Electromagnetic enhanced method and device for removing heavy metals and pops from organic waste

An organic waste and electromagnetic strengthening technology, applied in the field of resource utilization of organic waste, can solve the problems of low efficiency and slow effect, and achieve the effect of promoting removal and improving activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1: The method of electromagnetically strengthening the removal of heavy metals and POPs in organic wastes of urban sewage plants, the specific operations are as follows:

[0047] 1. This method treats 800kg of municipal organic waste

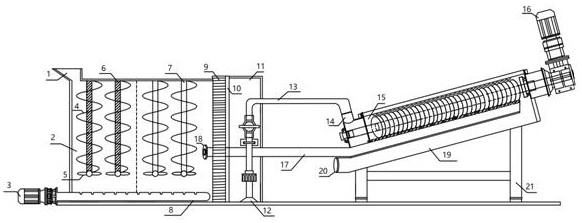

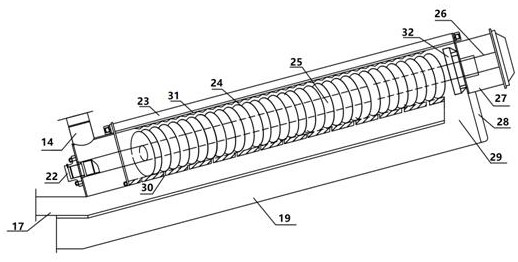

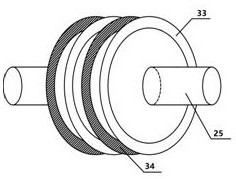

[0048] The electromagnetic reactor is a cuboid with a height of 1m, a length of 1.5m, and a width of 0.8m; the length of the electrodes is 80cm, and the distance between the negative and positive electrode pairs is 30cm; The number of turns of the coil is 10, the inductance is 2μH; the external power supply voltage of the cathode electrode and the anode electrode is 2V, the frequency is 50Hz, the cathode electrode and the anode electrode are graphite electrodes; the length of the aeration tube is 1.2m, and the density of micropores on the aeration tube It is 20 pieces / cm², adopts continuous air blowing method, and the aeration speed is 5m / s.

[0049] 2. The specific method is:

[0050] (1) Prepare the organic waste into a slu...

Embodiment 2

[0054] Embodiment 2: Electromagnetic strengthening removes the method for heavy metal and POPs in livestock and poultry excrement, concrete operation is as follows:

[0055] 1. This method handles 500kg of livestock and poultry manure

[0056] The electromagnetic reactor is a cuboid with a height of 0.5m, a length of 1m, and a width of 0.5m; the length of the electrodes is 45cm, and the distance between the negative and positive electrode pairs is 10cm; The number of turns of the coil is 20, the inductance is 9μH; the external power supply voltage of the negative electrode and the positive electrode is 1V, the frequency is 50Hz, and the negative electrode and the positive electrode are both carbon electrodes; the length of the aeration tube is 0.8m, and the micropore density on the aeration tube is 20 pcs / cm², using continuous air blowing method, the aeration speed is 10m / s.

[0057] 2. The specific method is:

[0058] (1) Prepare the organic waste into a slurry with a water...

Embodiment 3

[0063] In the remaining organic waste of a certain urban sewage treatment plant, the contents of heavy metals Cu, As, and Zn were 80.8 mg / kg, 26.8 mg / kg, and 468 mg / kg, respectively. Weighed 30 g of organic waste and put it into the electromagnetic reactor experimental device. The reactor is a cuboid, 10cm high, 20cm long, and 8cm wide; the electrode is 18cm long, and the interval between the negative and positive electrode pairs is 5cm; the negative electrode and the positive electrode are fixed on the top of the reaction pool, and the magnetic induction coil is connected to an external power supply voltage of 30V. 15, the inductance is 5μH; the external power supply voltage of the electrode is 4V, the frequency is 50Hz, the cathode electrode and the anode electrode are both graphite electrodes; the length of the aeration tube is 15m, and the micropore density on the aeration tube is 10 / cm² 10m / s.

[0064] The method and device of this embodiment are the same as those in Embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com