Metal-loaded covalent organic framework composite material, and preparation method and application thereof

A technology of covalent organic frameworks and composite materials, which is applied in the field of metal-supported covalent organic framework composite materials and its preparation, can solve the problems of reduced catalytic activity, reduced catalytic applications, and hazards, and achieve improved catalytic performance and excellent stability , good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1) Preparation method of covalent organic framework material TpMA

[0041] A planetary ball mill (AM400, Ant Source Scientific Instruments (Beijing) Co., Ltd., Beijing, China) was used. Specific steps are as follows:

[0042] (1) Add 5 pieces of 5mm diameter grinding balls and 15 pieces of 7mm diameter grinding balls in a 50mL zirconia grinding jar. 1 mL of p-toluenesulfonic acid catalyst and 340 mg of melamine (MA) were added to the grinding jar, then the mixture was ground at 300 rpm for 15 min.

[0043] (2) Add 378 mg of 1,3,5-triformylphloroglucinol (TP) to the mixture, and continue grinding for 2.75 h by utilizing the kinetic energy between the grinding ball and the grinding jar. Subsequently, 0.5 mL of water was added to the mixture and triturated for 5 h.

[0044] (3) Wash twice with DMF, then vacuum-dry at 60° C. to collect TpMA.

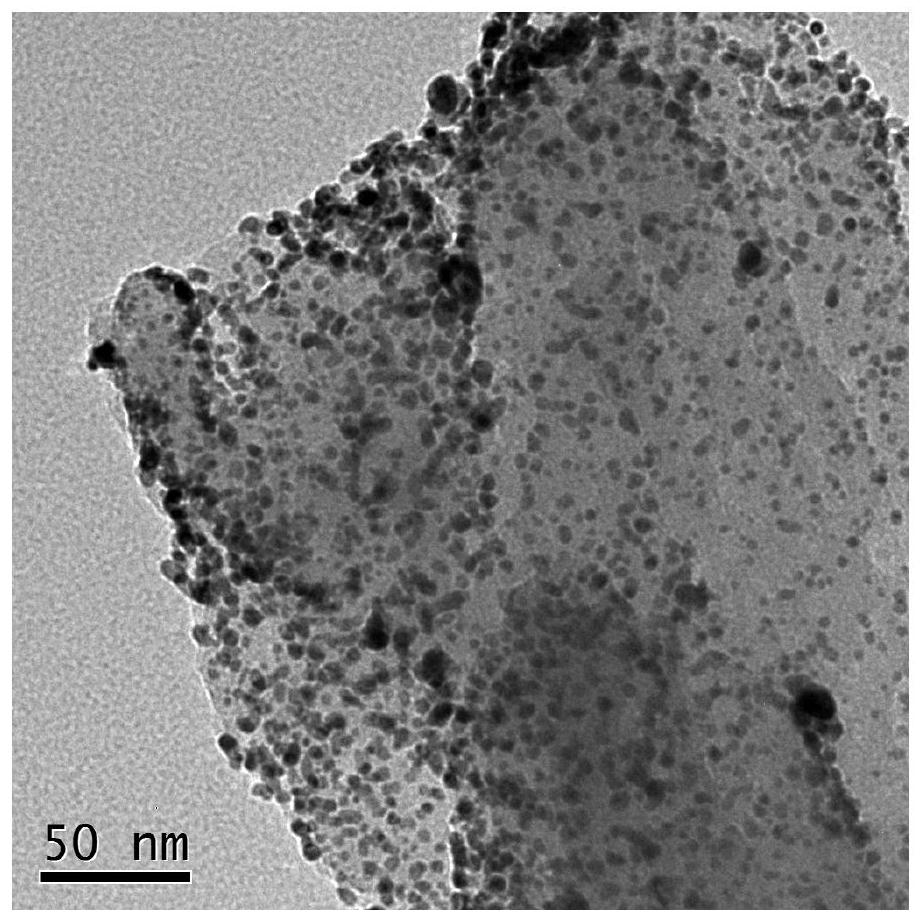

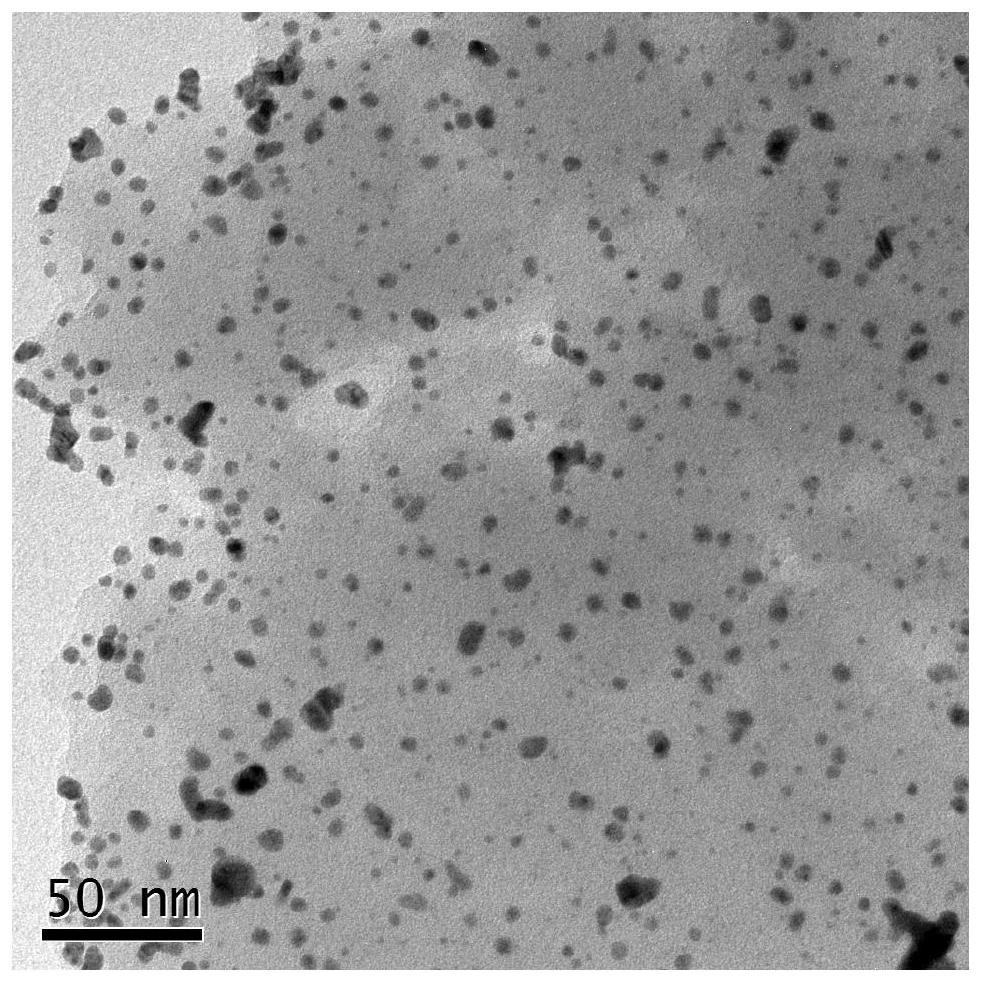

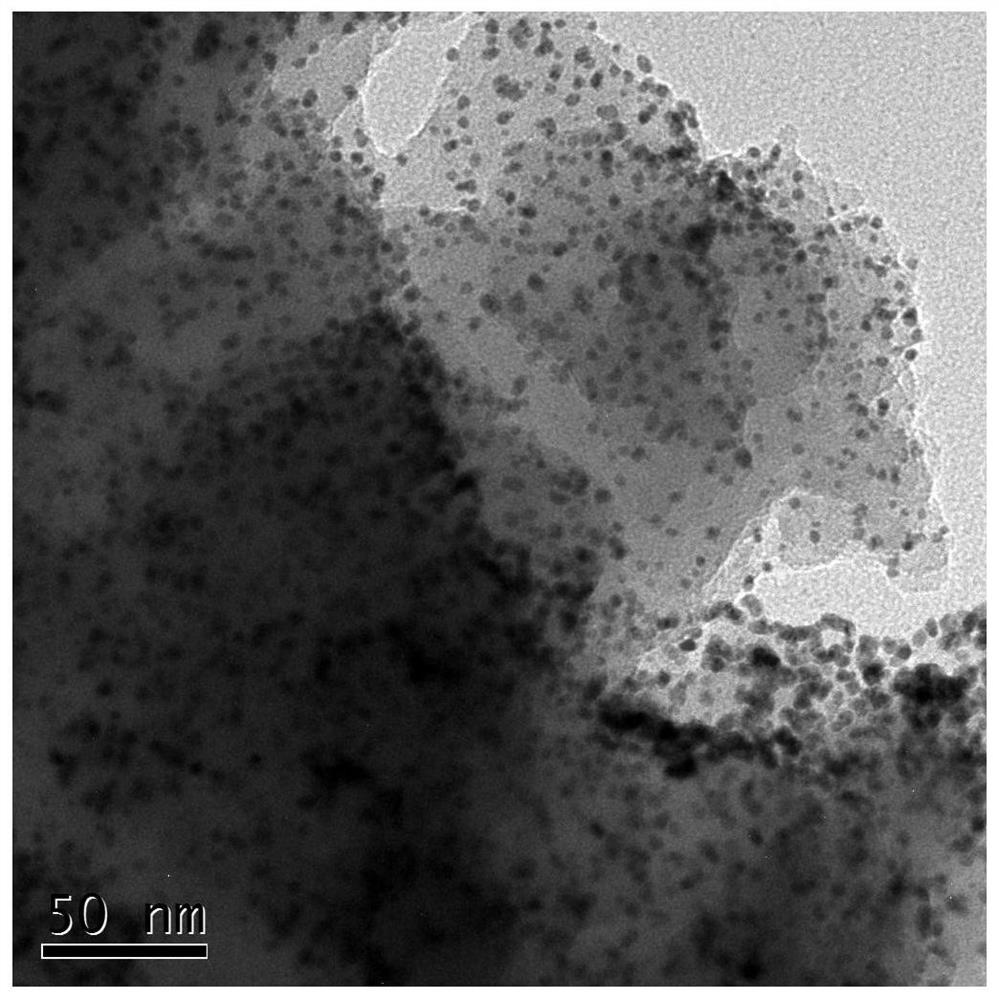

[0045] 2) Preparation method of covalent organic framework materials supported by gold nanoparticles (Au NPs)

[0046] (1) Weig...

Embodiment 2

[0050] 1) Preparation method of covalent organic framework material TpMA

[0051] A planetary ball mill (AM400, Ant Source Scientific Instruments (Beijing) Co., Ltd., Beijing, China) was used. Specific steps are as follows:

[0052] (1) Add 5 pieces of 5mm diameter grinding balls and 15 pieces of 7mm diameter grinding balls in a 50mL zirconia grinding jar. 1.5 mL of p-toluenesulfonic acid catalyst and 360 mg of melamine (MA) were added to the grinding jar, then the mixture was ground at 300 rpm for 30 min.

[0053] (2) 390 mg of 1,3,5-triformylphloroglucinol (TP) was added to the mixture, and grinding was continued for 2.75 h by utilizing the kinetic energy between the grinding ball and the grinding jar. Subsequently, 0.2 mL of water was added to the mixture and triturated for 6 h.

[0054] (3) Wash 3 times with DMF, then vacuum dry at 65°C to collect TpMA.

[0055] 2) Preparation method of covalent organic framework materials supported by gold nanoparticles (Au NPs)

[0...

Embodiment 3

[0061] 1) Preparation method of covalent organic framework material TpMA

[0062] A planetary ball mill (AM400, Ant Source Scientific Instruments (Beijing) Co., Ltd., Beijing, China) was used. Specific steps are as follows:

[0063] (1) Add 5 pieces of 5mm diameter grinding balls and 15 pieces of 7mm diameter grinding balls in a 50mL zirconia grinding jar. 0.5 mL of p-toluenesulfonic acid catalyst and 320 mg of melamine (MA) were added to the grinding jar, and then the mixture was ground at 300 rpm for 12 min.

[0064] (2) Add 370 mg of 1,3,5-triformylphloroglucinol (TP) to the mixture, and continue grinding for 2 h by utilizing the kinetic energy between the grinding ball and the grinding jar. Subsequently, 0.5 mL of water was added to the mixture and triturated for 4 h.

[0065] (3) Wash twice with DMF, then vacuum-dry at 55° C. to collect TpMA.

[0066] 2) Preparation method of covalent organic framework materials supported by gold nanoparticles (Au NPs)

[0067] (1) W...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com