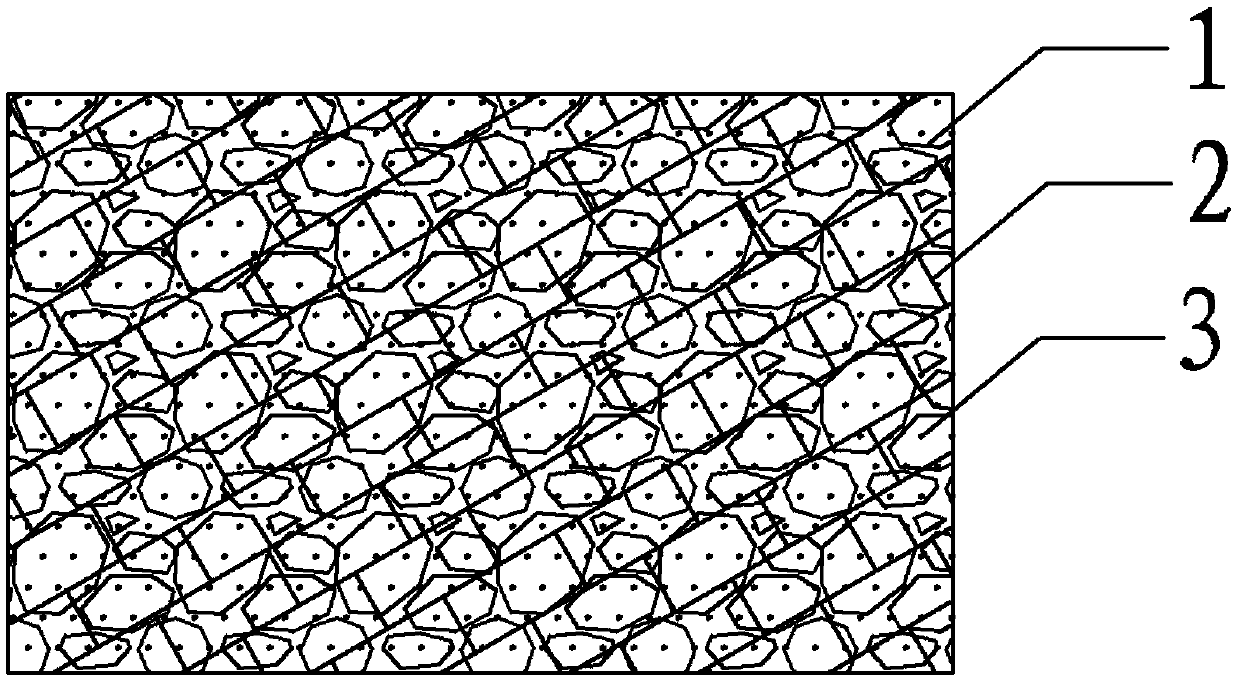

A kind of fibroin/bacterial cellulose composite hydrogel and its preparation method and application

A bacterial cellulose and composite hydrogel technology, applied in prosthesis, tissue regeneration, medical science and other directions, can solve the problems affecting the biocompatibility of bacterial cellulose and silk protein composite materials, the hidden dangers of the safety performance of biological materials, and the impact of materials It can improve the histological morphology and biochemical properties of cartilage, promote load and stable dispersion, and accelerate the repair of full-thickness articular cartilage defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

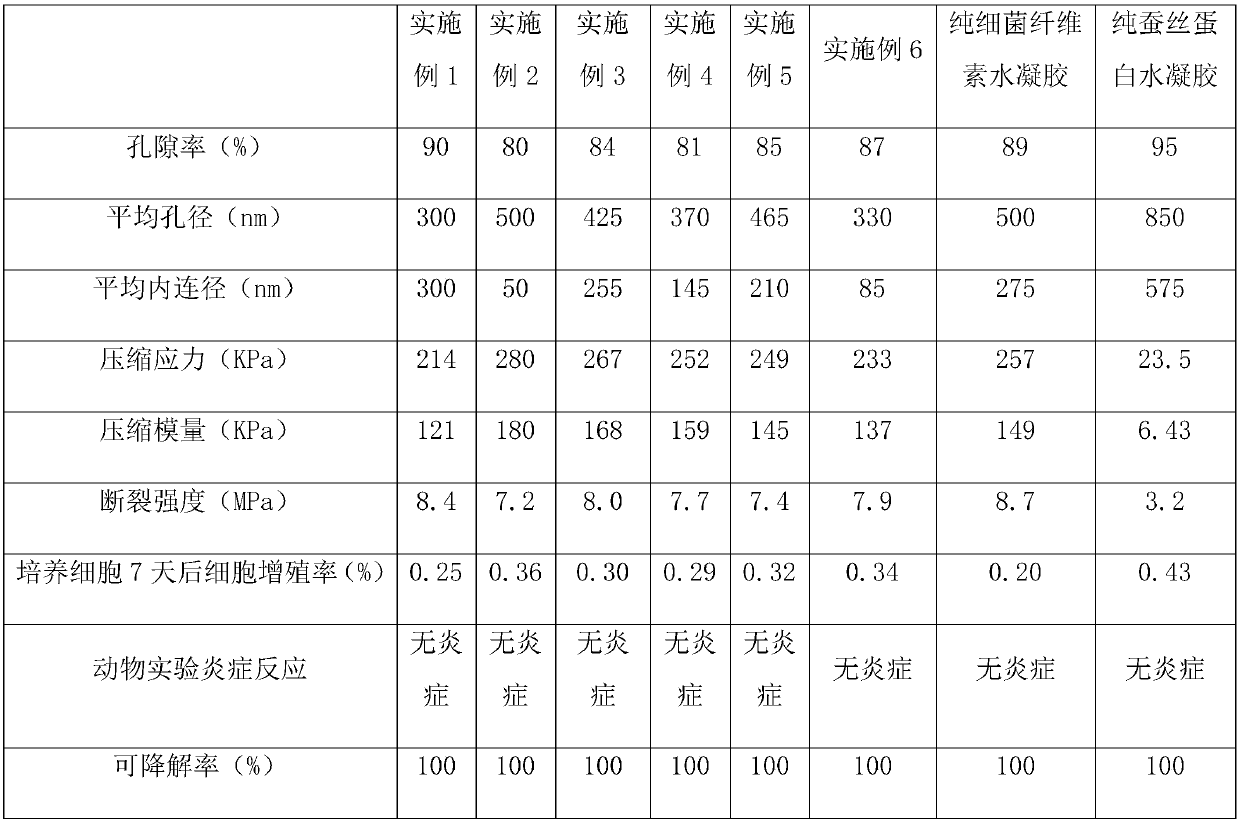

Embodiment 1

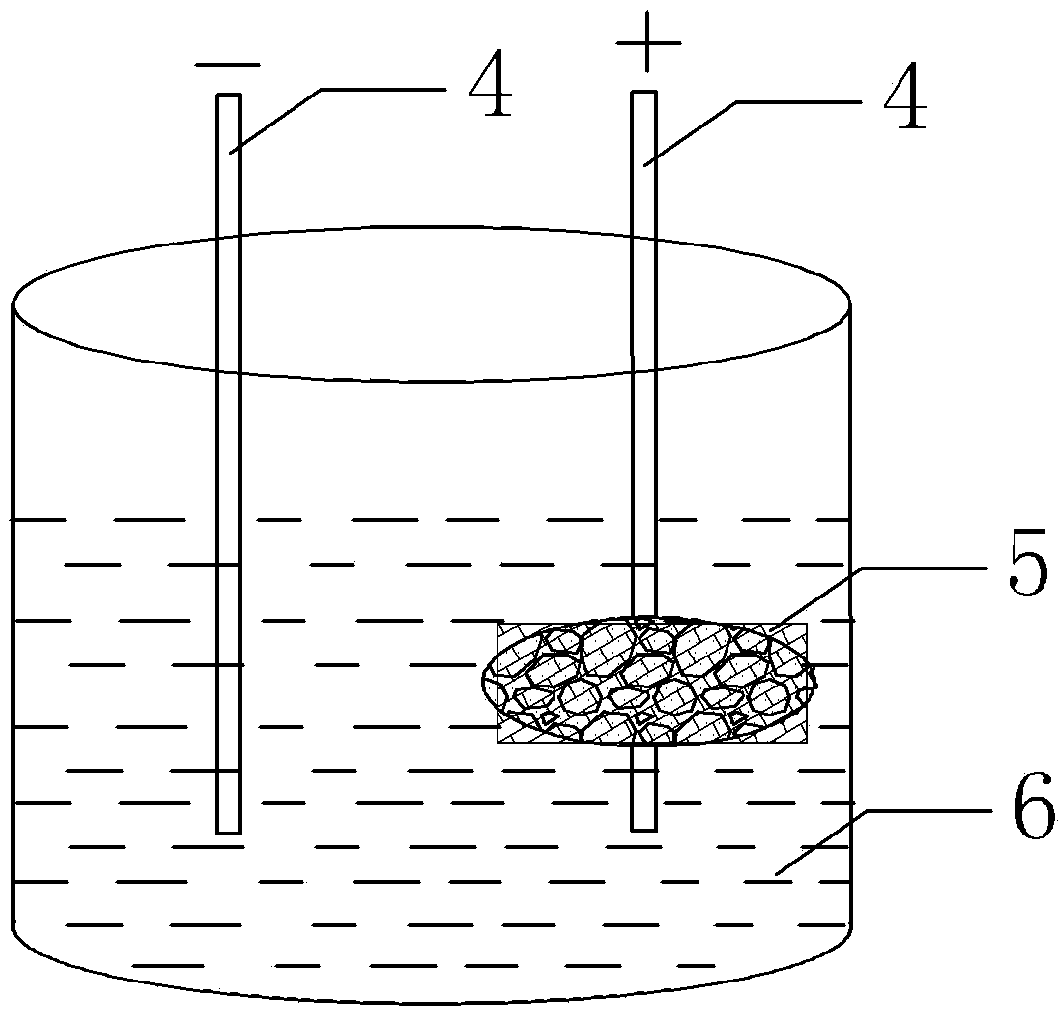

[0031](1) Acetobacter xylinum is used as the strain, and liquid seed medium, Acetobacter xylinum slant medium and fermentation medium are configured, and after high-temperature sterilization at 121° C. for 20 minutes, the seed medium and the activated strain slant are taken, Use an inoculation loop to pick two loops of bacteria into the liquid medium, and the whole process is aseptically operated. After the medium was shaken evenly, it was placed in a temperature-controlled shaker cabinet, and cultured at a temperature of 30° C. and a rotational speed of 160 r / min for 24 hours. Put the cultured seed liquid into the fermentation medium, and cultivate it at a constant temperature of 30°C for 10 days, and form a gelatinous bacterial cellulose film at the interface between the medium and the air, take out the gelatinous bacterial cellulose film, and use After rinsing with deionized water, immerse in 0.5mol / L NaOH aqueous solution, treat at 80°C for 2 hours, and then immerse in dei...

Embodiment 2

[0037] (1) Acetobacter xylinum is used as the strain, and liquid seed medium, Acetobacter xylinum slant medium and fermentation medium are configured, and after high-temperature sterilization at 121° C. for 20 minutes, the seed medium and the activated strain slant are taken, Use an inoculation loop to pick two loops of bacteria into the liquid medium, and the whole process is aseptically operated. After the medium was shaken evenly, it was placed in a temperature-controlled shaker cabinet, and cultured at a temperature of 30° C. and a rotational speed of 160 r / min for 24 hours. Put the cultured seed liquid into the fermentation medium, and cultivate it at a constant temperature of 30°C for 10 days, and form a gelatinous bacterial cellulose film at the interface between the medium and the air, take out the gelatinous bacterial cellulose film, and use After rinsing with deionized water, immerse in 0.5mol / L NaOH aqueous solution, treat at 80°C for 2 hours, and then immerse in de...

Embodiment 3

[0043] (1) Acetobacter xylinum is used as the strain, and liquid seed medium, Acetobacter xylinum slant medium and fermentation medium are configured, and after high-temperature sterilization at 121° C. for 20 minutes, the seed medium and the activated strain slant are taken, Use an inoculation loop to pick two loops of bacteria into the liquid medium, and the whole process is aseptically operated. After the medium was shaken evenly, it was placed in a temperature-controlled shaker cabinet, and cultured at a temperature of 30° C. and a rotational speed of 160 r / min for 24 hours. Put the cultured seed liquid into the fermentation medium, and cultivate it at a constant temperature of 30°C for 10 days, and form a gelatinous bacterial cellulose film at the interface between the medium and the air, take out the gelatinous bacterial cellulose film, and use After rinsing with deionized water, immerse in 0.5mol / L NaOH aqueous solution, treat at 80°C for 2 hours, then immerse in deioni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com