Application of magnesium-aluminum double-metal hydroxide loaded ferrous sulfide composite material in soil remediation

A hydroxide and composite material technology, applied in the field of environmental functional materials and soil treatment, can solve problems such as lack of research, damage to soil structure, soil acidification, etc., to achieve wide application prospects, improve reaction performance, and stabilize the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1FeS@Mg 2 Preparation of Al-LDH

[0034] (1)Mg 2 Al-LDH is prepared by the following method:

[0035] With water as the carrier, the AlCl 3 ·6H 2 O and MgCl 2 ·6H 2 O (mass ratio = 1:1.68) was mixed and reacted under magnetic stirring at room temperature for 30 minutes, and the pH was adjusted to 10 with ammonia water. After the white colloid was formed, it was allowed to stand at room temperature for 60 minutes, and the white colloid was centrifuged and washed with deionized water. Dry in an oven at 80°C for 24 hours to obtain Mg 2 Al-LDH material.

[0036] (2) FeS@Mg 2 Al-LDH is prepared by the following method:

[0037] Under the condition of nitrogen protection (removal of dissolved oxygen), 1.58g of FeSO 4 ·7H 2 O(0.0057mol Fe 2+ ) into 485mL deionized water; then add 0.5g of Mg 2 Al-LDH, magnetic stirring for 30min; then add 15mL of 378.80mM Na dropwise 2 S·9H 2 O, magnetic stirring for 30 minutes. To ensure complete reaction and nanomaterial...

Embodiment 2

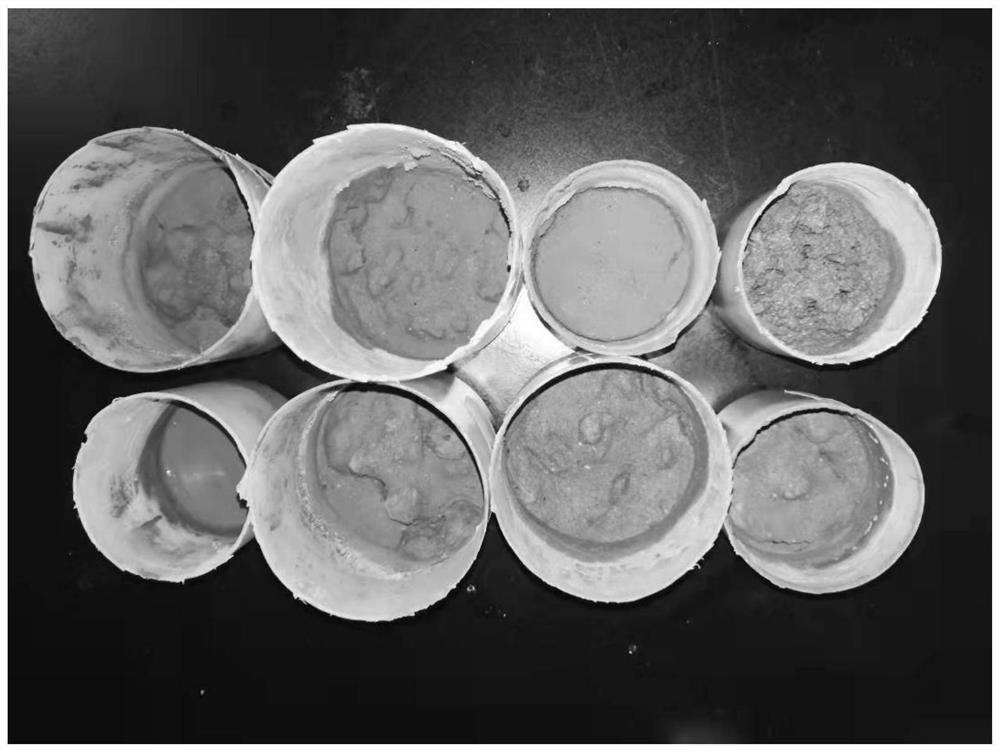

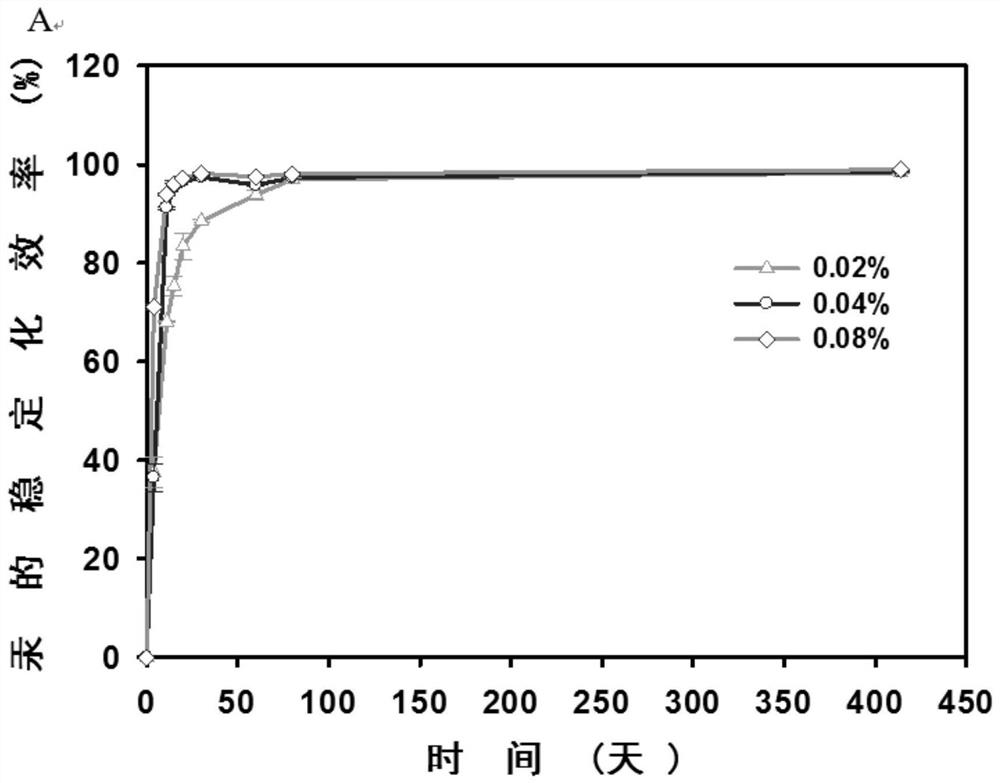

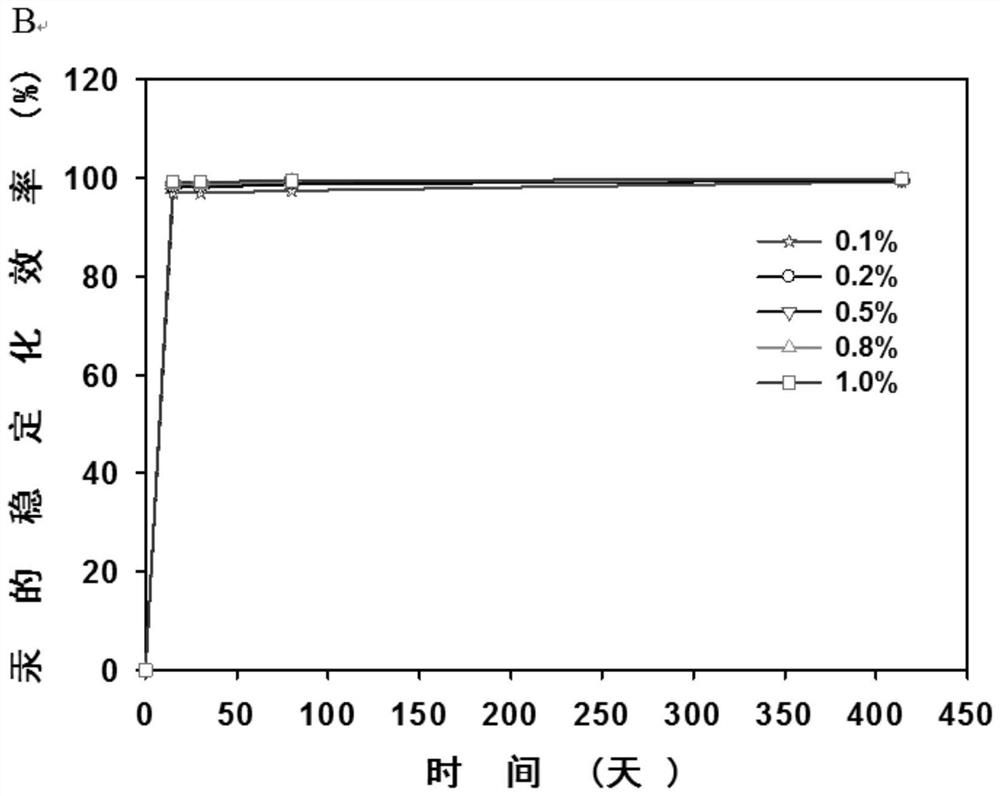

[0038] Example 2 FeS@Mg of different times and different dosages 2 Effect of Al-LDH on Stabilization Efficiency of Mercury in Contaminated Soil

[0039] The soil is silty loam (36.8% sandy soil, 51.6% silt content, 14.0% clay content), collected from 0-30cm mercury-free surface soil of Nankai University in Tianjin (the latitude and longitude of the site is 117.34 / 38.99). After the samples are often warm and air-dried, impurities such as gravel are removed, ground, passed through a 10-mesh sieve, washed three times with tap water to remove suspended colloids and water-leaching components, then air-dried, and stored in sealed plastic buckets for later use. The pretreated soil was mixed with mercury nitrate solution in a closed polyethylene container for 90 days, and after 24 hours of gravity sedimentation, the supernatant was separated and the soil was air-dried at room temperature for 7 days. It was determined that the final mercury content in the soil was 200-240mg / kg.

[00...

Embodiment 3

[0045] Example 3FeS@Mg 2 Changes of mercury in soil before and after Al-LDH treatment

[0046] image 3 Compared with FeS@Mg 2 Al-LDH (amount of 0.1% and 1%) treated soil before and after the change of mercury in the soil form. The exchangeable (EX), carbonate-bound (CB), iron-manganese oxide-bound (OX), organic-bound (OM) and residual (RS) mercury in the untreated soil accounted for 3% respectively , 0.1%, 0.9%, 86.1%, 9.9%. Add 0.1% FeS@Mg 2 In the Al-LDH soil, the exchangeable state and the carbonate-bound state were almost completely transformed into the organic-bound state (88.8%) and the residue state (10.2%). When FeS@Mg 2 When the amount of Al-LDH increased to 1%, the contents of organic bound state and residue state were 70.3% and 29.0%, respectively. The increase of residue state may be due to the increase in the amount of composite materials, and the heavy metal state continues to be more stable and difficult to migrate. migrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com