Preparation method for carbon nano tube/conducting polymer composite material

一种导电聚合物、碳纳米管的技术,应用在导电材料、导电材料、电解涂料等方向,能够解决接触性差、比电容量低、内阻大等问题,达到结构完整、制备工艺简单、成本低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

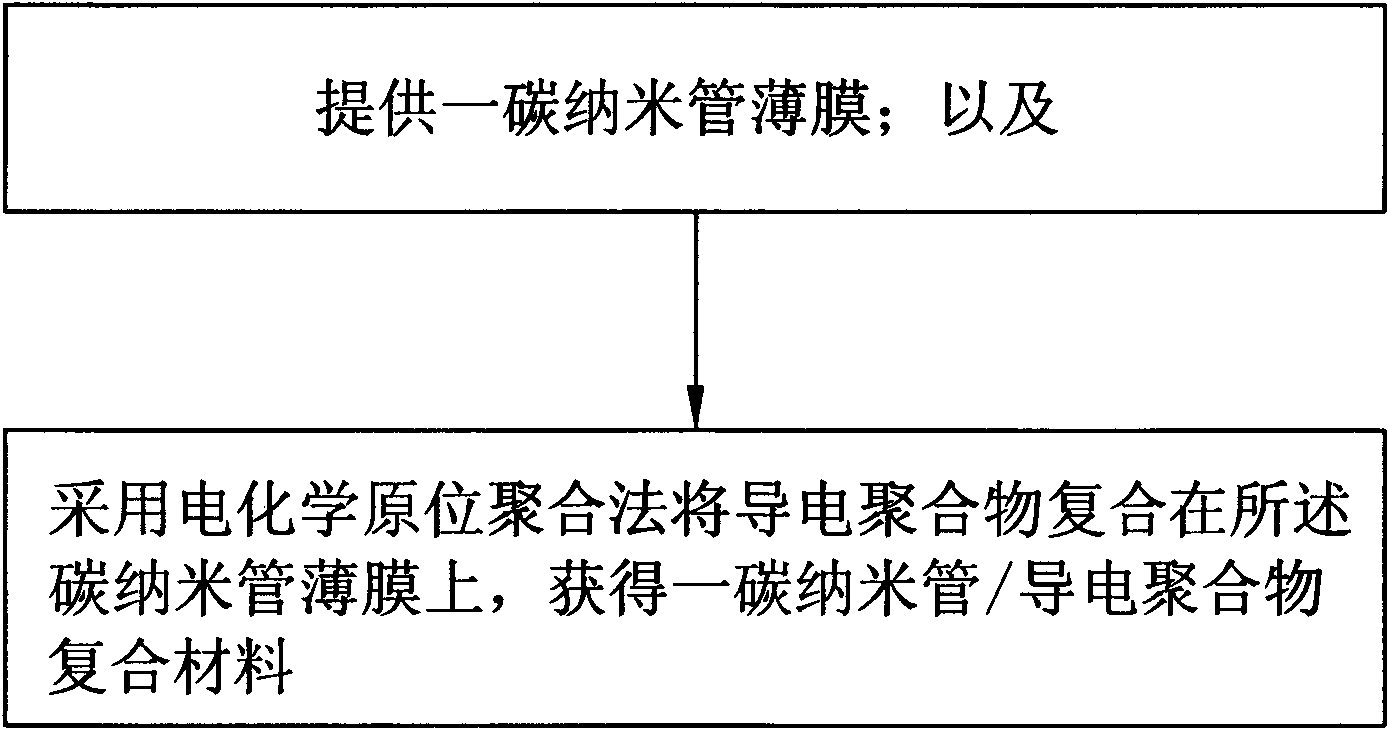

[0010] see figure 1 The embodiment of this technical solution provides a method for preparing a carbon nanotube / conductive polymer composite material, which specifically includes the following steps:

[0011] Step 1, preparing a carbon nanotube film.

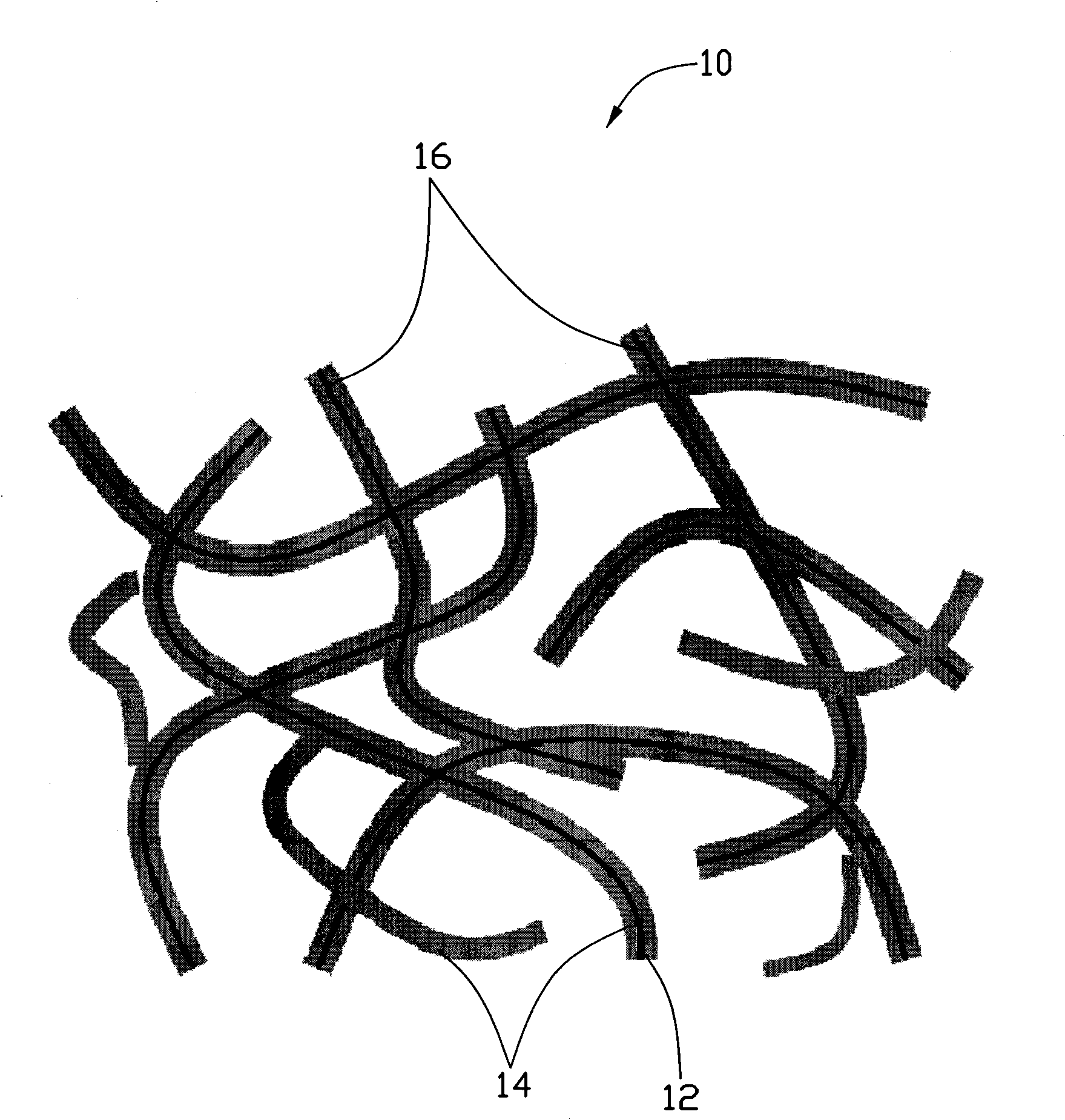

[0012] The method for preparing the carbon nanotube film includes other methods such as direct growth method, flocculation method, rolling method or film pulling method. The carbon nanotube film includes a plurality of uniformly distributed carbon nanotubes, and the plurality of carbon nanotubes are interconnected to form a conductive network structure.

[0013] In this embodiment, the carbon nanotube film is prepared by the flocculation method, and the method specifically includes the following steps:

[0014] (1) Provide a carbon nanotube raw material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com