Method for preparing graphene aqueous solution by using water soluble coronene derivative as solubilizer

A graphene solution, alkene aqueous solution technology, applied in chemical instruments and methods, dissolution, chemical/physical processes, etc., can solve problems such as limited application and application effect, graphene structure damage, low product concentration, etc., to improve electrical properties. , stable nature, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

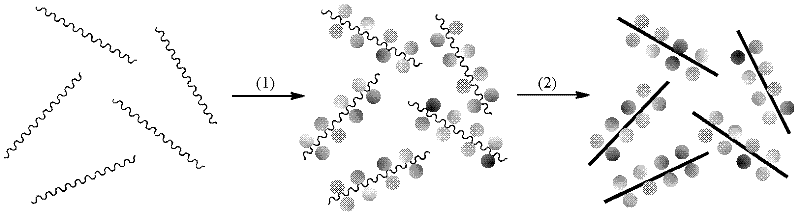

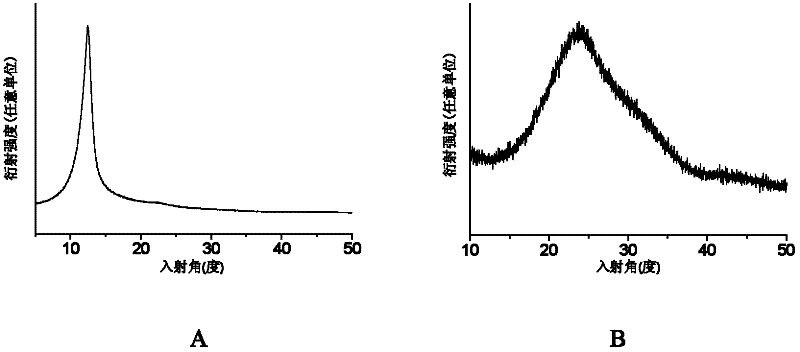

Method used

Image

Examples

Embodiment 1

[0040] A method for preparing an aqueous graphene solution using a water-soluble hexabenzocoronene derivative (1) as a solubilizer, wherein the structure of the water-soluble hexabenzocoronene derivative (1) is as follows:

[0041]

[0042] Include the following steps:

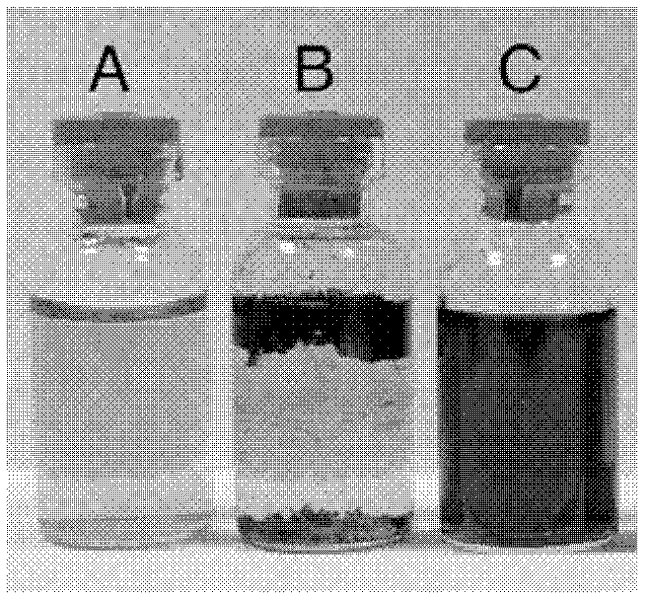

[0043] 1. Under the condition of 10°C, put 1mg of graphene oxide solid in 10ml of ultrapure water, and ultrasonically disperse for 10 minutes to obtain the following: figure 2 The stable brown-yellow solution shown in A;

[0044] 2. Add 4 mg of water-soluble hexabenzocoronene derivative (1) to the solution obtained in step 1, and mix thoroughly;

[0045] 3. Add 50 μl of hydrazine hydrate to the solution obtained in step 2, and stir at 60° C. for 5 hours to obtain a graphene solution;

[0046] 4. Centrifuge the graphene solution obtained in step 3 at 5000 rpm for 30 minutes, remove excess free water-soluble hexabenzocoronene derivative molecule (1) and remaining hydrazine hydrate in the supernatant, and c...

Embodiment 2

[0049] A method for preparing an aqueous graphene solution using a water-soluble hexabenzocoronene derivative (2) as a solubilizer, wherein the structural formula of the water-soluble hexabenzocoronene derivative (2) is as follows:

[0050]

[0051] Include the following steps:

[0052] 1. At 20°C, put 1 mg of graphene oxide solid in 10 ml of ultrapure water and disperse it ultrasonically for 20 minutes to obtain a stable brown-yellow solution;

[0053] 2. Add 30 mg of water-soluble hexabenzocoronene derivative (2) to the solution obtained in step 1, and mix thoroughly;

[0054] 3. Add 80 μl of hydrazine hydrate to the solution obtained in step 2, and stir at 70° C. for 9 hours to obtain a graphene solution;

[0055] 4. Centrifuge the graphene solution obtained in step 3 for 1 hour at 7000 rpm, remove excess free water-soluble hexabenzocoronene derivative molecule (2) and remaining hydrazine hydrate in the supernatant, and centrifuge The obtained solid was dissolved in ul...

Embodiment 3

[0058] A method for preparing an aqueous graphene solution using a water-soluble hexabenzocoronene derivative (3) as a solubilizer, wherein the structural formula of the water-soluble hexabenzocoronene derivative (3) is as follows:

[0059]

[0060] Include the following steps:

[0061] 1. At 20°C, put 1 mg of graphene oxide solid in 10 ml of ultrapure water and disperse it ultrasonically for 20 minutes to obtain a stable brown-yellow solution;

[0062] 2. Add 30 mg of water-soluble hexabenzocoronene derivative (3) to the solution obtained in step 1, and mix thoroughly;

[0063] 3. Add 80 μl of hydrazine hydrate to the solution obtained in step 2, and stir at 70° C. for 9 hours to obtain a graphene solution;

[0064] 4. Centrifuge the graphene solution obtained in step 3 for 1 hour at 7000 rpm, remove excess free water-soluble hexabenzocoronene derivative molecule (3) and remaining hydrazine hydrate in the supernatant, and centrifuge The obtained solid was dissolved in ul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com