Engine room test equipment rack fixing adapter structure

A test equipment and cabin technology, applied in the field of aircraft structure, can solve the problems of numerous procedures, complicated installation steps of test equipment racks, affecting the use of parts such as aircraft cockpit seats, etc., and achieves the effect of rapid and reliable assembly and improved assembly efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

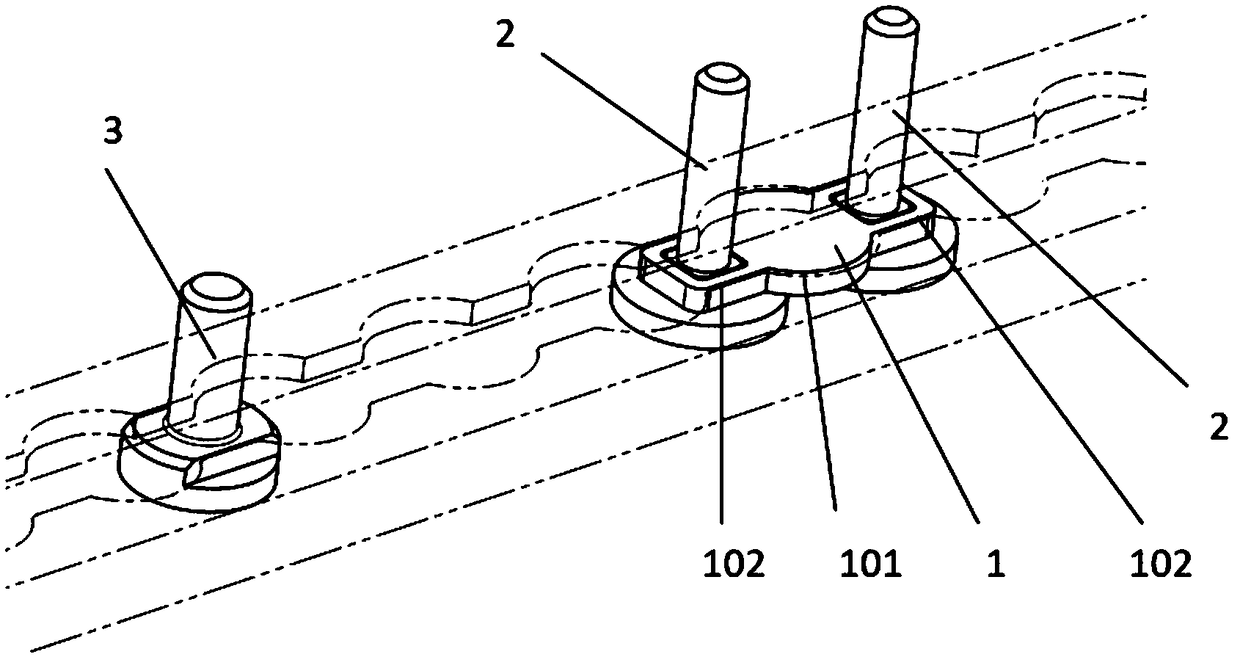

[0014] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. see Figure 1 to Figure 7 .

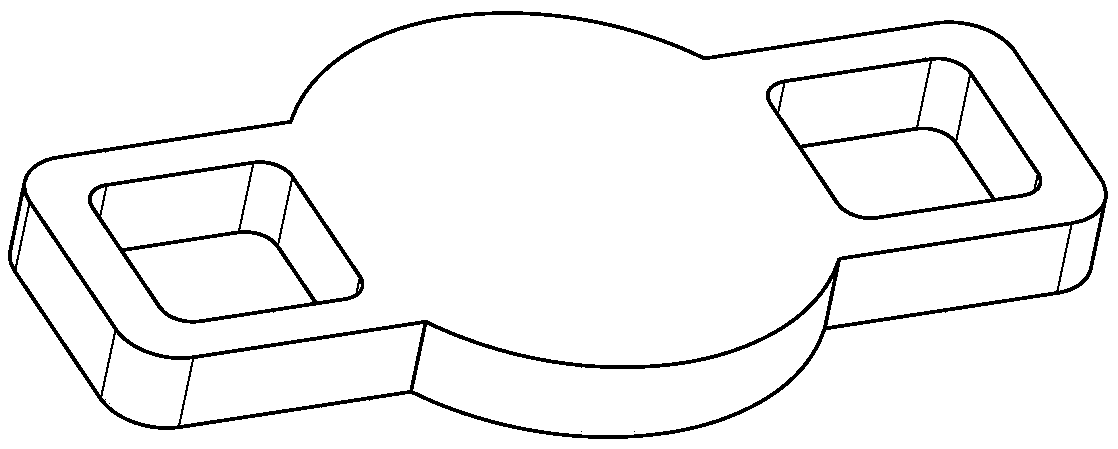

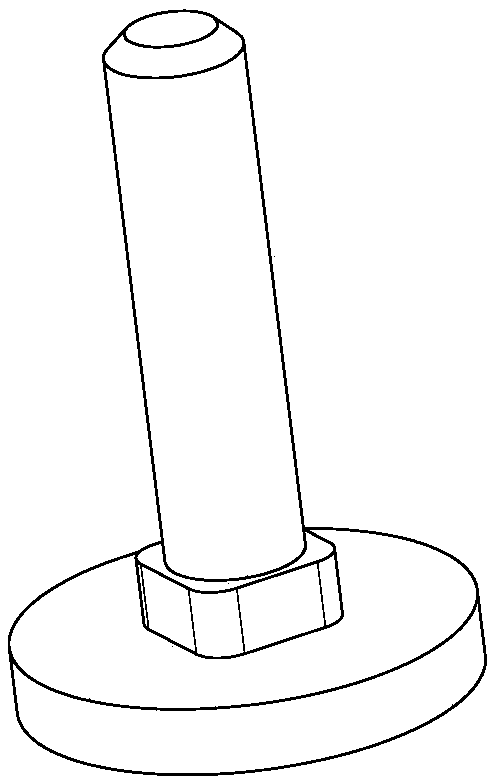

[0015] The present invention is mainly composed of the following parts: a stop gasket 1, a stop bolt 2 and an anchor bolt 3. The middle of the stop washer 1 is a circular arc surface 101 to match the circular track on the aircraft guide rail. Both sides of the stop washer 1 are rectangular planes 102, and both sides are provided with rectangular through holes. The stop bolt 2 is a bolt head with a round head, consisting of a polished rod with a rectangular cross-section and a circular threaded part. It is used in conjunction with the stop washer 1 in actual application to limit the movement of the equipment rack along the front and rear directions of the aircraft guide rail; The bolt head of bolt 3 is circular, and there are L-shaped through grooves symmetrically on both sides of the upper part, and its width ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com