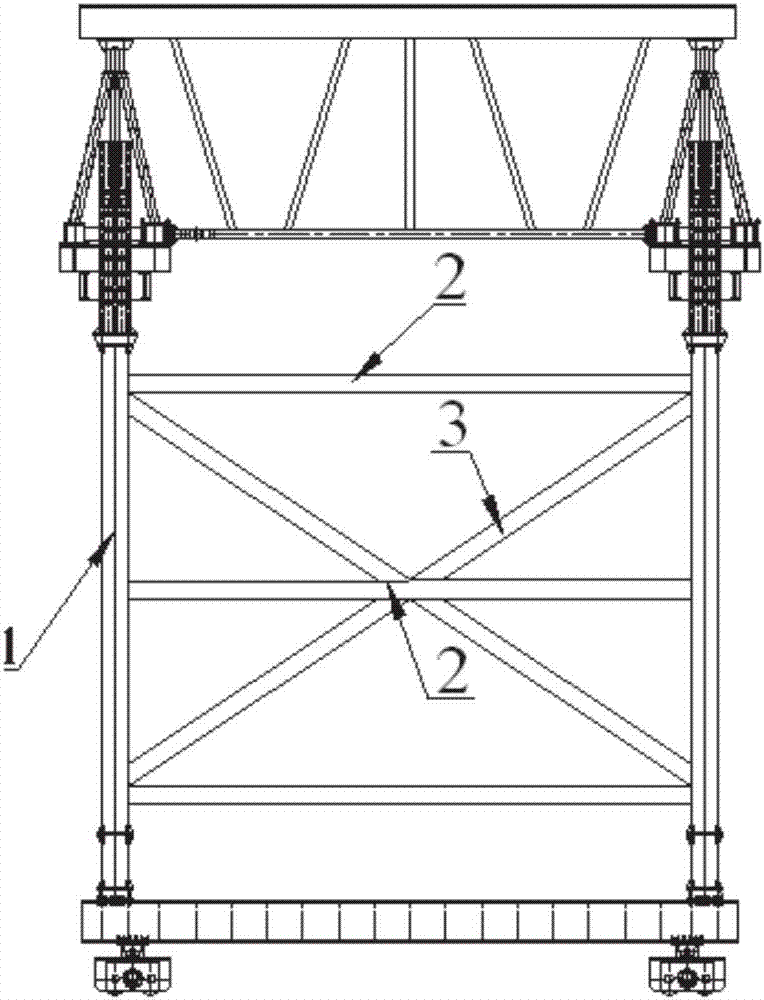

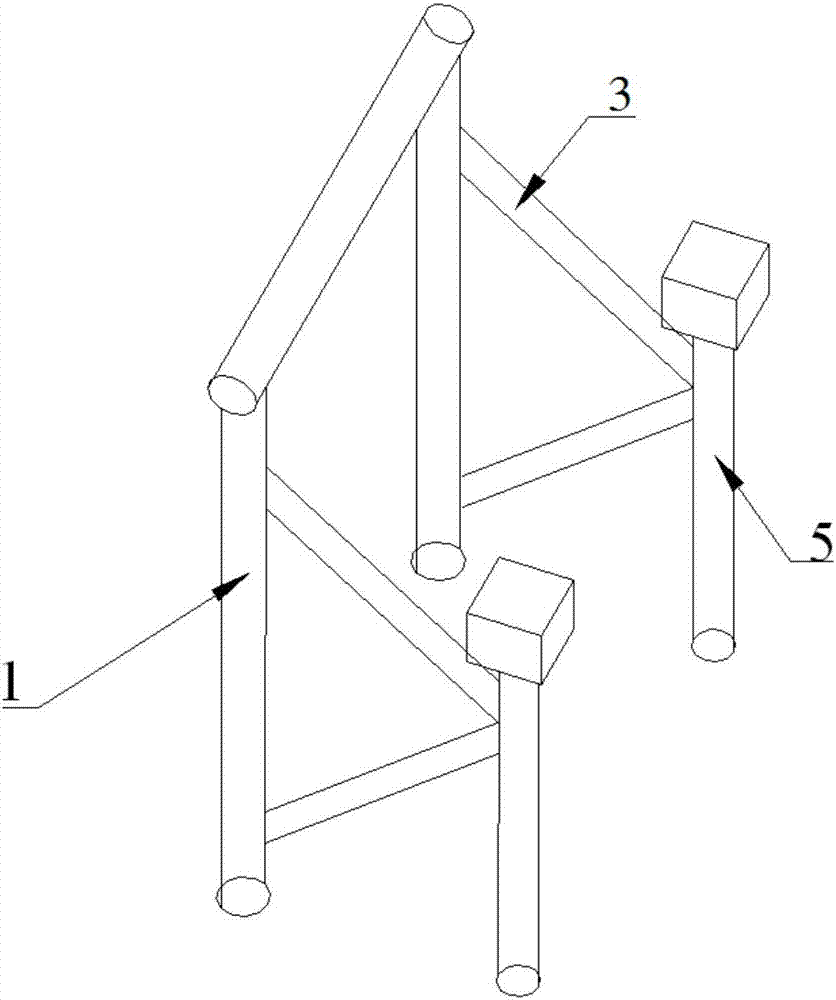

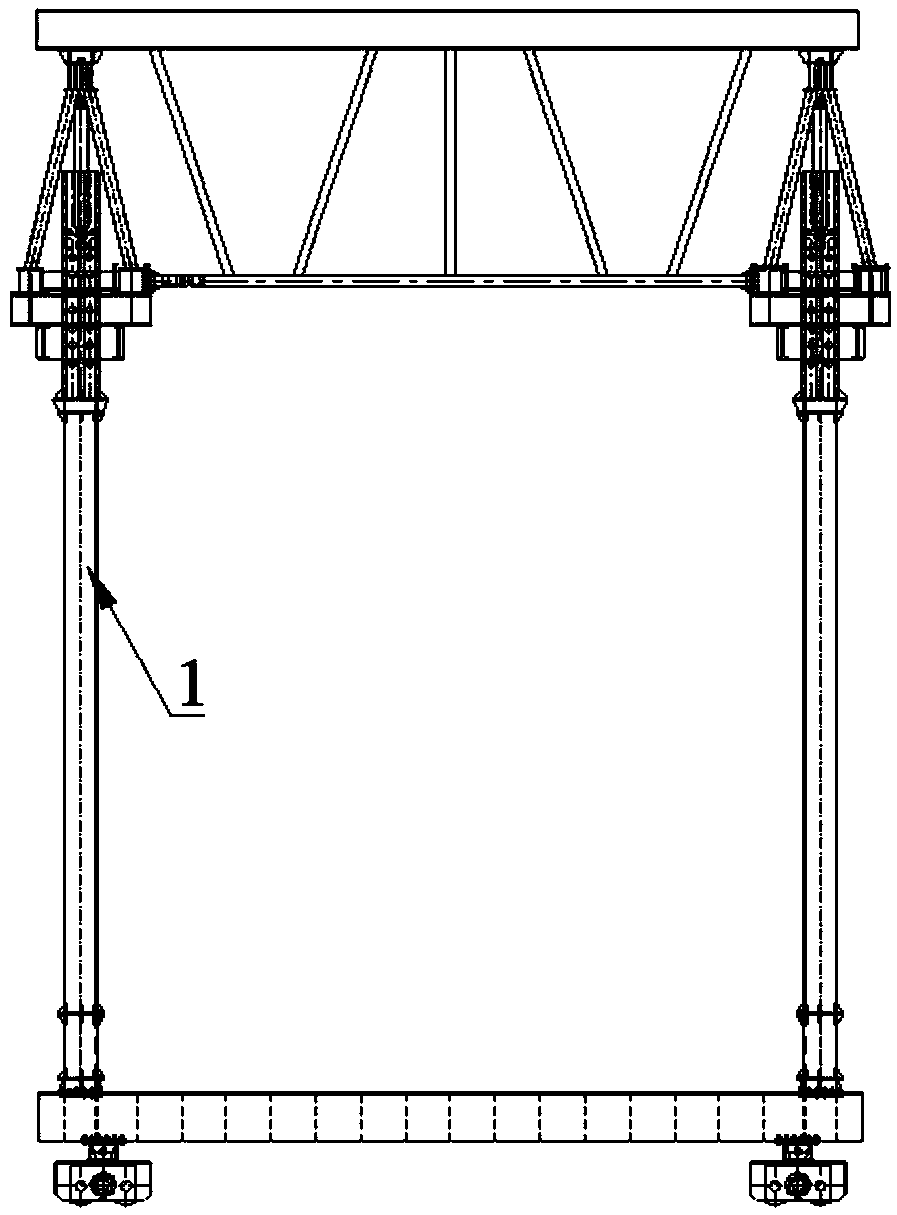

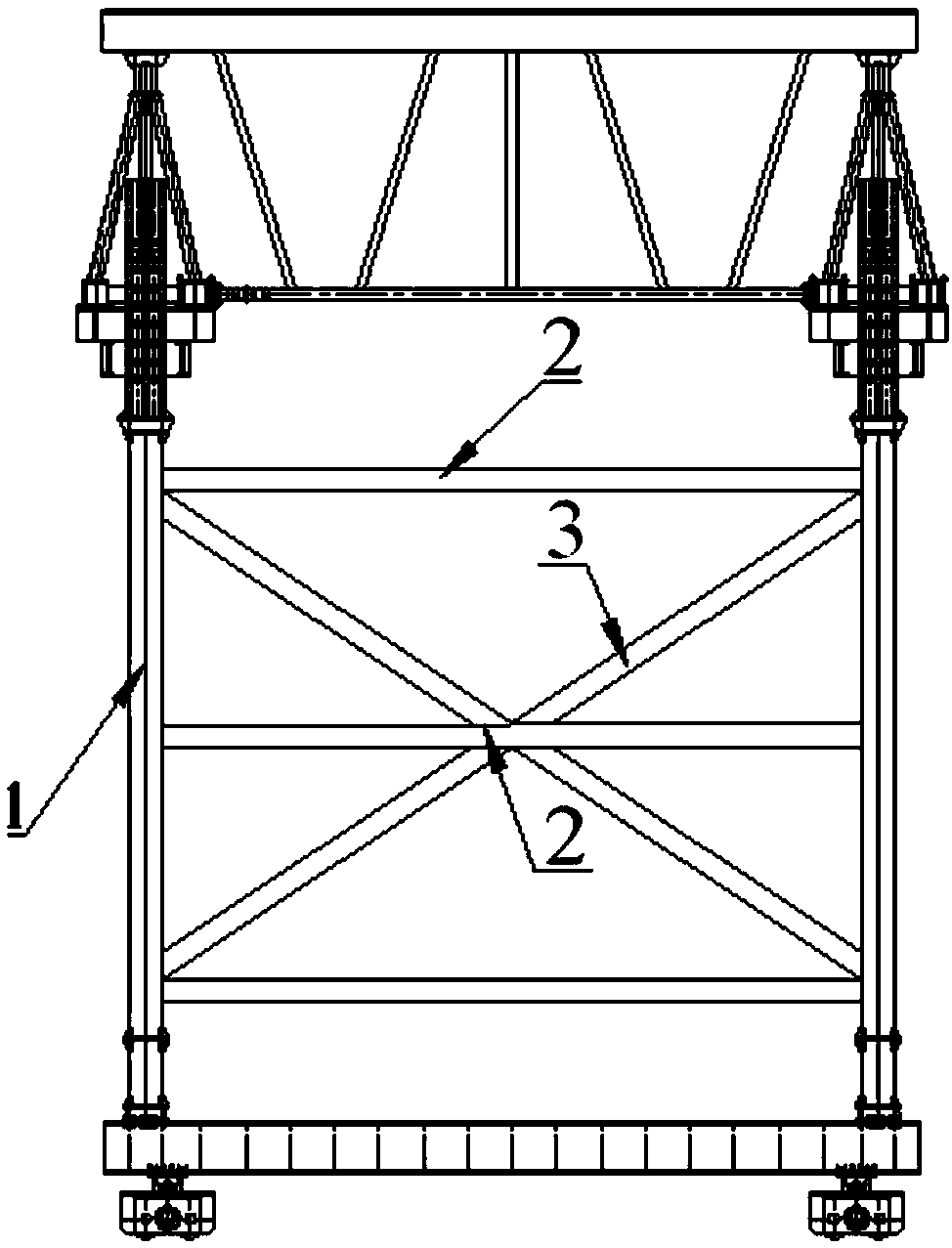

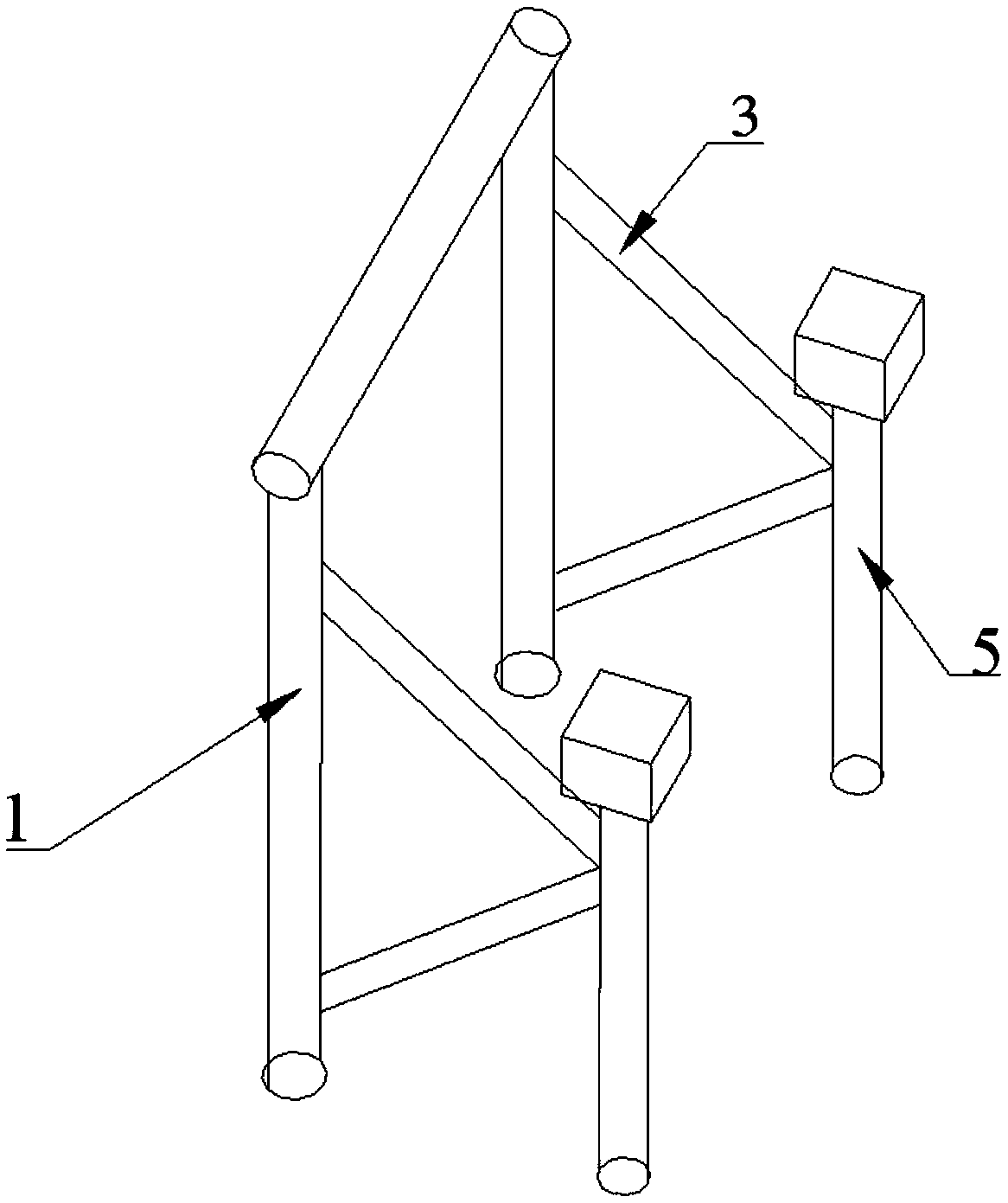

Method for reinforcing bridge erecting machine

ActiveCN106996083AHigh strengthAvoid instabilityBuilding repairsBridge strengtheningStructural engineering

The invention discloses a method for reinforcing a bridge erecting machine. The method comprises the following steps that A, relative parameters such as the length and the diameter of each front supporting leg and the diameter of each pier column are measured; B, direct calculating or finite element calculating is conducted to determine a transverse reinforcing scheme and a longitudinal reinforcing scheme, wherein the transverse reinforcing scheme comprises the step that a plurality of supporting rods are connected between the two front supporting legs, and the longitudinal reinforcing scheme comprises the step that a plurality of supporting rods are connected between the pier columns and the front supporting legs; C, steel materials with corresponding section parameters and the corresponding lengths are selected; and D, the steel materials with the selected models and parameters in the step C are cut, and the front supporting legs and the pier columns are connected and reinforced according to the reinforcing schemes in the step B. By means of extra reinforcing measures, the weight of the whole machine can be reduced, and the manual labor of workers in the detaching process also can be reduced, most importantly, the problems of stability losing and fracturing of the front supporting legs the in the process of detaching and erecting a beam body is avoided, and the method can be widely applied to reinforcing of front supporting legs of various bridge erecting machines.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

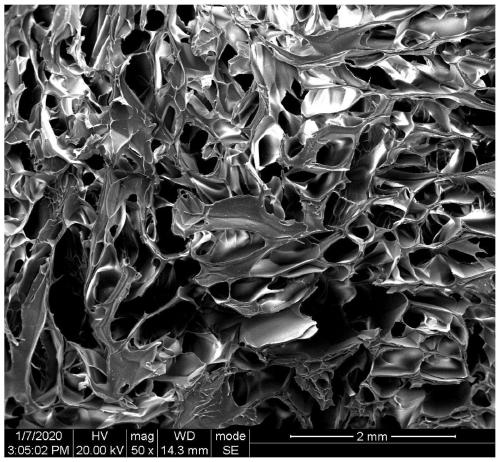

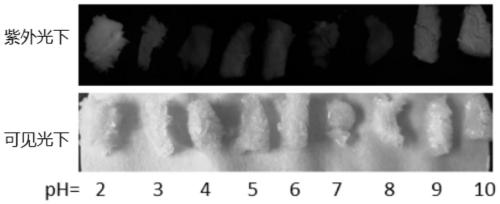

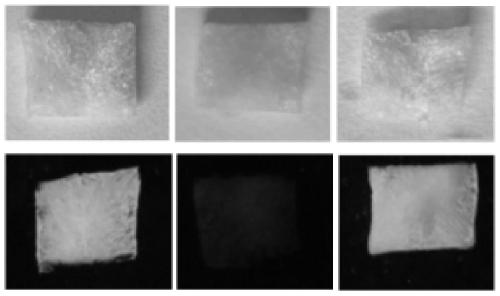

Cellulose foam capable of visually identifying and removing chromium as well as preparation method thereof and chromium removal method

ActiveCN111250062AFast regenerationDestruction will notOther chemical processesWater contaminantsCelluloseFreeze-drying

The invention provides cellulose foam capable of visually identifying and removing chromium as well as a preparation method thereof and a chromium removal method. The preparation method comprises thefollowing steps: adding epichlorohydrin into a cellulose solution, stirring until the color of the solution becomes light, adding a PEI solution, uniformly stirring, crosslinking at 25-60 DEG C for 5-60 minutes to form hydrogel, washing with deionized water, and carrying out freezing and freeze-drying, thereby obtaining the product. The cellulose foam prepared by the invention can be used for quickly identifying and removing Cr(VI) in a relatively wide pH range. According to the method, the electrostatic adsorption and subsequent oxidation-reduction process of Cr(VI) can be regulated and controlled, it is guaranteed that the structure of the adsorbent cannot be damaged due to the oxidation reaction while Cr(VI) is removed, the regeneration speed of the material adsorbing Cr(VI) is high, and the structure of the adsorbent cannot be damaged in the regeneration process.

Owner:SOUTHWEST JIAOTONG UNIV

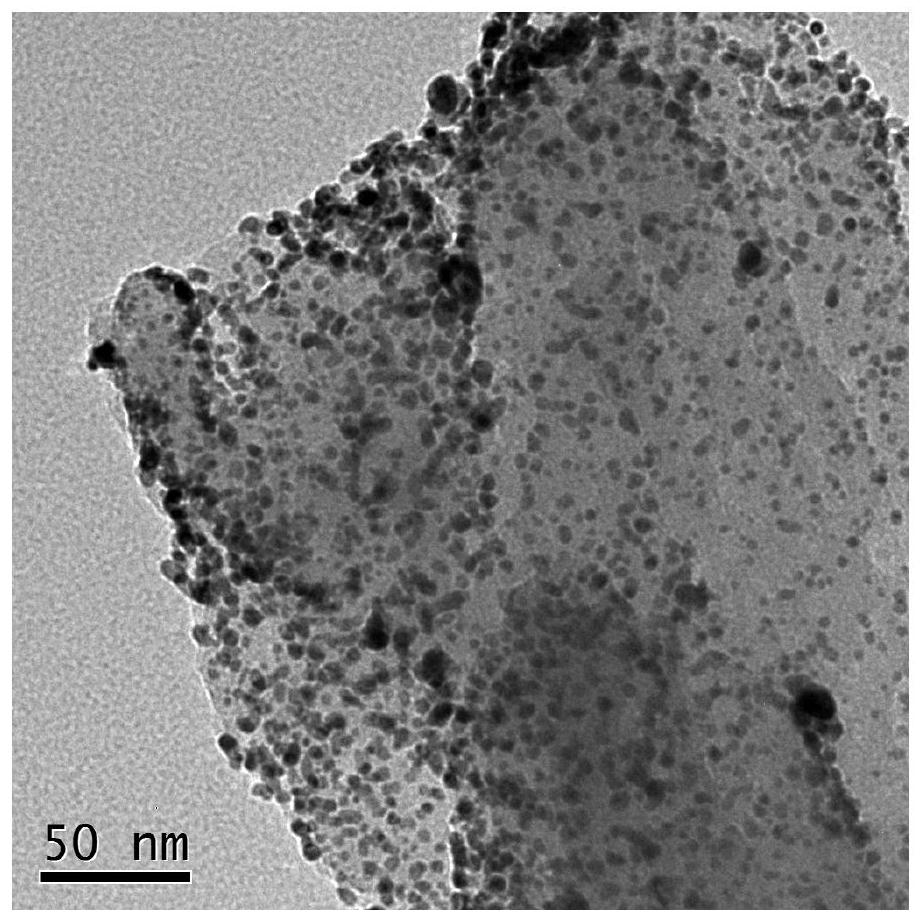

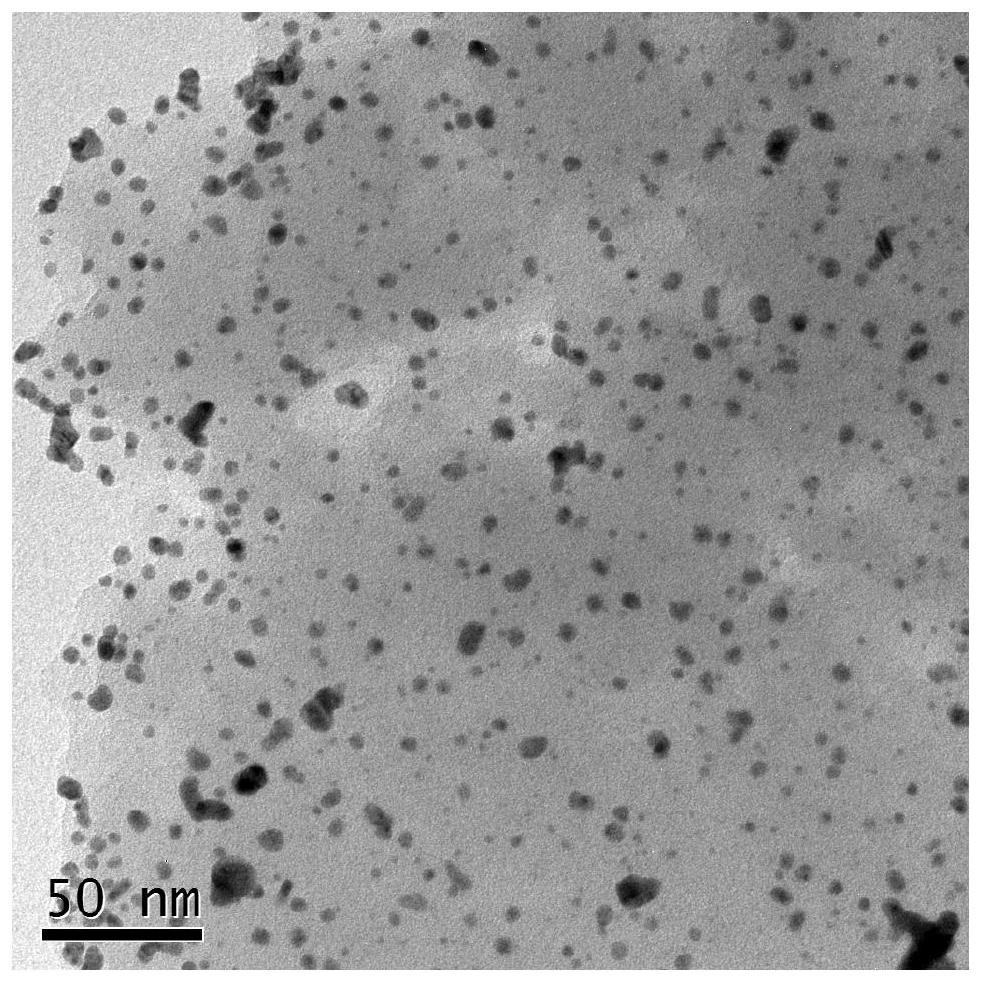

Metal-loaded covalent organic framework composite material, and preparation method and application thereof

ActiveCN113477277AOvercome the disadvantages of easy reunionImprove catalytic performanceWater treatment compoundsOrganic-compounds/hydrides/coordination-complexes catalystsHigh concentrationPtru catalyst

The invention belongs to the field of material preparation and environment, and particularly relates to a metal-loaded covalent organic framework composite material, and a preparation method and application thereof. The composite material is prepared from the following components: metal nanoparticles and TpMA. The preparation method comprises the following steps: mixing TpMA, chloroauric acid and methanol; and then adding sodium borohydride, and reacting to obtain the product. The metal nanoparticle loaded covalent organic framework material prepared by the invention is a novel heterogeneous catalyst which is simple to prepare, green and efficient, has high catalytic activity, high degradation rate and short time, and can catalytically reduce high-concentration pollutants.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

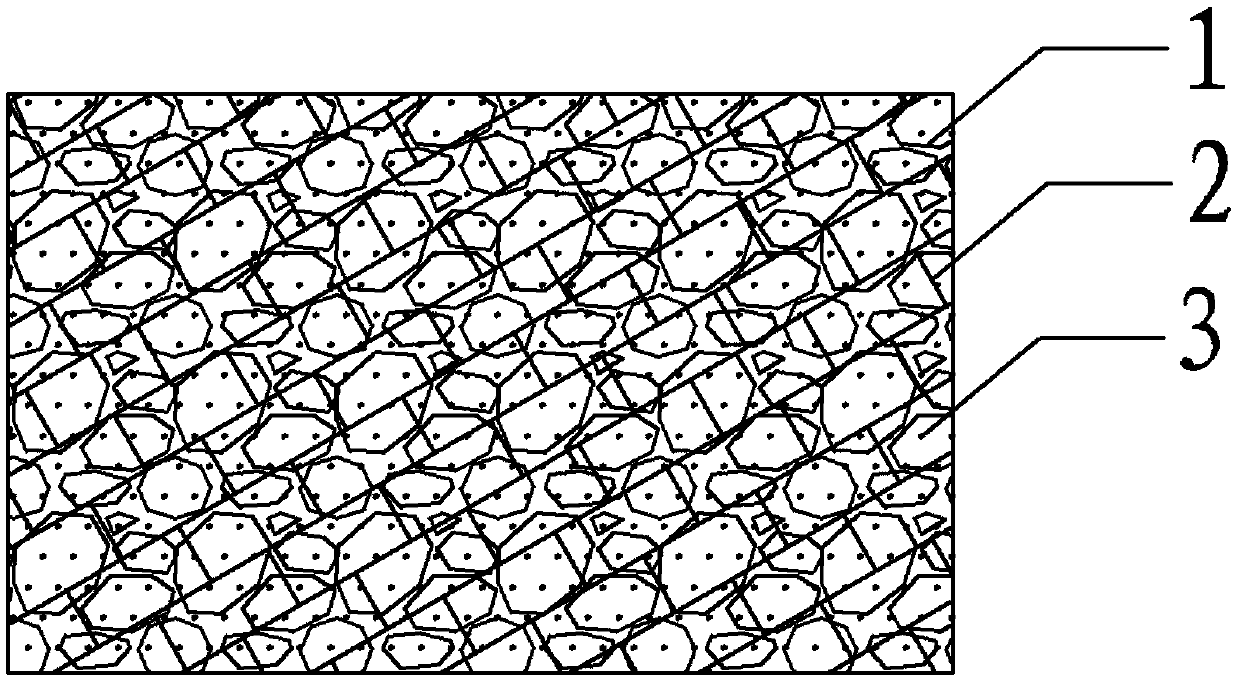

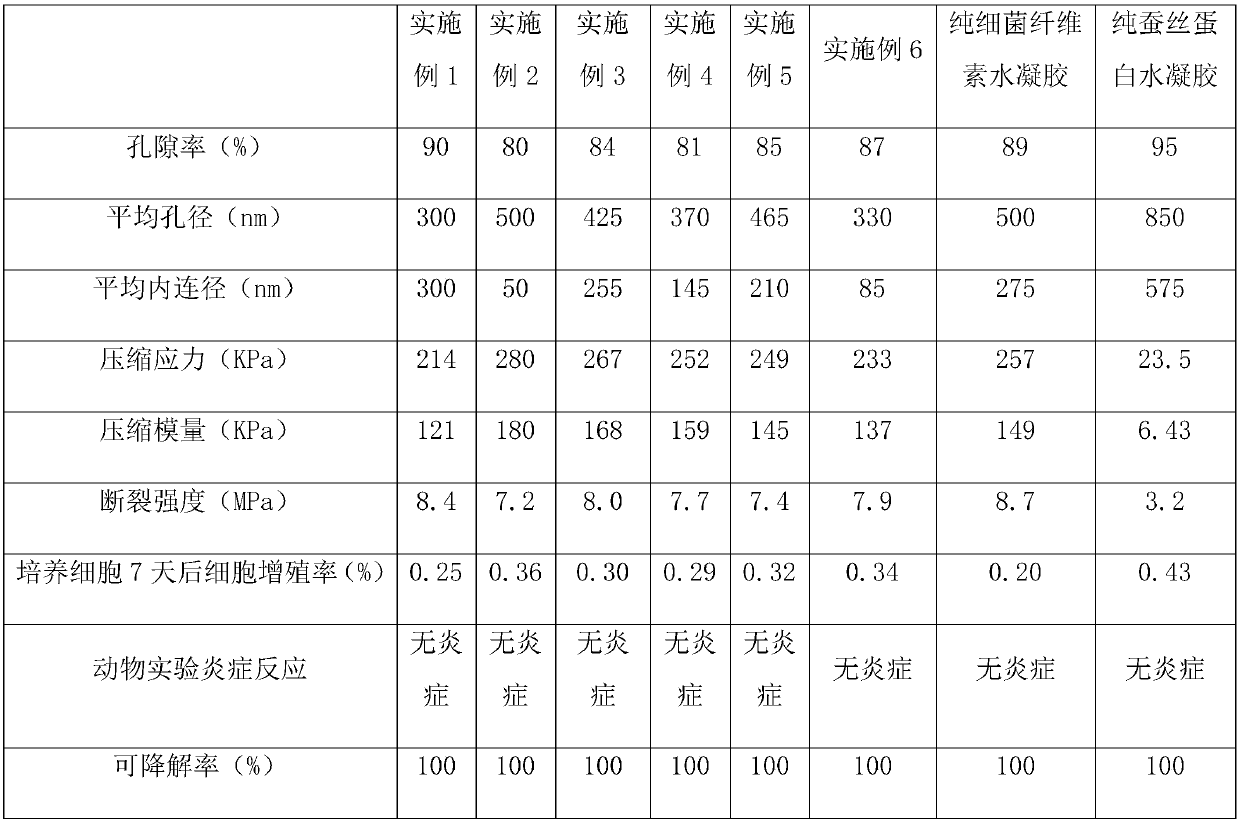

A kind of fibroin/bacterial cellulose composite hydrogel and its preparation method and application

ActiveCN106492286BPromote repairIncrease loadTissue regenerationProsthesisPorosityBiocompatibility Testing

The invention provides a fibroin / bacterial cellulose composite hydrogel, and a preparation method and application thereof. According to the invention, bacterial cellulose hydrogel surface-modified by glycidyl trimethyl ammonium chloride, bone morphogenetic protein-2 and fibroin are used as raw materials; electrical gel technology is employed for formation of a network pore structure by the fibroin on the surface and in the internal network pore structure of the surface-modified bacterial cellulose hydrogel so as to compose a dual-network pore structure; and the morphogenetic protein-2 is adhered into the dual-network pore structure so as to form the fibroin / bacterial cellulose composite hydrogel. The preparation method is simple, highly efficient, green and environment-friendly; and the prepared composite hydrogel has high mechanical strength, high porosity, good connectivity of the interiors of pores and good biocompatibility, and is applicable as a cartilage repairing scaffold to the field of cartilage-repairing tissue engineering.

Owner:江苏臻中滤料科技有限公司

Preparation method of cotton stalk printing paper pulp

InactiveCN103669062AHigh strengthIncrease the number ofNon-macromolecular organic additionWax additionToluene diisocyanatePaper sheet

A preparation method of cotton stalk printing paper pulp particularly includes the following steps that firstly, cleaned dry cotton stalks are exploded through a steam explosion method, and then granules with the average grain diameter being below 120 micrometers are obtained; secondly, the granules are placed in water, toluene diisocyanate, insectwax, glyceride maleic anhydride resin and 1-2 parts by weight of polyurethane resin are added, temperature rises to the range from 60 DEG C to 80 DEG C, and the mixture is stirred for 1-2 hours; thirdly, water at the temperature ranging from 35 DEG C to 50 DEG C is added to the mixture obtained through the second step, and meanwhile 2-4 parts by weight of alums are added, the mixture is filtered after being stirred for 15-30 minutes, filter liquor is drained, and filter materials are reserved; fourthly, the filter materials are placed in a reaction kettle, titanium dioxide with the average grain diameter being below 10 micrometers, 1-3 parts by weight of starch, phenolic resin and octyl alcohol are added, and the mixture is stirred. Paper products prepared through the paper pulp is bright in color, tough and durable, good in printing performance, long in service life, and suitable for large-scale industrial production.

Owner:SUZHOU YIHENG PRINTING

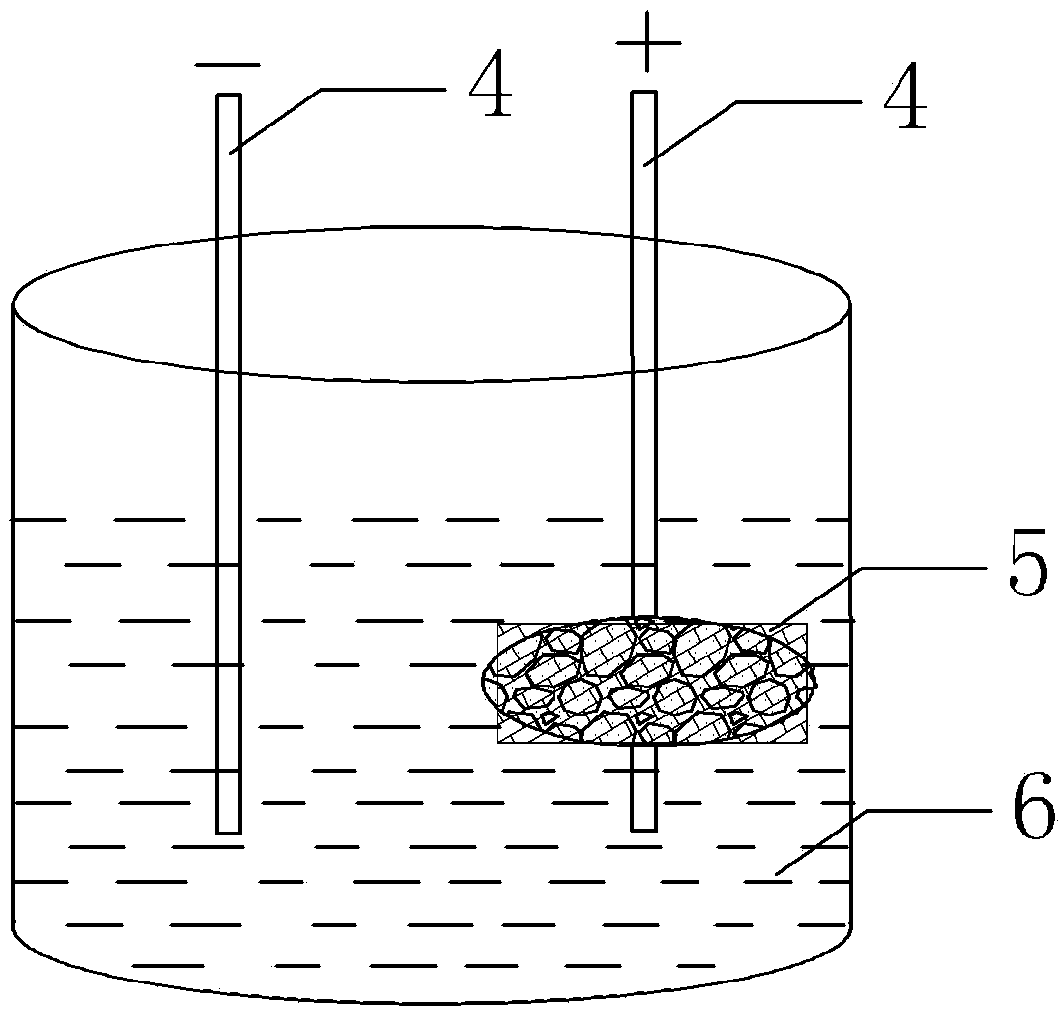

Method for soil remediation through electric power method

InactiveCN107983763AStructure will not breakReduce permeabilityContaminated soil reclamationElectrical forceVoltage

The invention provides a method for soil remediation through an electric power method. The method for soil remediation through the electric power method comprises the following steps that 1, the periphery of to-be-remediated soil is plugged; 2, an electrode is inserted into the to-be-remediated soil; 3, water is discharged, wherein the water discharge amount is 8-15 kg per square meter of the soil; and 4, the electrode is electrified, wherein the voltage is 110-220 V, and the electrifying time is 3-6 hours. The method has the advantages that the soil remediation effect is good, and the secondary pollution can be effectively avoided.

Owner:南京化学工业园环保产业协同创新有限公司

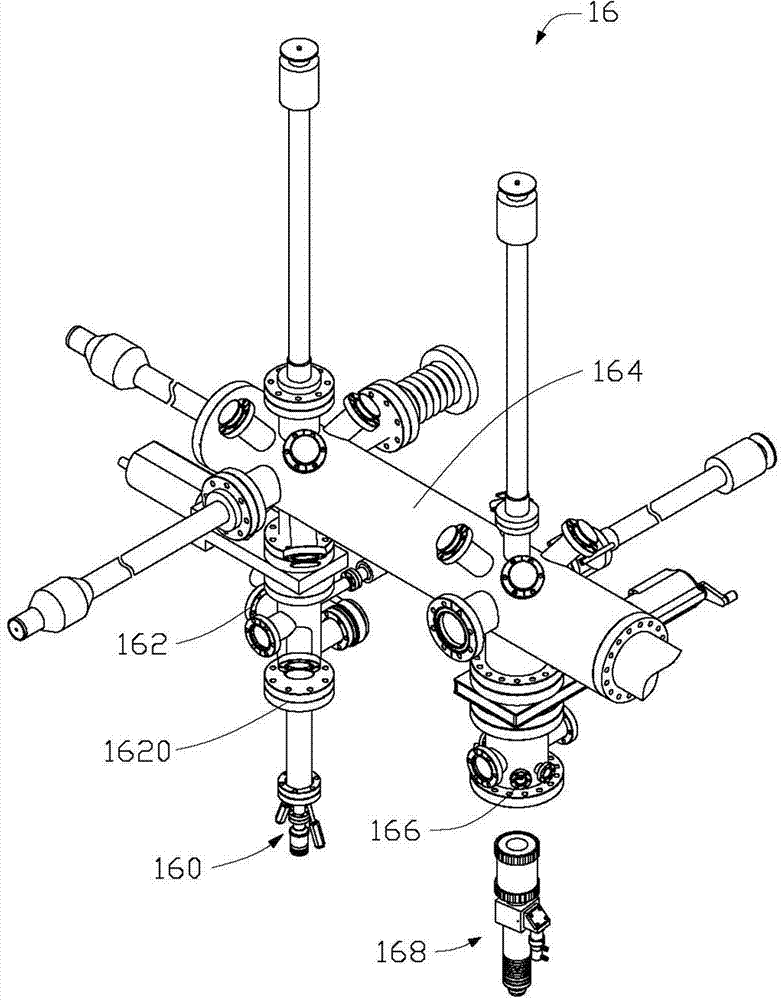

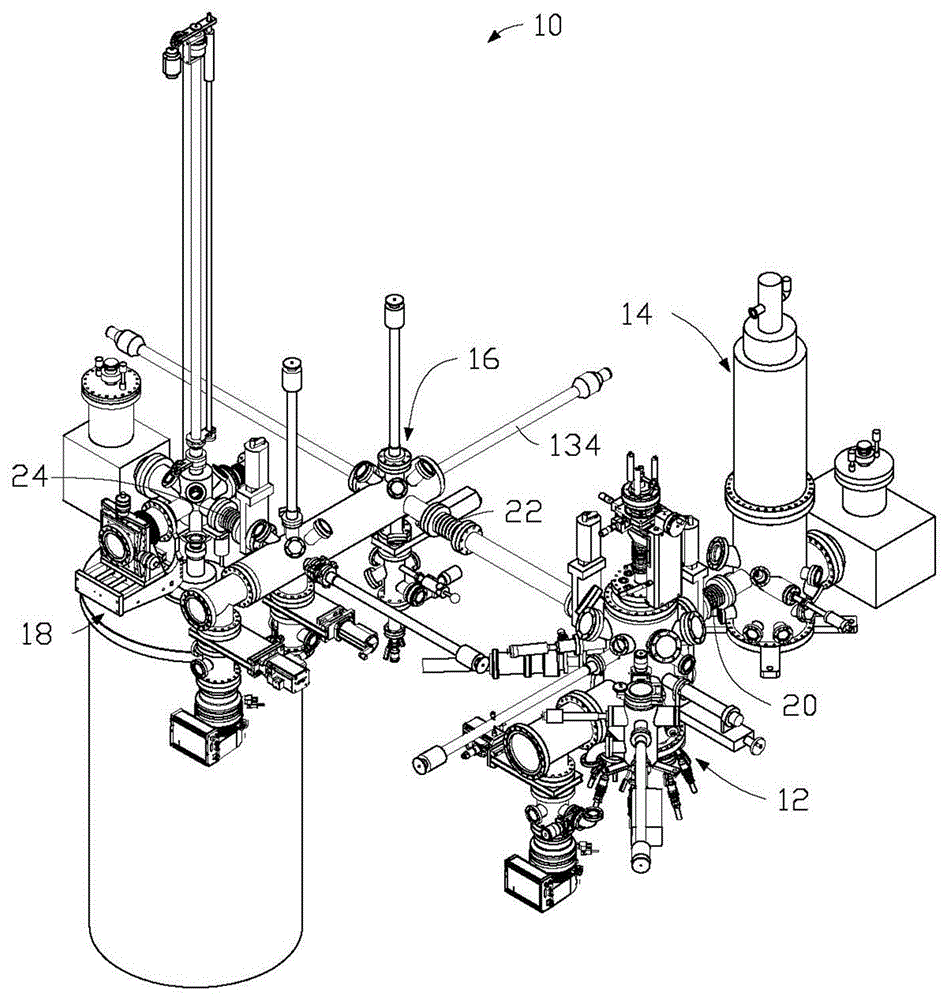

In-situ transport property measurement method

ActiveCN104749325AStructure will not breakNo pollutionMaterial analysisMeasurement deviceMembrane configuration

The invention discloses an in-situ transport property measurement method. The in-situ transport property measurement method comprises the following steps: preparing a membrane-shaped structure on a substrate in a first vacuum environment; arranging an electrode on the surface away from the substrate, of the membrane-shaped structure, carrying out micro-cutting treatment on the surface away from the substrate, of the membrane-shaped structure, cutting a micro-cutting area, and locating the electrode in the micro-cutting area in a second vacuum environment; enabling a probe array to contact with the electrode, and carrying out measurement on transport property in a third vacuum environment, wherein the first vacuum environment, the second vacuum environment and the third vacuum environment are a continuous vacuum environment, the continuous vacuum environment means that the membrane-shaped structure directly enters the second vacuum environment from the first vacuum environment, and directly enters the third vacuum environment from the second vacuum environment, and the membrane-shaped structure is out of contact with air. The invention further relates to an in-situ transport property measurement device.

Owner:TSINGHUA UNIV

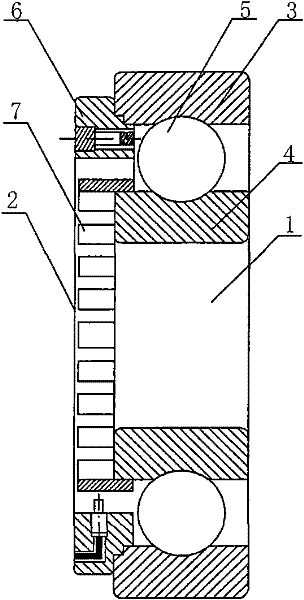

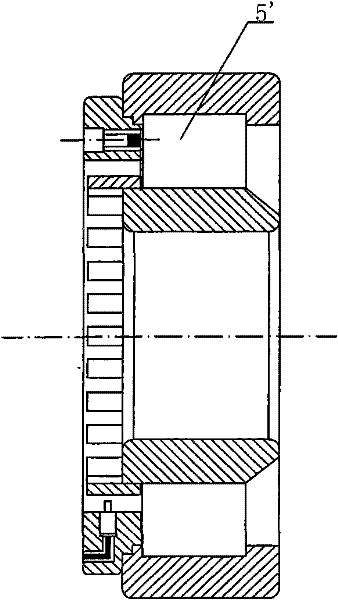

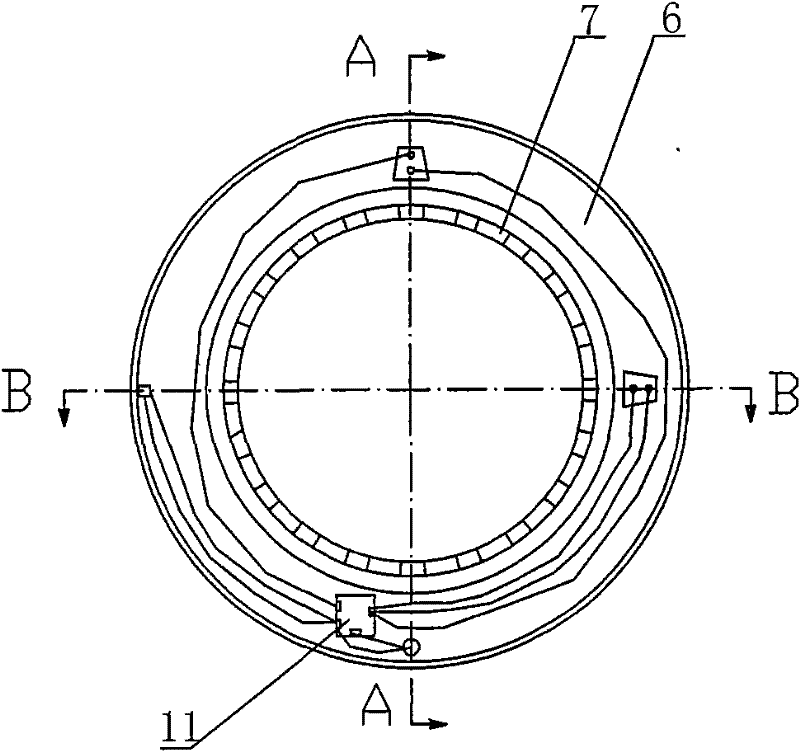

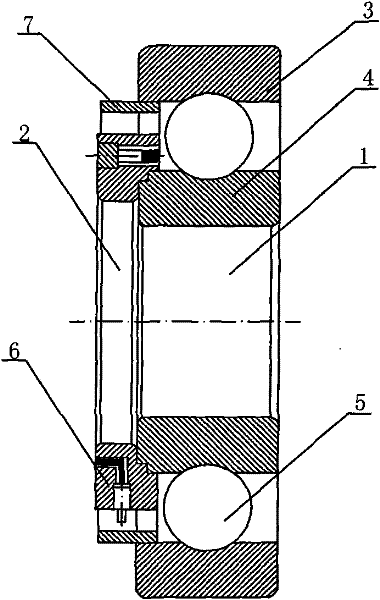

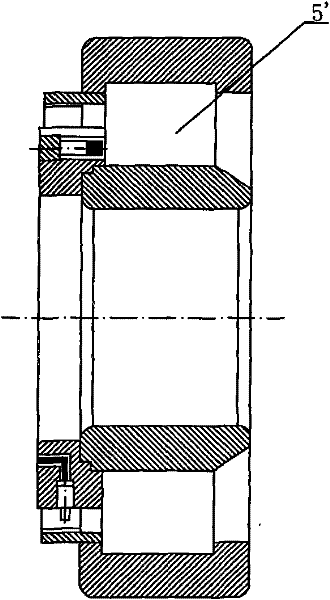

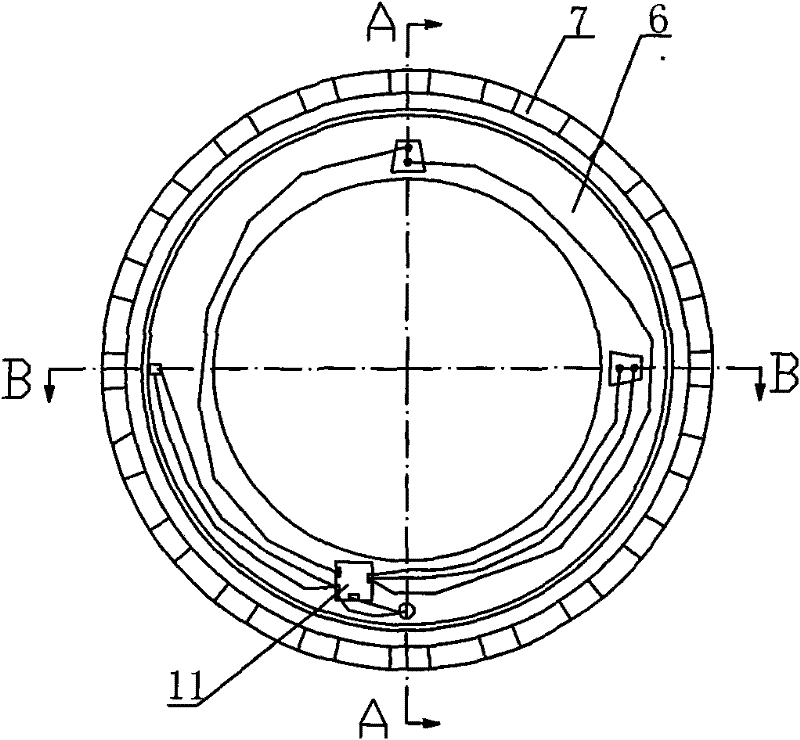

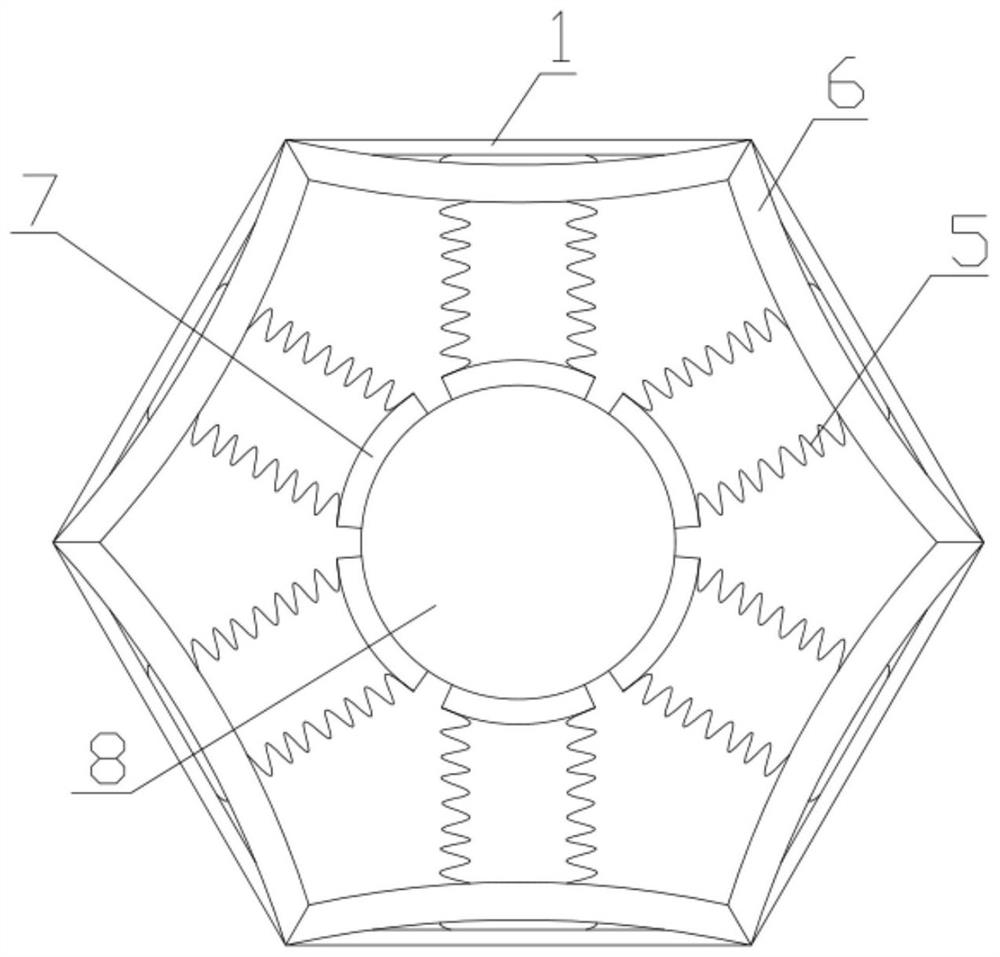

Integrated coupling type intelligent monitoring bearing

ActiveCN101818755BQuickly sense temperature changesStructure will not breakRolling contact bearingsBearing assemblyControl engineeringElectrical and Electronics engineering

The invention discloses an integrated coupling type intelligent monitoring bearing, which comprises a bearing (1) and an intelligent monitor (2) which is arranged on the bearing (1), the bearing (1) comprises an immovable outer ring (3) and a rotatable inner ring (4), a rolling ball (5) or a rolling post (5') is arranged between the immovable outer ring (3) and the rotatable inner ring (4), the intelligent monitor (2) comprises a shell body (6) and a rotational speed code disc (7) which is a round code disc which is arranged in the shell body (6) and has the same axial core as the shell body (6), the intelligent monitor (2) is arranged at one side of the bearing (1), and the intelligent monitoring bearing has the beneficial effects of detecting fault information of the bearing at short distance under the premise of not damaging the structure of the bearing and relatively actually obtaining the operating acceleration, rotational speed and temperature of the bearing without damaging thestructure of the bearing and causing the problem of stress concentration of the bearing.

Owner:CHONGQING UNIV

A kind of preparation method of lithium battery hard carbon negative electrode material

ActiveCN109786694BIncrease battery capacityImproved magnification performanceMaterial nanotechnologyCell electrodesChemical synthesisElectrical battery

Owner:云南中晟新材料有限责任公司

Oat drying and pre-curing equipment

The invention discloses oat drying and pre-curing equipment. The oat drying and pre-curing equipment comprises a drying oven for drying and pre-curing oat and further comprises a conveying unit for sending the oat into the drying oven, wherein the conveying unit comprises a conveying pipe communicating with a conveying channel arranged on an oven body to guide the oat into a cavity of the drying oven, an air inlet channel for blowing air is arranged on an air guide channel to blow air into the oat, and an airflow valve is arranged on the air inlet channel; a stirring box arranged on an outer ring in the drying oven stirs the oat, and a heating box is arranged in the stirring box to make contact with the oat and preheat the oat in a rotary vibration manner. The oat drying and pre-curing equipment fully ensures that the oat can be humidified in the drying process, active components of the oat can be kept, and particularly, protein, amino acid and glucose components in the oat cannot be lost due to drying.

Owner:内蒙古阴山优麦食品有限公司

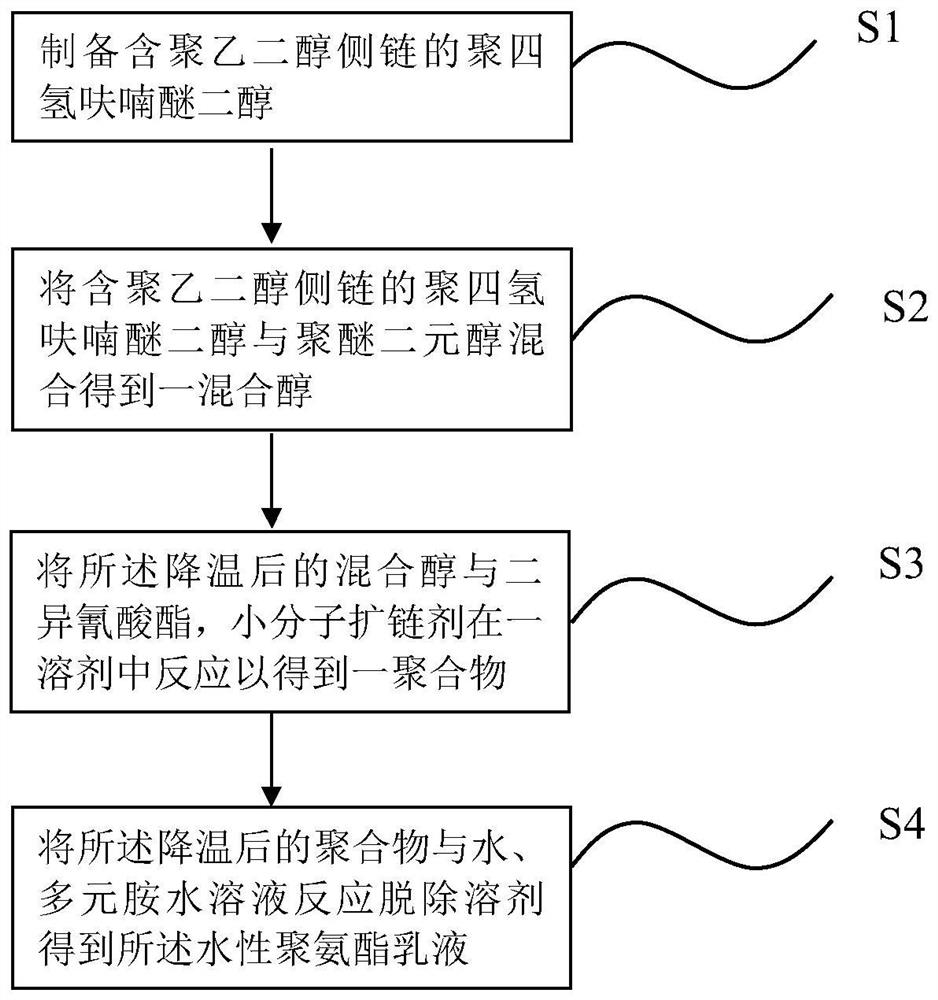

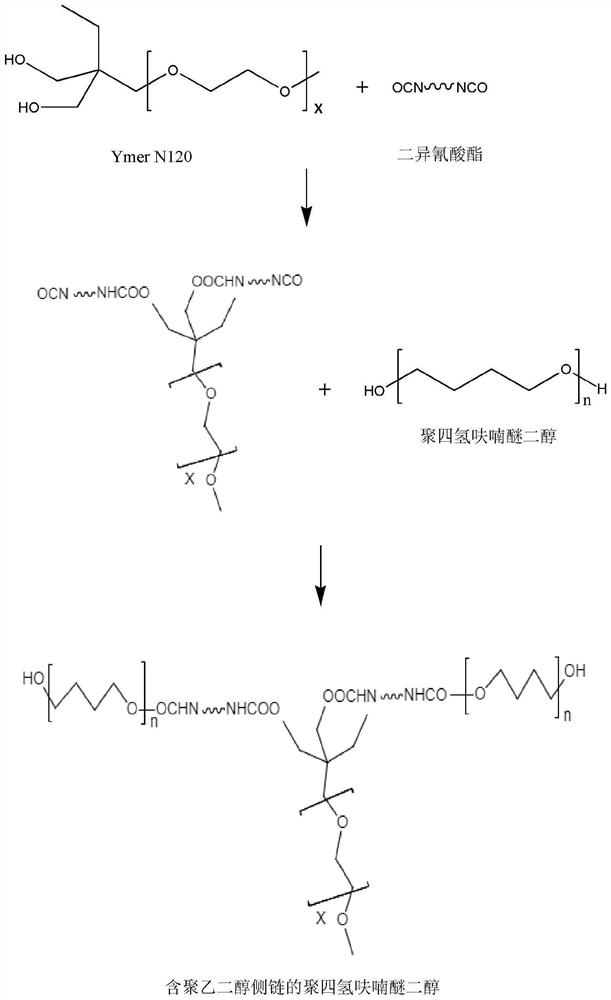

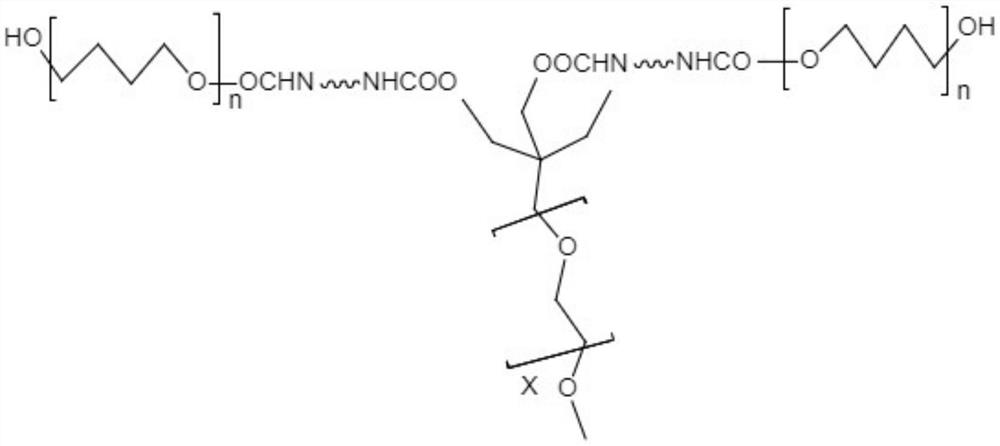

A kind of aqueous polyurethane emulsion and its preparation method and application

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD +1

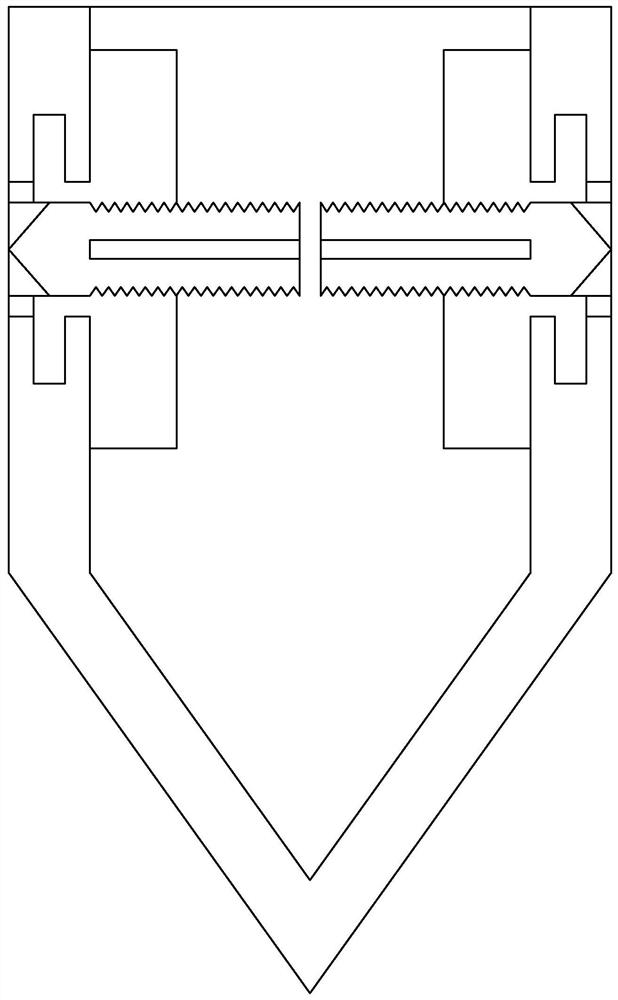

Wind-resistant reinforcing nail

InactiveCN111636755AStructure will not breakEasy to fixTents/canopiesBulkheads/pilesStructural engineeringMechanical engineering

The invention discloses a wind-resistant reinforcing nail. The wind-resistant reinforcing nail comprises an outer nail body and an inner nail body, wherein the outer nail body comprises a nail body part and a nail point part, an open groove is formed in the nail body part, first through holes are formed in the side wall of the open groove, side nails are slidably connected into the first through holes, gears are rotatably connected into the open groove, the gears and the first through holes are arranged concentrically, inner threaded holes are formed in the gear, outer threads matched with theinner threaded holes are arranged on the side nails, the side nails and the gears form lead screw structures, the inner nail body is inserted into the outer nail body, racks are arranged on the innernail body, and the racks are used for driving the gears to rotate. According to the reinforcing nail, after the outer nail body is inserted into soil, the inner nail body can be nailed into the outernail body, then the side nails can stretch out of the first through holes to be inserted into soil, on one hand, the reinforcing effect is good, and on the other hand, loosening caused by soil structure damage is avoided.

Owner:温州安荷桥科技有限公司

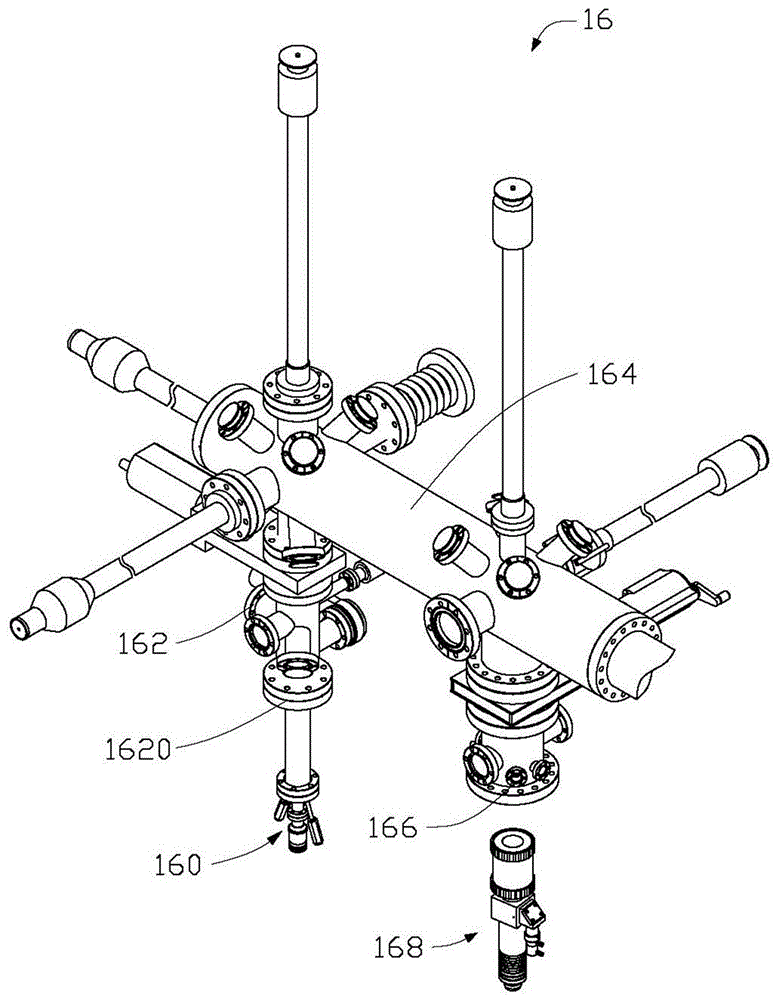

Electromagnetic enhanced method and device for removing heavy metals and pops from organic waste

ActiveCN108856240BSimple and flexible structureImprove removal efficiencySolid waste disposalWaste processingSlurry

The invention discloses a method and a device for removing heavy metals and POPs in organic wastes by electromagnetic reinforcement. The method comprises the following steps of: firstly preparing theorganic wastes into slurry; applying a magnetic field to the slurry to make sure that the heavy metals and the POPs in the slurry are transformed into a water solution state; separating the organic waste slurry into two components; afterwards applying an electric field to the slurry, migrating water molecules and the heavy metals and POPs which are continuously transformed into the water solutionstate to a cathode region of the electric field under the effect of electro-migration, and meanwhile migrating the components of the organic wastes to an anode region of the electric field so as to realize separation of the two components; and filtering and dehydrating the organic waste slurry to finally obtain harmless low-water-content organic wastes. The method and the device disclosed by the invention can be used for efficiently removing large-particle impurities, some heavy metals and the POPs in the organic wastes, can also reduce the water content of the organic wastes to 30% to 50%, thereby overcoming the defects that a traditional organic waste treatment method is low in efficiency, takes effect slowly and has no oneness.

Owner:KUNMING UNIV OF SCI & TECH

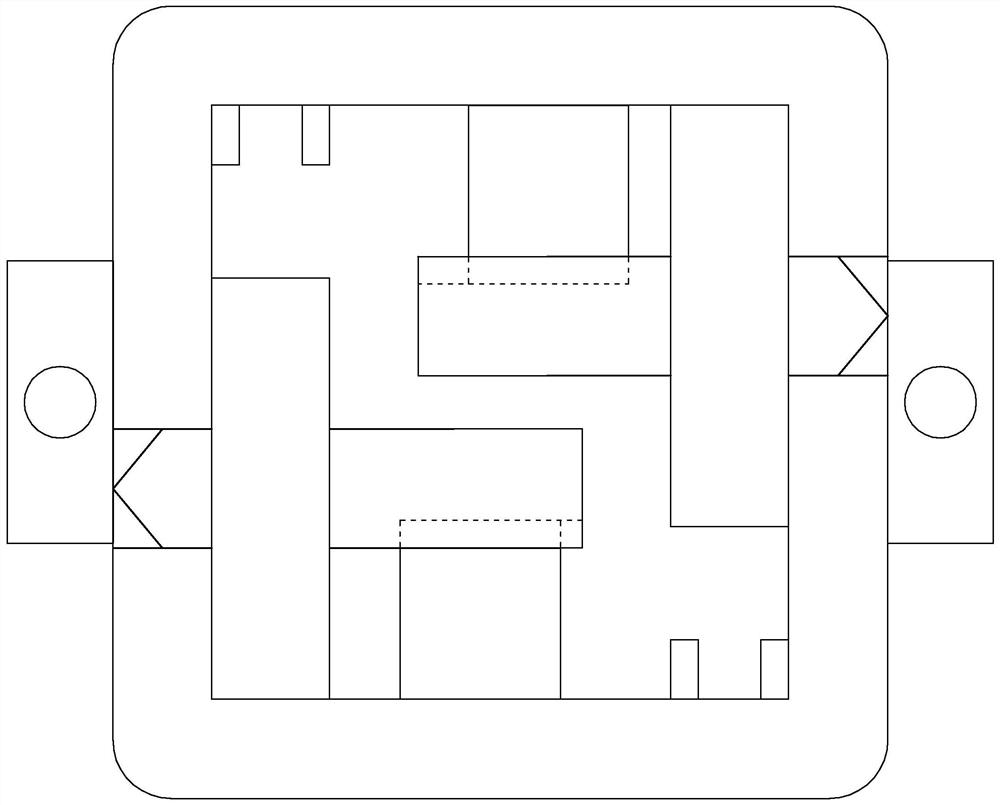

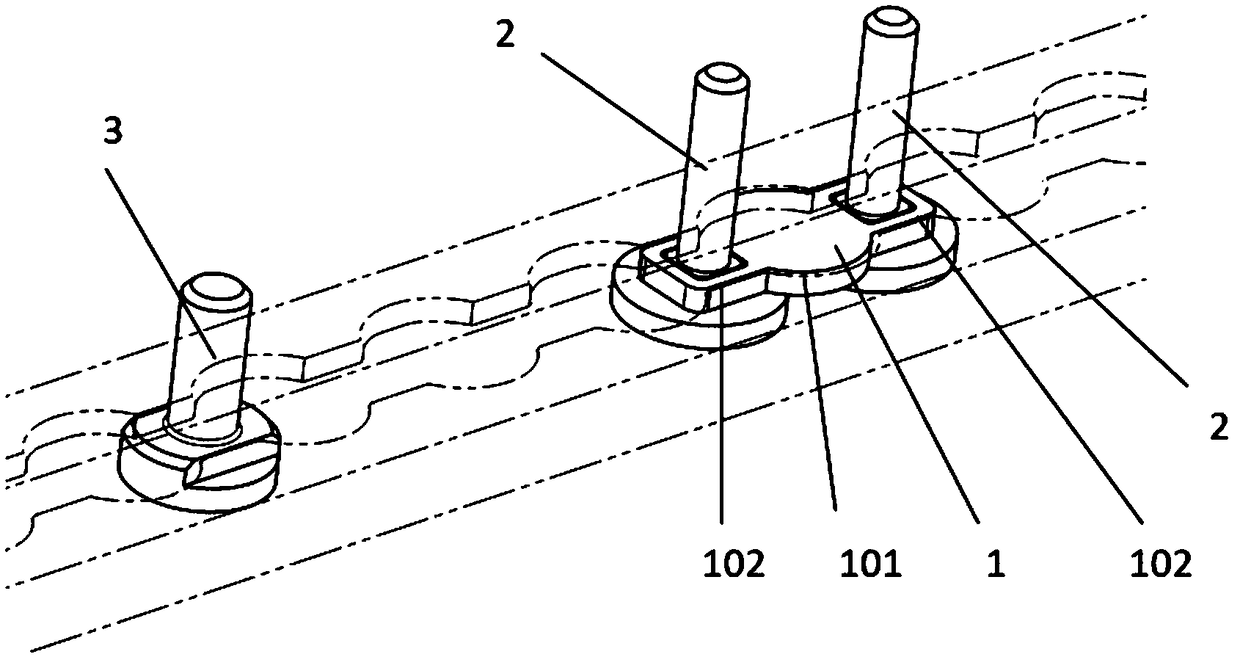

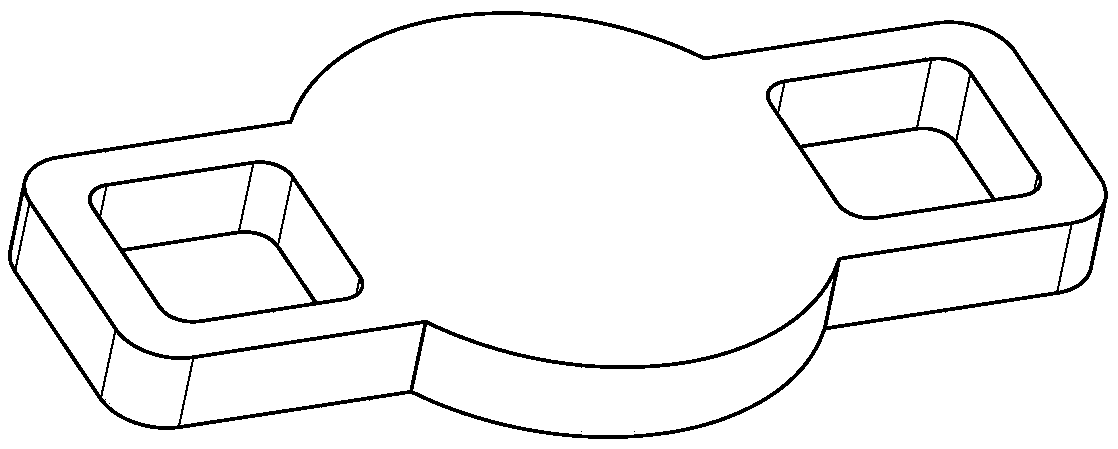

Engine room test equipment rack fixing adapter structure

InactiveCN109131934AStructure will not breakStructure is not destroyedAircraft components testingEngineeringTest equipment

The invention relates to an engine room test equipment rack fixing adapter structure. The invention comprises a stopping washer, a stopping bolt and an anchor bolt; a circular arc surface in the middle of the stopper gasket is matched with a circular track on the aircraft guide rail, and two sides of the stopper gasket are rectangular planes; the stopping bolt is divided into a circular head bolthead, a polished rod with a rectangular cross section and a thread with a circular cross section from bottom to top; When in use, the stopping bolt and the stopping washer cooperate to limit the movement of the equipment rack in the front-back direction of the guide rail; the bolt head of the anchor bolt is circular, and L-shaped through grooves are symmetrically formed on both sides of the upperpart; In use, the two parallel vertical surfaces formed by the through grooves engage the anchor bolts on the inner wall of the aircraft guide rail to avoid rotation during bolt tightening. The invention can effectively borrow the internal plate slide rail of the aircraft cabin, fix the equipment rack through the transfer structure, avoid disassembling the internal structure of the engine cabin when installing the equipment rack, assemble quickly and reliably, and improve the assembly efficiency of the equipment rack by more than 80%.

Owner:HARBIN

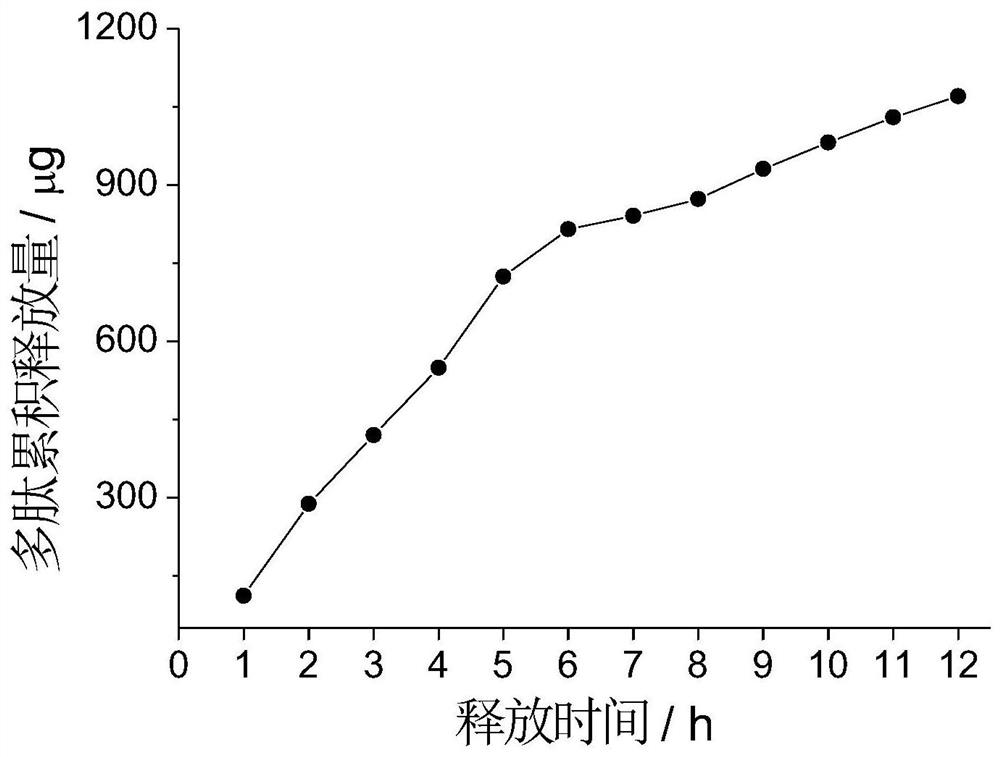

A kind of supramolecular polypeptide with self-assembled aggregate structure and preparation method thereof

ActiveCN110123658BStructure will not breakMaintain biological activityCosmetic preparationsToilet preparationsMicron scalePolymer science

Owner:上海璞萃生物科技有限公司

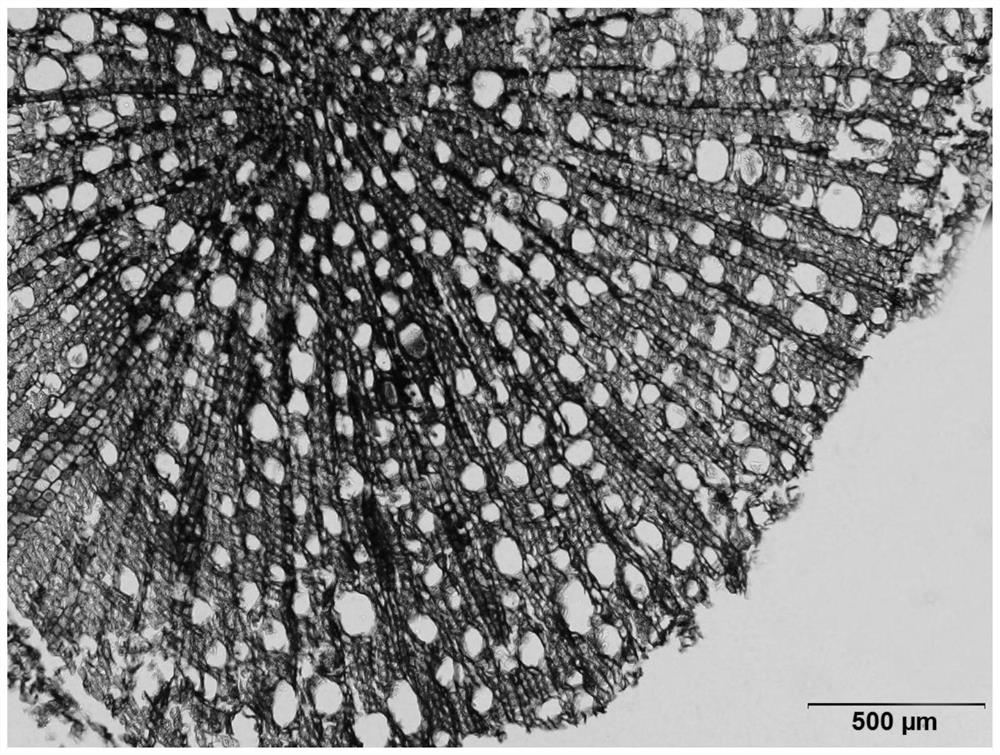

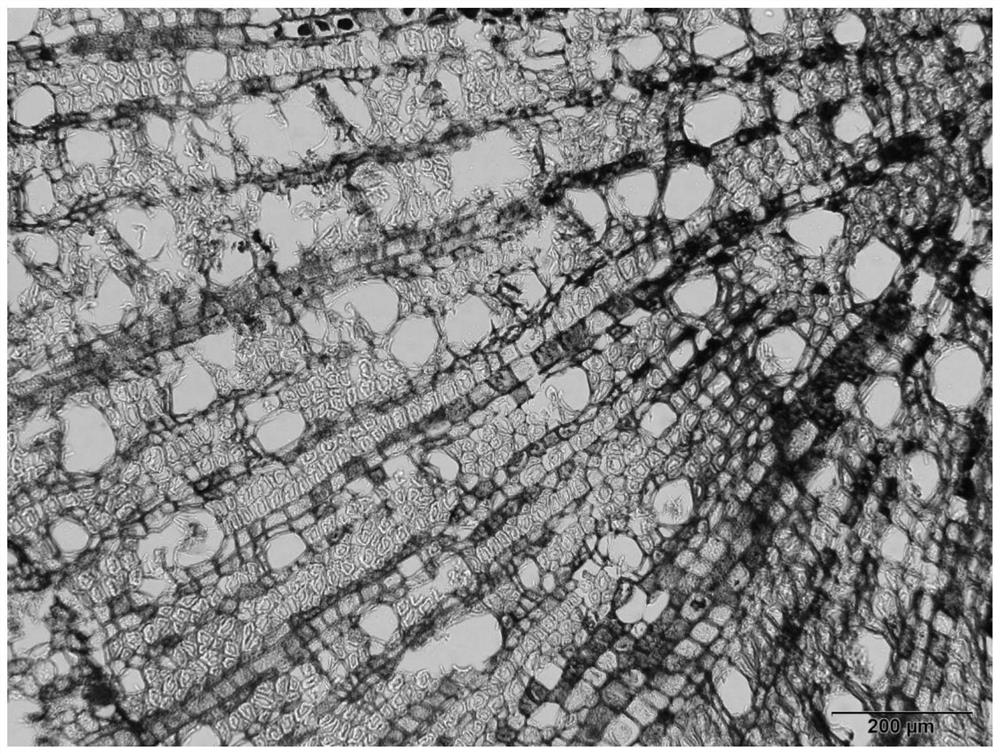

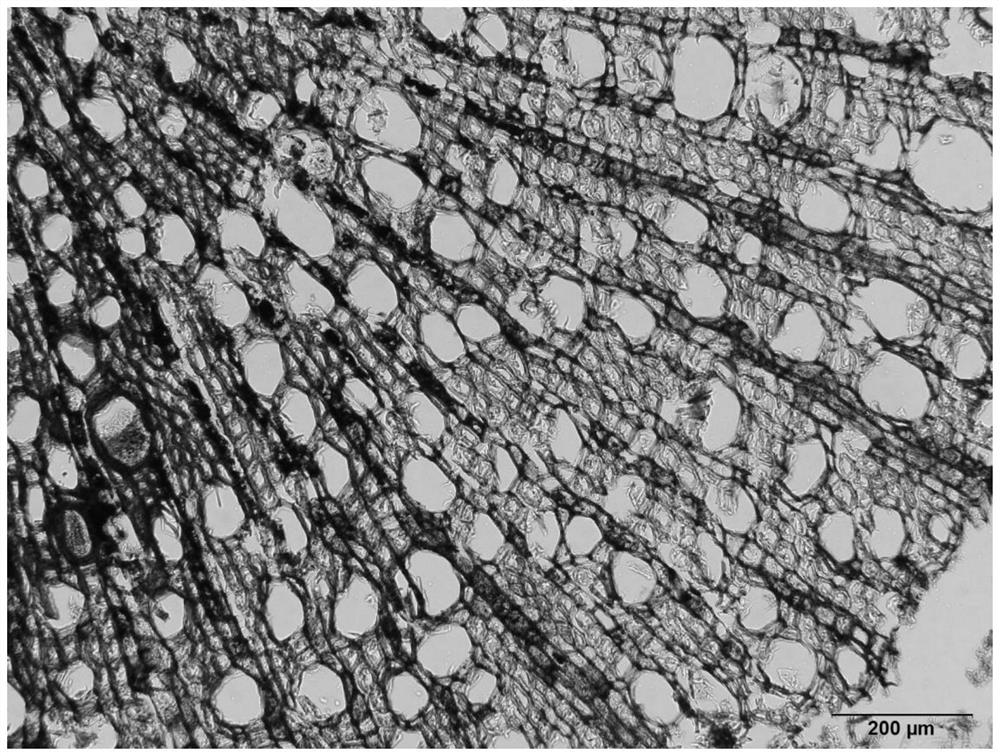

Method for preparing slices of black tiger root

ActiveCN110006721BShorten softening treatment timeConvenient sourcePreparing sample for investigationPhysical chemistryPotassium hydroxide

The invention discloses a method for preparing black tiger root slices, which uses the black tiger root as a raw material, soaks in a softener and adopts ultrasonic treatment to obtain the slices of the black tiger root. Wherein, the softening agent includes the following raw materials in parts by weight: 5 parts of potassium hydroxide or sodium hydroxide solution with a concentration of 50%, 3 parts of glycerol with a volume fraction of 30%, and 2 parts of ultrapure water. The softener prepared from strong alkali, glycerin and water can not only quickly and effectively soften the roots of the black tiger, but also has simple raw materials, convenient sources, and low toxicity. Combined with ultrasonic heating technology, the softening process is more effective. Sufficient, making the prepared slices better.

Owner:GUANGXI BOTANICAL GARDEN OF MEDICINAL PLANTS

A method for reinforcing a bridge erecting machine

ActiveCN106996083BHigh strengthReduce loadBuilding repairsBridge strengtheningPhysical hard workStructural engineering

The invention discloses a method for reinforcing a bridge erecting machine. The method comprises the following steps that A, relative parameters such as the length and the diameter of each front supporting leg and the diameter of each pier column are measured; B, direct calculating or finite element calculating is conducted to determine a transverse reinforcing scheme and a longitudinal reinforcing scheme, wherein the transverse reinforcing scheme comprises the step that a plurality of supporting rods are connected between the two front supporting legs, and the longitudinal reinforcing scheme comprises the step that a plurality of supporting rods are connected between the pier columns and the front supporting legs; C, steel materials with corresponding section parameters and the corresponding lengths are selected; and D, the steel materials with the selected models and parameters in the step C are cut, and the front supporting legs and the pier columns are connected and reinforced according to the reinforcing schemes in the step B. By means of extra reinforcing measures, the weight of the whole machine can be reduced, and the manual labor of workers in the detaching process also can be reduced, most importantly, the problems of stability losing and fracturing of the front supporting legs the in the process of detaching and erecting a beam body is avoided, and the method can be widely applied to reinforcing of front supporting legs of various bridge erecting machines.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

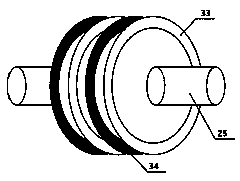

Combined intelligent monitoring bearing

ActiveCN101819091BStructure will not breakDoes not cause stress concentration problemsAcceleration measurement using interia forcesMachine bearings testingInterference fitStress concentration

The invention discloses a combined intelligent monitoring bearing, which comprises a bearing (1) and an intelligent monitor (2) arranged on the bearing. The bearing (1) comprises a rotary outer ring (3) and a fixed inner ring (4); and a ball (5) or roller (5') is arranged between the rotary outer ring (3) and the fixed inner ring (4). The combined intelligent monitoring bearing is characterized in that the intelligent monitor (2) comprises a shell (6) and a rotation speed code disc (7) which is sleeved outside the shell (6) and is coaxial with the shell (6); the intelligent monitor (2) is axially inserted in a gap between the rotary outer ring (3) and the fixed inner ring (4) of the bearing (1) to be in interference fit with the bearing. The combined intelligent monitoring bearing has theadvantages of realizing short-distance detection of fault information of the bearing without damaging the bearing structure, truly achieving the acceleration, rotation speed and temperature for the work of the bearing without damaging the structure of the bearing or causing stress concentration of the bearing.

Owner:CHONGQING UNIV

In situ transport property measurement method

ActiveCN104749325BStructure will not breakNo pollutionMaterial analysisMeasurement deviceProbe array

The invention discloses an in-situ transport property measurement method. The in-situ transport property measurement method comprises the following steps: preparing a membrane-shaped structure on a substrate in a first vacuum environment; arranging an electrode on the surface away from the substrate, of the membrane-shaped structure, carrying out micro-cutting treatment on the surface away from the substrate, of the membrane-shaped structure, cutting a micro-cutting area, and locating the electrode in the micro-cutting area in a second vacuum environment; enabling a probe array to contact with the electrode, and carrying out measurement on transport property in a third vacuum environment, wherein the first vacuum environment, the second vacuum environment and the third vacuum environment are a continuous vacuum environment, the continuous vacuum environment means that the membrane-shaped structure directly enters the second vacuum environment from the first vacuum environment, and directly enters the third vacuum environment from the second vacuum environment, and the membrane-shaped structure is out of contact with air. The invention further relates to an in-situ transport property measurement device.

Owner:TSINGHUA UNIV

A janus droplet with structural color based on 3D droplet printing and its preparation method

ActiveCN111171341BPrecise size controlPrecise control ratioAdditive manufacturing apparatus3D object support structuresComputer printingActive agent

The invention discloses a Janus droplet with structural color based on 3D droplet printing and a preparation method thereof. The hydrogel with shear-thinning property is used as the matrix, and the two oil phases that are mutually soluble at high temperature and phase-separated at low temperature are used as the dispersed phase. The injection pump is controlled by a 3D printer, and the dispersed phase at high temperature is injected into the matrix to form Droplets, and by lowering the temperature, induce phase separation of the two oil phases to form Janus droplets. Because the two oil phases have different refractive indices, the incident light can interfere at the interface, showing a ring-shaped structural color. The structural color of Janus droplets can be tuned by the type or ratio of non-ionic surfactants in the hydrogel, while its position and size can be precisely controlled by 3D printing, and a colorful pattern composed of Janus droplets can be generated, which is in the functional Display, sensing and other fields have high application value.

Owner:ZHEJIANG UNIV

Bridge pier protection device

InactiveCN112695618ASimple structureStructure will not breakClimate change adaptationBridge structural detailsArchitectural engineeringPier

The invention discloses a pier protection device which solves the problems that an existing pier protection device is complex in structure and inconvenient to maintain. The device comprises at least three stand columns and a steel wire rope net, the axes of all the stand columns are parallel, and all the stand columns are arranged in a regular polygon shape along the radial sections of the stand columns; the steel wire rope net is rotationally connected with the two adjacent stand columns, and the steel wire rope net rotates around the axes of the stand columns. The device has the advantages of being simple in structure, easy to construct, convenient to maintain, low in cost and the like.

Owner:四川省交通勘察设计研究院有限公司

Wire drawing device for welding strip

PendingCN110576276AImprove welding qualityUniform tensionWelding/cutting auxillary devicesOther manufacturing equipments/toolsEngineeringMechanical engineering

The invention provides a wire drawing device for a welding strip. By means of the device, wire drawing of the welding strip is achieved through mechanical standard operation, the wire drawing qualityis guaranteed, and the wire drawing efficiency is improved. The input end of a horizontal conveying guide groove is provided with a press roller assembly, the input end of the press roller assembly isprovided with a feeding guide groove, and the horizontal conveying guide groove is formed in the upper end face of a vertical support; the middle rear conveying end of the horizontal conveying guidegroove is provided with a wire press clamping jaw, the wire press part of the wire press clamping jaw is vertical to an inner groove body of the horizontal conveying guide groove, and a vertical air cylinder is connected to the input end of the wire press clamping jaw; a wire drawing device is distributed at the outer side of the tail conveying end of the horizontal conveying guide groove and comprises a wire drawing base plate, a wire drawing base and a wire drawing driving device, the bottom of the wire drawing base is supported at a wire drawing rail and connected with the power input end of the wire drawing driving device, and the wire drawing base plate is located on the upper end face of the wire drawing base.

Owner:SUZHOU AUTOWAY SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com