Method and device for preparing consumable material of continuous fiber bundles

A continuous fiber and preparation device technology, applied in the field of 3D printing consumables manufacturing, can solve the problems of limited mechanical properties of consumables forming components, limit the scope of industrial application, and cannot meet the needs of 3D printing technology market development, etc., to achieve good wire forming effect, The structure of the preparation device is reasonable and the effect of saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] This embodiment is a preferred implementation mode of the present invention, and other principles and basic structures that are the same or similar to this embodiment are within the protection scope of the present invention.

[0032] The present invention mainly protects a preparation device for continuous fiber bundle 3D printing wire, including a motor, a feeding device, an extrusion molding device, a cooling device, a tractor and a winding device, and the feeding device is arranged at the left end of the motor and the extrusion molding device At the right end of the machine, the air cooling device is arranged between the extrusion molding device and the tractor, and the winding device is arranged at the very end.

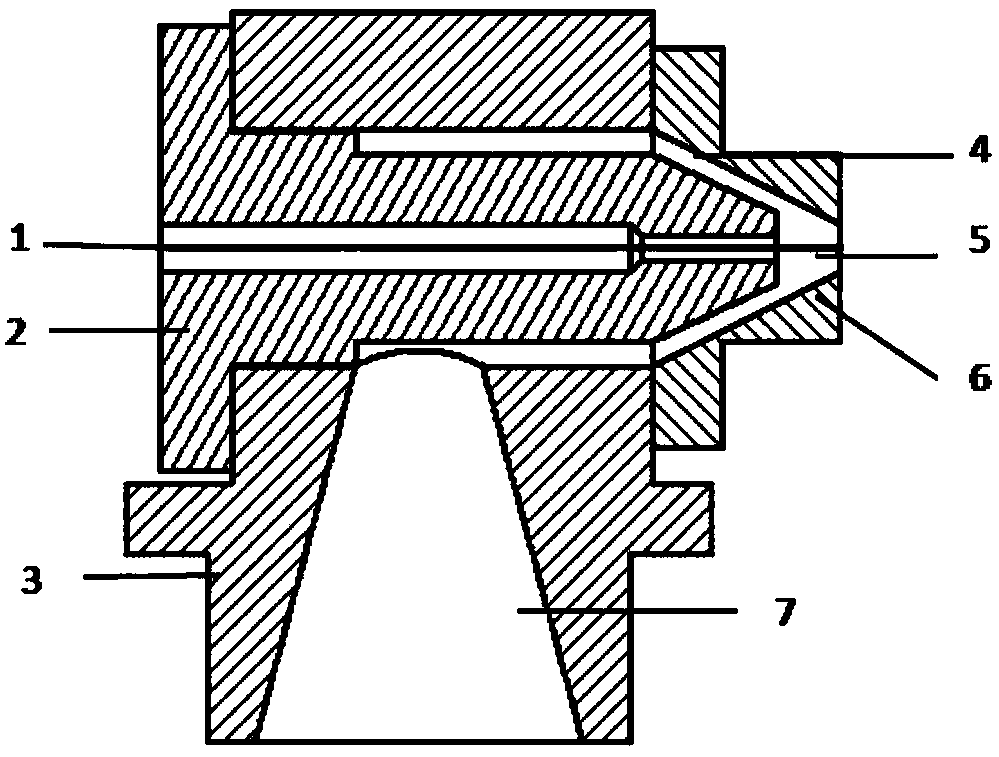

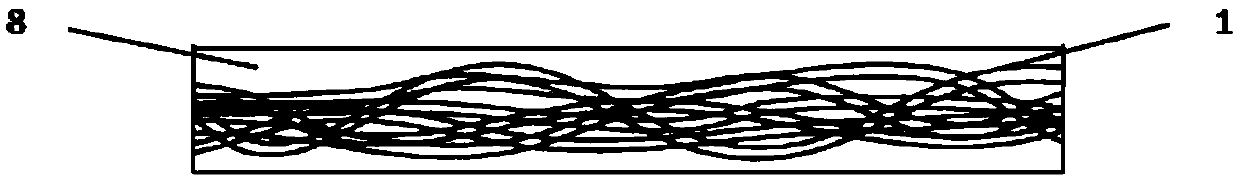

[0033] Such as figure 1 As shown, the extrusion head molding die in the extrusion molding device includes a mold cover 3, a mold core 2, and a die head 6. The mold core 2 is provided with a cylindrical central cavity and the top end of the cylindrical cent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com