Synthesis method of mixing ketoxime type cross-linking agent

A synthesis method and cross-linking agent technology, which is applied in the field of synthesis of mixed ketoxime cross-linking agents, can solve the problems of cumbersome synthesis process, poor color stability, long synthesis time, etc., and achieve simple precipitation and separation, easy separation and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

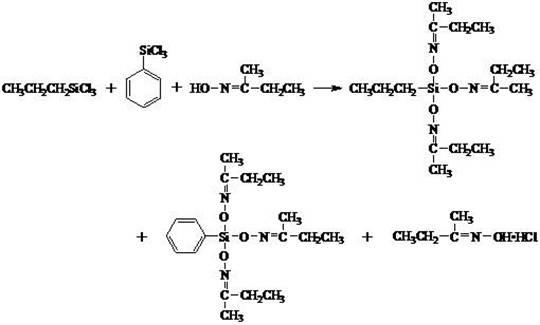

Image

Examples

Embodiment 1

[0024] Put 808 g of butanone oxime and 273.1 g of industrial heptane into a 2000 ml three-necked reaction flask, and add 273.1 g of a mixture of propyltrichlorosilane and phenyltrichlorosilane dropwise under stirring at 300 rpm. Among them, 1.3mol of propyl trichlorosilane, 230.8g in total; 0.2mol of phenyltrichlorosilane, 42.3g in total, the temperature is controlled at 25°C, and the dropping time is controlled at 3 hours; after the dropping is completed, continue to react for 1 hour to generate propylene A mixture of phenyltributanoximinosilane and phenyltributanoximinosilane. After the reaction, the mixture was left to stand for 8 hours, and the mixture system was divided into two distinct upper and lower layers. The upper layer was the crude product of propyl tributylketoxime silane and phenyl tributylketoxime silane, and the lower layer was butanone oxime hydrochloride. . After the stratification is completed, the butanone oxime hydrochloride in the lower layer is separa...

Embodiment 2

[0026] Put 808g of butanone oxime and 273.1g of industrial heptane into a 2000ml three-necked reaction flask, and add 273.1g of propyltrichlorosilane and phenyltrichlorosilane mixture dropwise under stirring at 250 rpm; wherein 1.3 propyltrichlorosilane mol, 230.8g in total, 0.2 mol of phenyltrichlorosilane, 42.3g in total. During the reaction process, the temperature was controlled at 35° C., and the dropwise addition time was controlled at 2 hours. After the dropwise addition was completed, the reaction was continued for 1 hour to generate a mixture of propyl tributylketoxime silane and phenyl tributylketoxime silane. After the reaction, the mixture was left to stand for 10 hours, and the mixture system was divided into two distinct upper and lower layers. The upper layer was the crude product of propyl tributylketoxime silane and phenyl tributylketoxime silane, and the lower layer was butanone oxime hydrochloride. . After the stratification is completed, after separating ...

Embodiment 3

[0028] 808g of butanone oxime and 273.1g of industrial heptane were dropped into a 2000ml three-necked reaction flask, and 273.1g of propyltrichlorosilane and phenyltrichlorosilane mixture were added dropwise under stirring at 300 rpm; wherein propyltrichlorosilane 1.3 mol, 230.8g in total, 0.2 mol of phenyltrichlorosilane, 42.3g in total. During the reaction process, the temperature was controlled at 40° C., and the dropwise addition time was controlled at 1 hour. After the dropwise addition was completed, the reaction was continued for 1 hour to generate a mixture of propyl tributylketoxime silane and phenyl tributylketoxime silane. After the reaction, the mixture was left to stand for 9 hours, and the mixture system was divided into two obvious upper and lower layers. The upper layer was the crude product of propyl tributylketoxime silane and phenyl tributylketoxime silane, and the lower layer was butanone oxime hydrochloride . After the stratification is completed, after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com